System and method for preparing polymer-grade propylene through absorption and separation of catalytic cracking product gas

A polymer-grade propylene, catalytic cracking technology, applied in absorption purification/separation, chemical instruments and methods, hydrocarbons, etc., can solve the problems of high refrigerant energy consumption, increased equipment investment, and high energy consumption

Active Publication Date: 2013-06-19

CHINA PETROLEUM & CHEM CORP +1

View PDF3 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This conventional separation method has high energy consumption and high equipment investment. The reason is that the carbon three and lighter components need to be compressed to enter the ethylene tower for separation, which has high energy consumption and requires an additional compressor or A special compression section is added to the product gas compressor, which increases equipment investment; at the same time, the top of the ethylene tower needs to be condensed with -15°C refrigerant, which consumes high energy. If a refrigeration unit is installed separately, the device investment will increase

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0057] The present invention will be described in detail in combination with the above drawings and the following specific embodiments, but the scope of rights of the present invention is not limited by the specific embodiments.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

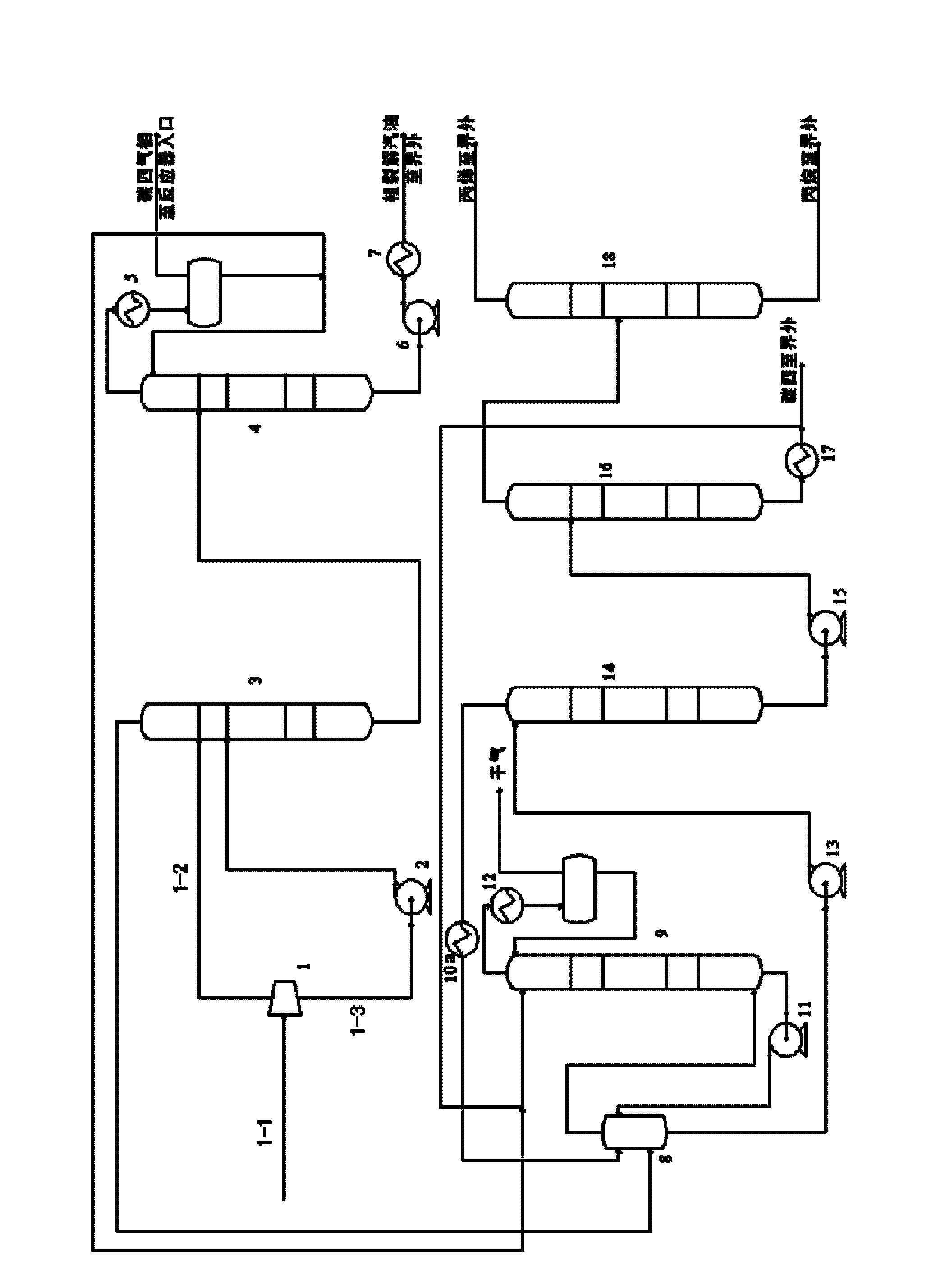

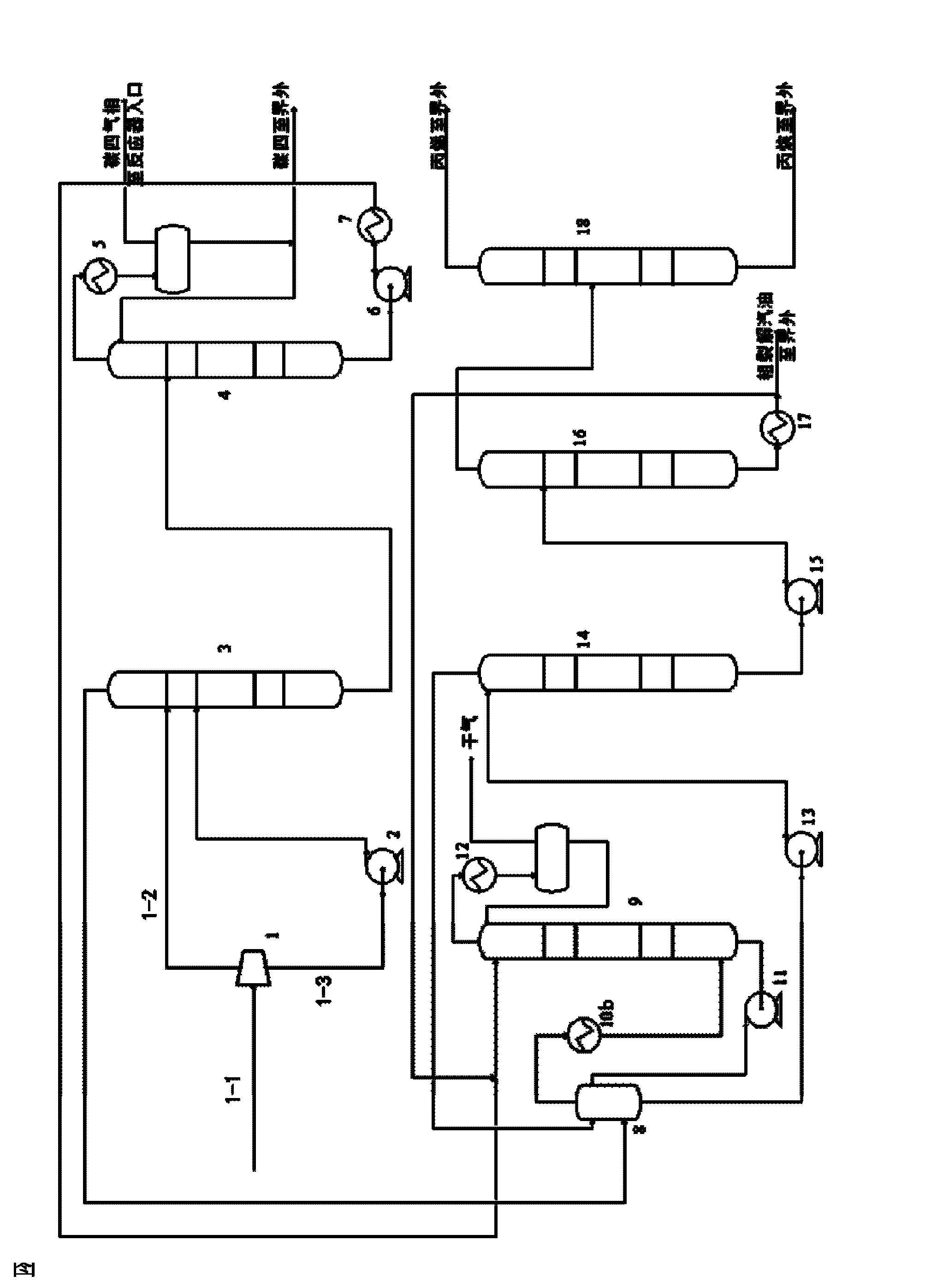

The invention provides a system and a method for preparing polymer-grade propylene through absorption and separation of catalytic cracking product gas. A debutanizing tower, an absorption tower, and a desorption tower are sequentially arranged between a pre depropanizing tower and a post depropanizing tower. A propylene tower is arranged behind the post depropanizing tower. A gas enrichment balancing tank is arranged between the absorption tower and the desorption tower. Through the pre depropanizing tower, catalytic cracking product gas is separated into C3 and lighter components and C4 and heavier components. The C4 and heavier components are processed by using the debutanizing tower, such that C4 component or C5 and heavier components are obtained. The obtained component is adopted as an absorption agent, and is used for absorbing the C3 and lighter components of the pre depropanizing tower top gas in the absorption tower. With the desorption tower, C3 component and C2 and lighter components are separated through desorption. The tower kettle liquid of the desorption tower is delivered to the post depropanizing tower. Post depropanizing tower top gas is subjected to propane-propylene separation in the propylene tower, such that the polymer-grade propylene product is obtained at the top of the propylene tower. With the system and method provided by the invention, an oil absorption method is adopted; the application of low-temperature cold energy is avoided; energy consumption is reduced; and equipment investment is saved.

Description

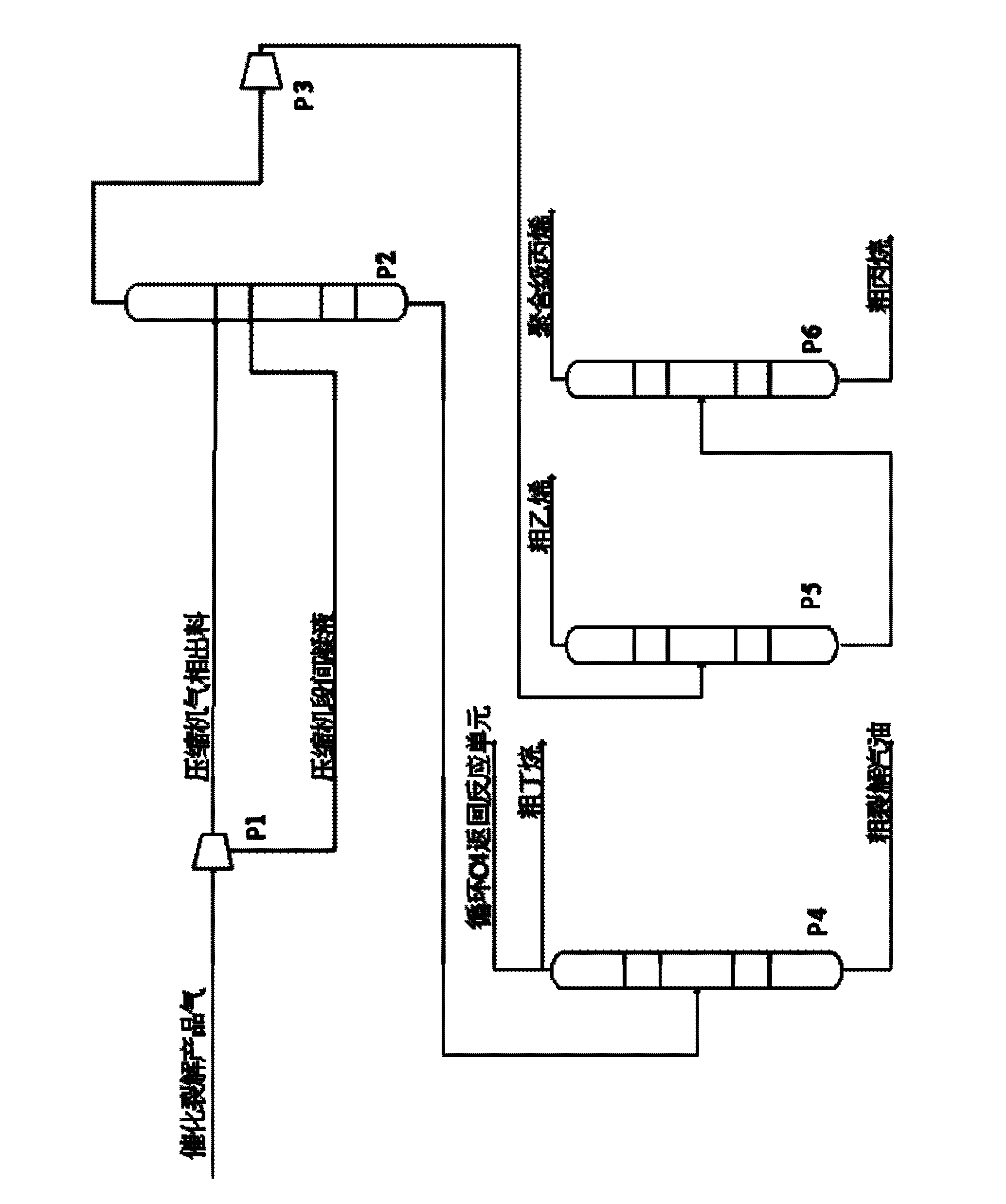

Technical field [0001] The invention relates to a method for oil absorption and separation of catalytic cracking reaction product gas. More specifically, it relates to a system and method for preparing polymerization-grade propylene from catalytic cracking product gas by using an oil absorption method to replace the traditional cryogenic distillation separation method. Background technique [0002] The catalytic cracking reaction product gas, which mainly contains methane, carbon two, carbon three, carbon four, carbon five and heavier components, is generally separated by a traditional cryogenic distillation separation method that is pressurized and condensed by a low-temperature refrigerant. Usually the process flow of this method can be seen figure 1 , Firstly, the catalytic cracking product gas is compressed to 1.0MPa-1.6MPa by the first compressor P1, and then the gas phase and the condensate between the compressor sections are sent to the depropanizer P2 to separate the carb...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C07C11/06C07C9/08C07C7/11C07C7/00C07C4/06C10G5/04

Inventor 时海涛王鑫泉高耸

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com