Carbon dioxide transcrisis refrigeration circulation rotor type expansion energy-saving device

A refrigeration cycle and carbon dioxide technology, which is applied in refrigerators, refrigeration and liquefaction, gas cycle refrigerators, etc., can solve the problems of efficiency reduction, difficulty in coaxial expansion between the expander and the main compressor, and difficulty in guaranteeing the life of the generator.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

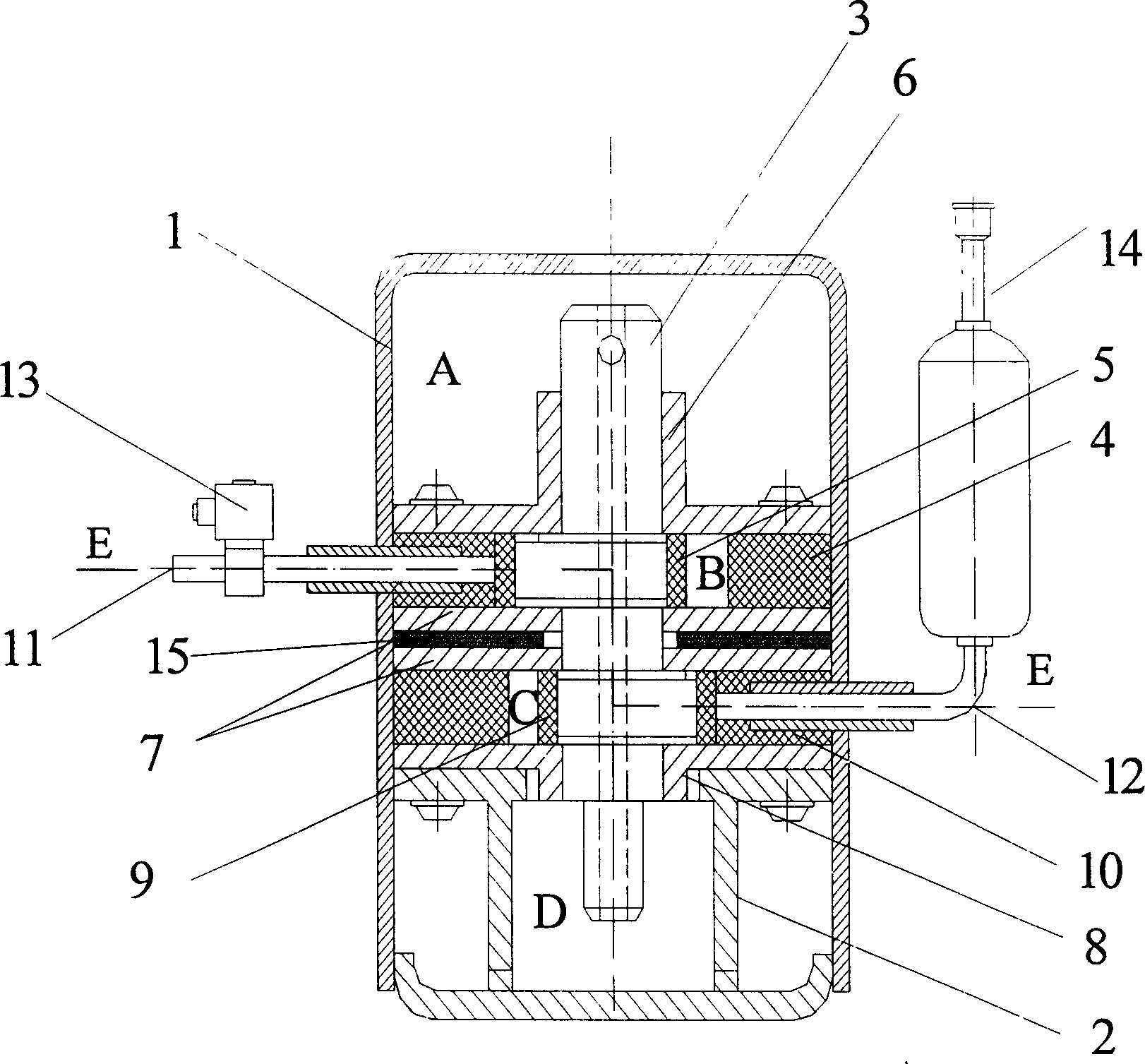

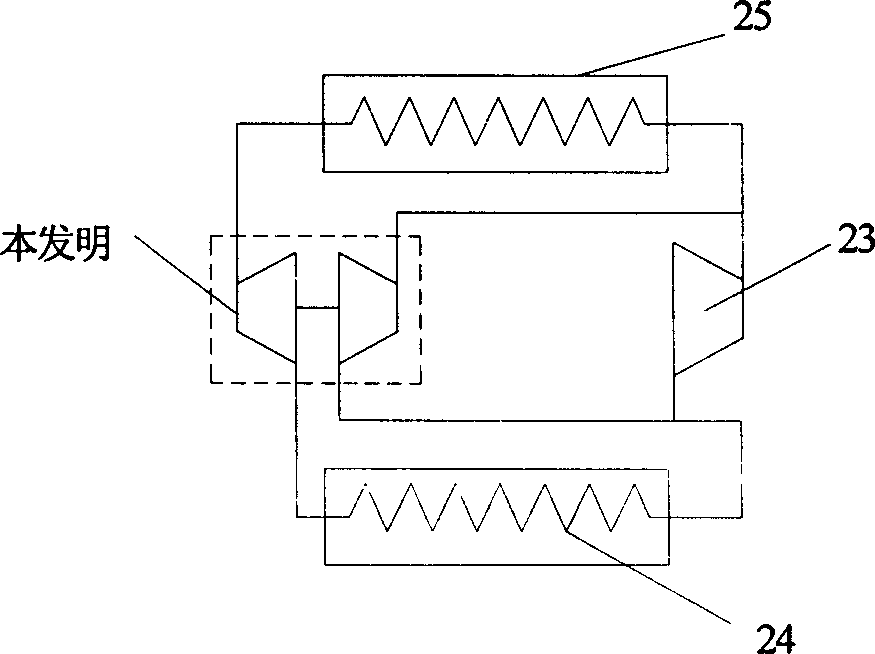

[0009] The present invention is in the layout of the system as attached image 3 The dotted box part in .

[0010] During installation, the inlet pipe port (11) of the expansion cylinder of the carbon dioxide transcritical refrigeration cycle rotor type expansion economizer (the present invention) is connected with the outlet of the gas cooler (25), and the exhaust port (18) is connected with the evaporator ( 24) is connected to the inlet, and the inlet of the compression cylinder is a gas-liquid separator, which separates the gas from the evaporator, and the exhaust gas at the outlet of the compression cylinder is mixed with the exhaust gas of the main compressor and enters the gas cooler.

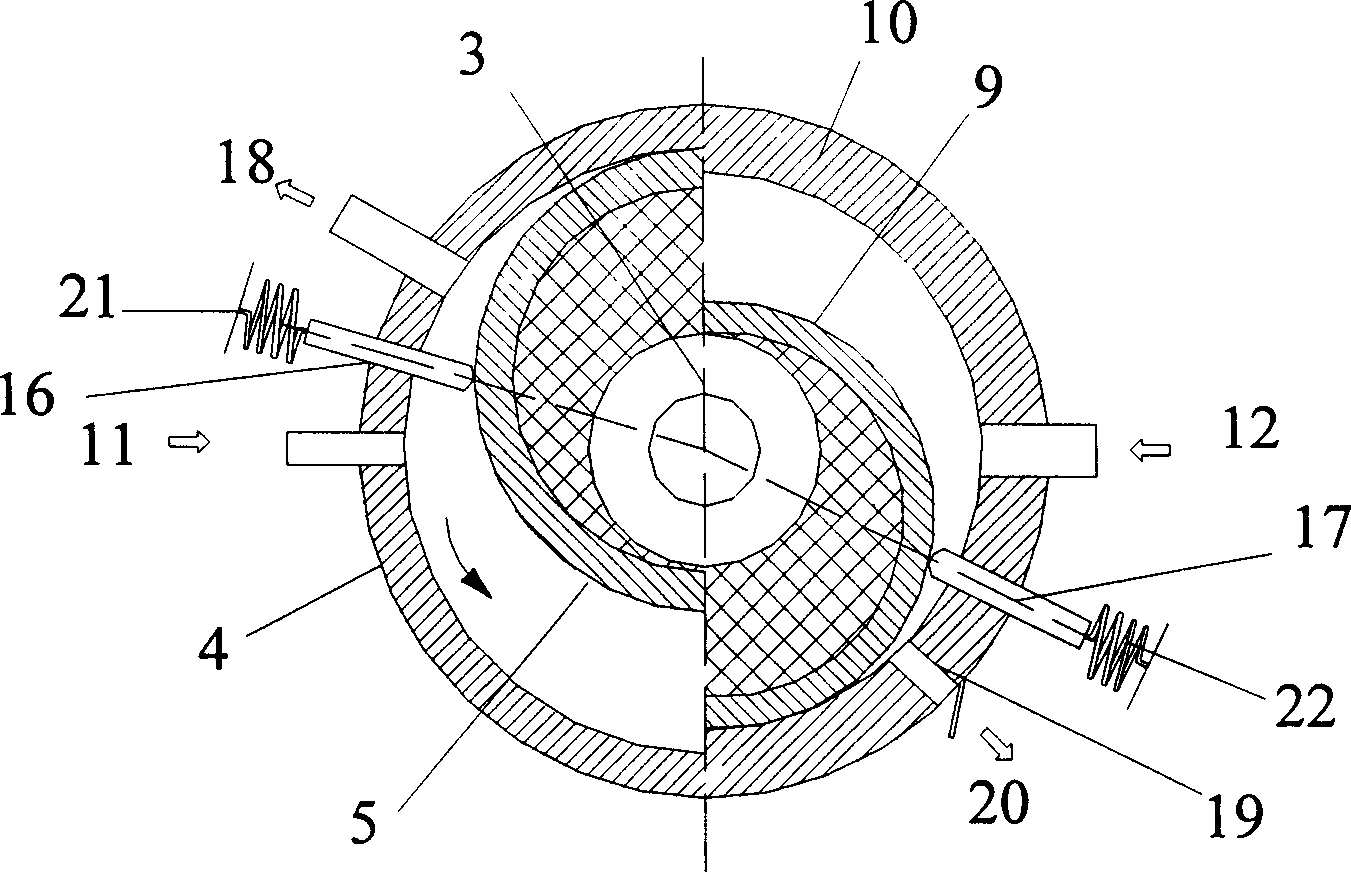

[0011] When working, the supercritical high-pressure carbon dioxide fluid (usually with a pressure of about 10Mpa) enters the high-pressure chamber (B) from the intake pipe (11). (5) Rotate and drive the eccentric shaft (3) according to the attached figure 2 Rotate in the direction sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com