Air separation device for preparing oxygen and nitrogen through isobaric separation

An air separation unit, a technology for producing oxygen, applied in the field of deep freezing, can solve the problems that no clear answer is given, and the air separation unit cannot be explained concisely, clearly, and intuitively.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

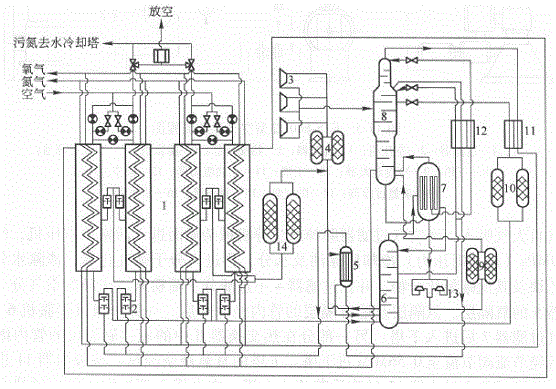

[0096] Such as figure 1 Shown, a kind of air separation unit of air isobaric separation oxygen nitrogen, specific embodiment is as follows:

[0097] The refrigerant is liquid nitrogen, and the specific implementation steps are as follows:

[0098] (1) Raw air 1 passes through the air filter 2 to remove dust and mechanical impurities, enters the compressor, and is compressed to the required pressure in 3;

[0099] (2) The pre-cooled compressed air enters the purifier 4 to remove water, carbon dioxide and a small amount of acetylene and hydrocarbons, then cools to the liquefaction temperature through the main cold exchanger 6, and enters the lower tower 8 of the rectification device;

[0100] (3) The oxygen-enriched liquid air 11 obtained by the crude distillation of the lower tower 8 is directly sent to the middle of the upper tower without throttling after the acetylene is removed by the liquid air adsorber 12, and the nitrogen gas is evaporated by the condensing evaporator 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com