Annular tesla turbine

A Tesla turbine, annular technology, applied in the directions of blade support elements, engine elements, machines/engines, etc., can solve the problems of large inter-disk eddy current torsion, large vibration, insufficient rigidity and easy deformation, etc., to achieve stable and reliable operation. , the effect of increasing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

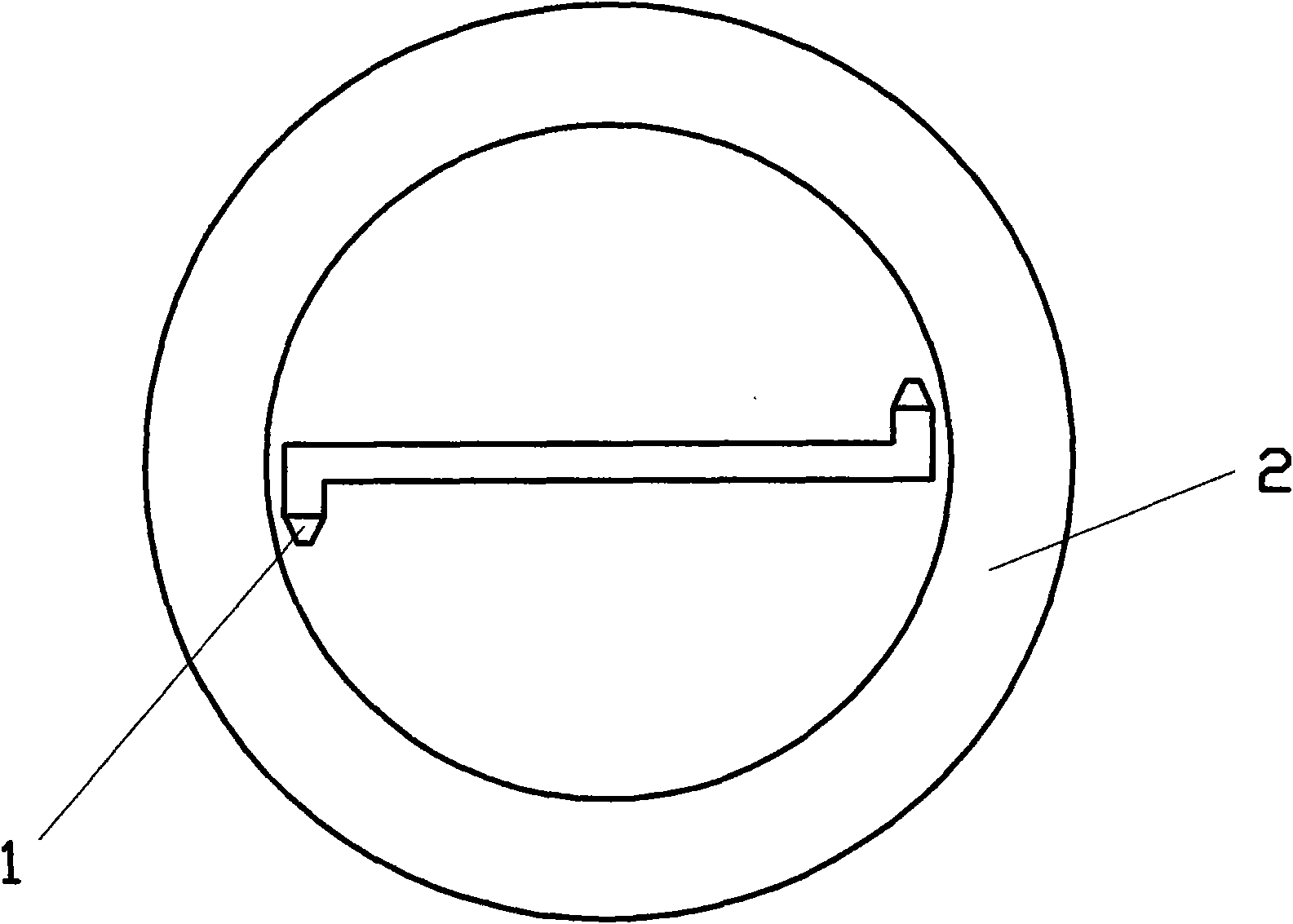

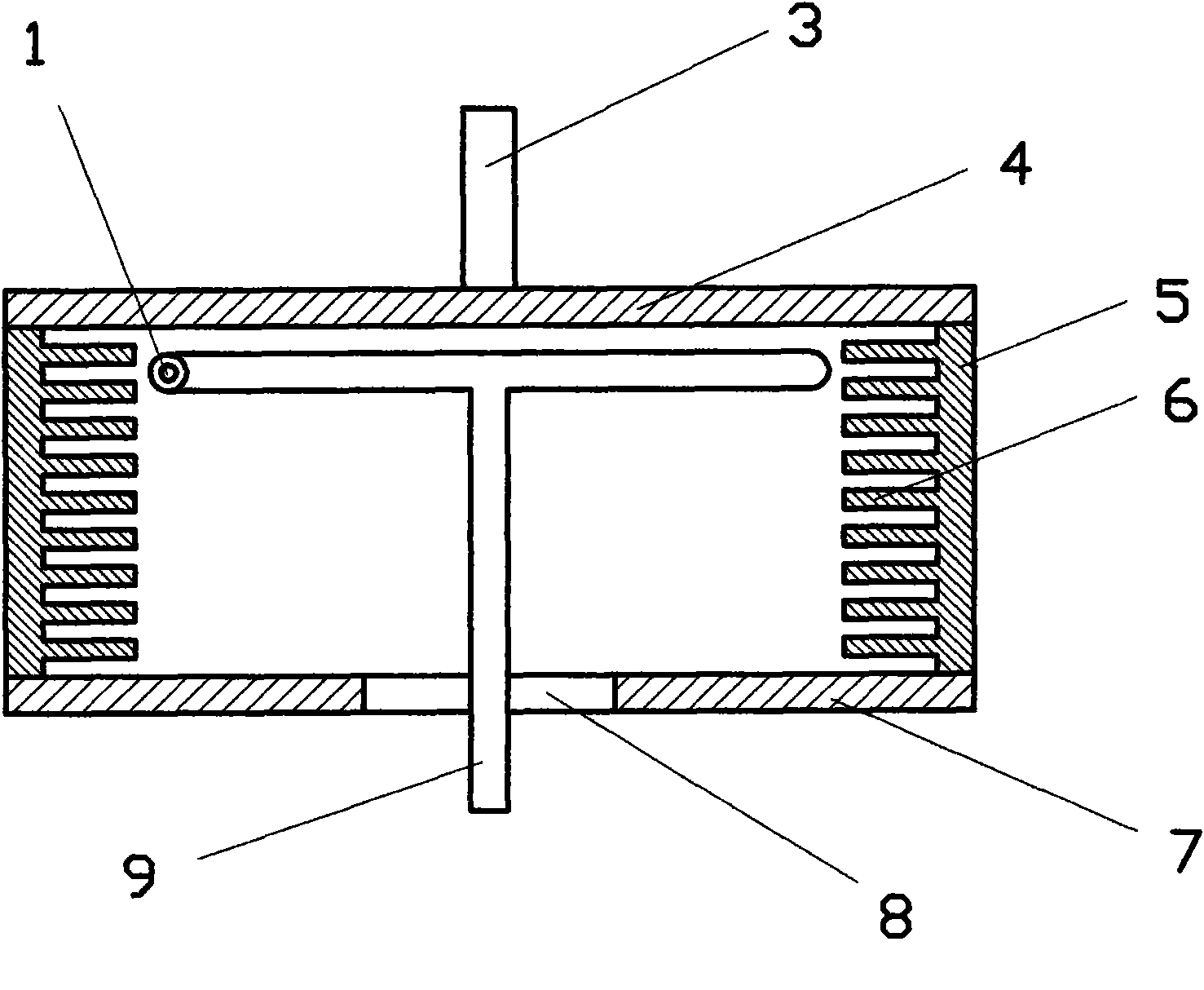

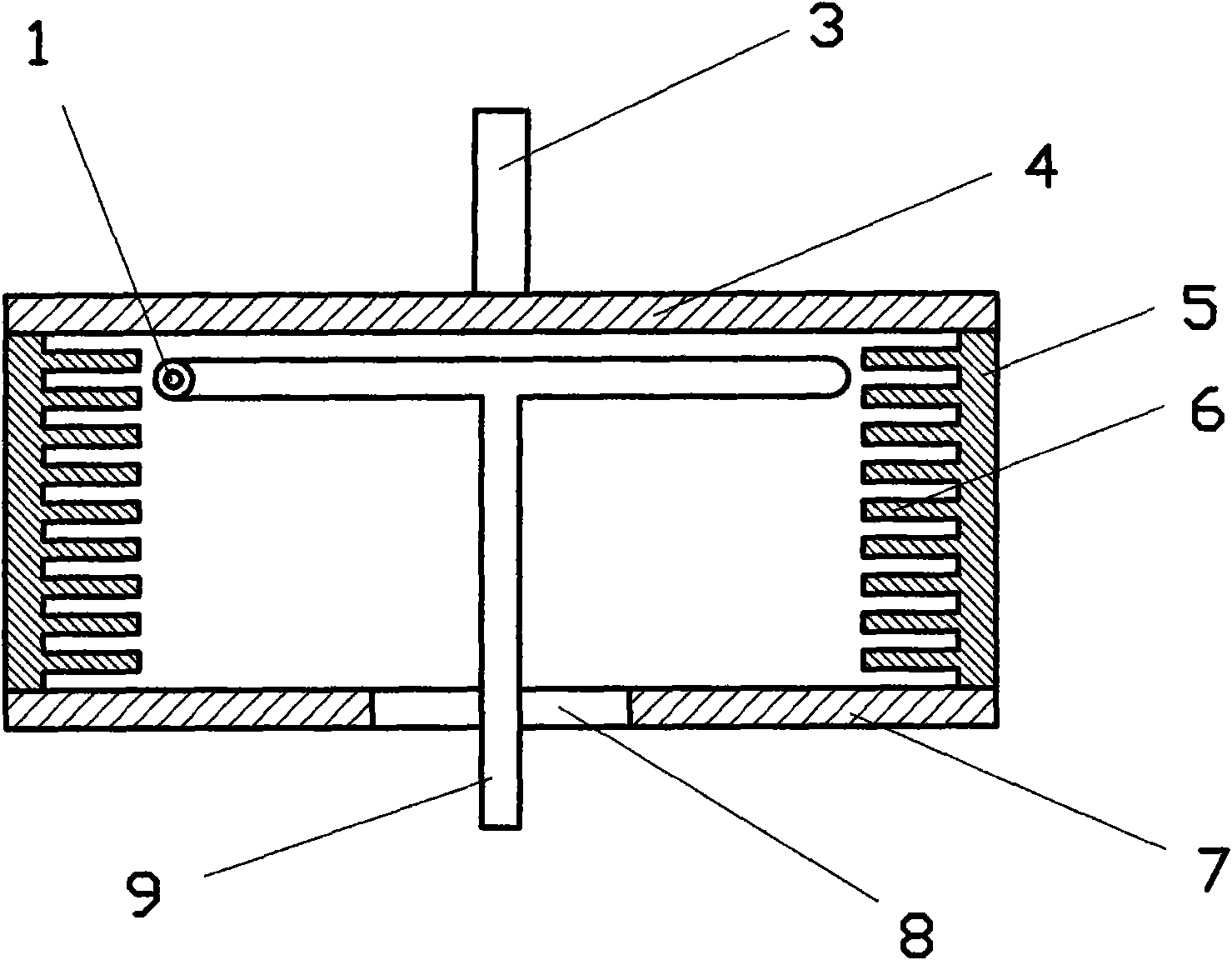

[0008] exist figure 1 Among them, there are nozzles (1) inside the rotor (2), and there can be multiple nozzles, which should be evenly distributed so that the rotor (2) can be evenly stressed when the air is sprayed out. The cross-sectional structure of the rotor (2) is as follows figure 2 As shown, from top to bottom are the rotating shaft (3), the rotor upper cover (4), the ring (5), the rotor lower cover (7), wherein the inner side of the ring (5) is distributed with annular slices (6), The rotor lower cover (7) has an exhaust port (8), and the air pipe (9) extends into the rotor (2) from the exhaust port (8) and is connected to the nozzle (1).

[0009] When working, the gas is passed from the air pipe (9) to the nozzle (1), and the nozzle (1) is sprayed to the inner side of the ring (5), and the air flow will form a vortex under the guidance of the inner side of the ring (5). The annular sheet (6) inside the ring (5) greatly increases the contact surface between the rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com