Rotor-free through-flow measurement method for steam turbine

A technology without rotors and steam turbines, applied in the field of flow measurement, can solve the problems of complex operation, low safety, and increased labor intensity of workers, and achieve the effect of simple operation, high safety, and shortened delivery time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

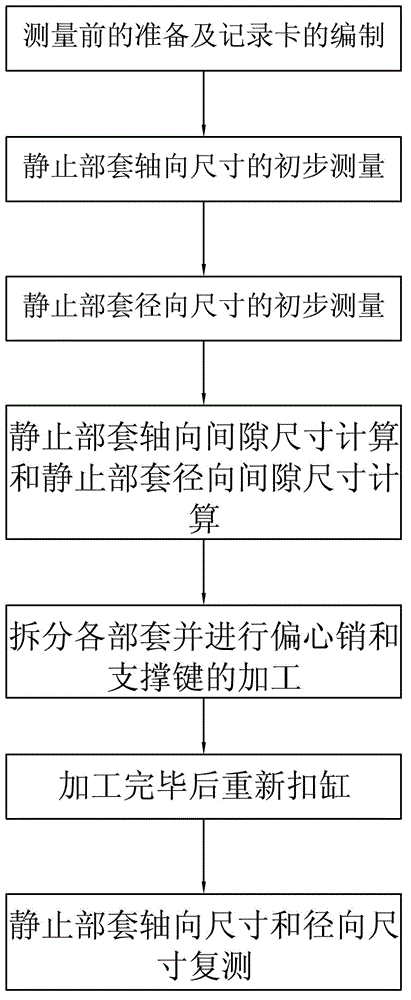

[0022] Specific implementation mode one: combine figure 1 To illustrate this embodiment, the specific steps of a method for measuring through-flow without a rotor of a steam turbine described in this embodiment are as follows:

[0023] Step 1. Preparation before measurement and preparation of record card: According to the drawing of the flow gap of the steam turbine assembly, the size of the flow gap is decomposed into the record card of the static part sleeve and the rotor respectively, and the preliminary measurement is compiled according to the characteristics of the two measurements before and after. Record card and precision measurement record card to determine the position of each measurement point;

[0024] Step 2. Preliminary measurement of the axial dimension of the static part sleeve: the measurement of the axial dimension of the stationary part sleeve is to drop the partition sleeve, partition plate and air seal into the lower half of the cylinder under the conditio...

Embodiment

[0039] Take AP1000 million nuclear power unit low-voltage rotorless flow measurement as an example:

[0040] The specific steps of axial clearance measurement for low-voltage rotorless measuring flow of AP1000 million nuclear power units are as follows:

[0041] Step 1. Axial dimension measurement is to measure the lower half of the low-pressure cylinder that has completed the assembly of the diaphragm sleeve, diaphragm and air seal, and has not been equipped with an exhaust guide ring under the state of the cylinder without the rotor. The low-pressure cylinder The horizontal split surface, the end face of the low-voltage inner cylinder ESC, the alignment reference circle of the low-voltage inner cylinder, the planes of the steam inlet side of the baffles at all levels and the steam outlet side planes of the baffles at all levels are cleaned, free of oil, silt and other sundries. The mid-section bolts go out to ensure that there is no light blocking during measurement. The las...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com