System and process for preparing methanol through hydrogenation of carbon dioxide

A technology for the preparation of carbon dioxide and hydrogen, applied in the preparation of hydroxyl compounds, the preparation of organic compounds, the separation/purification of hydroxyl compounds, etc., can solve the problems of increased operating costs, complicated operation and maintenance, etc., and achieve the goal of saving compression work and reducing energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

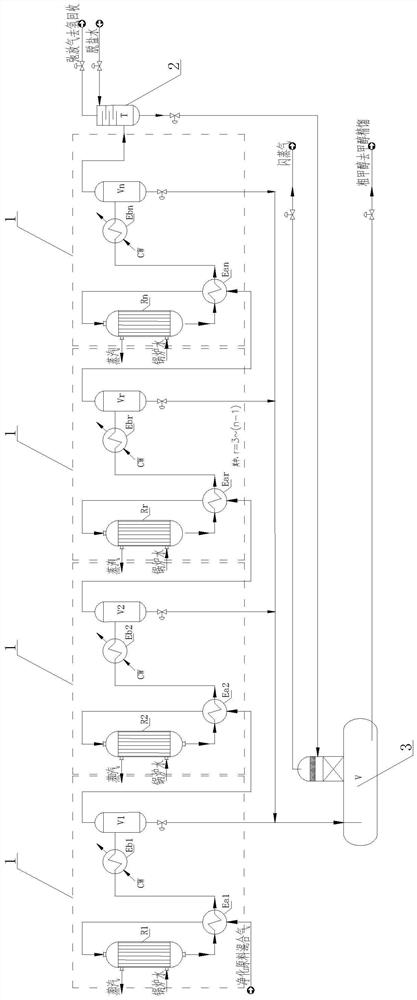

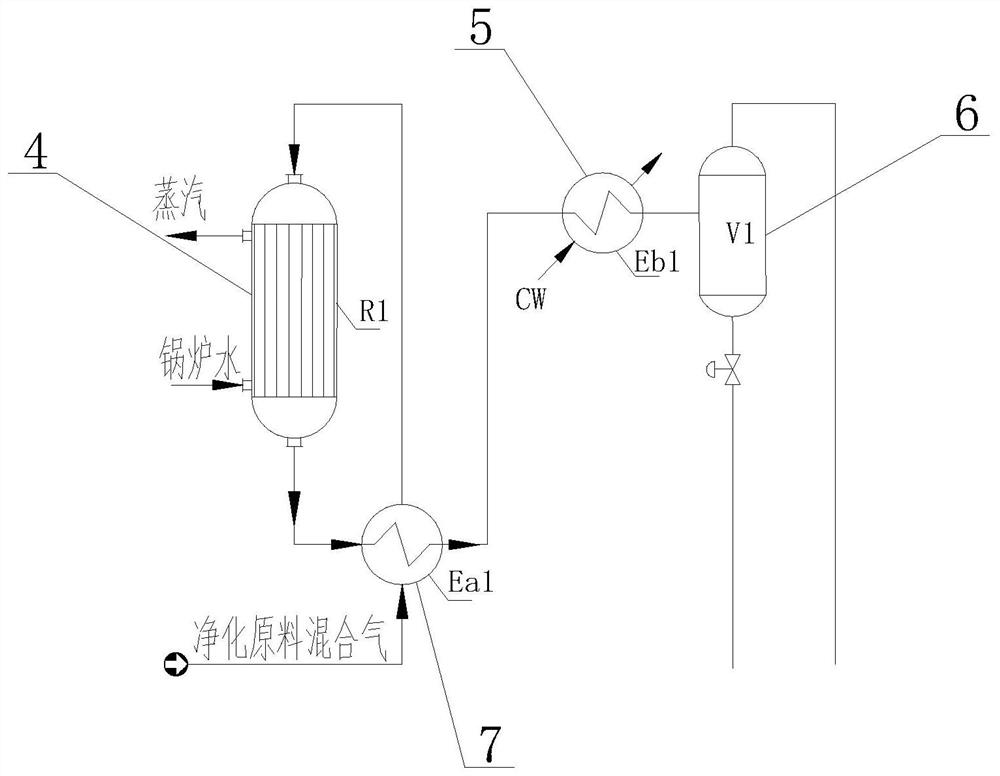

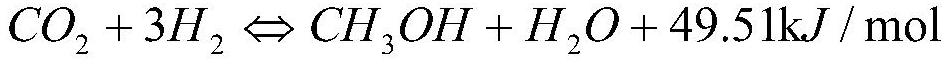

[0025] System embodiment 1 of the present invention: a system for producing methanol by hydrogenation of carbon dioxide, comprising at least three methanol production units 1 connected in series, the methanol production unit 1 includes a tower preheater 7, a methanol synthesis tower 4, a methanol water cooling device 5 and methanol separator 6; the raw material inlet of the tower preheater 7 is connected with the purified raw material mixing gas pipe, and the raw material gas outlet of the tower preheater 7 is connected with the inlet of the methanol synthesis tower 4; the methanol synthesis tower The gas outlet of 4 is connected with the high-temperature air inlet of the tower preheater 7, the high-temperature gas outlet of the tower preheater 7 is connected with the feed port of the methanol water cooler 5, and the outlet of the methanol water cooler 5 is separated from methanol The feed port of the device 6 is connected; the gas outlet of the methanol separator 6 of the uppe...

Embodiment 2

[0028] Process Example 2: A process for producing methanol by hydrogenation of carbon dioxide, using the system for producing methanol by hydrogenation of carbon dioxide described in Example 1, including the following method: adding the mixed gas of raw materials to the first-stage methanol production unit 1 The raw material inlet of the tower preheater 7, the raw material mixture gas in the tower preheater 7 is heated to a specified temperature, and then introduced into the methanol synthesis tower 4, the synthesis gas reacts in the catalytic bed of the methanol synthesis tower, and the heat of reaction Removed by the boiler water, by-product steam, the outlet gas after the reaction of the methanol synthesis tower 4 enters the high-temperature air inlet of the tower preheater 7 as a heat source; the reacted outlet gas enters the tower preheater 7 After being discharged, it is lowered to the specified temperature through the methanol water cooler 5, and then introduced into the...

Embodiment 3

[0030]Process Example 3: A process for producing methanol by hydrogenation of carbon dioxide, using the system for producing methanol by hydrogenation of carbon dioxide described in Example 1, including the following method: adding the mixed gas of raw materials to the first-stage methanol production unit 1 The raw material inlet of the tower preheater 7, the raw material mixture gas in the tower preheater 7 is heated to a specified temperature, and then introduced into the methanol synthesis tower 4, the synthesis gas reacts in the catalytic bed of the methanol synthesis tower, and the heat of reaction Removed by the boiler water, by-product steam, the outlet gas after the reaction of the methanol synthesis tower 4 enters the high-temperature air inlet of the tower preheater 7 as a heat source; the reacted outlet gas enters the tower preheater 7 After being discharged, it is lowered to the specified temperature through the methanol water cooler 5, and then introduced into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com