a clamping device

A clamping device and component technology, used in auxiliary devices, auxiliary welding equipment, welding equipment, etc., can solve the problems of inability to support clamping and the internal structure of thin-walled cylinders, and achieve the effect of controlling deformation under force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the above objects, features and advantages of the present invention more comprehensible, the specific implementation manners of the present invention will be described in detail below with reference to the accompanying drawings.

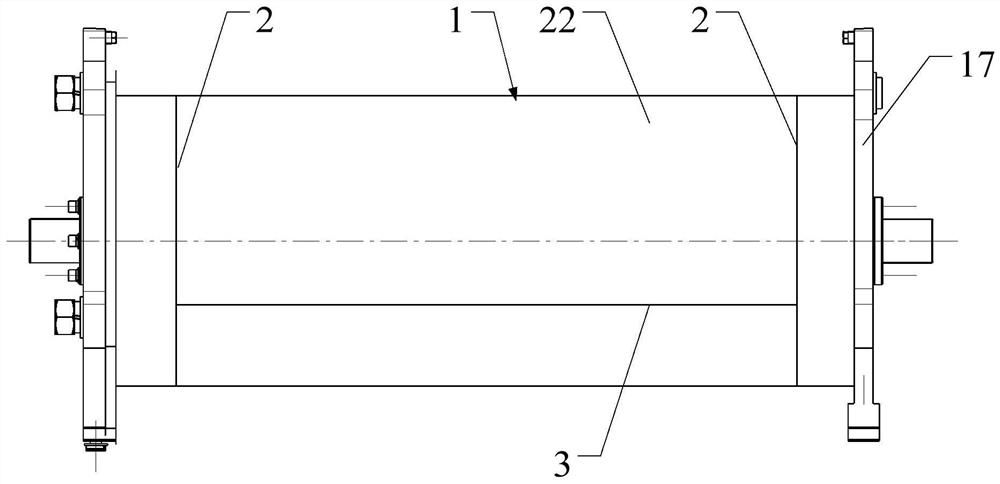

[0025] Such as figure 1 As shown, the cylindrical member of the present invention is pre-assembled and mainly consists of four parts, namely the front and rear end frames and two skin parts, wherein the two skin parts are butted to form two longitudinal Seam 3, the two skin parts constitute the whole skin as the circumferential side wall 22 of the cylindrical member, and the front and rear end frames are integrally butted with the skin to form two circular seams 2 to be welded.

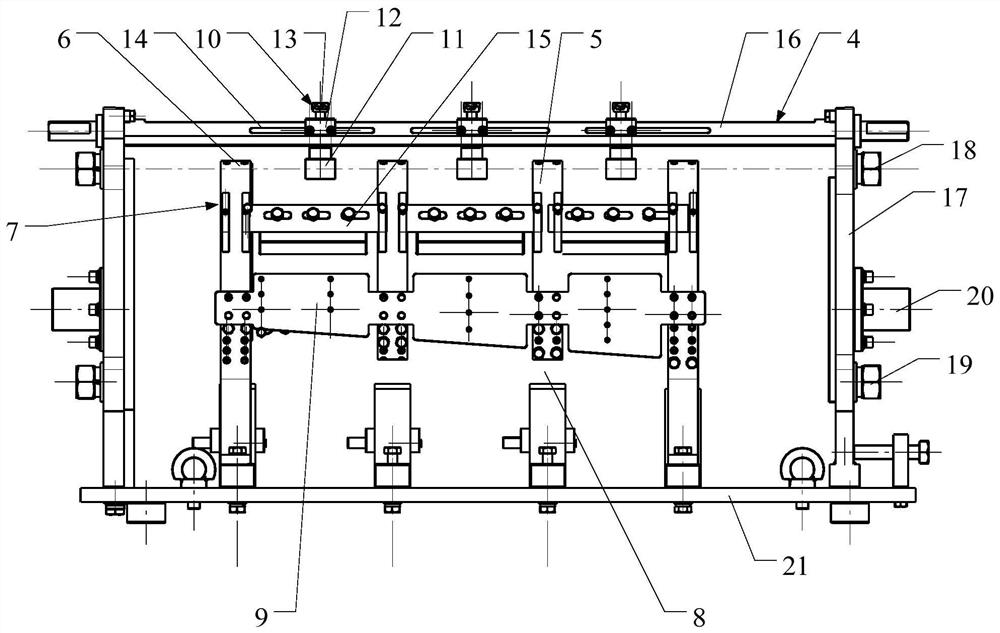

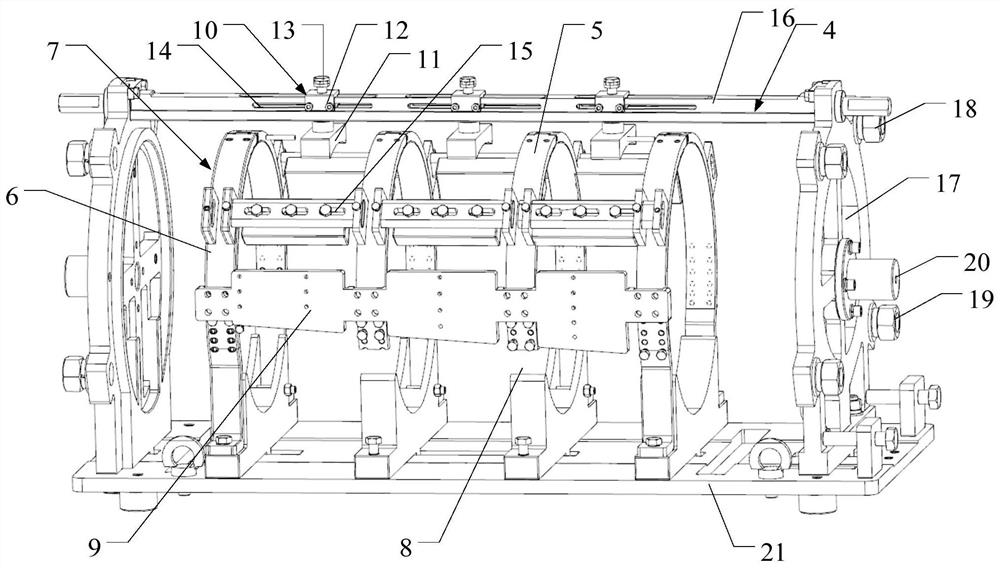

[0026] Such as figure 2 , image 3 and Figure 4 As shown, the present invention provides a clamping device for clamping the cylindrical member 1, including: a frame 4, which is used to clamp the two ends of the cylindrical member 1 so that the cy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com