A high current DC contactor

A DC contactor and high current technology, applied in the direction of relays, electromagnetic relays, detailed information of electromagnetic relays, etc., can solve the problems of increasing the opening distance of the contactor and increasing the volume of the contactor, so as to improve the current level, save space and ensure effective Effect of insulation distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

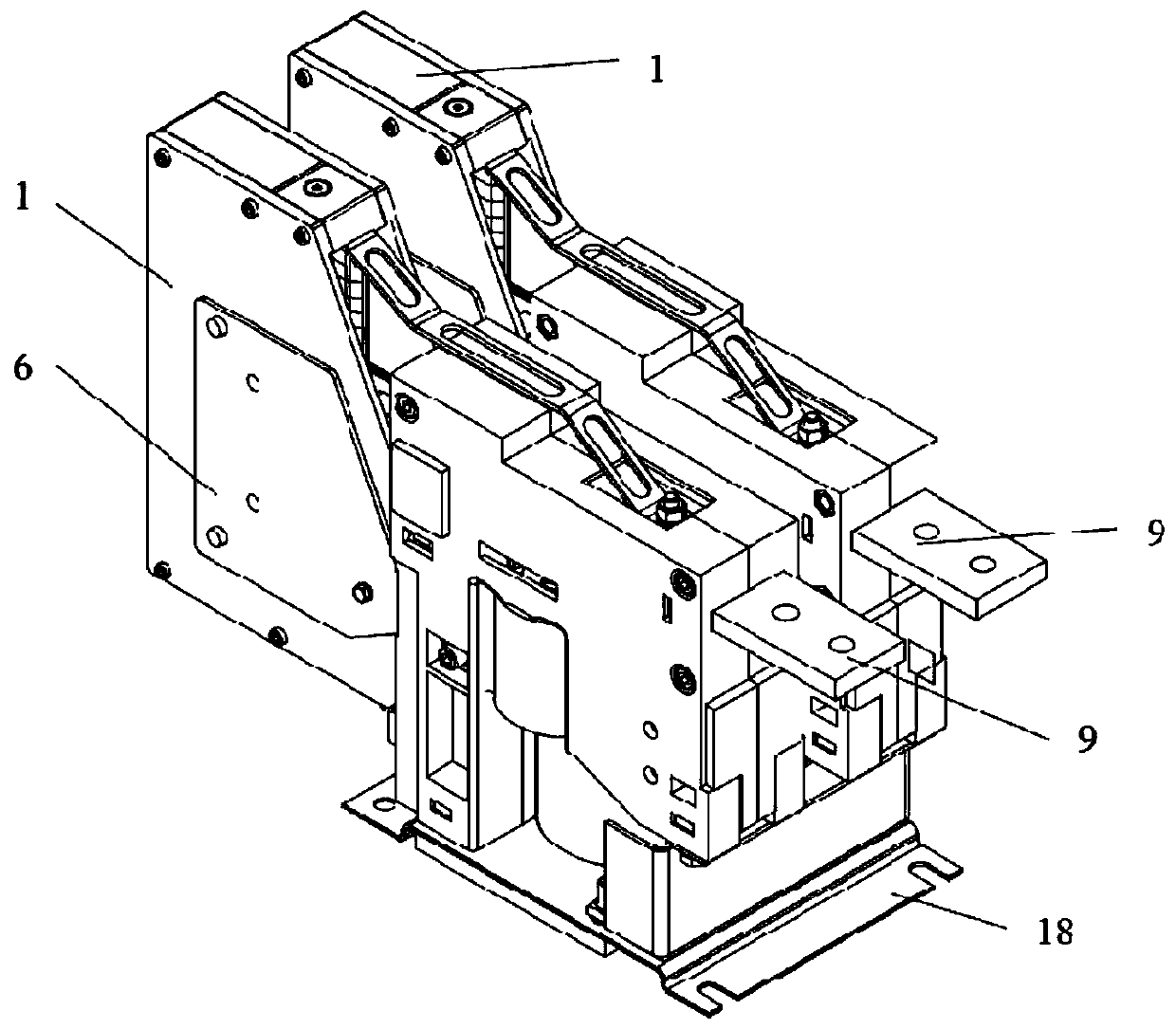

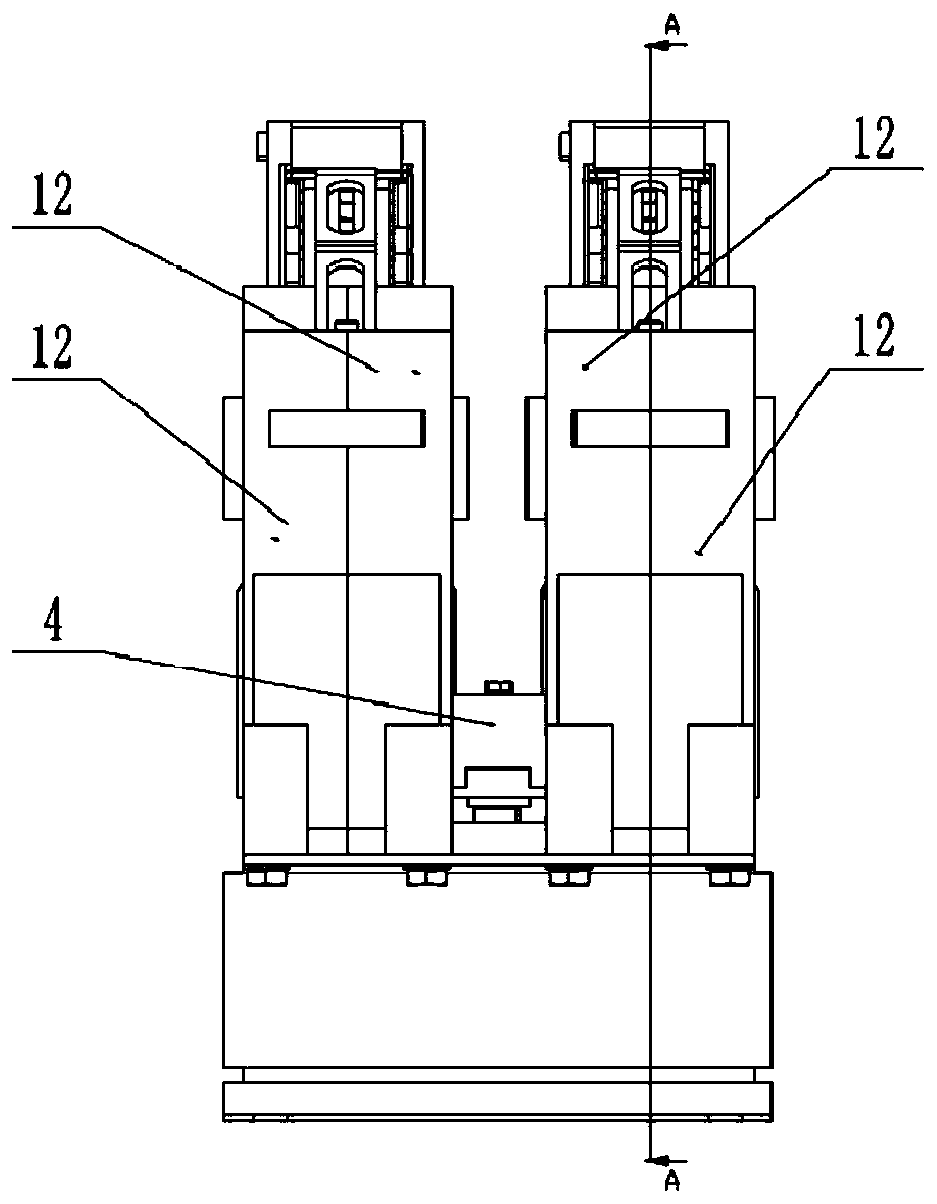

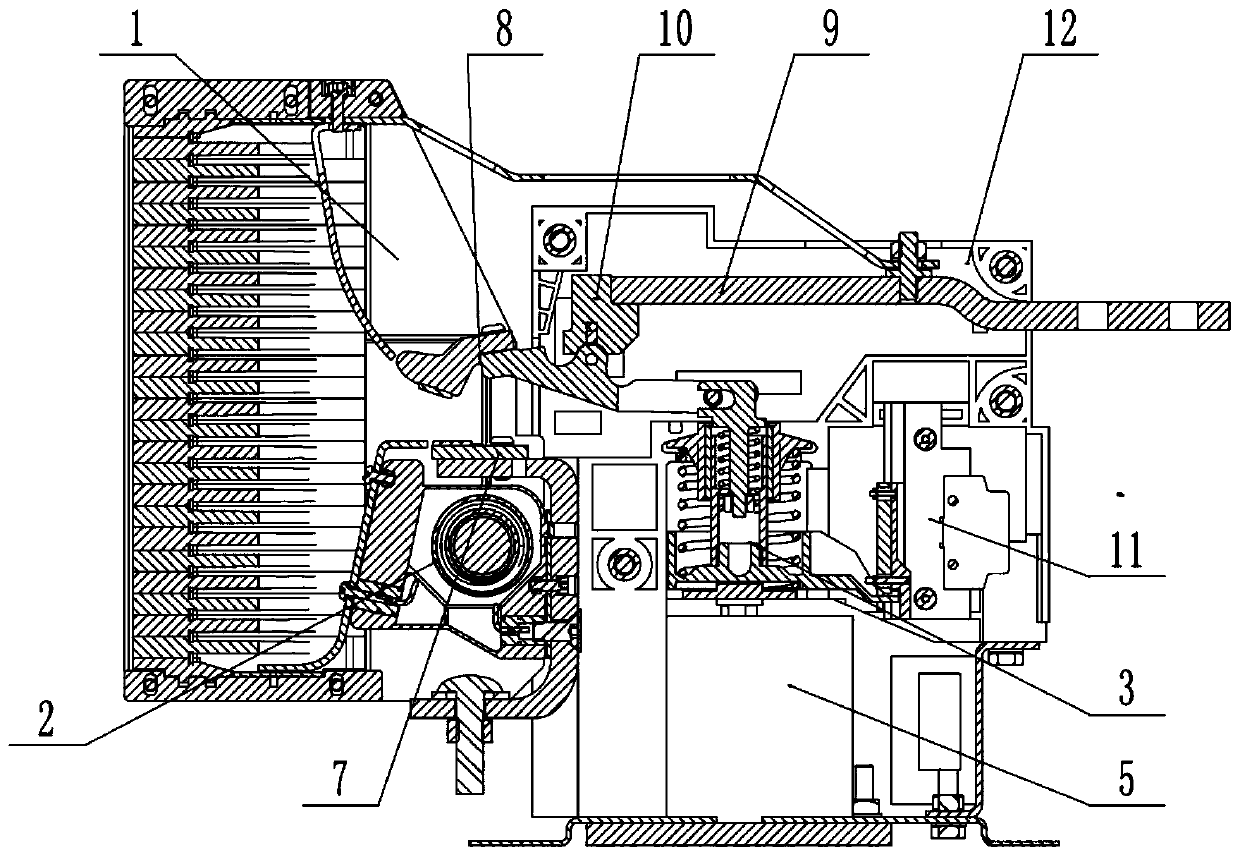

[0036] like Figures 1 to 10 As shown, a high-current DC contactor includes two sets of DC contact bodies and a set of electromagnetic drive mechanism. The DC contact body includes an arc extinguishing chamber 1, a magnetic blowing system 2, a spring system 3, a magnetic guide plate 6, Static contact 7, moving contact 8, conductive copper bar 9, support seat 10, micro switch assembly 11 and contactor housing 12; the electromagnetic drive mechanism includes a guide drive block 4, an electromagnet 5 and a base 18; Among them, the arc extinguishing chamber 1 and the magnetic blowing system 2 constitute the arc extinguishing system. The arc extinguishing chamber 1 here includes a plurality of clay grids, and the multi-clay grids and the contactor shell 12 constitute the arc extinguishing chamber 1. The magnetic blowing system 2 adopts a magnetic Blowing coil structure; the spring system 3 and the guide drive block 4 constitute the dynamic system, the electromagnet 5 and the magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com