Tower body structure for ship crane

A technology for marine cranes and towers, which is applied to cranes and other directions, can solve problems such as weak firmness, uneven force, and high manufacturing costs, and achieve the effects of small dimensions, reduced self-weight, and low manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

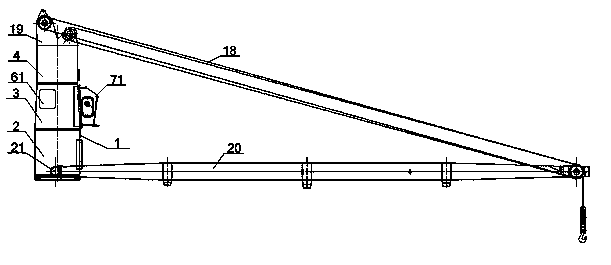

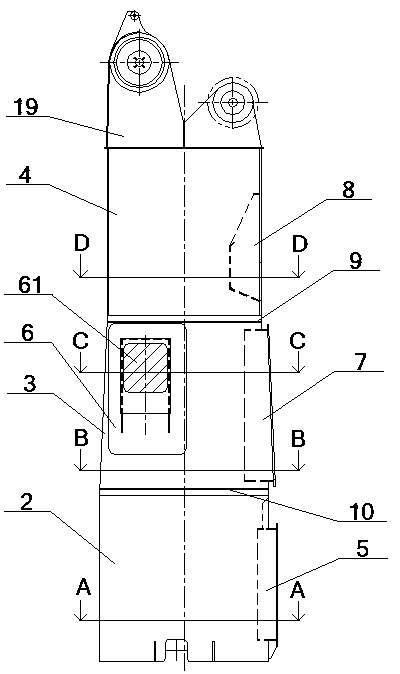

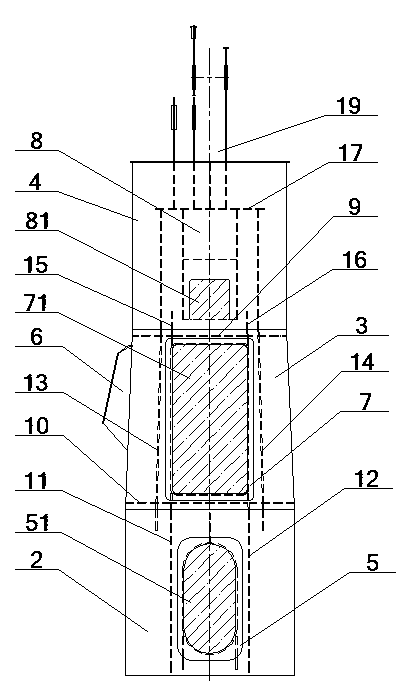

[0040] see figure 1 – Figure 10 , a tower body structure of a marine crane, including a tower body 1 and a driver's cab 71, the top of the tower body 1 is provided with a pulley part 19 matched with a wire rope 18, and the bottom is provided with a boom matched with a boom 20 The installation part 21, and the ventilation window 61 and the driver's cab 71 are arranged on the tower body 1;

[0041] The tower body 1 includes a lower cylindrical structure 2, a middle conical structure 3 and an upper cylindrical structure 4. The upper and lower ends of the middle conical structure 3 are respectively connected with the upper cylindrical structure 4 and the lower cylindrical structure 2, and in the lower part The cylindrical structure 2 is provided with the maintenance door opening 5 matched with the maintenance door 51, and the central c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com