Tesla turbine disk and production method thereof

A Tesla turbine and carbon fiber technology, applied in the direction of mechanical equipment, blade support components, engine components, etc., can solve problems such as large differences in thermal expansion coefficients, large differences in physical and chemical properties, residual thermal stress at joints, etc., to maintain The shape and size are unchanged, the effect of resisting the erosion of high-temperature jets and improving the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

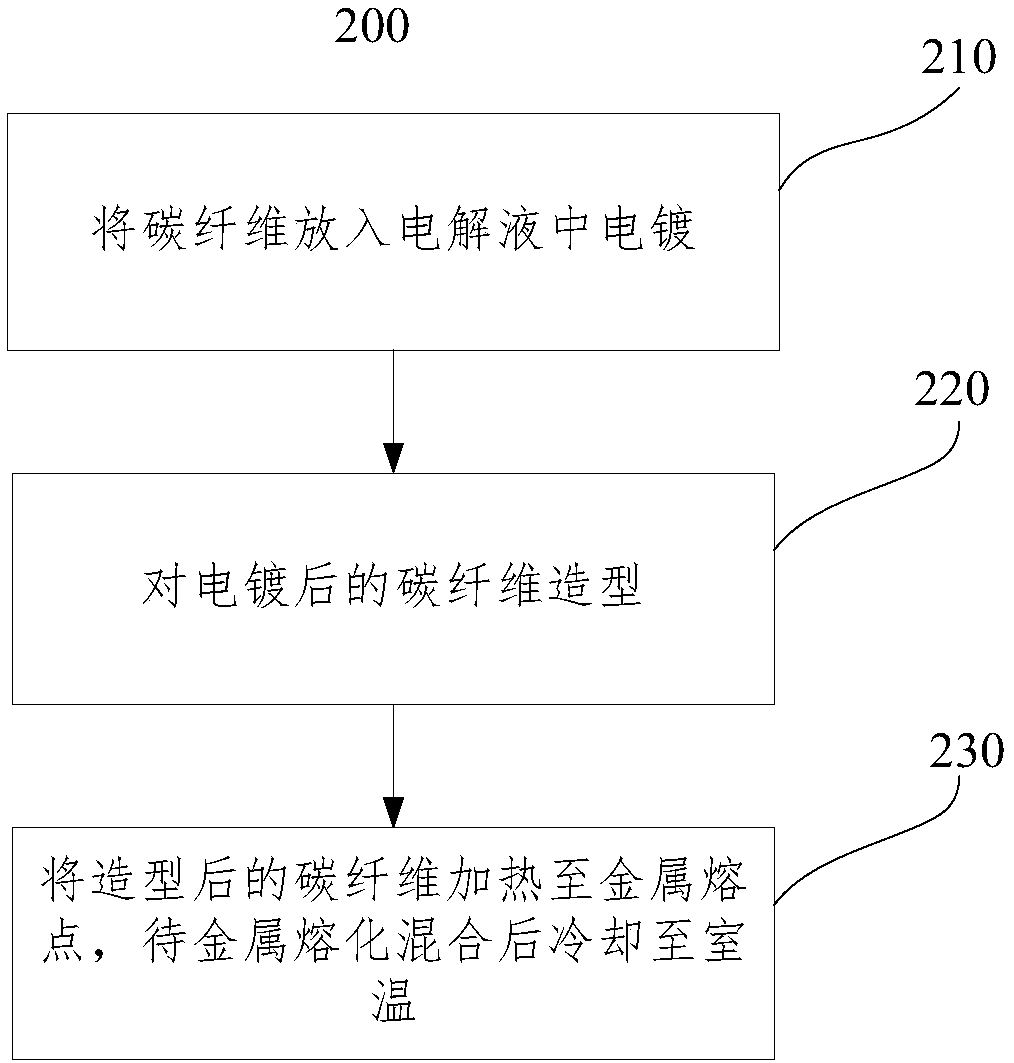

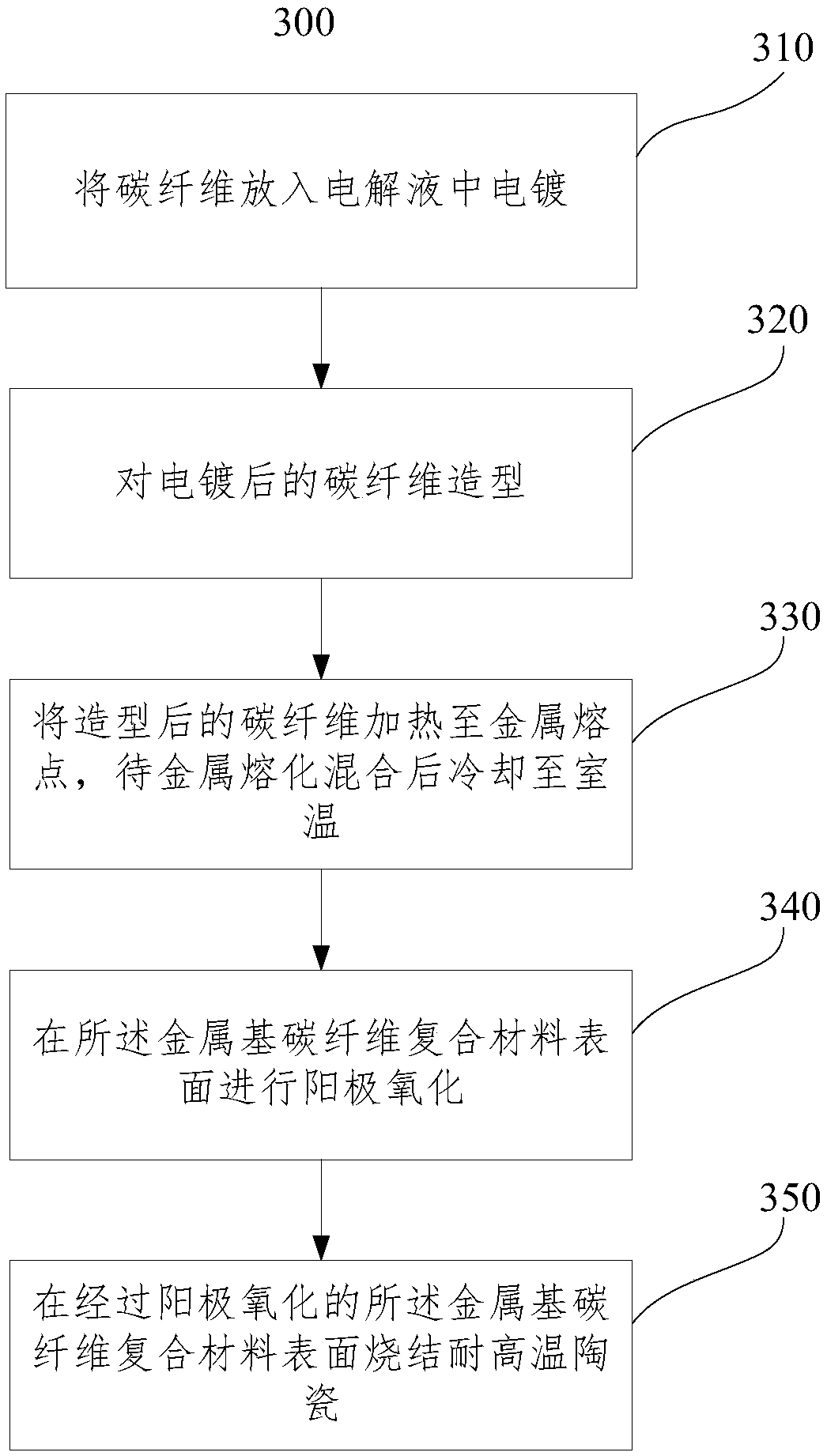

[0038] A preparation method 200 of a metal matrix carbon fiber composite material, such as figure 2 shown, including the following steps:

[0039] Step 210, electroplating the carbon fiber in the electrolyte;

[0040] Step 220, molding the electroplated carbon fiber to obtain a predetermined shape of carbon fiber;

[0041] Step 230 , heating the molded carbon fiber to the melting point of the metal, cooling to room temperature after the metal is melted and mixed, and discharging, so as to obtain the metal-based carbon fiber composite material.

[0042] The metal-based carbon fiber composite material is a nickel-based carbon fiber composite material.

[0043] Specifically, the step 210 includes putting the carbon fiber into an electroplating pool equipped with a nickel-containing electrolyte for electroplating, wherein, in the nickel-containing electrolyte, the mass percentage of nickel is greater than 25%, and the diameter of the carbon fiber is 0.1- 0.3mm, preferably 0.2m...

Embodiment 1

[0070] Preparation method of Tesla turbine disk using nickel-based carbon fiber composite ceramics:

[0071] First, put the carbon fiber into a nickel-containing electrolyte for electroplating; the electrolyte contains 500 g / L of nickel sulfate; 70 g / L of nickel chloride; 40 g / L of boric acid; and 0.1 g / L of sodium lauryl sulfate. Wherein the nickel sulfate is the main salt, the boric acid is the buffer, the nickel chloride is the anti-passivation agent, and the sodium lauryl sulfate is the dispersant. Experimental conditions: pH value is 3-4; temperature is 25°C; electroplating time is 1-12min; current density is 0.1-0.5A / dm2. The carbon fiber has a diameter of 0.2mm. Nickel-based carbon fibers are obtained after electroplating.

[0072] The plated nickel-based carbon fiber is wound on a mandrel to form a disc-shaped carbon fiber; the mandrel is selected from one or more combinations of alumina, zirconium carbide and boron nitride.

[0073] Heat the disc-shaped carbon fibe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com