Precise positioner of bonder terminal in coating and injection moulding process

A connector terminal and precise positioning technology, which is applied in the field of injection molding, can solve problems that affect the company's benefits, high failure rate, increase production costs and inspection costs, etc., to improve customer satisfaction, improve economic benefits, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

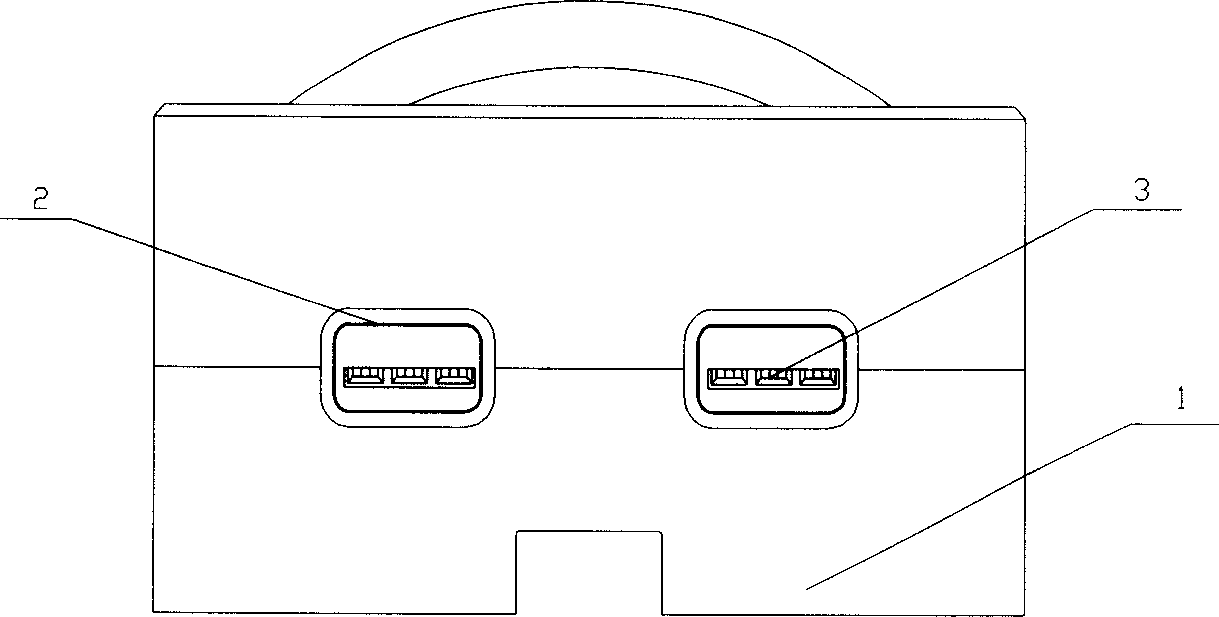

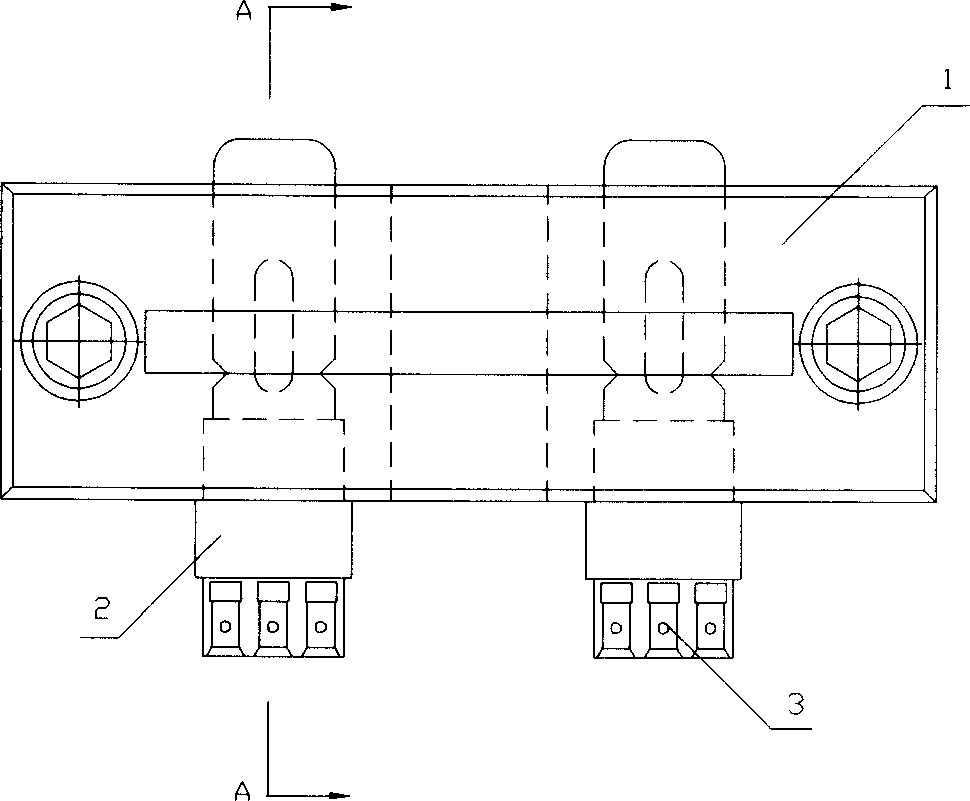

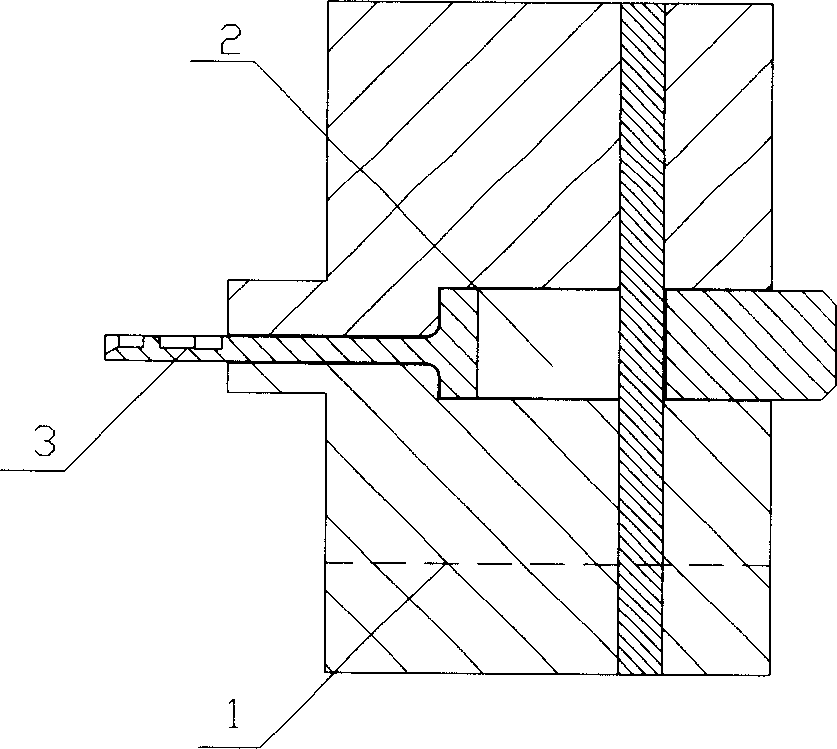

[0011] Such as figure 1 , 2 As shown, a detachable insert 3 connected to the insert 2 is added to the original integral mold core 1 for connector injection. The insert 3 is a movable drawer structure, that is, the insert 3 can be placed inside the insert 2 slide. The length of the insert 3 is greater than the width of the mold core 1, so its sliding inside and outside the insert 2 can be controlled by pushing the part exposed outside the insert 2; a raised positioning pin is provided at one end of the insert 3 , and the corresponding position of the terminal is also provided with a matching round hole; at the same time, the insert 3 is provided with grooves, the number of grooves is consistent with the number of terminals to be processed, and its width is slightly larger than the width of the terminals to be processed.

[0012] The method of processing the connector by using the precise positioning device of the connector terminal in the overmolding process: push out the end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com