Patents

Literature

46 results about "Disk size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

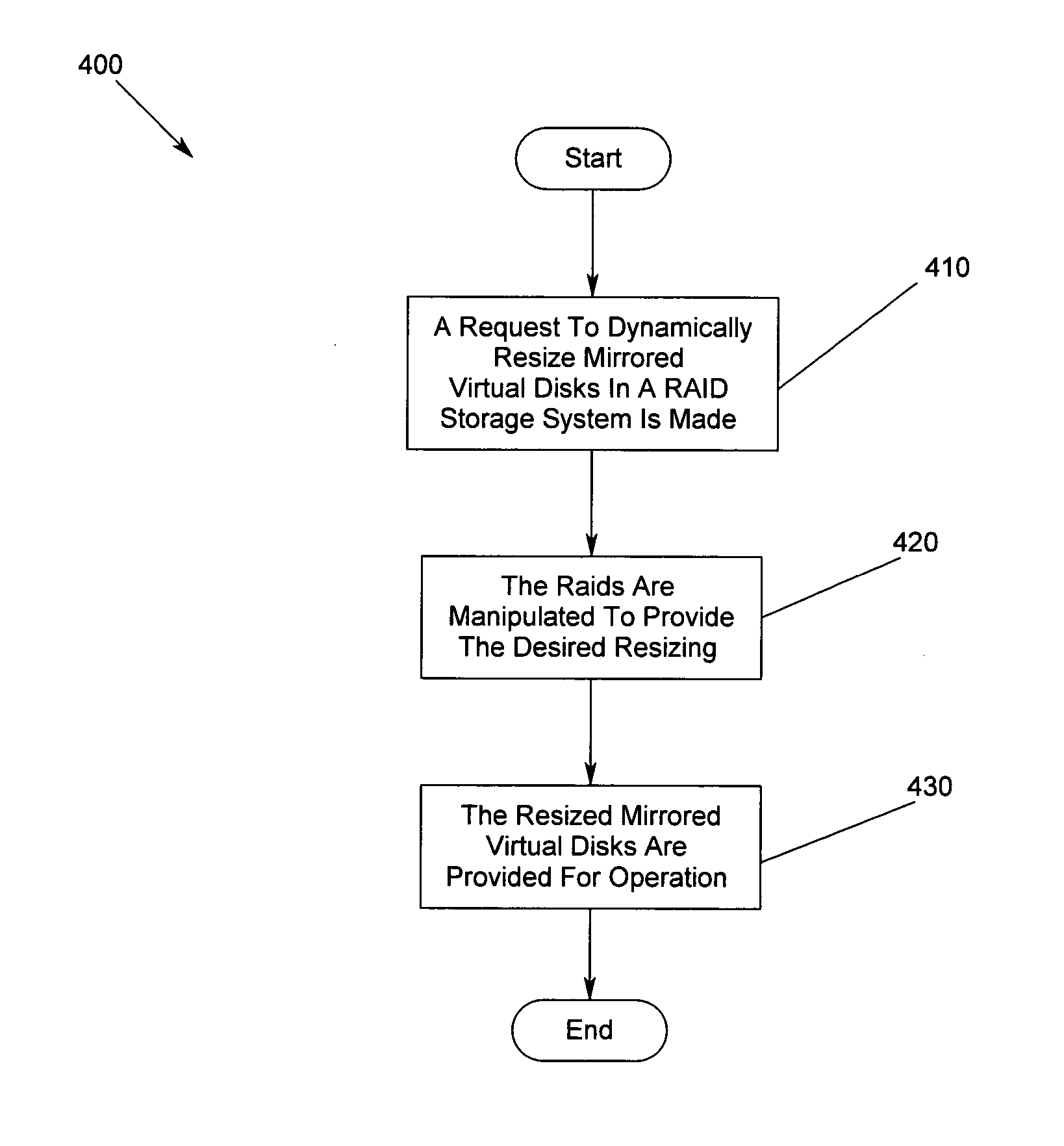

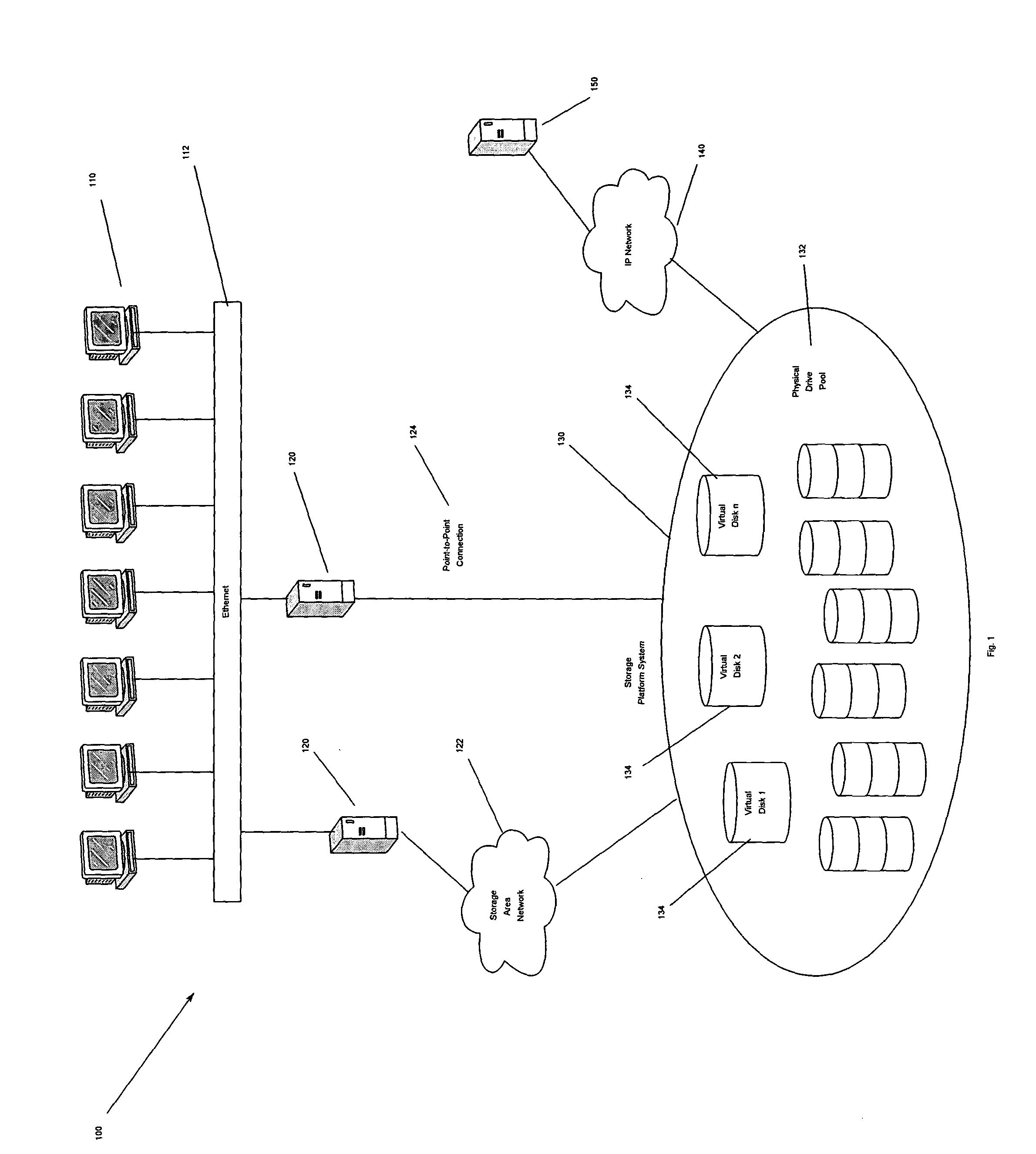

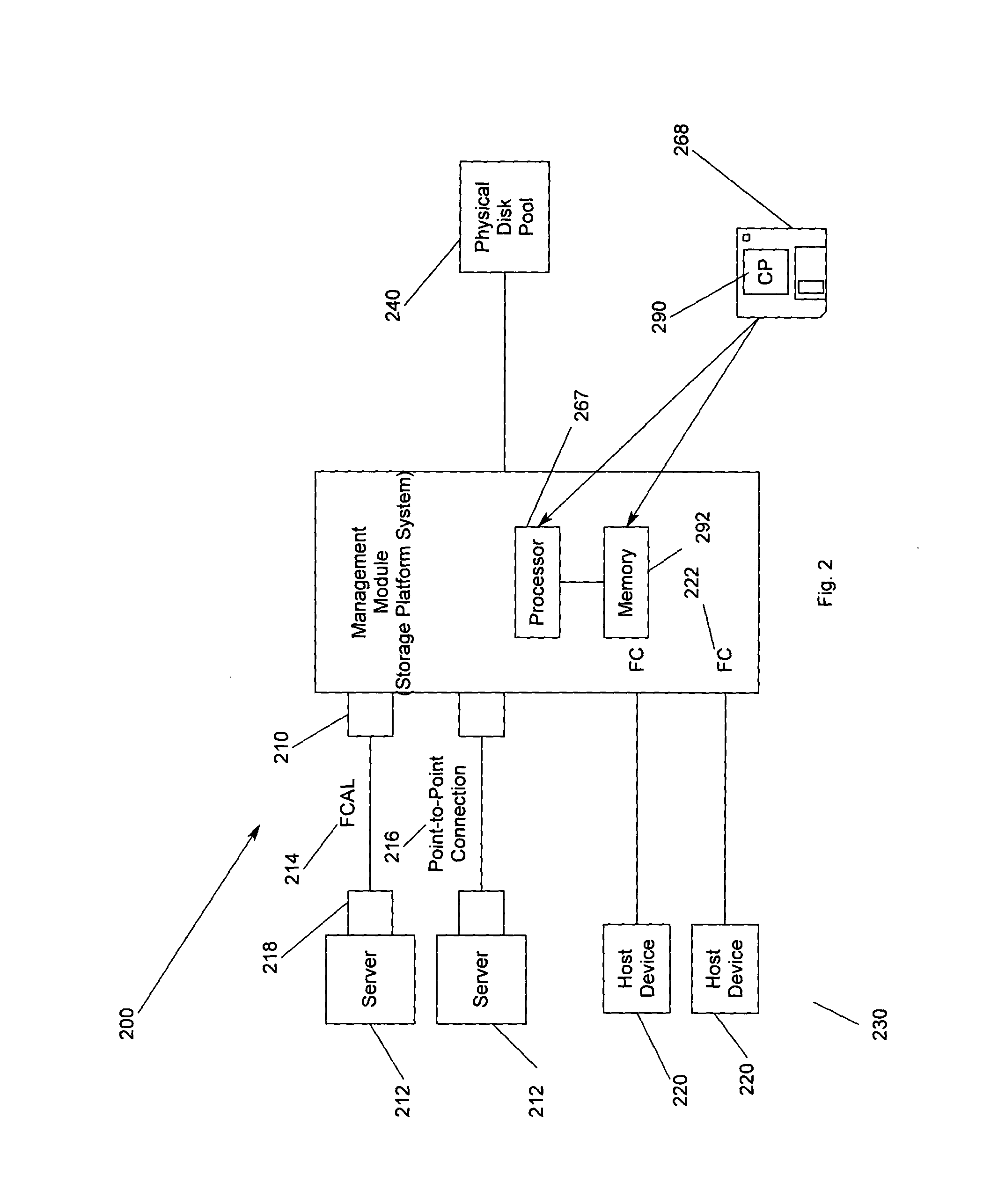

Method, apparatus and program storage device for dynamically resizing mirrored virtual disks in a RAID storage system

Owner:VIOLIN MEMORY INC

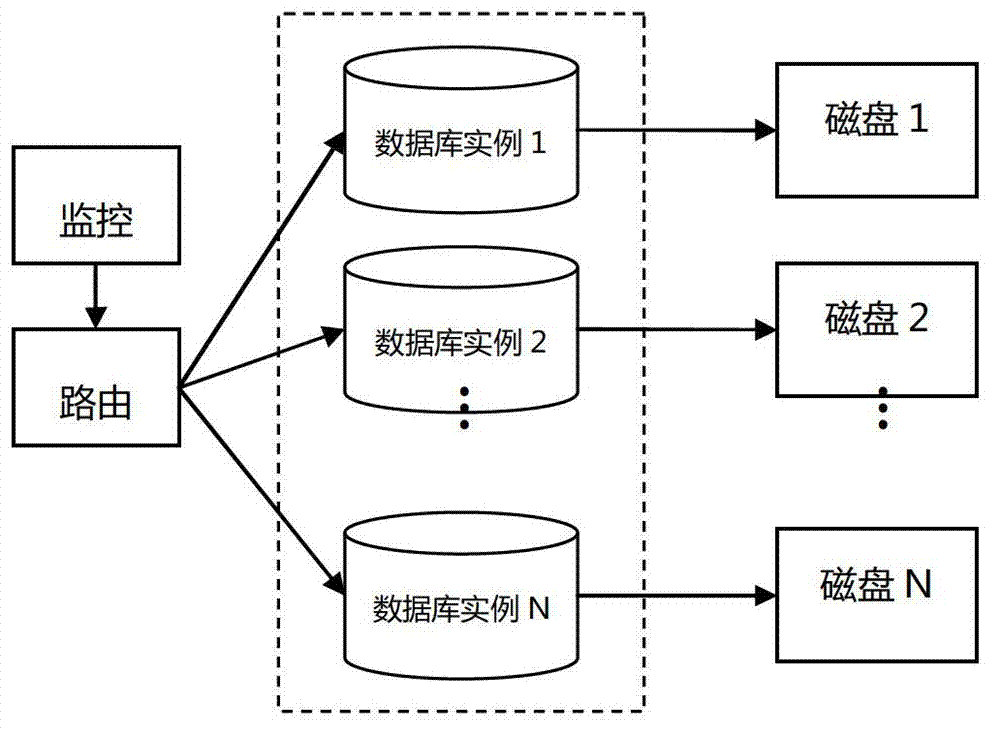

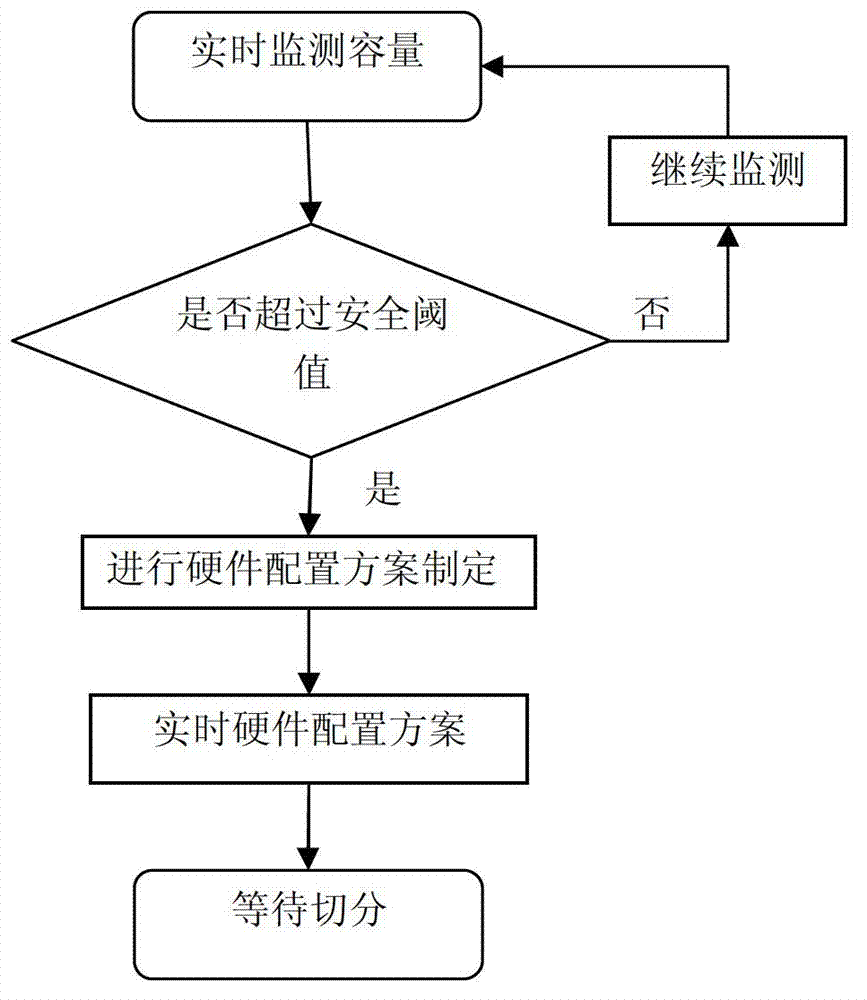

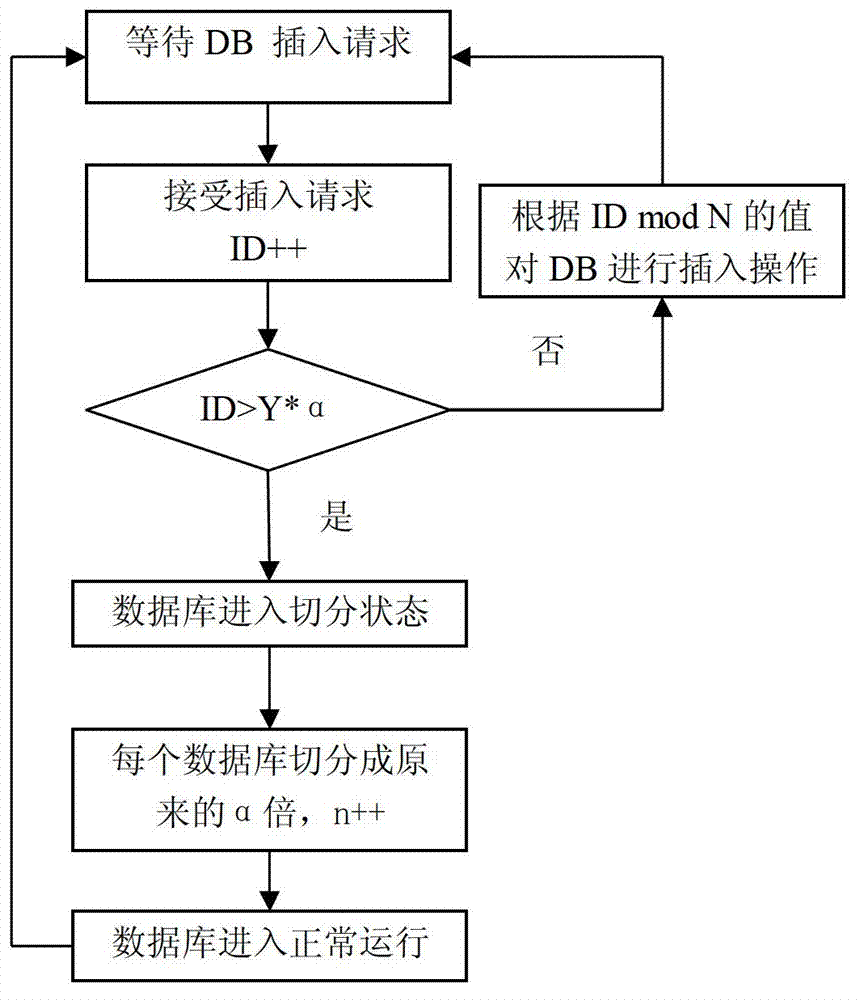

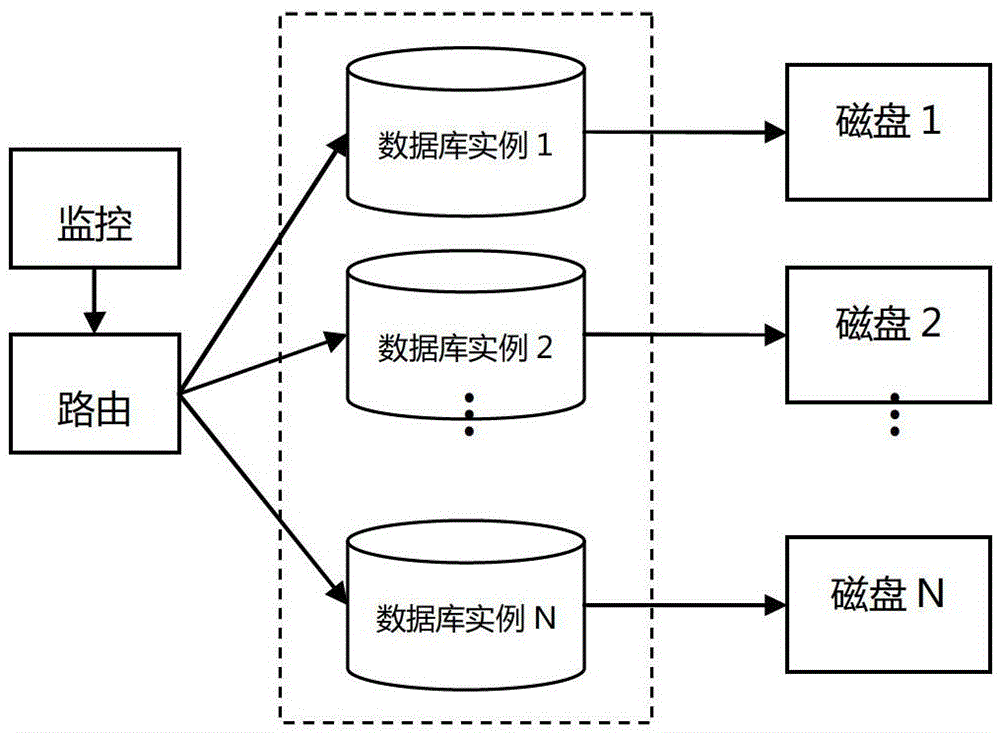

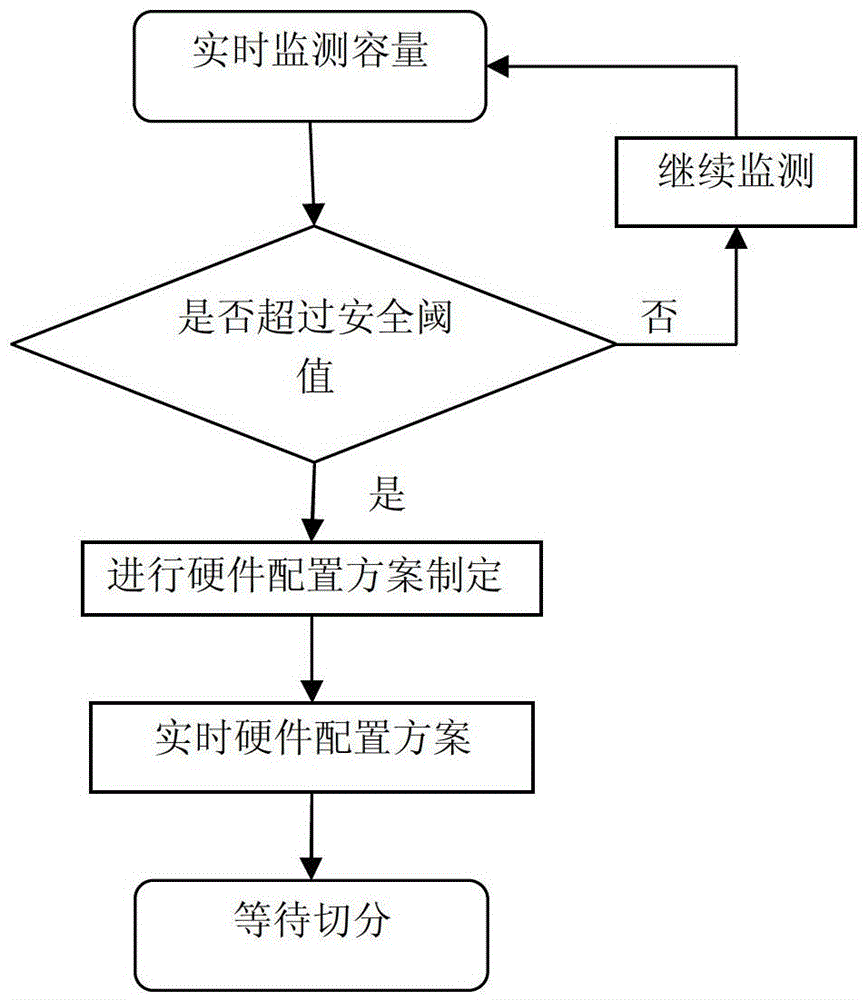

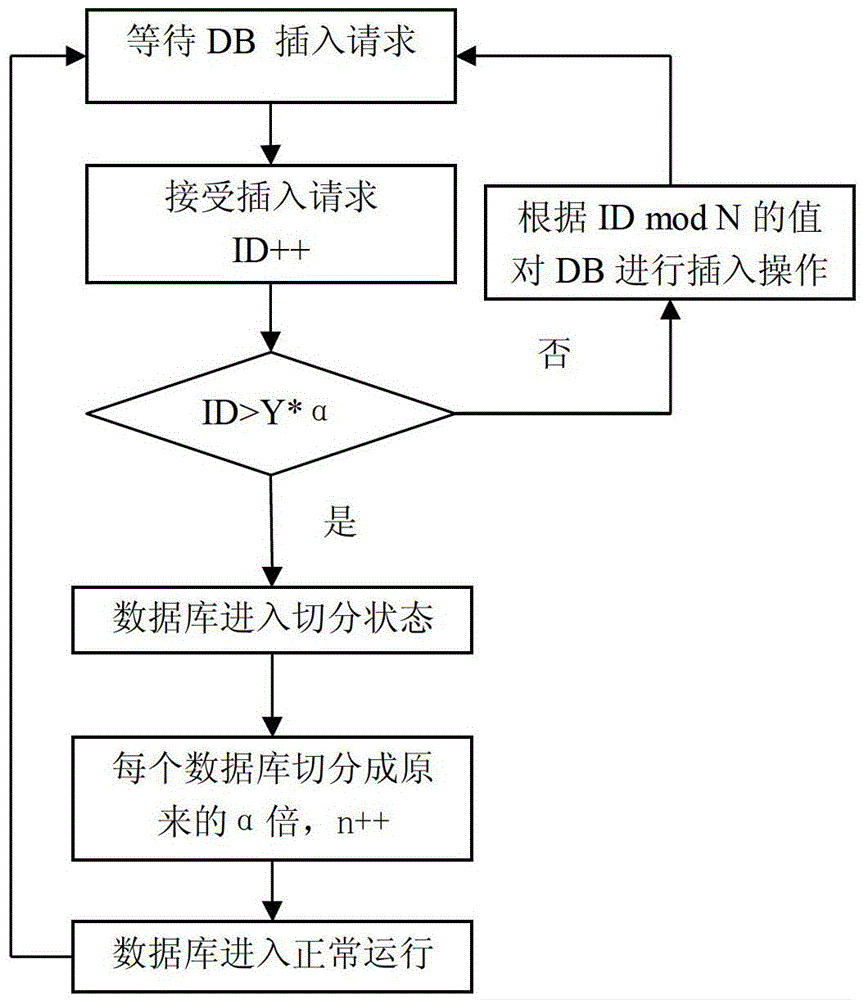

Rapid horizontal extending method for databases

ActiveCN102930062AImprove the speed of expansionEasy to monitorSpecial data processing applicationsData segmentDisk size

The invention discloses a rapid horizontal extending method for databases, which belongs to the field of data migration and storage. The method comprises the following steps: a monitoring and control system carries out monitoring on the disk storage space of the existing database, and when the disk size reaches a preset storage capacity threshold, the monitoring and control system triggers a hardware storage increasing action so as to make a hardware environment preparation for data migration; and a routing protocol carries out a modular computation on the instance number N of the current database according to a major key ID to be inserted currently, and routes the line number of data to be inserted into a specified database, and when the number of inserted lines exceeds a preset storage number threshold, the routing protocol triggers a database segmentation action so as to migrate specified data into a new database, thereby completing the rapid horizontal extending of the database. The method disclosed by the invention can be applied to disk databases or memory databases, and the method is easy to use and simple, and avoids the problem that hotspots are distributed nonuniformly caused by traditional horizontal extending of databases; in addition, as the scale of migration of data segmented each time is small, the extending speed is improved. In conclusion, the overall architecture meets the requirements on high availability, high reliability, high speed, high efficiency and the like.

Owner:NANJING FUJITSU NANDA SOFTWARE TECH

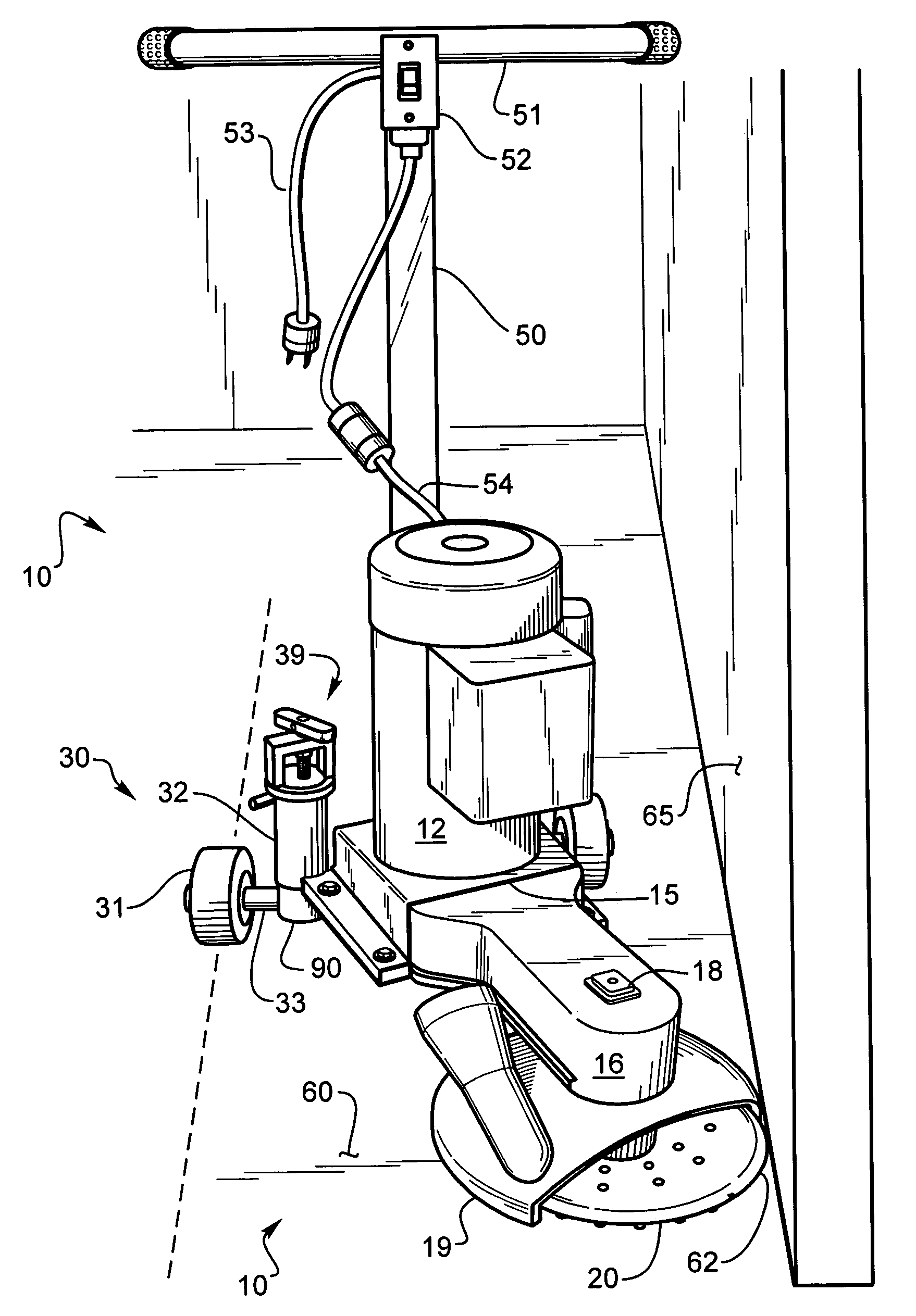

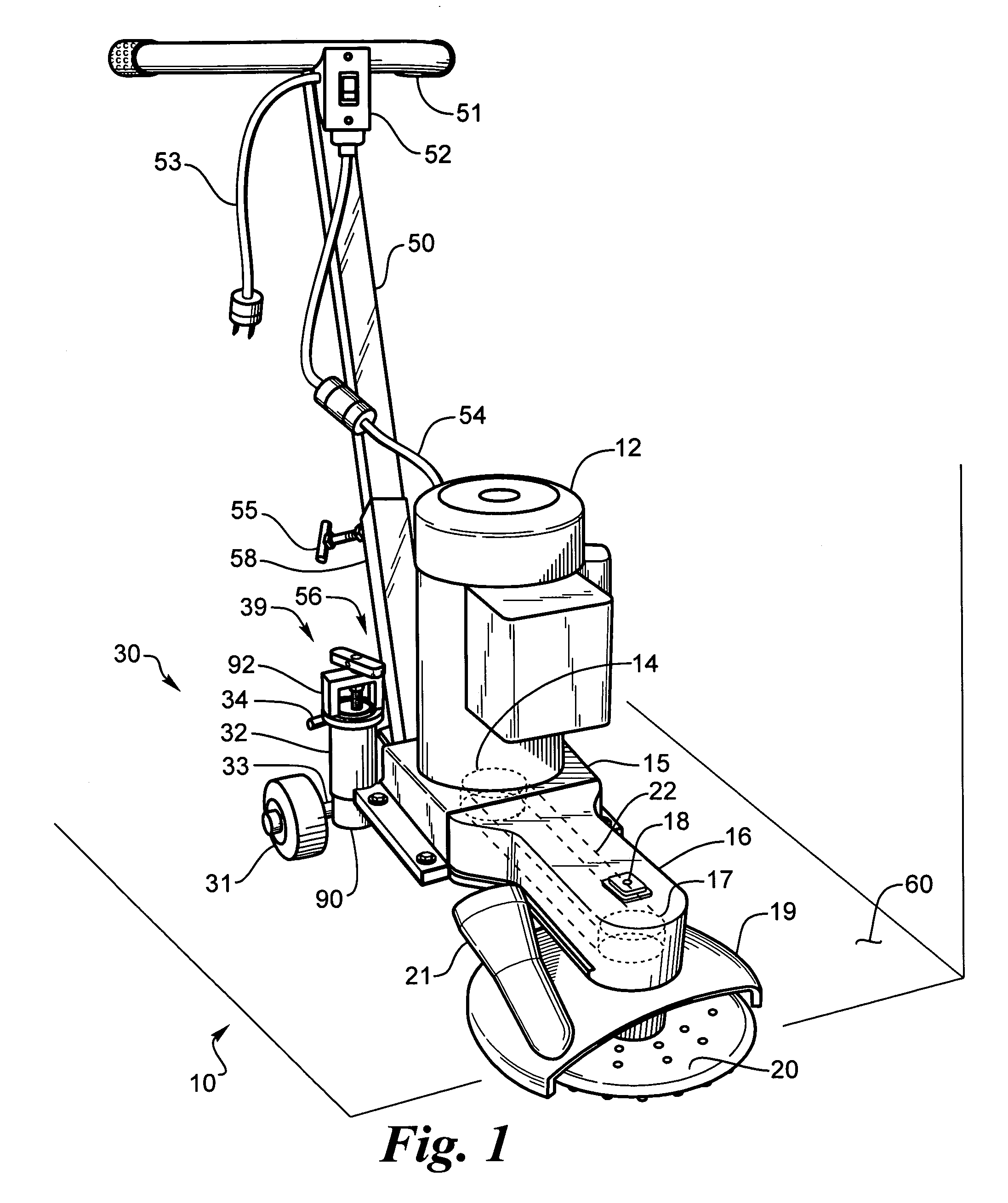

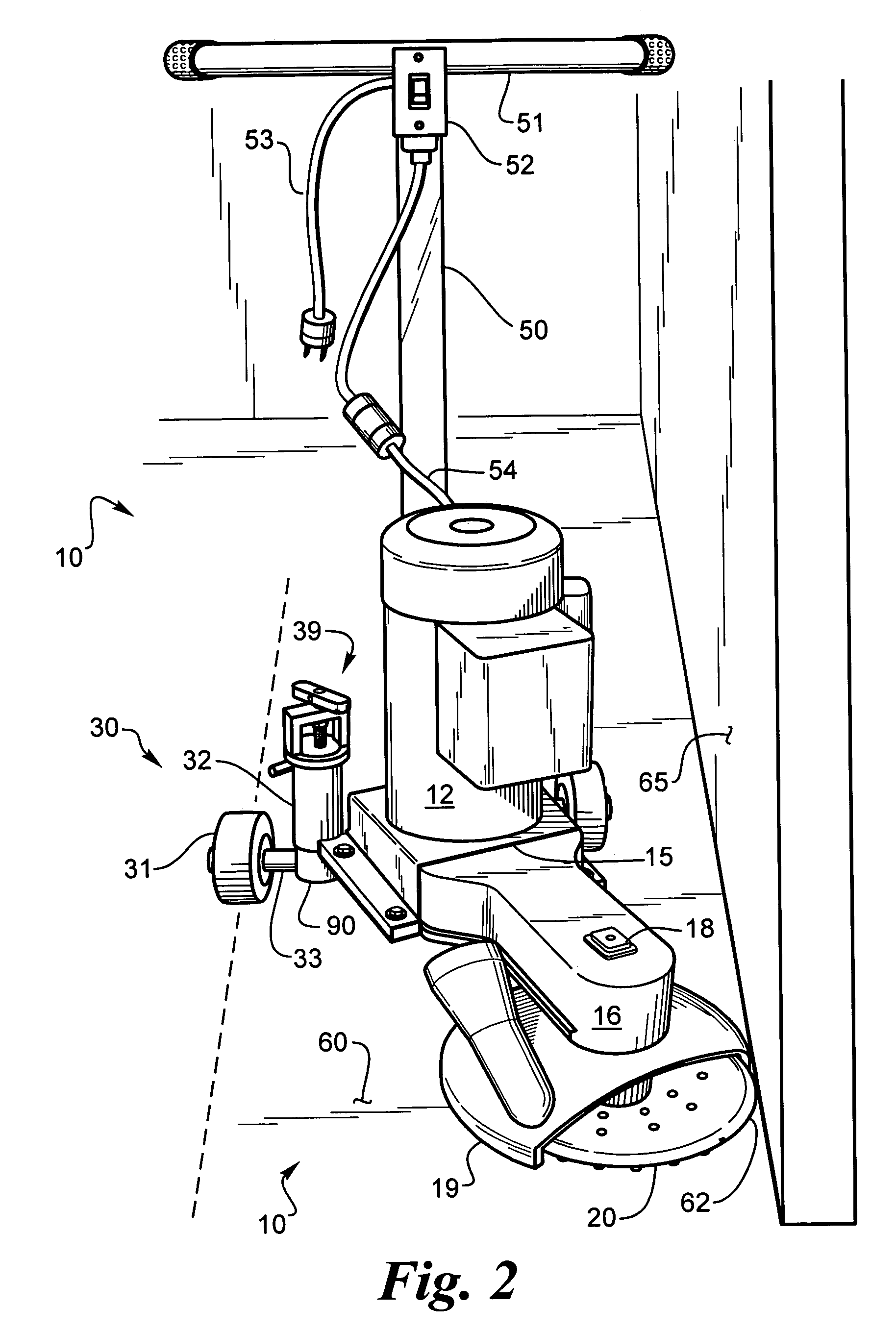

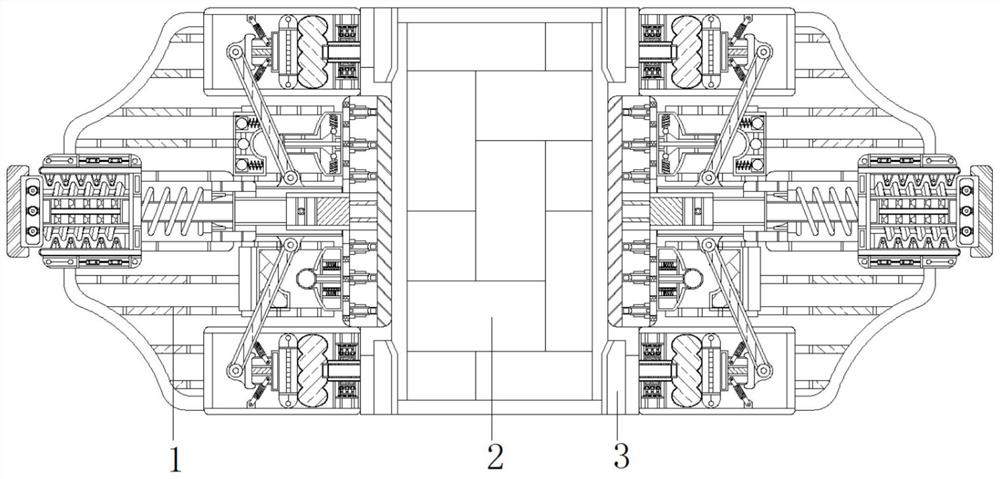

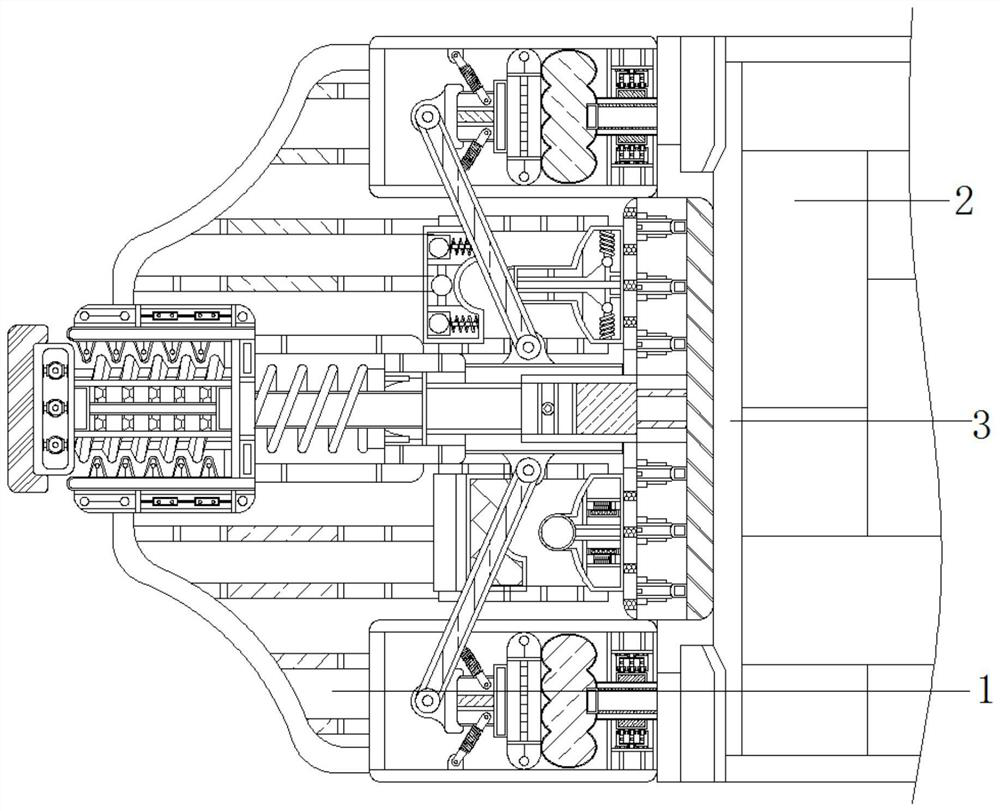

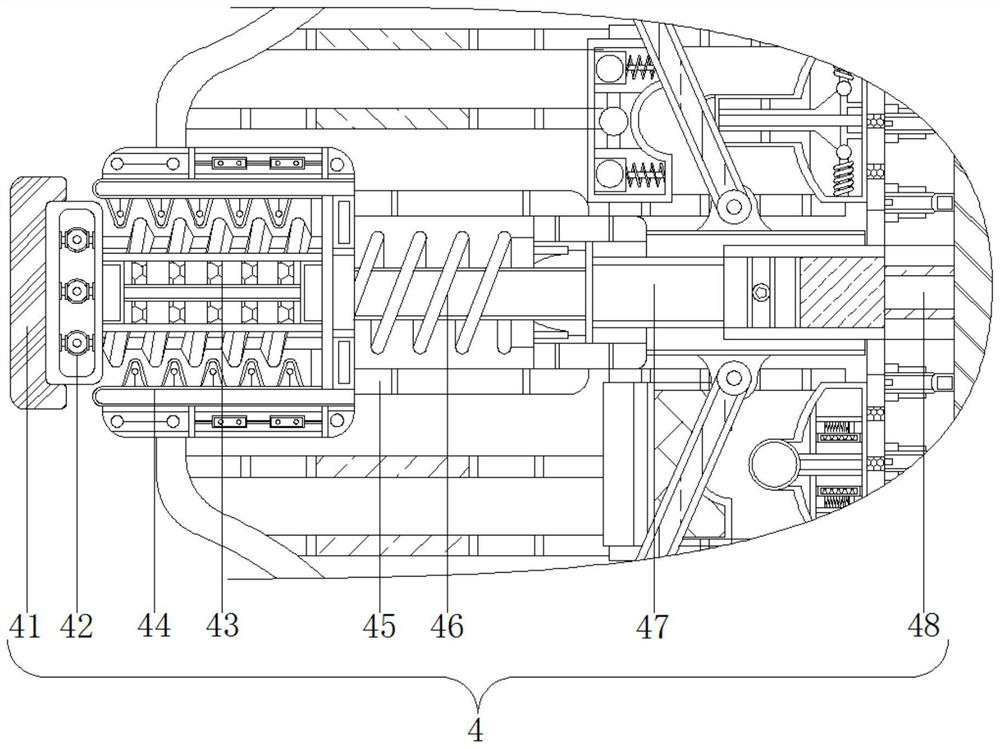

Combination edger and grinder for floors

InactiveUS7247085B1Faster and easy grindingQuickly and easy tiltCarpet cleanersFloor cleanersVehicle frameDisk size

A combined floor edger and grinder having a grinding disk which can be adjusted from engaging the floor while flat to engaging the floor along a front, back or side edge of the disk, depending on the height adjustment of the wheels on either side of the frame. The wheels, shroud and handle can also be adjustable relative to the frame for moving the frame straight back and forth or at an angle such that with the disk adjusted to engage the floor on one side of the frame the wheels and handle can be adjusted such that they are angled with respect to a wall for use as an edger whereby a user can push the device along the edge of a wall in a straight line while edging. The shroud and disk sizes may be easily changed for different jobs. The shroud can be open or close ended.

Owner:NAT FLOORING EQUIP INC

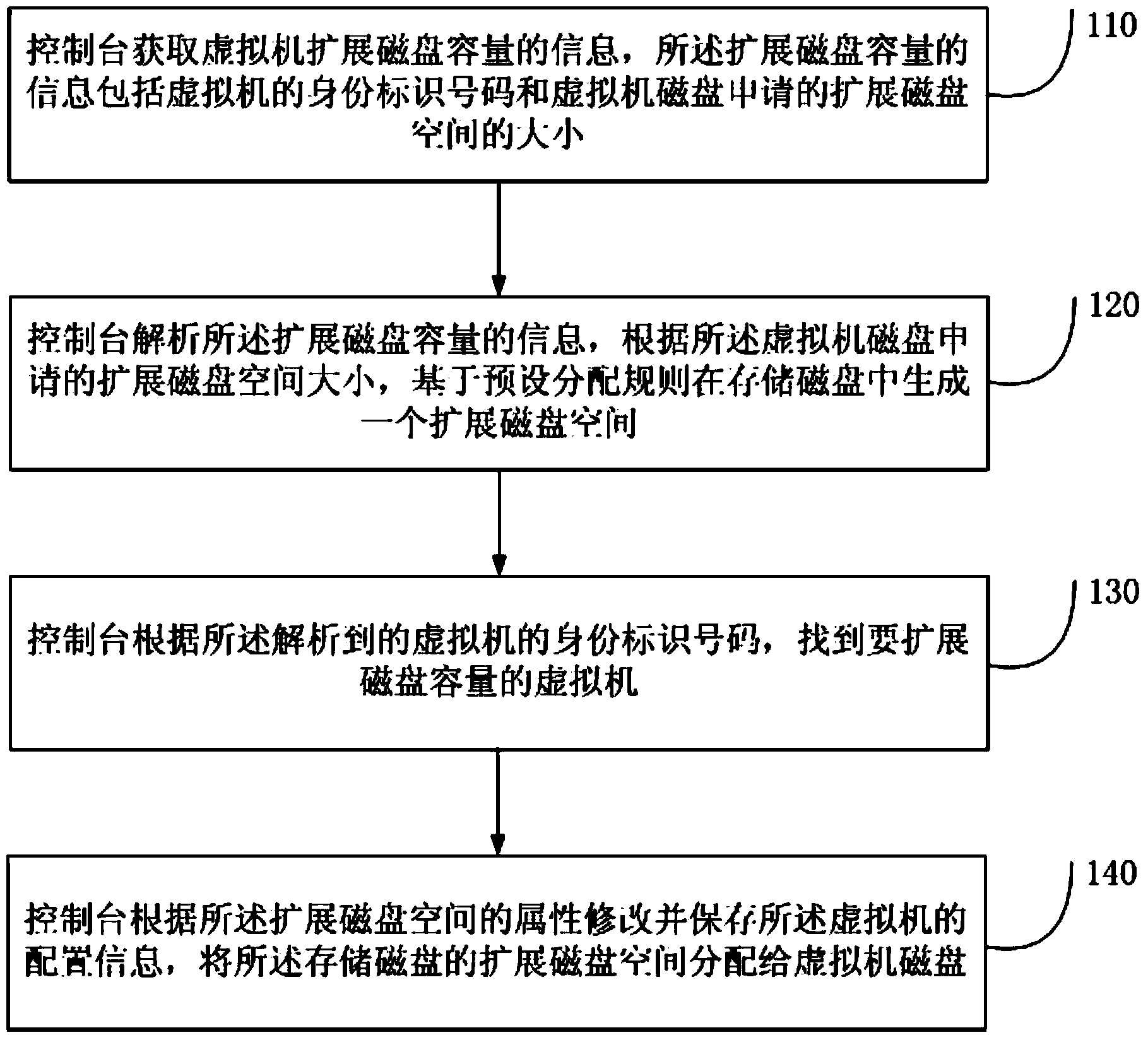

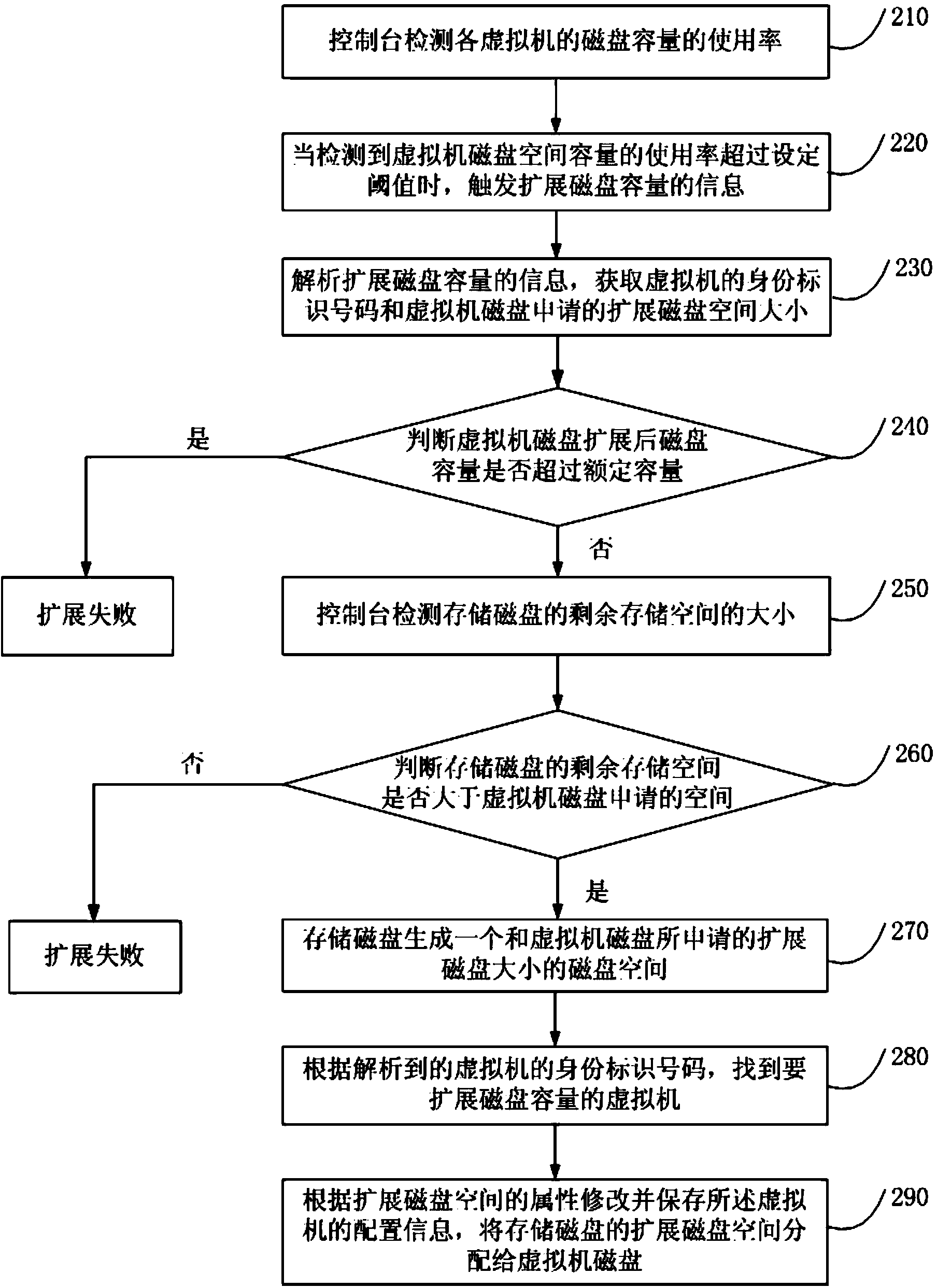

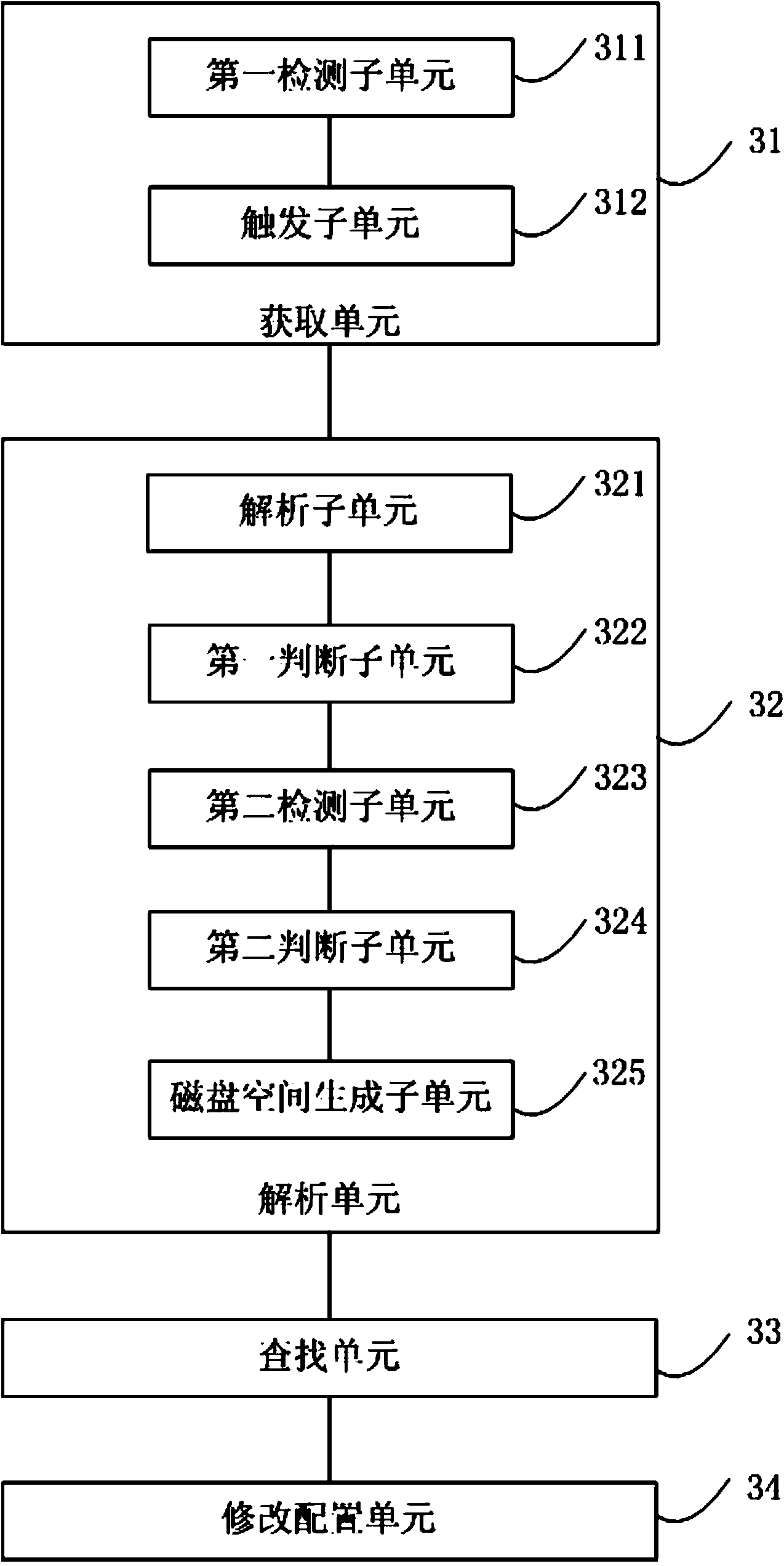

Method for on-line extension of disk size of virtual machine and virtual system console

Owner:BEIJING TEAMSUN TECH

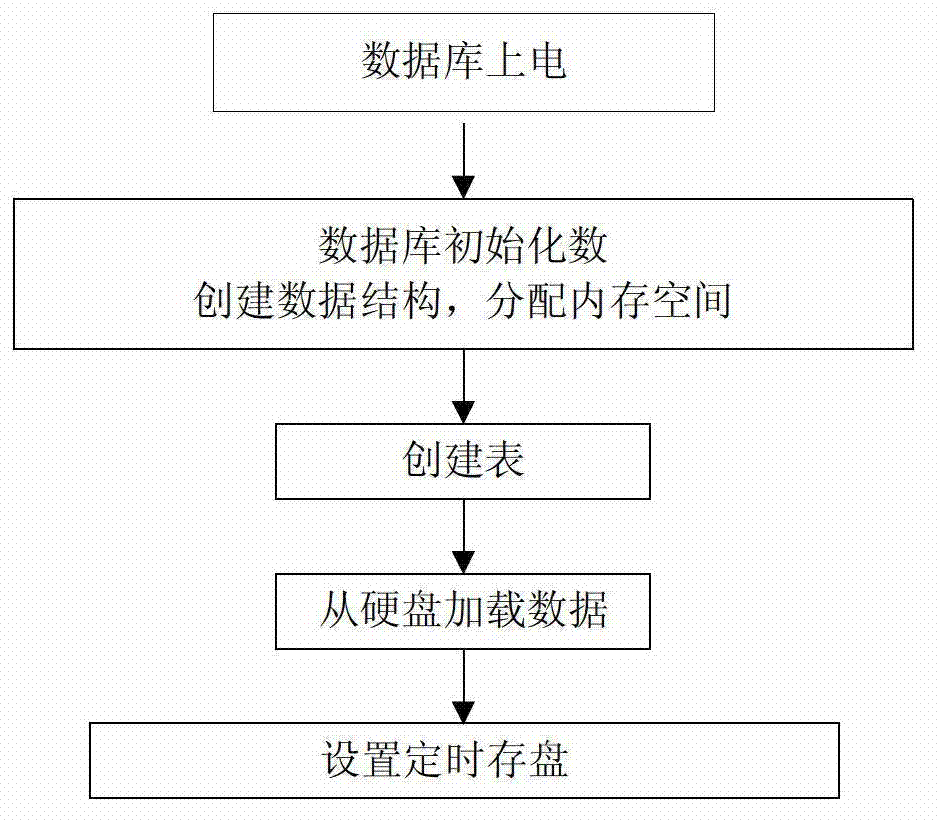

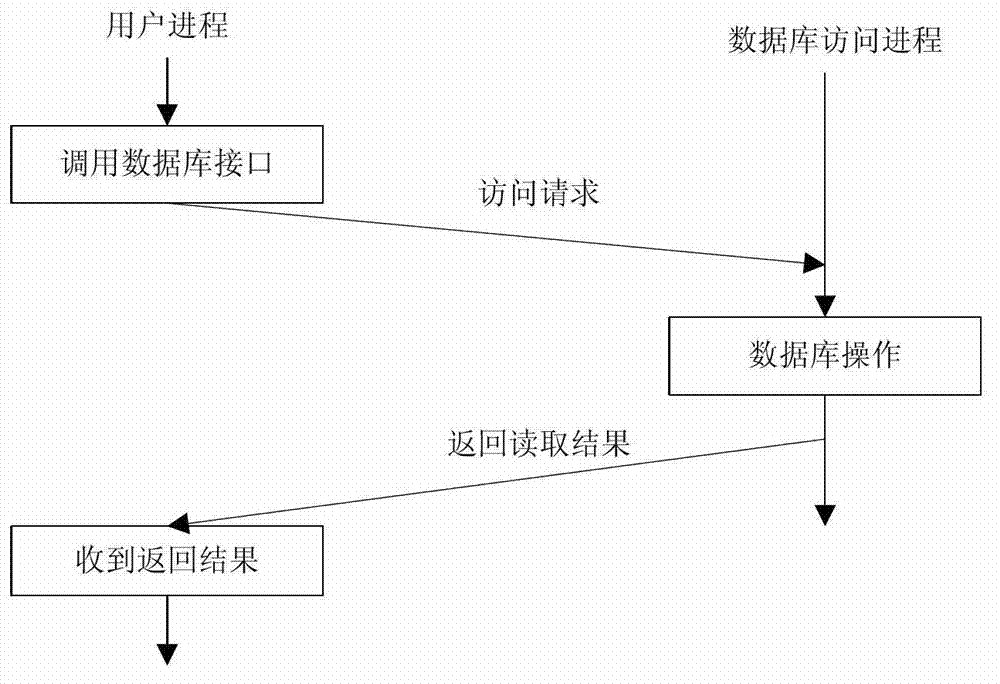

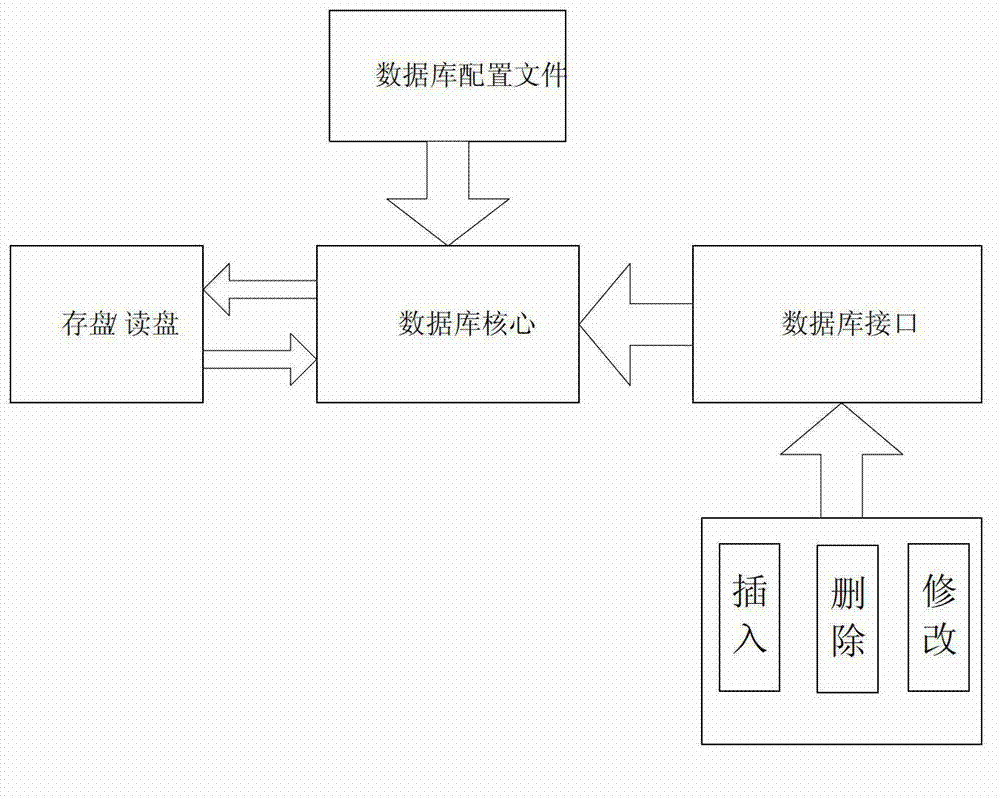

Embedded real-time memory database

InactiveCN102880678AImprove access speedIntegrity guaranteedSpecial data processing applicationsDatabase interfaceData control

The invention belongs to the field of application system data management and particularly relates to an embedded real-time memory database with high data reading-writing speed for storing data into a memory. The embedded real-time memory database comprises a database core, a database control management module and a database interface, wherein the database core is used for defining and organizing the data; the database interface is used for accessing the database; and the database control management module is used for controlling a state of the database. The embedded real-time memory database is different from the conventional database; the database is established in the memory, so that the data access speed is greatly accelerated, the dependence on the disk size is reduced, and the data access performance requirements of occasions with high real-time performance are met. Due to the introduction of a two-layer memory concept and a rollback mechanism, the completeness, the uniformity and the safety of the data are guaranteed, and the hardware investment and system maintenance costs can be directly saved by using the memory database while the working efficiency of the database is improved.

Owner:HARBIN ENG UNIV

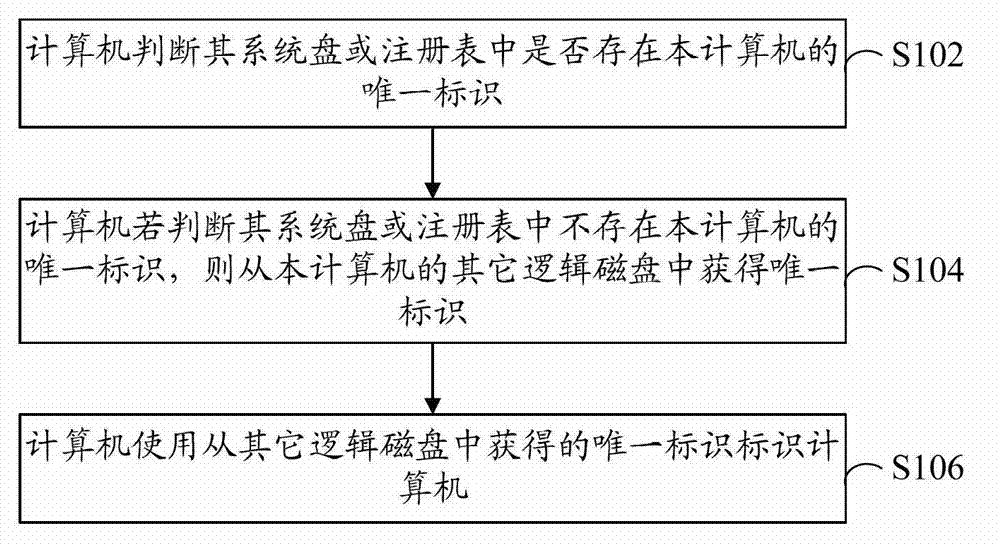

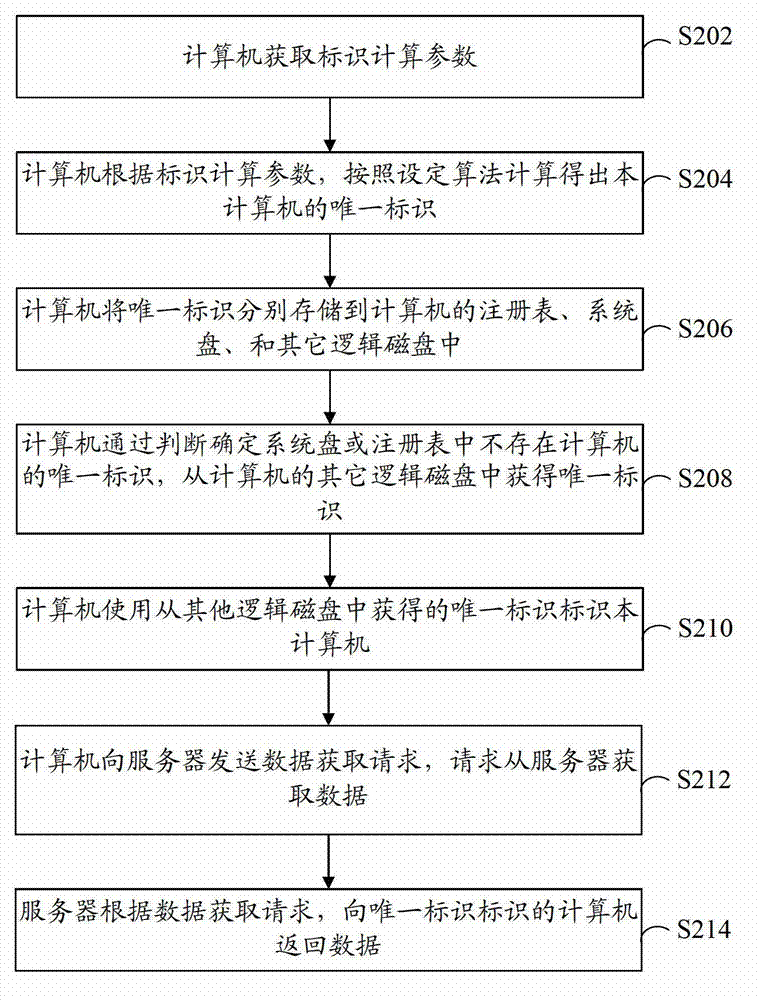

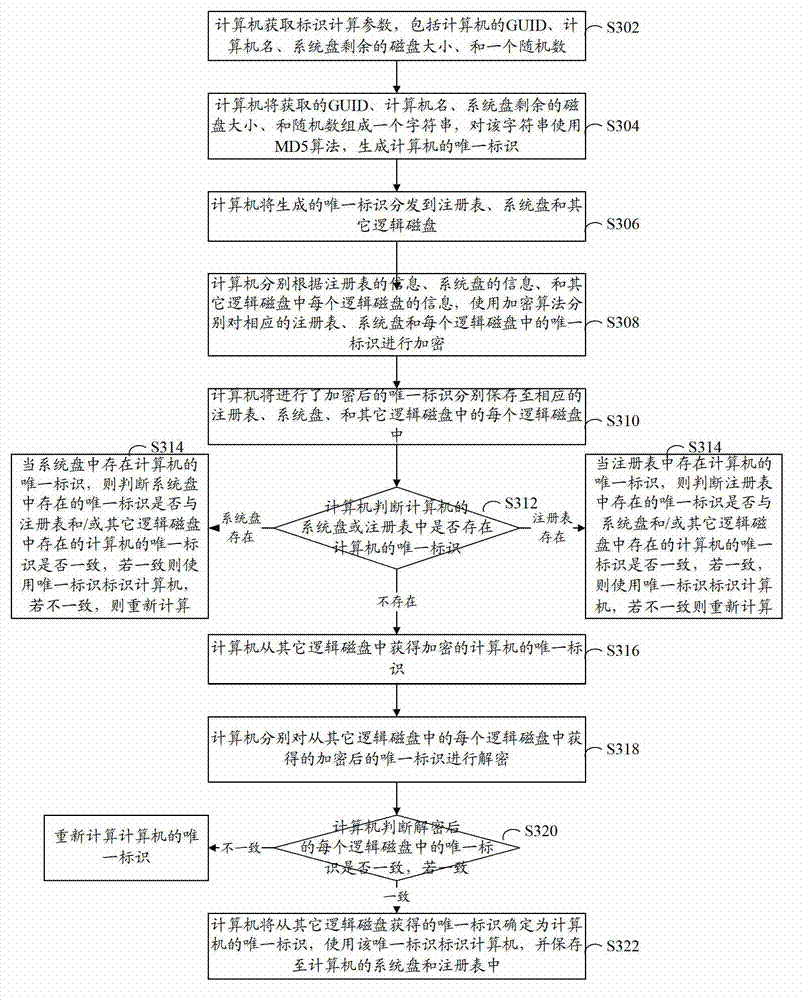

Terminal identification method and device

The invention provides a terminal identification method and a terminal identification device. The terminal identification method comprises the following steps of: judging whether a unique identifier of a terminal exists in a system disk or a registry of the terminal, wherein the unique identifier is obtained by computation according to identifier computation parameters which comprise at least one of a terminal name of the terminal, a globally unique identifier (GUID) and the remaining disk size of the system disk; if the unique identifier does not exist in the system disk or the registry of the terminal, acquiring the unique identifier from other logical disks of the terminal, wherein the unique identifier is pre-stored in the other logical disks; and identifying the terminal by using the unique identifier which is obtained from the other logical disks. By the invention, an effect of accurately identifying the terminal is achieved.

Owner:BEIJING QIANXIN TECH

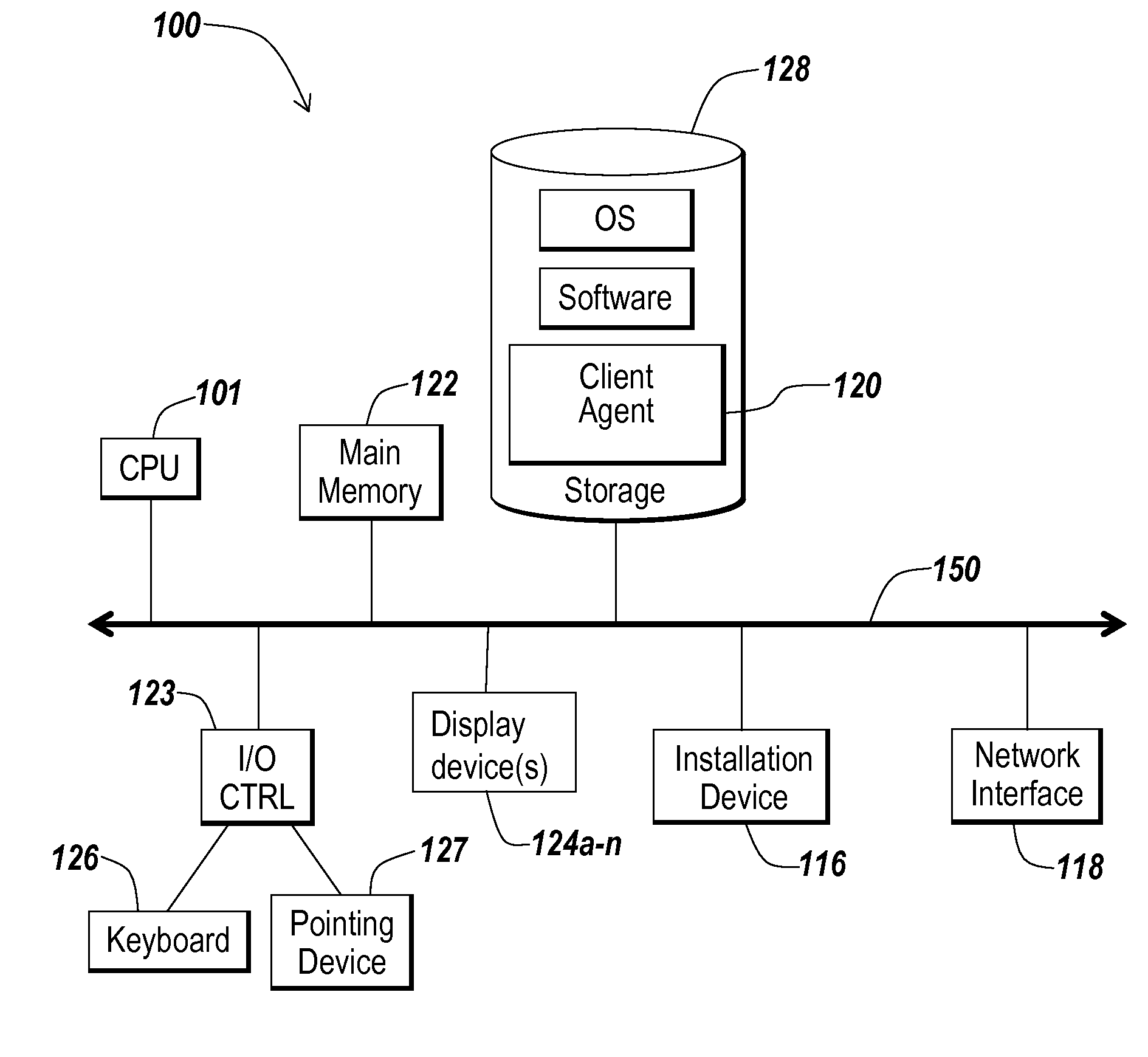

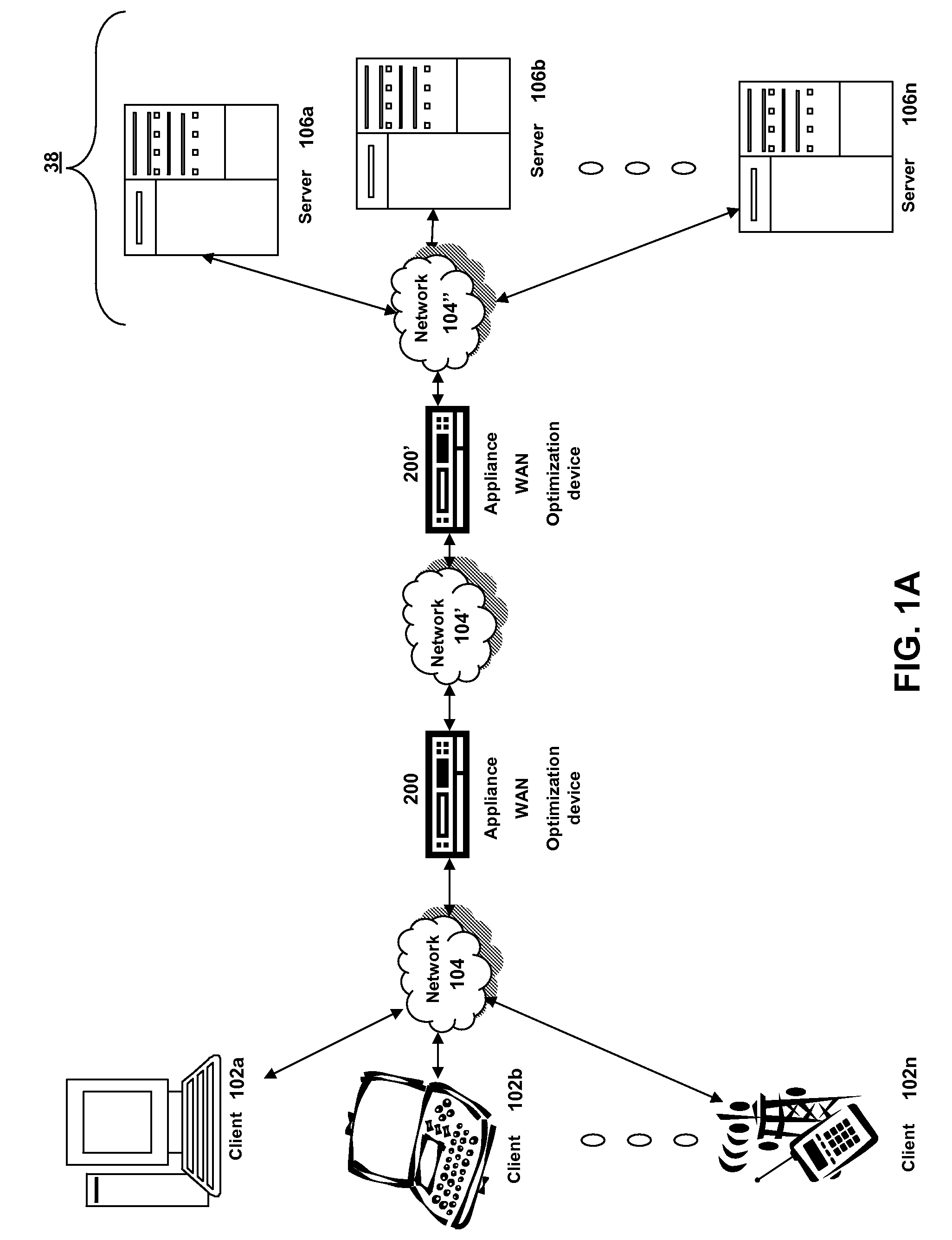

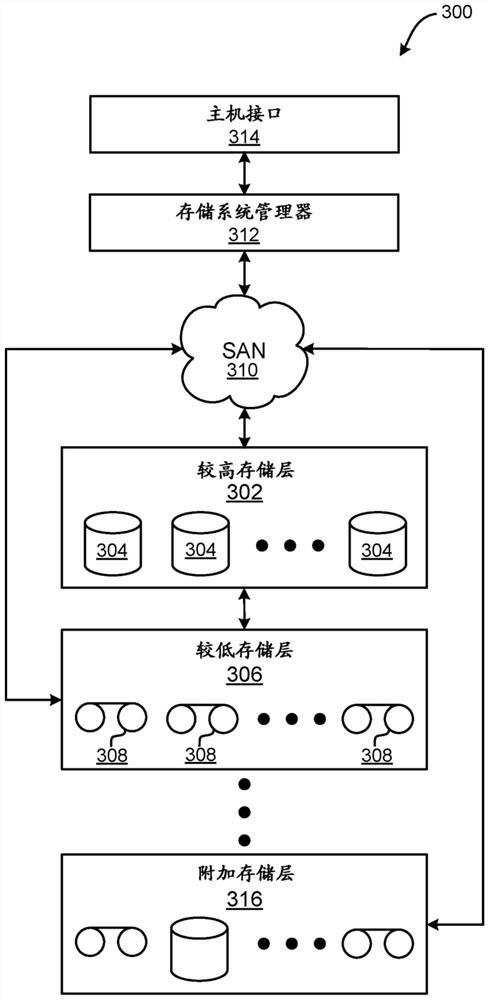

Systems and methods of providing a multi-tier cache

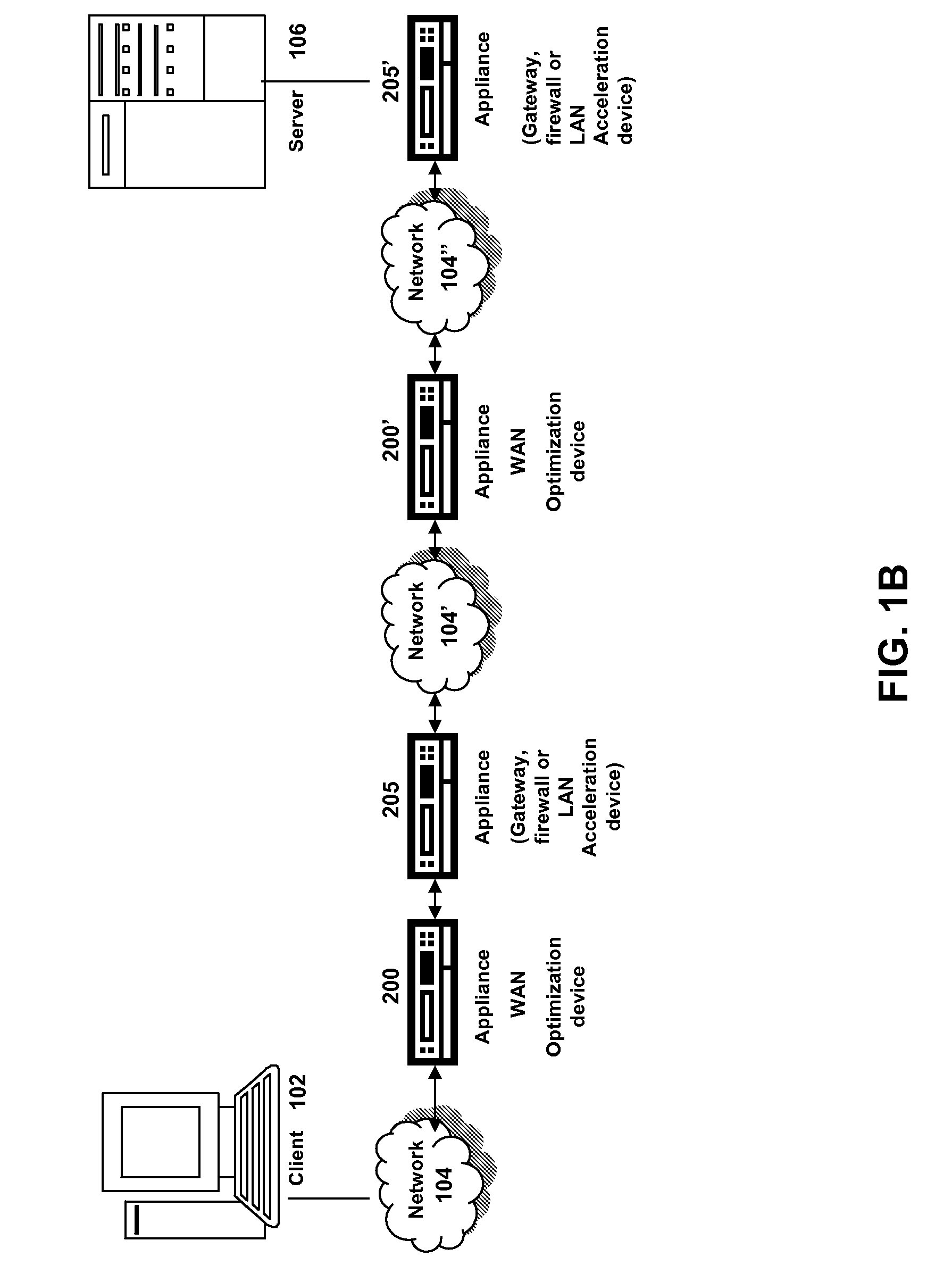

ActiveUS8074028B2Improve efficiencyImprove intermediary or proxy cachingTransmissionMemory systemsDisk sizeParallel computing

The present solution provides a multi-tiered caching and cache indexing system is depicted. A cache management system uses a memory based object index to reference or identify corresponding objects stored in disk. The memory used to index object may grow proportionally or in relation to growth in the size of the disk. The techniques described herein minimize, reduce or maintain the size of memory for an object index although the size of storage for storing objects is changed. These techniques allow for more optimal use of memory for object indexing while increasing or decreasing disk size for object storage.

Owner:CITRIX SYST INC

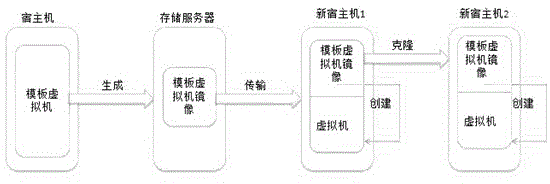

Quick and efficient cloud service disk mirroring management method

InactiveCN104156257AHigh speedSoftware simulation/interpretation/emulationOperational systemDisk size

The invention discloses a quick and efficient cloud service disk mirroring management method which solves the problems that an existing cloud mainframe disk is low in cloning efficiency and large in network delay and can not meet the requirements of different clients for disk sizes. The efficient and flexible cloud mainframe disk cloning method is characterized by comprising the following steps of (1) establishing a template virtual machine which comprises configuration information and a disk file, wherein the disk file is composed of a system disk, (2) setting the capacity of the system disk in the disk file in a template of the virtual machine to be capable of guaranteeing that the lowest requirement of an operating system for normal operation can be met, (3) cloning the configuration information and the disk file in the template virtual machine to a new virtual machine, wherein a data disk on the new virtual machine is set to be blank. The method has the advantages that consumed time is short, the deploying speed is increased, large-scale, quick and concurrent deployment can be achieved, requirements of the clients can be met flexibly, and the expansibility is high.

Owner:CHENGDU ZHIYUN SCI & TECH

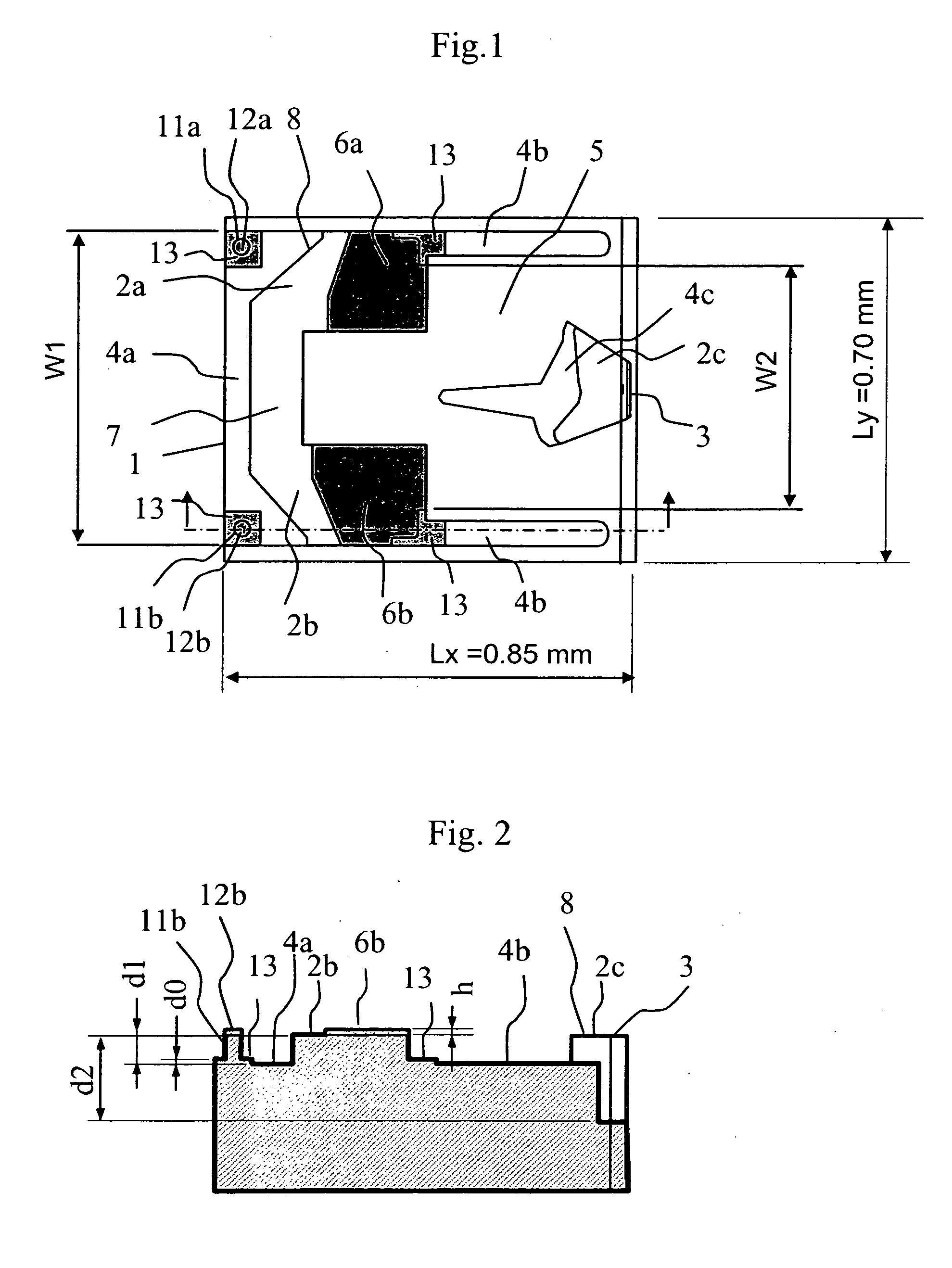

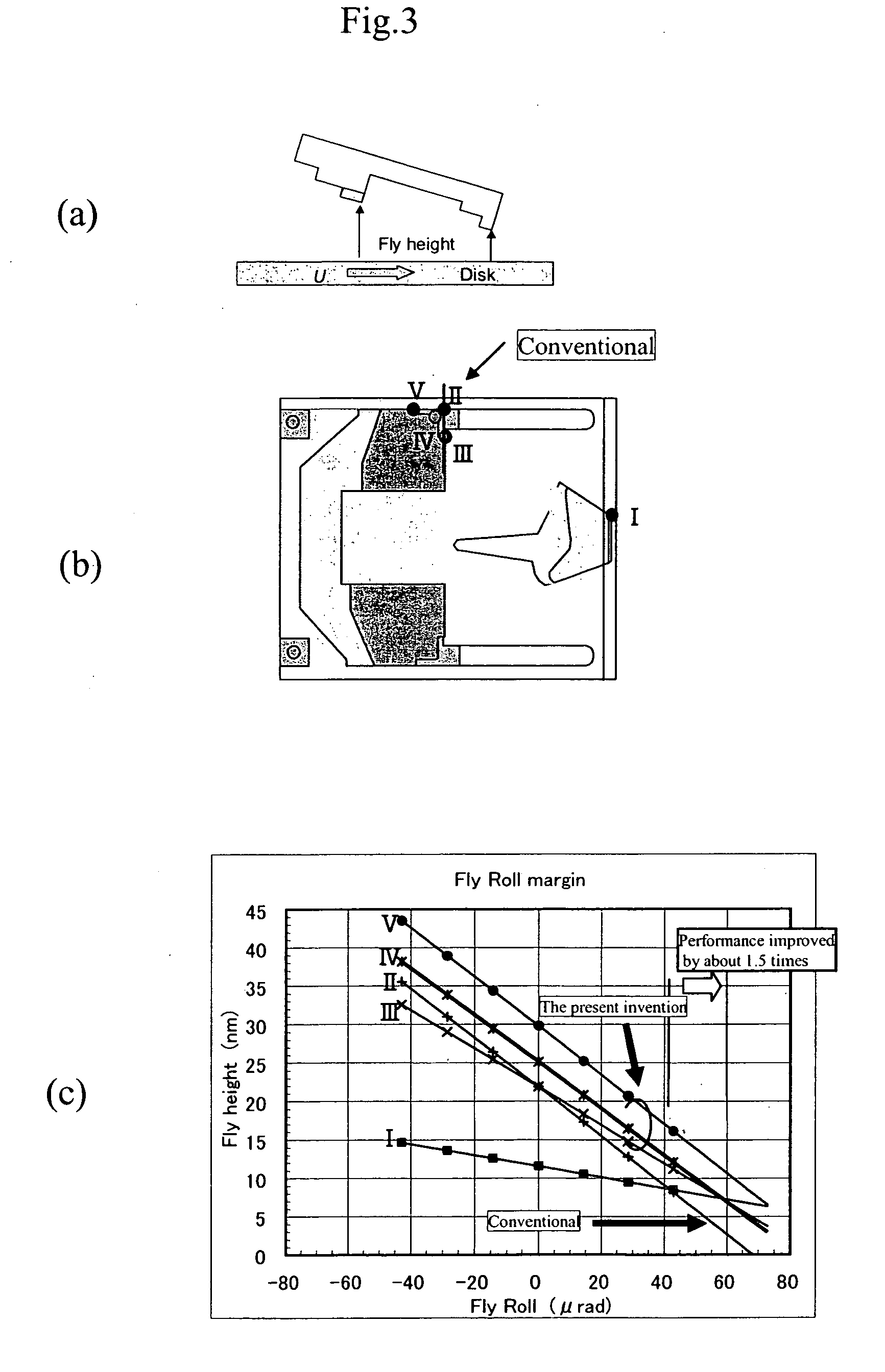

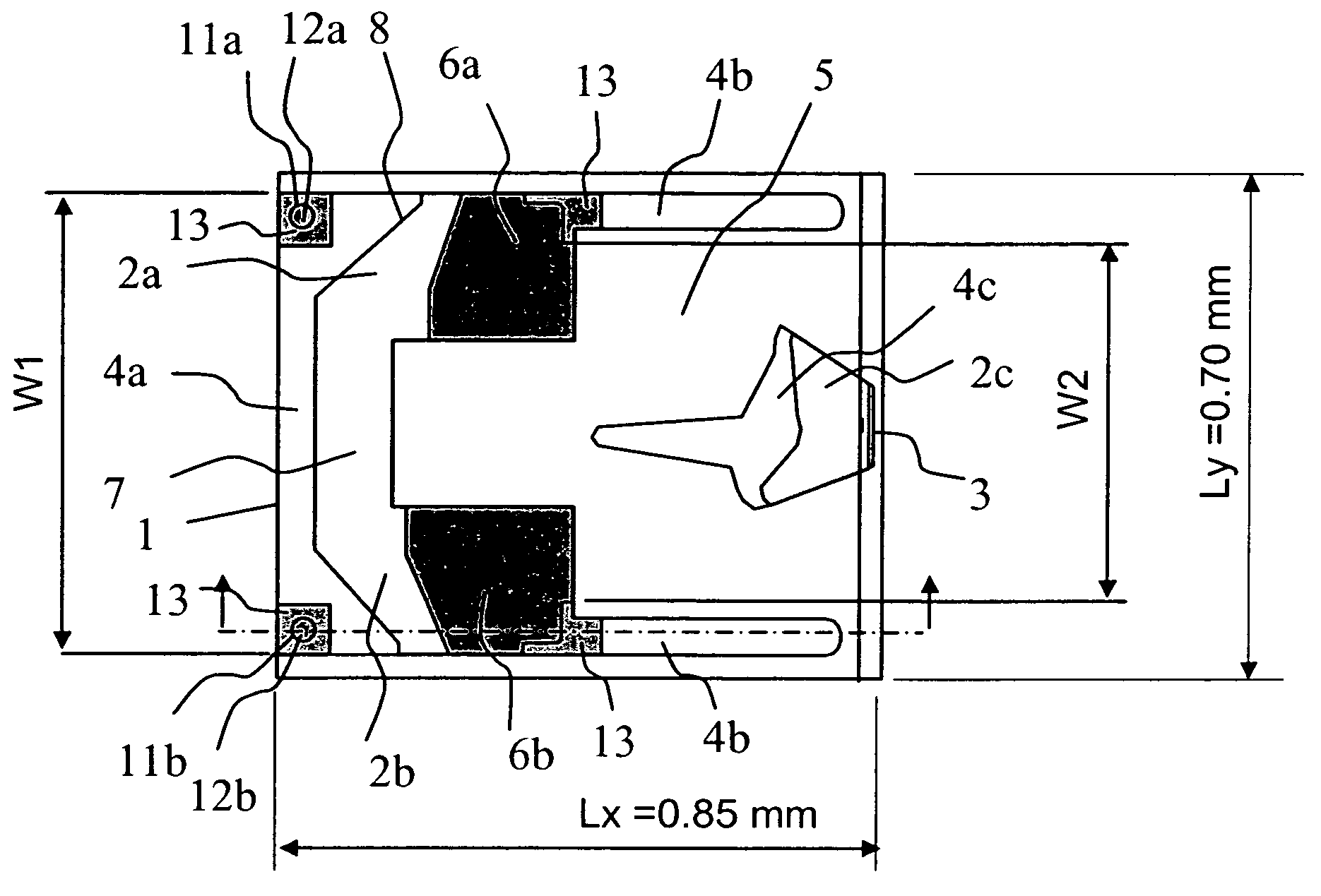

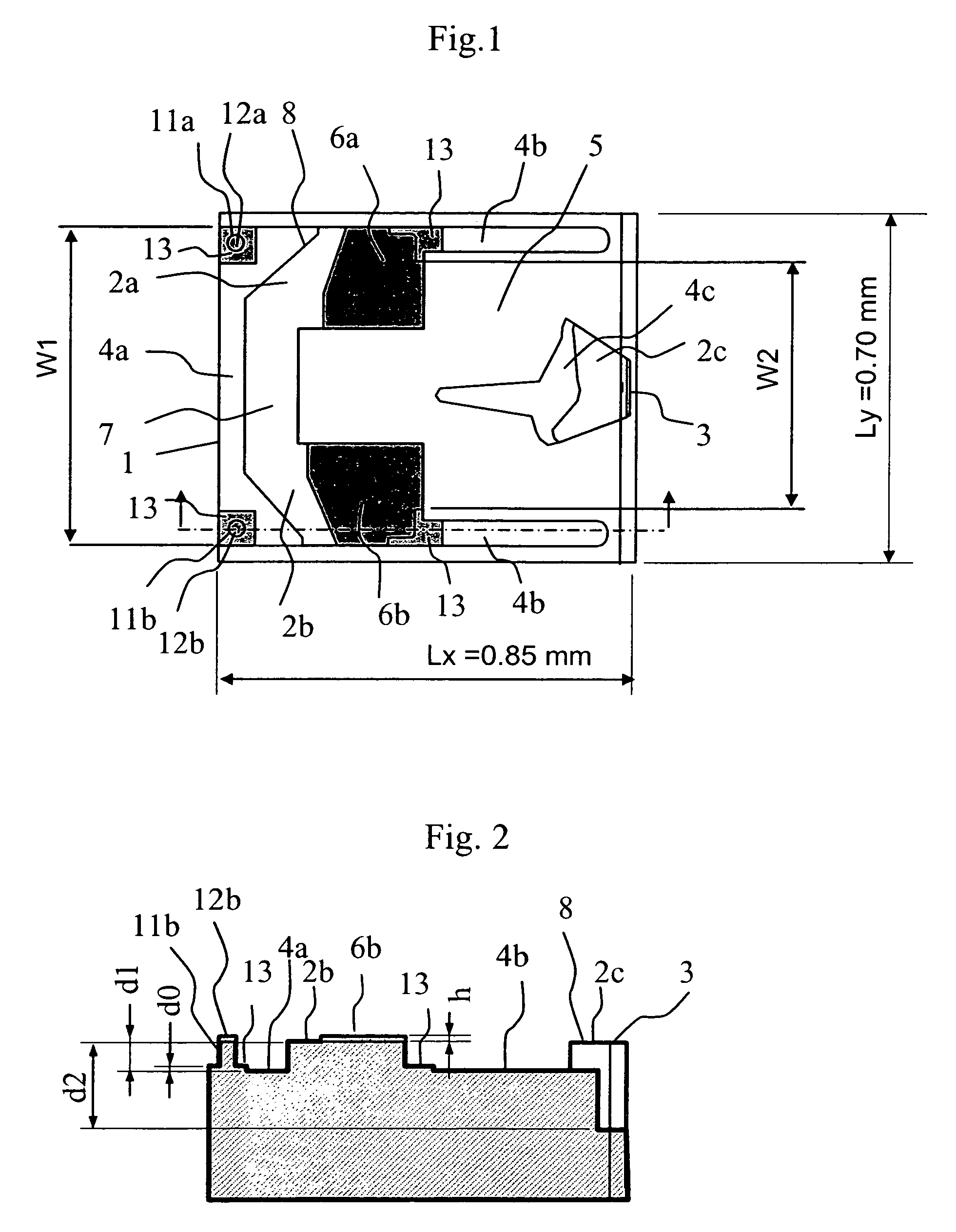

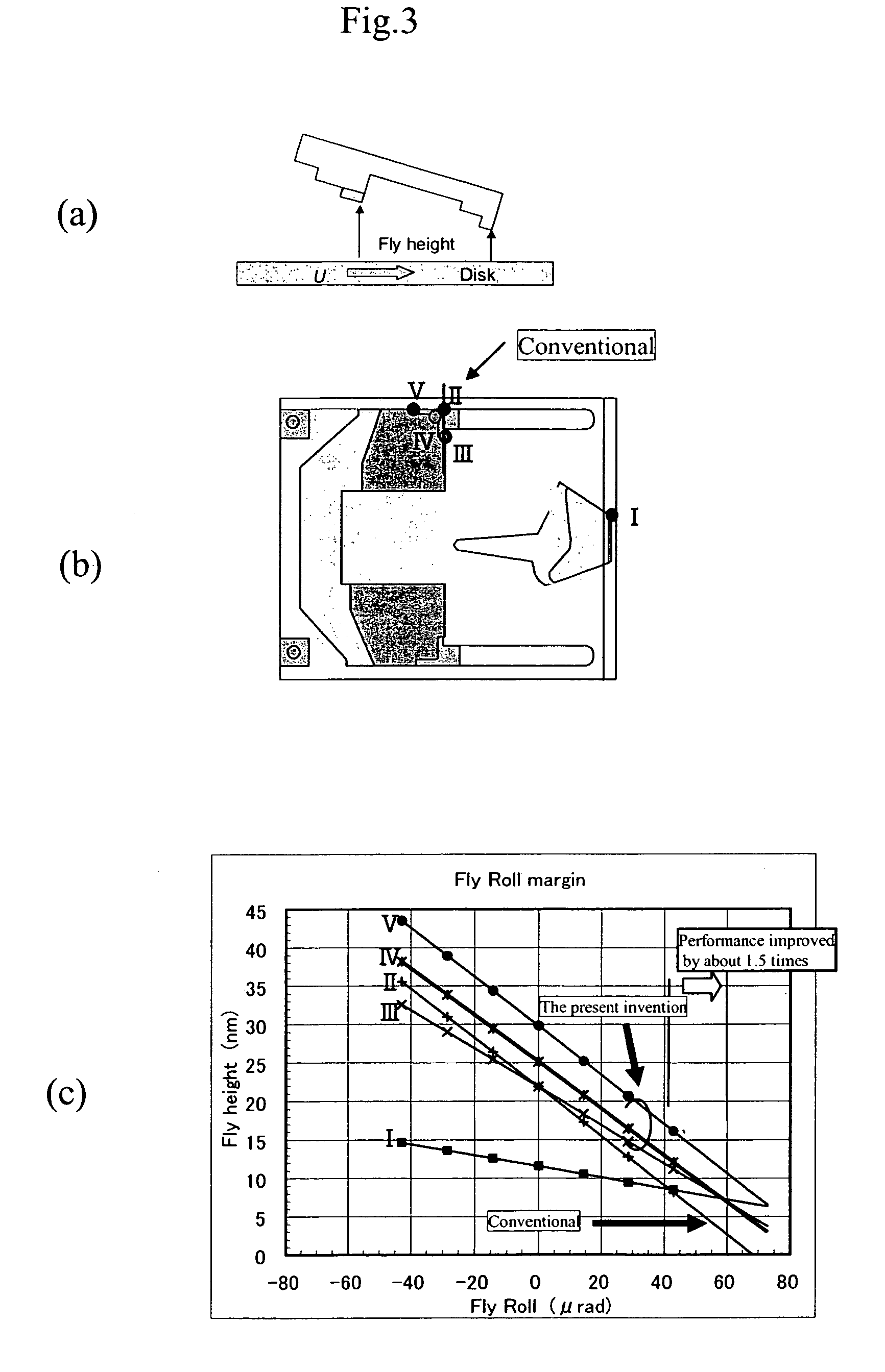

Magnetic disk slider having improved inclination margins in a rolling direction

A magnetic head slider suitable for a disk drive measuring 1.8 inches or less in disk size incorporates preventive measures against the decreases in lifting force that occur in small sliders with a slider width of 0.8 mm or less. The present invention improves the inclination margins of the flying slider in a rolling direction at the lowest flying point, and achieves low flying height and stable flying. The slider is constructed with stepped surfaces on the slider's leading-side flying surface formed up of shallow-grooved surfaces and a deep-grooved surface so that a trailing-side width W2 between the stepped surfaces is smaller than a leading-side width W1.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

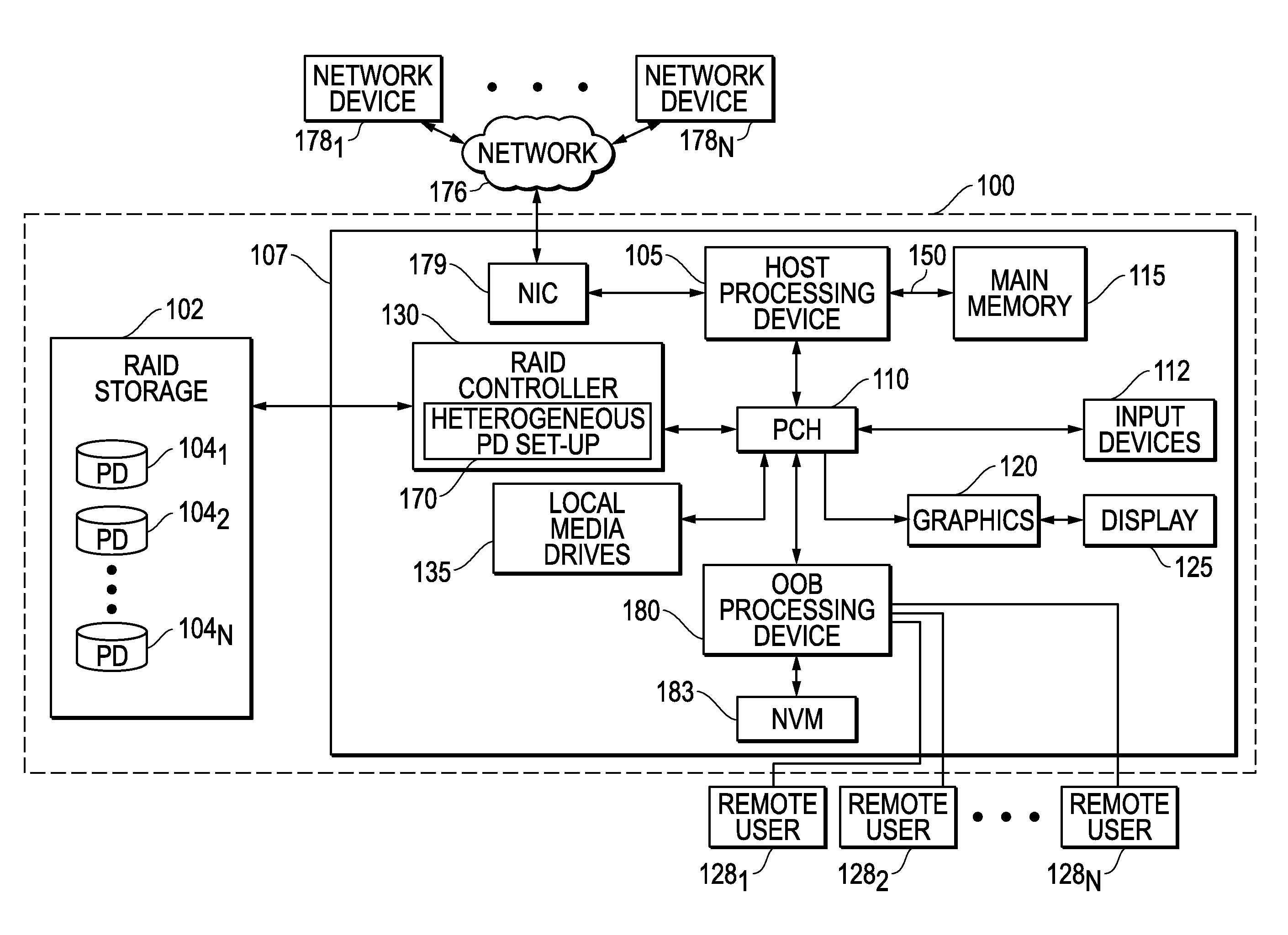

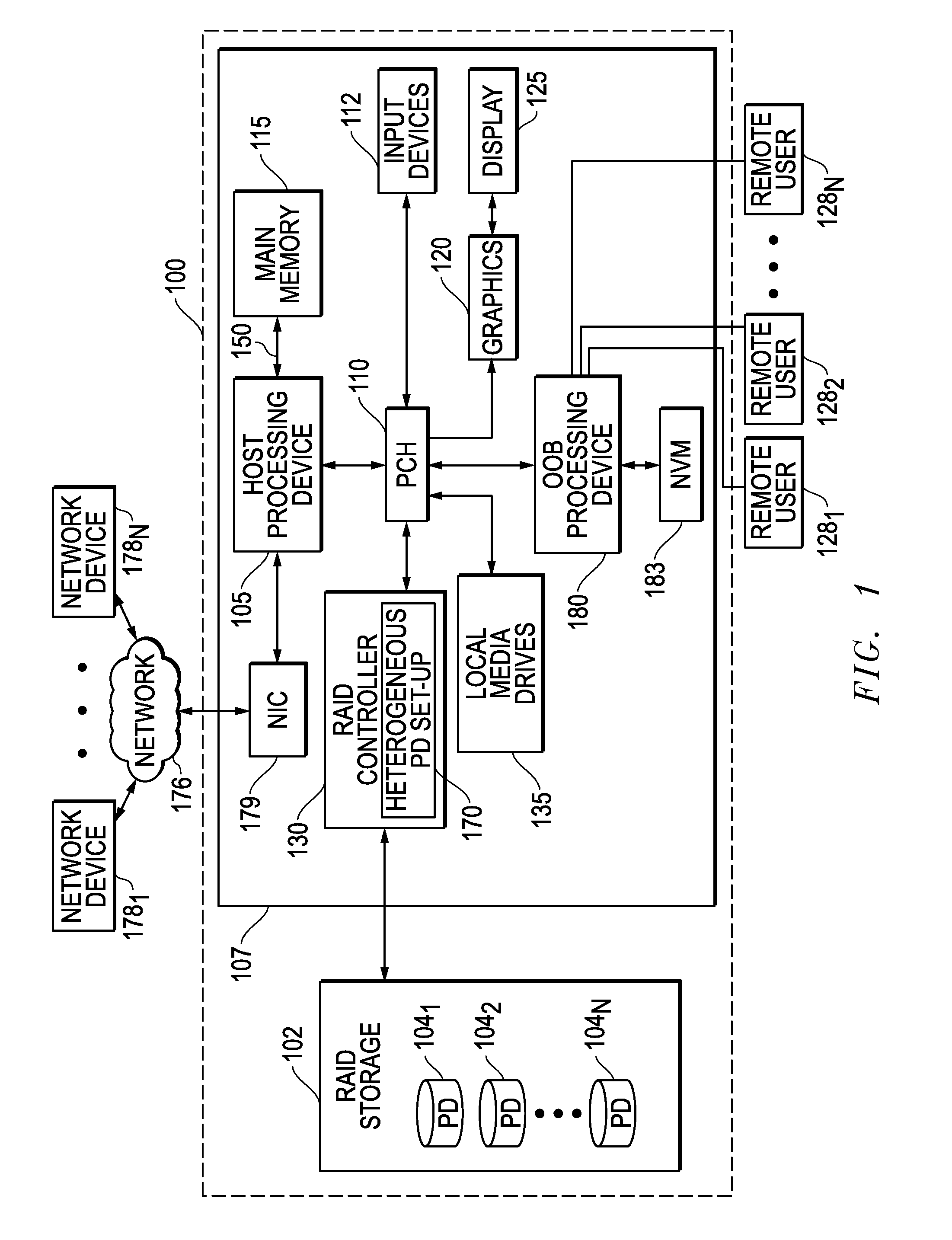

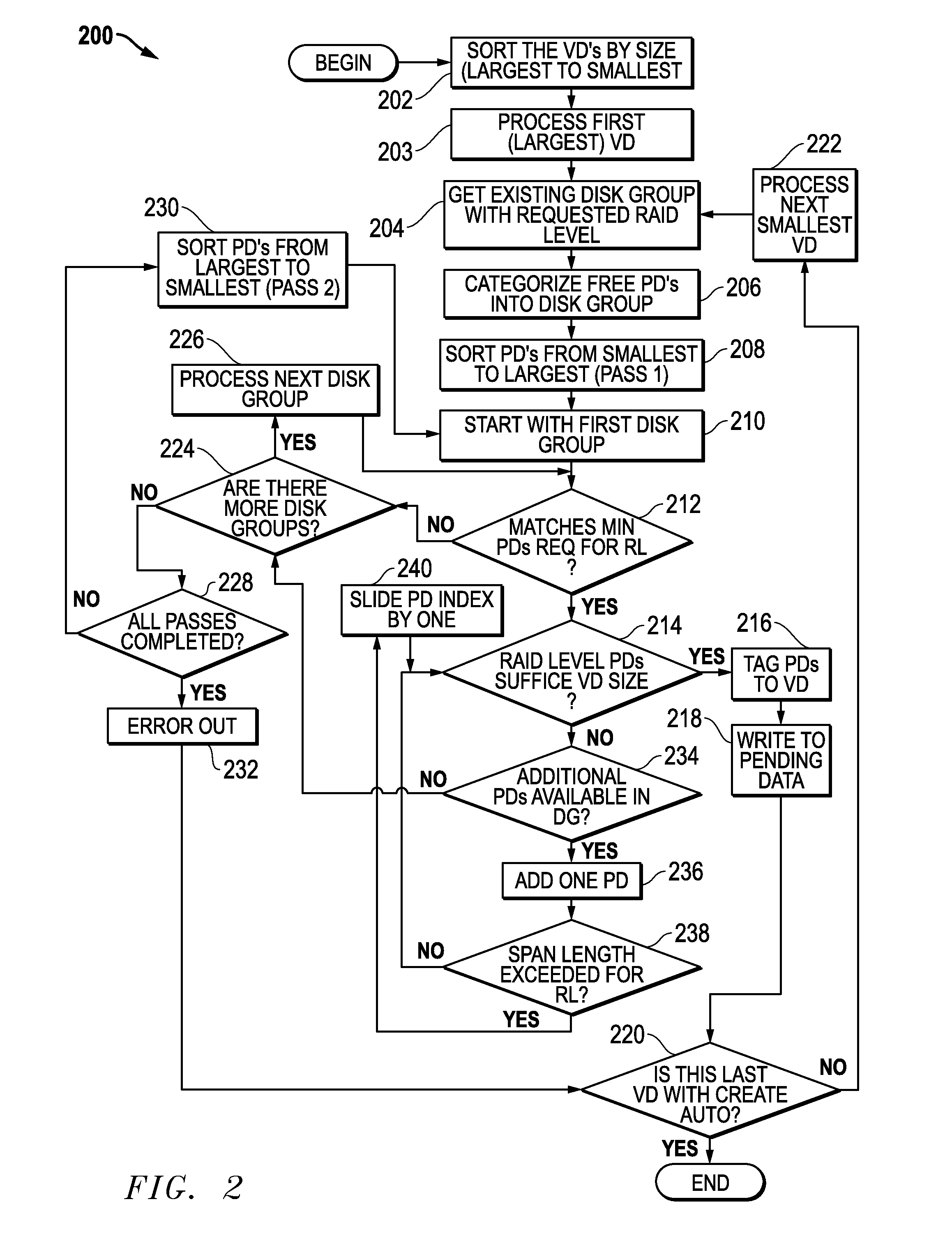

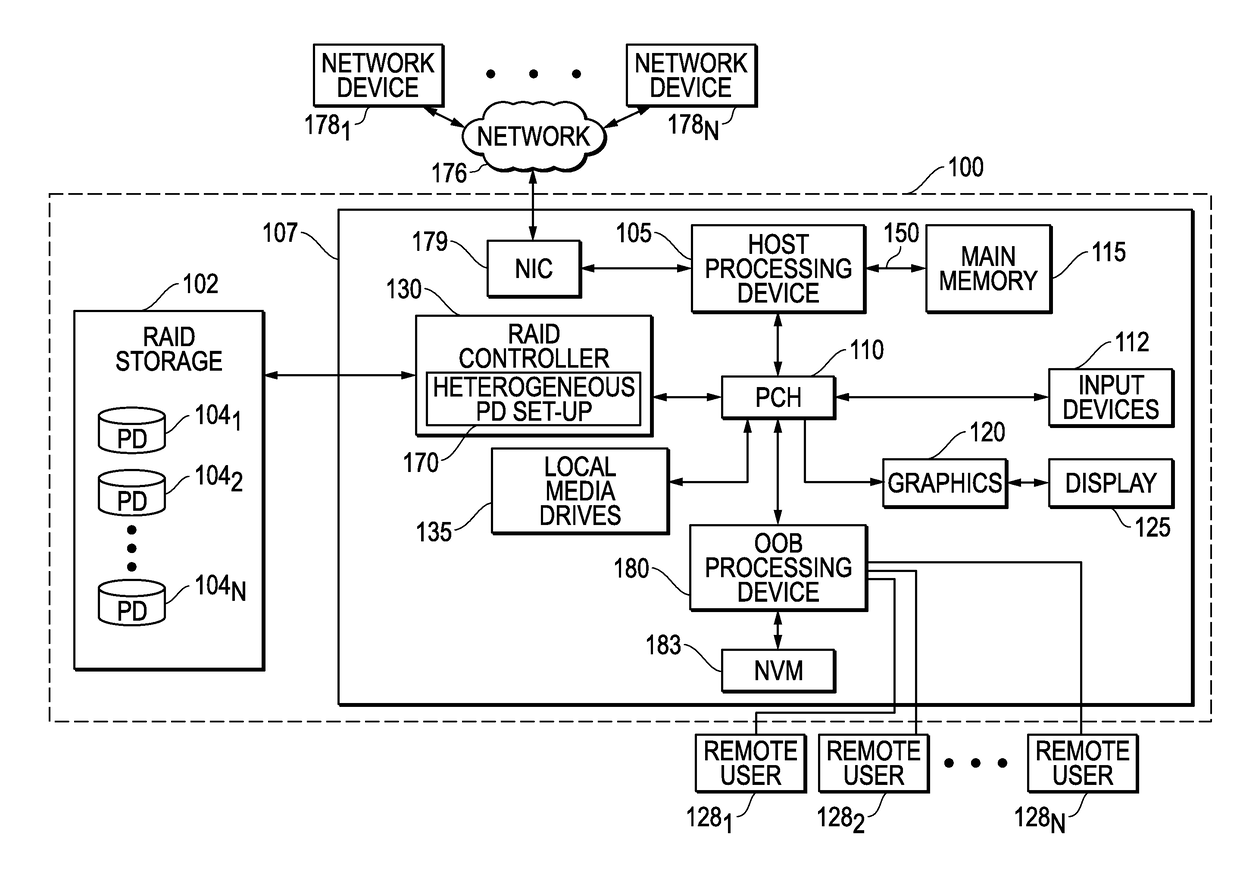

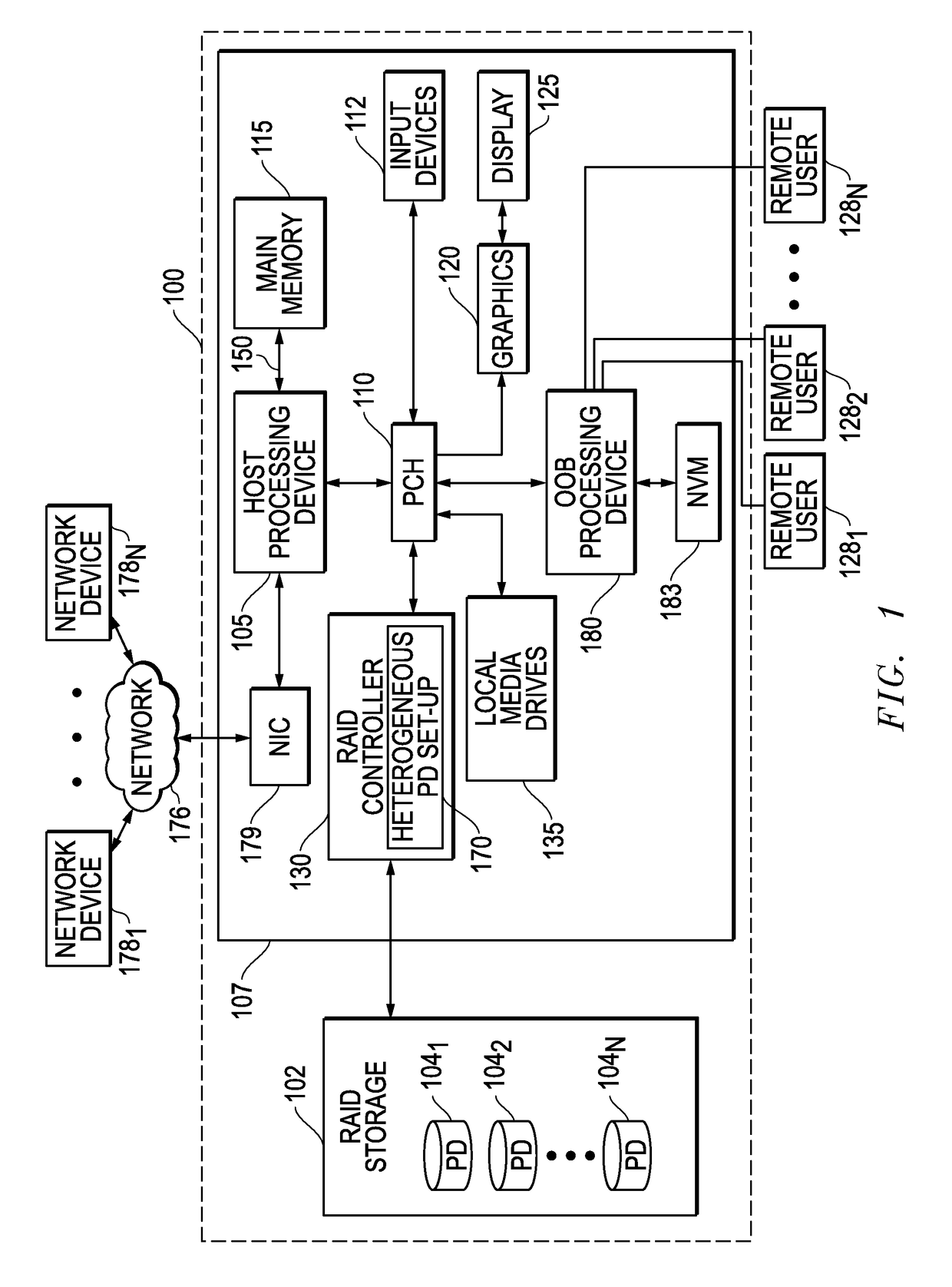

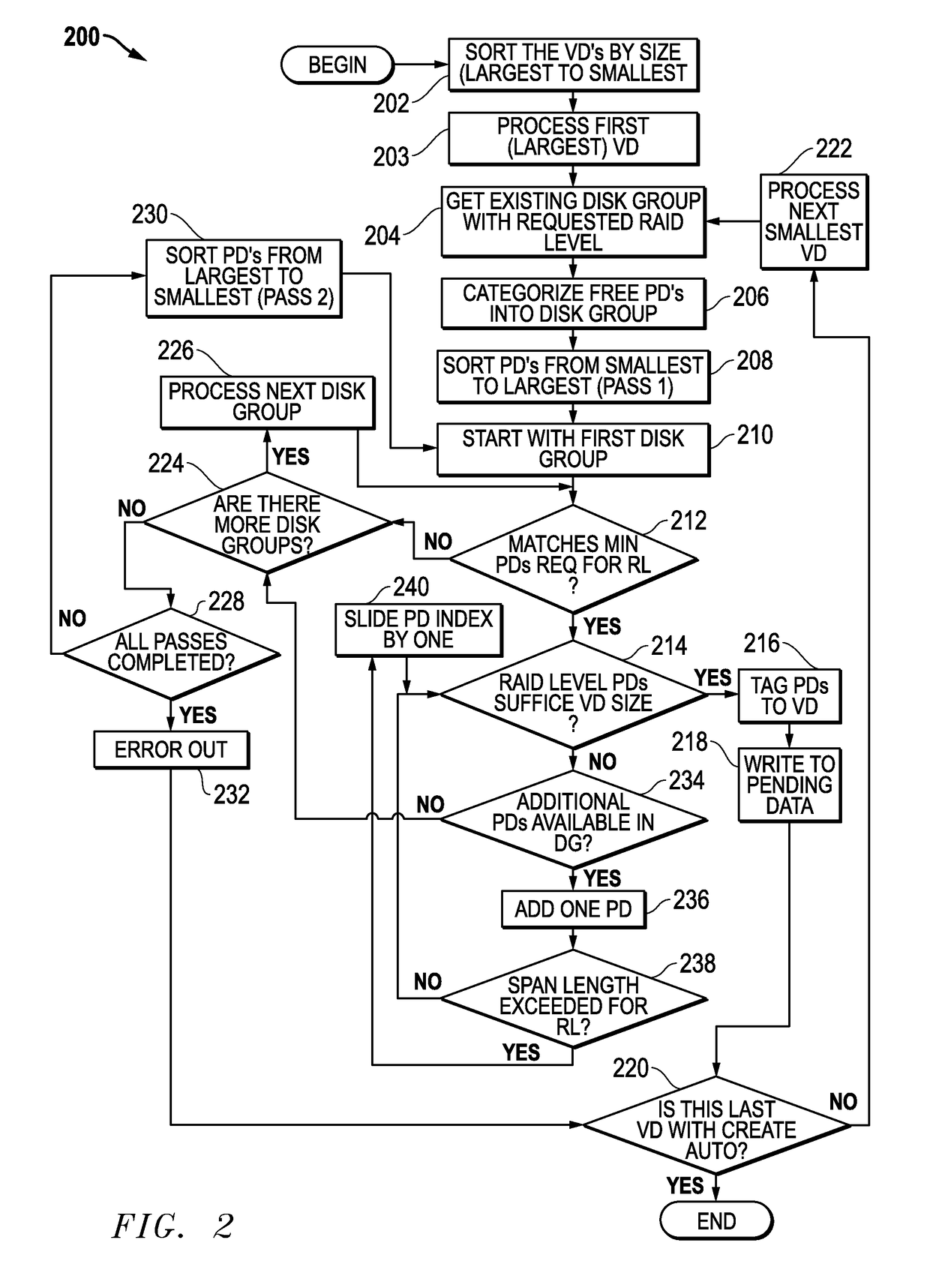

Systems And Methods For RAID Storage Configuration Using Hetereogenous Physical Disk (PD) Set Up

ActiveUS20160335008A1Simplifying improving user experienceMaximize available spaceInput/output to record carriersRAIDDisk size

Systems and methods are provided that may be used to automatically create RAID configuration with heterogeneous Physical Disk (PD) set up using Virtual Disk (VD) RAID Level and size, for example, to allow replication of a given RAID configuration across multiple different RAID platform systems regardless of the underlying storage disk sizes and / or storage disk types.

Owner:DELL PROD LP

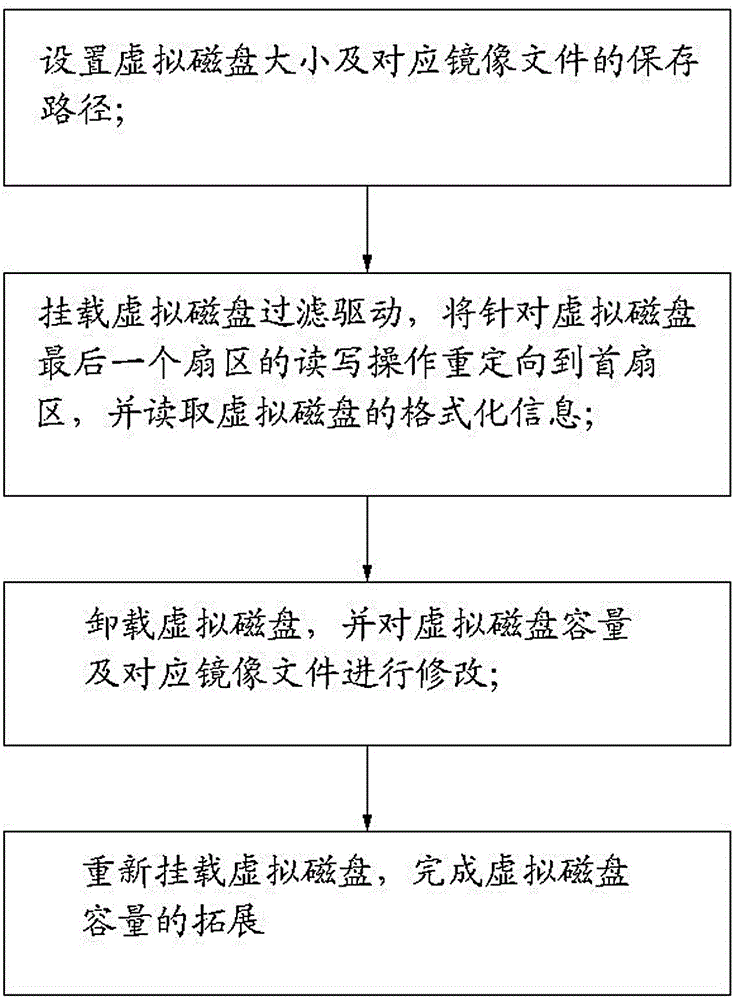

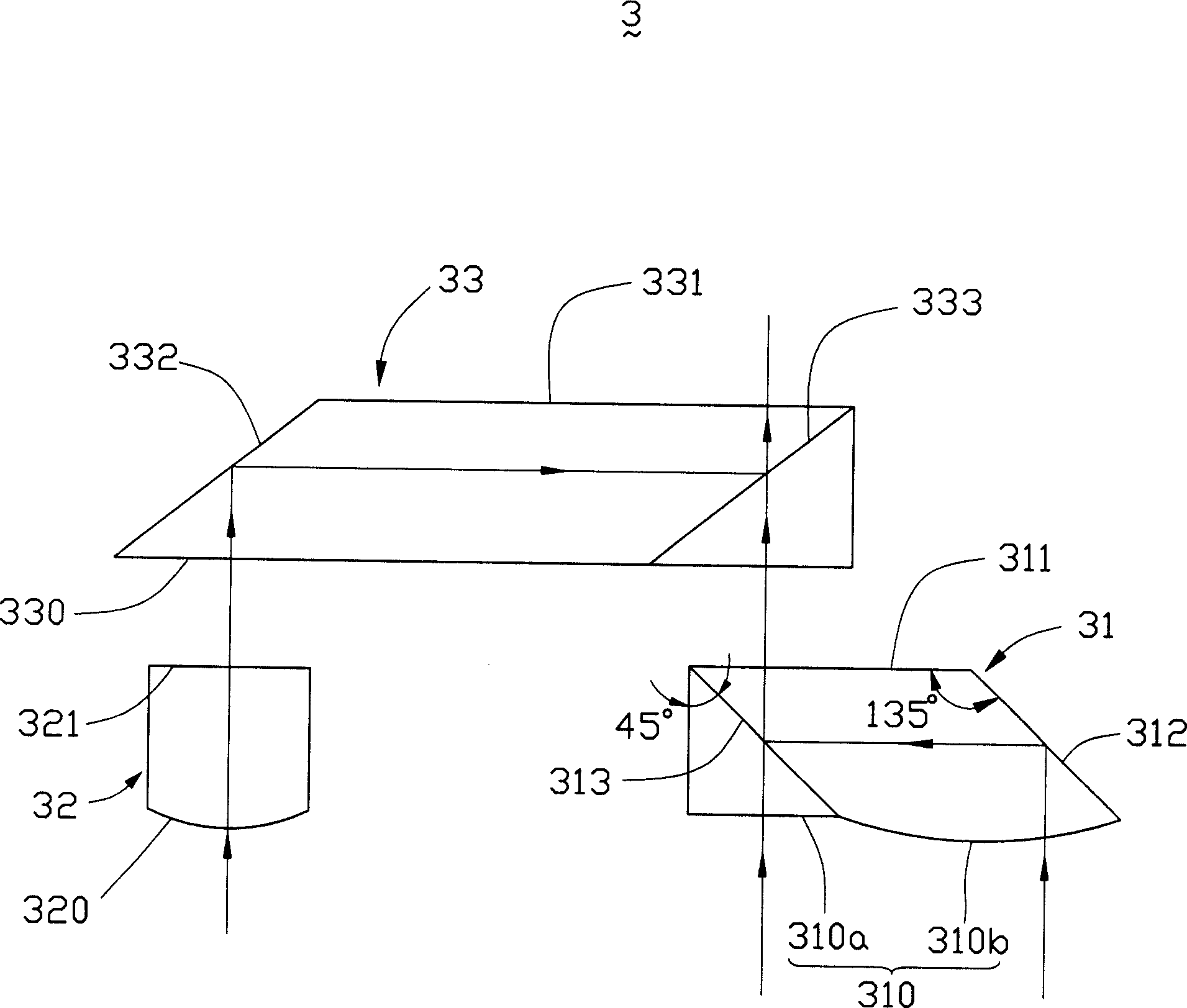

Virtual disk size smooth expansion method

ActiveCN104156175AAchieve smooth expansionReduce troubleInput/output to record carriersMemory adressing/allocation/relocationFiltrationDisk size

The invention provides a virtual disk size smooth expansion method. The method includes the following steps of firstly, setting the size of a virtual disk and the save path of a corresponding mirror image document; secondly, mounting a filtration driver of the virtual disk, redirecting the read-write operation for the last sector of the virtual disk to the first sector, and reading formatting information of the virtual disk; thirdly, uninstalling the virtual disk, and modifying the size of the virtual disk and the corresponding mirror image document; fourthly, remounting the virtual disk to complete expansion of the size of the virtual disk. The virtual disk size smooth expansion method has the advantages that rapid and smooth expansion can be conducted on the virtual disk; no reestablishment is needed when the virtual disk in the large size needs to be used; the problem that a system automatically conducts 0 value supplementation in the formatting process in the past is solved, the wait time is shortened when the virtual disk is established, and function experience of a user is improved.

Owner:厦门天锐科技股份有限公司

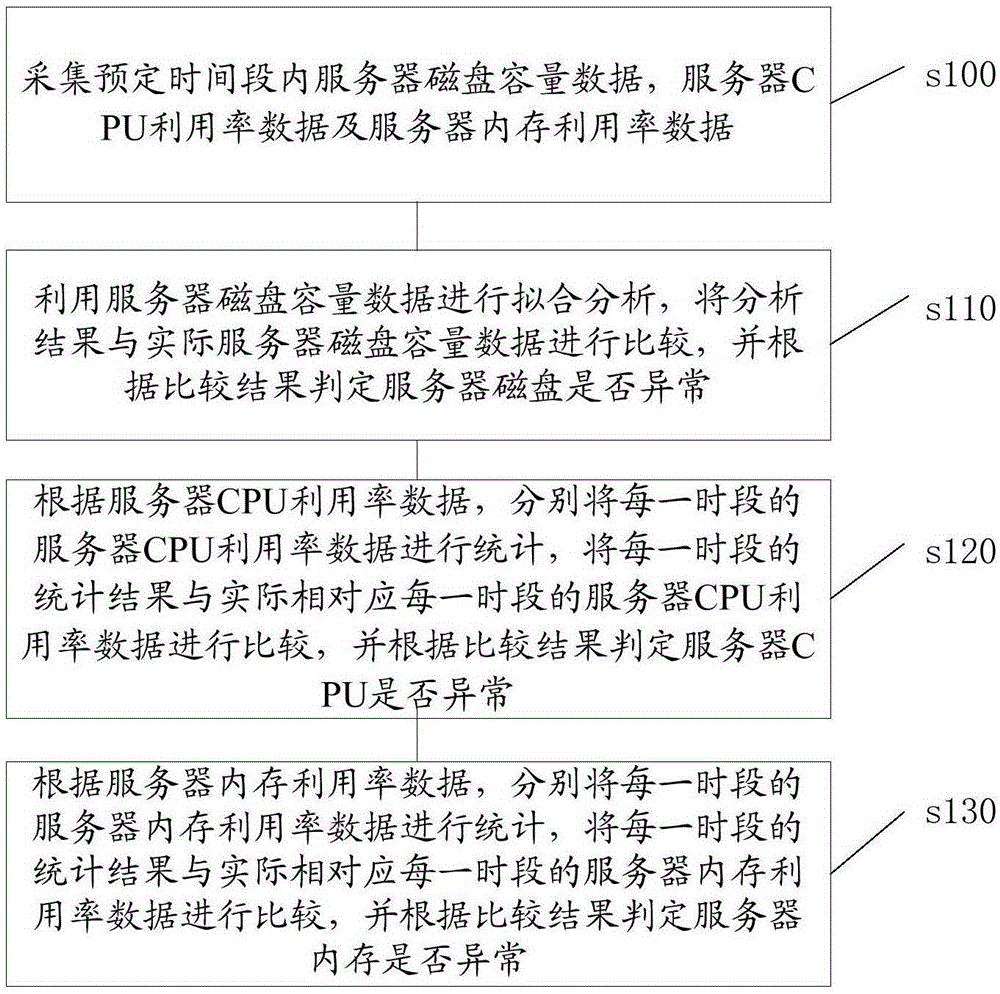

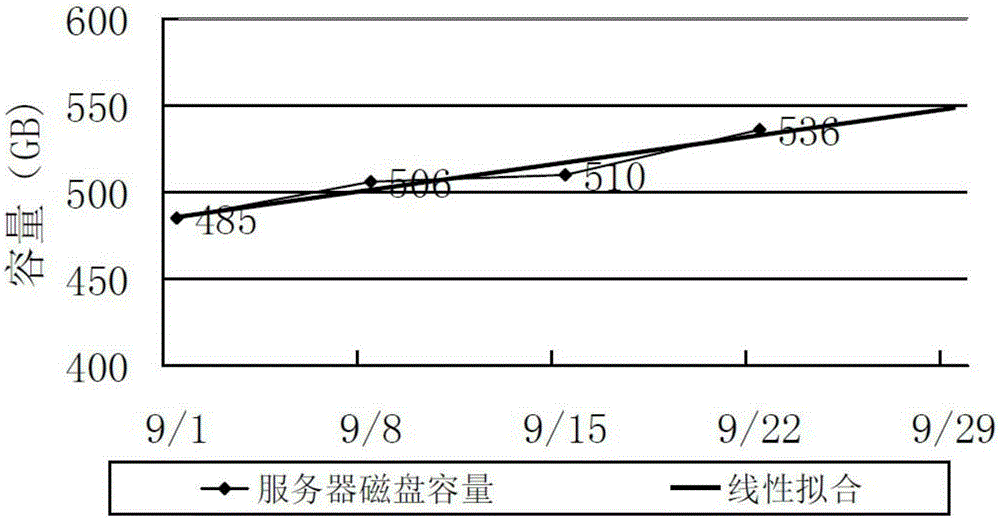

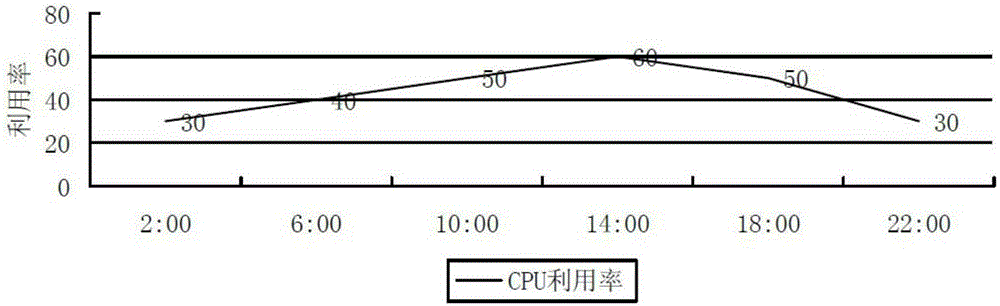

Server performance prediction method and system

The invention discloses a server performance prediction method and system. The method comprises the following steps: collecting server disk size data, server CPU utilization ratio data and server internal memory utilization ratio data; conducting fitting analysis by utilizing the disk size data, comparing the analysis result with actual disk size data, and judging whether a server magnetic disk is abnormal or not according to the comparative result; according to the CPU utilization ratio data, respectively conducting statistics on the CPU utilization ratio data in each time period, and comparing the statistical result in each time period with the actual corresponding CPU utilization ratio data, and judging whether an internal memory is abnormal or not according to the comparative result. Remedial measures can be adopted even if the server is not in failure, and stress of operation and maintenance personnel can be relieved.

Owner:INSPUR BEIJING ELECTRONICS INFORMATION IND

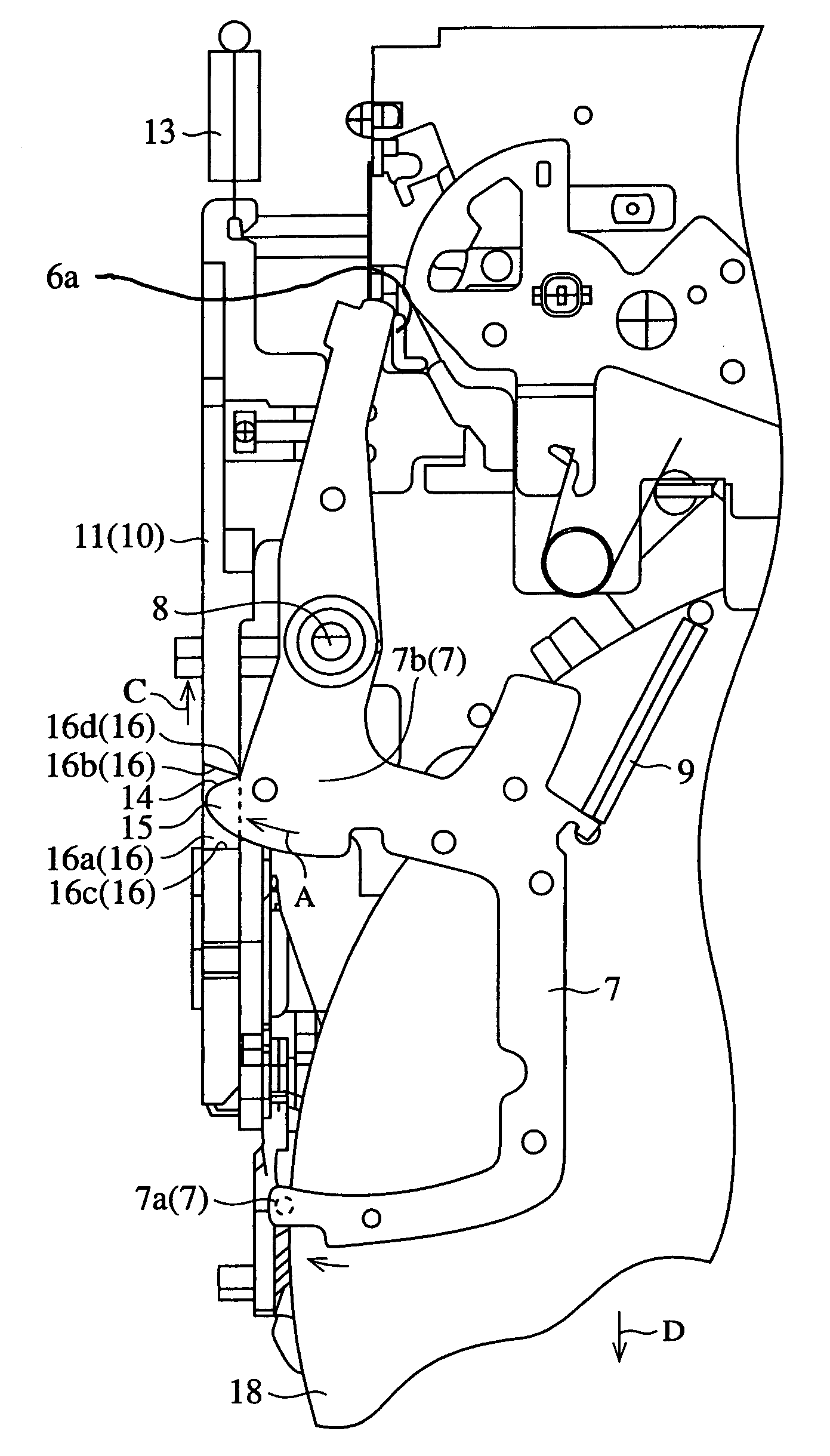

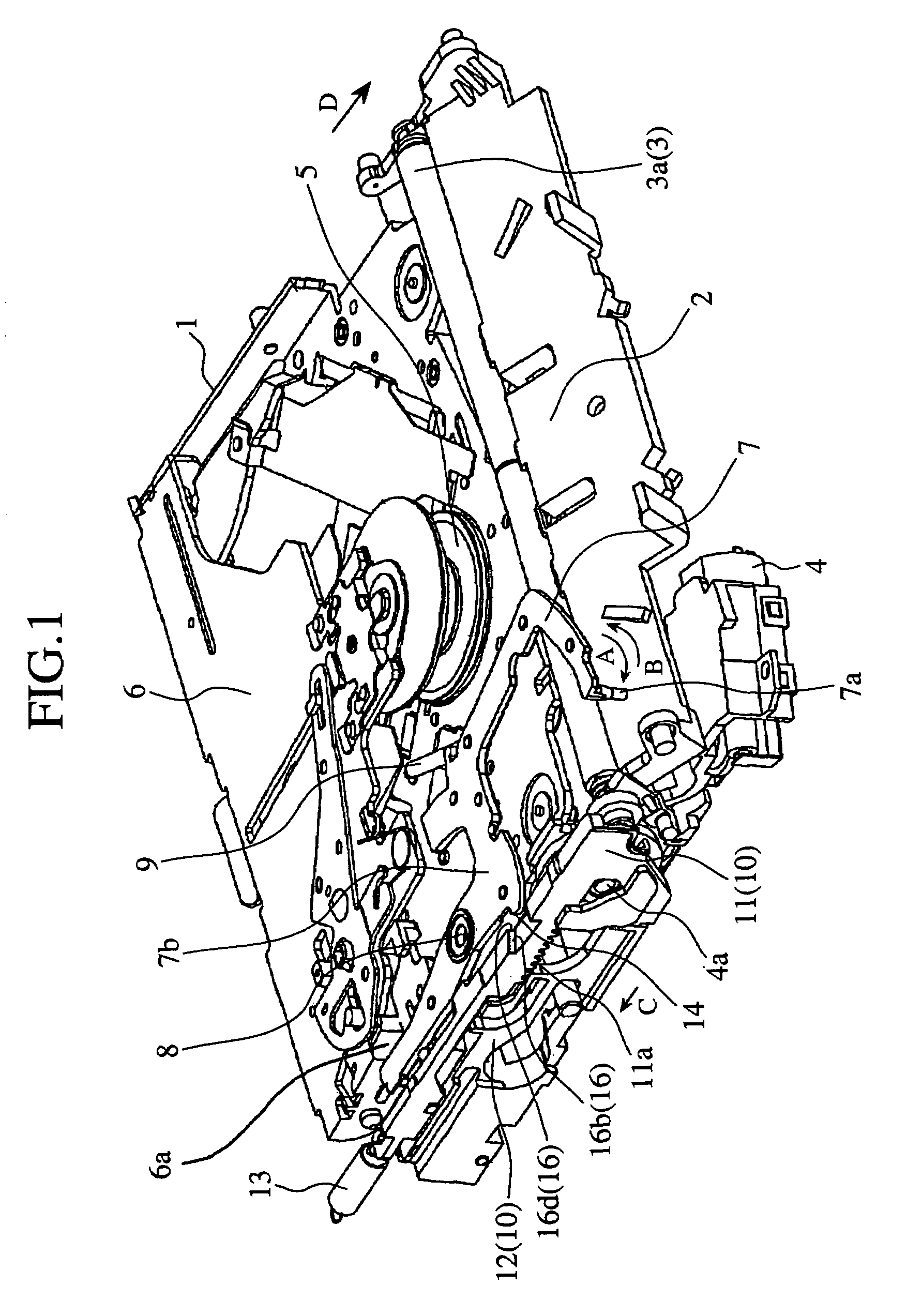

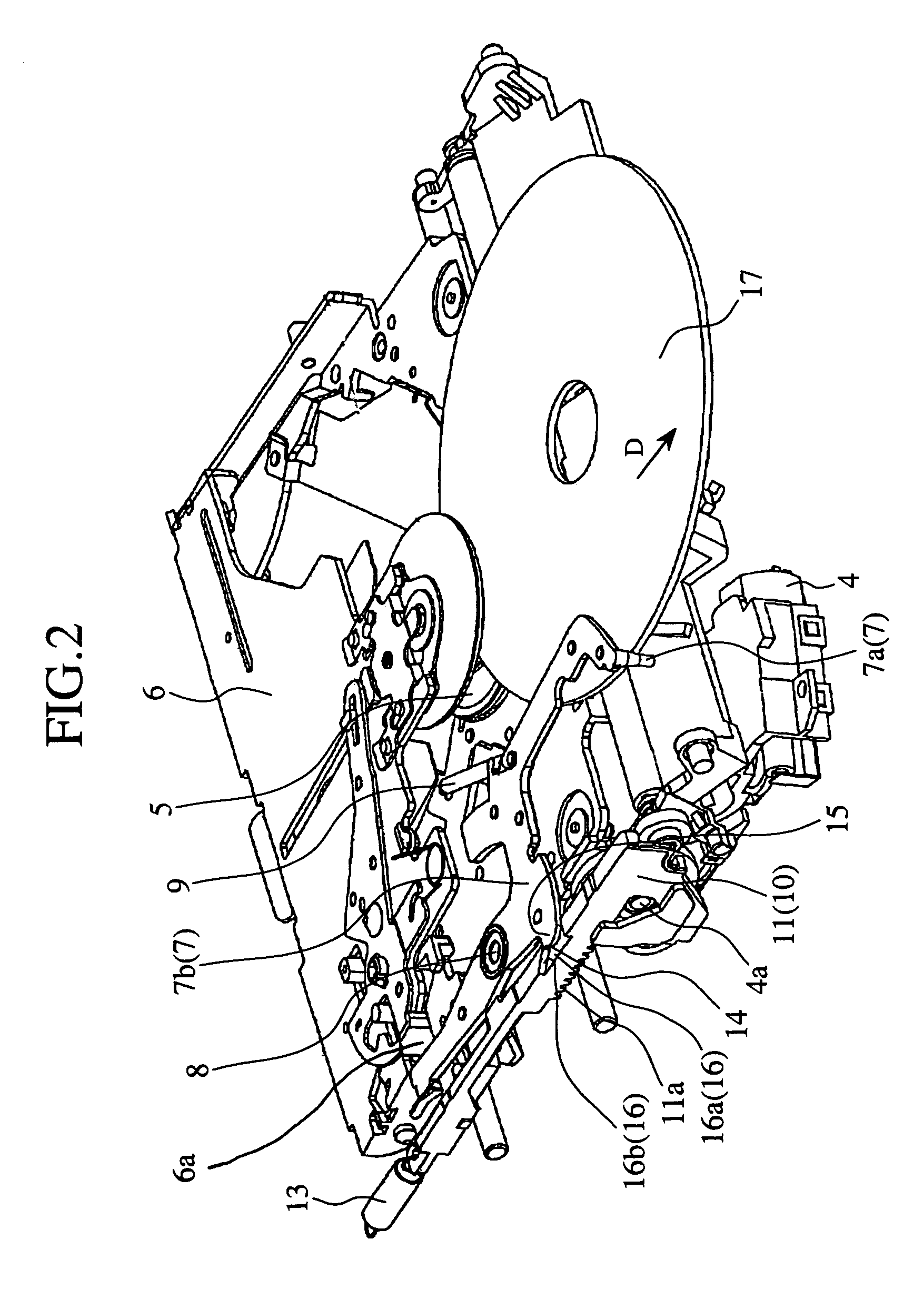

Disk reproducing device to prevent faulty operation in loading operation

InactiveUS7039925B2Avoid it happening againGuaranteed uptimeRecord information storageDisk sizeCoil spring

When a disk size selecting lever turns in a direction shown by an arrow A with an operation of ejecting a disk, its pushing surface pushes corner portion of a first slider rack in a state where it can not move, toward a direction shown by an arrow C. When the disk is completely ejected, the disk size selecting lever is returned in a direction shown by an arrow B by urging force of a coil spring and at the same time the first slider rack is forcibly returned to an original position by urging force of a coil spring.

Owner:MITSUBISHI ELECTRIC CORP

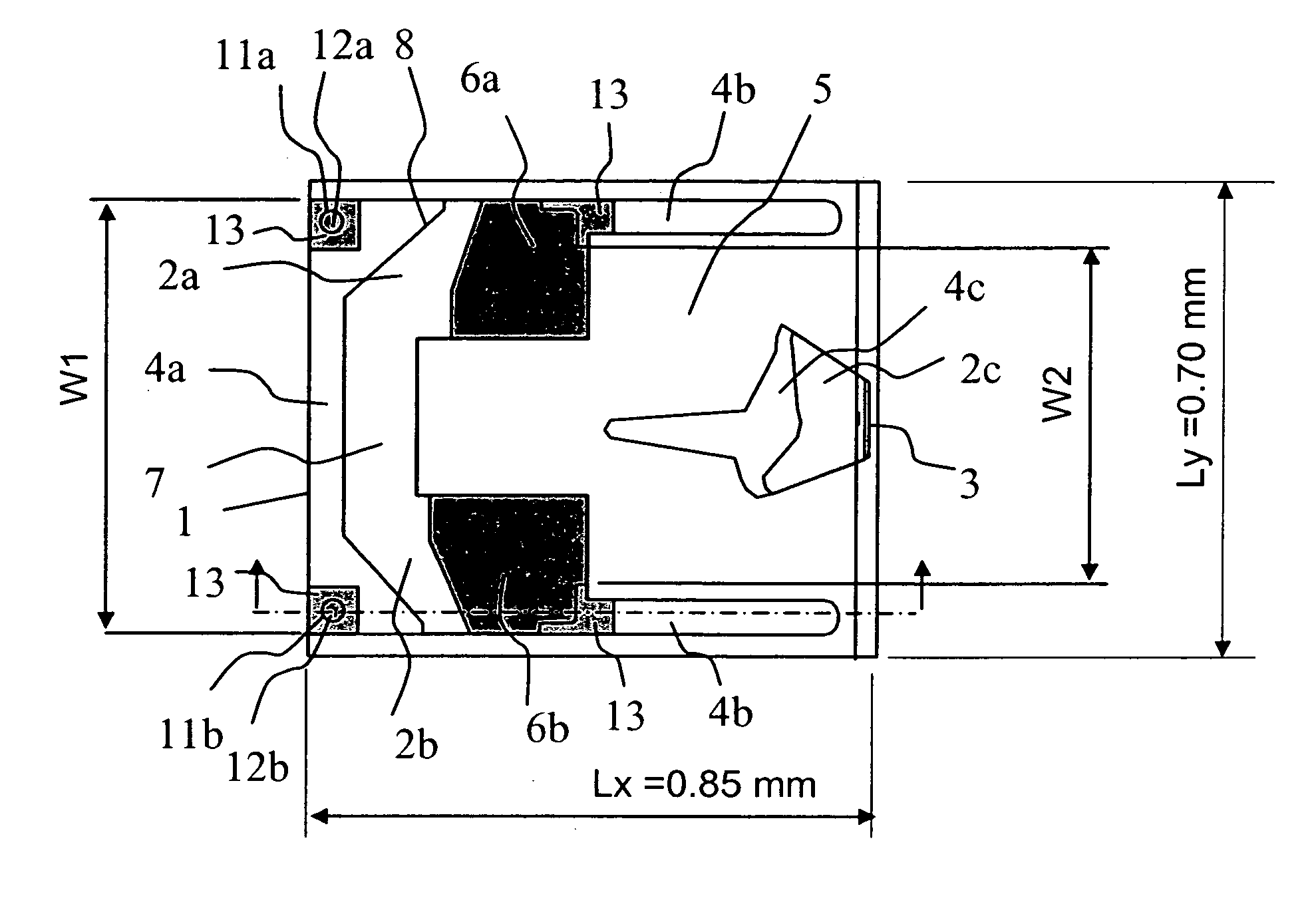

Magnetic disk slider having improved inclination margins in a rolling direction

A magnetic head slider suitable for a disk drive measuring 1.8 inches or less in disk size incorporates preventive measures against the decreases in lifting force that occur in small sliders with a slider width of 0.8 mm or less. The present invention improves the inclination margins of the flying slider in a rolling direction at the lowest flying point, and achieves low flying height and stable flying. The slider is constructed with stepped surfaces on the slider's leading-side flying surface formed up of shallow-grooved surfaces and a deep-grooved surface so that a trailing-side width W2 between the stepped surfaces is smaller than a leading-side width W1.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Systems and methods for RAID storage configuration using hetereogenous physical disk (PD) set up

ActiveUS9612759B2Simplifying improving user experienceMaximize available spaceInput/output to record carriersMemory systemsRAIDDisk size

Systems and methods are provided that may be used to automatically create RAID configuration with heterogeneous Physical Disk (PD) set up using Virtual Disk (VD) RAID Level and size, for example, to allow replication of a given RAID configuration across multiple different RAID platform systems regardless of the underlying storage disk sizes and / or storage disk types.

Owner:DELL PROD LP

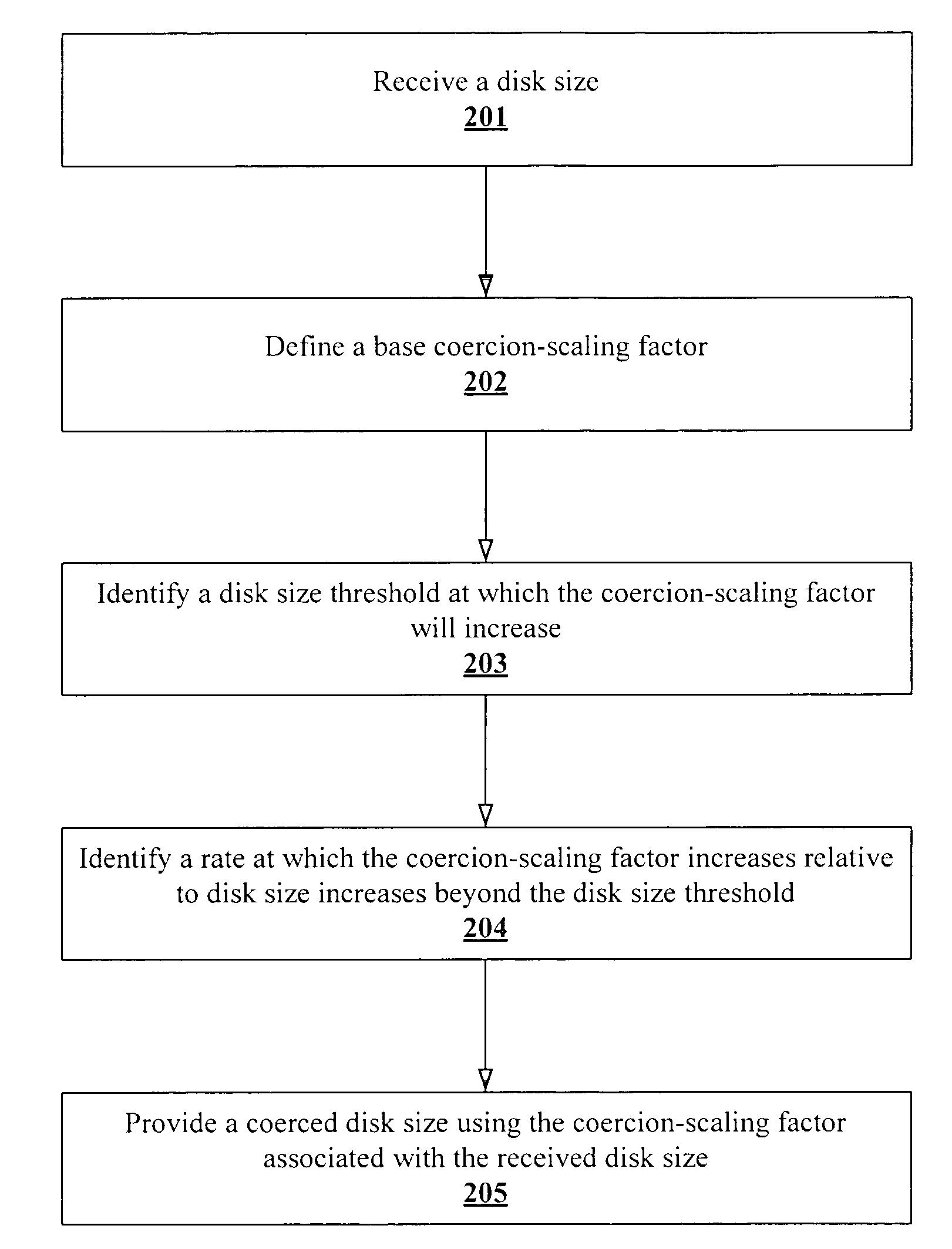

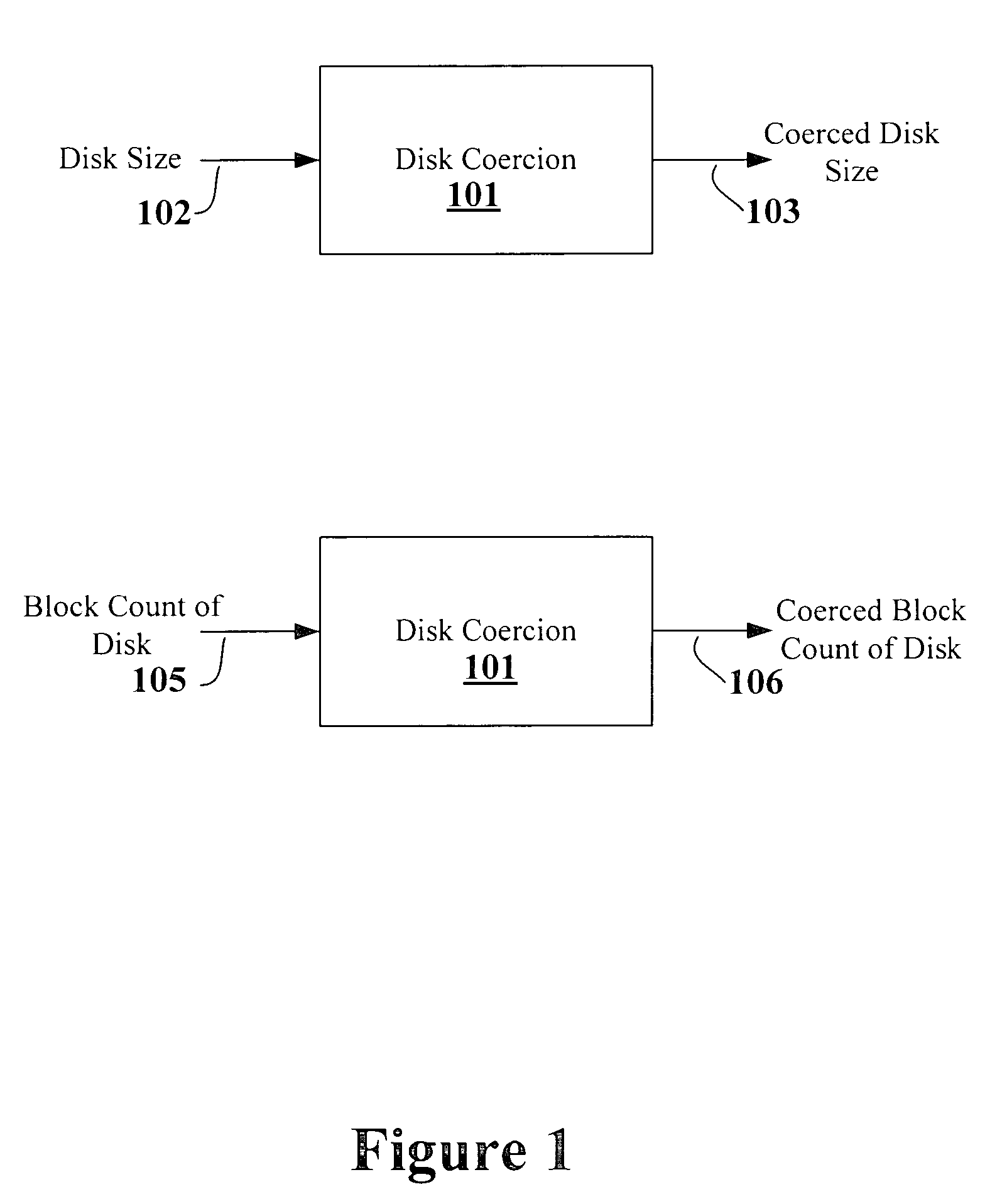

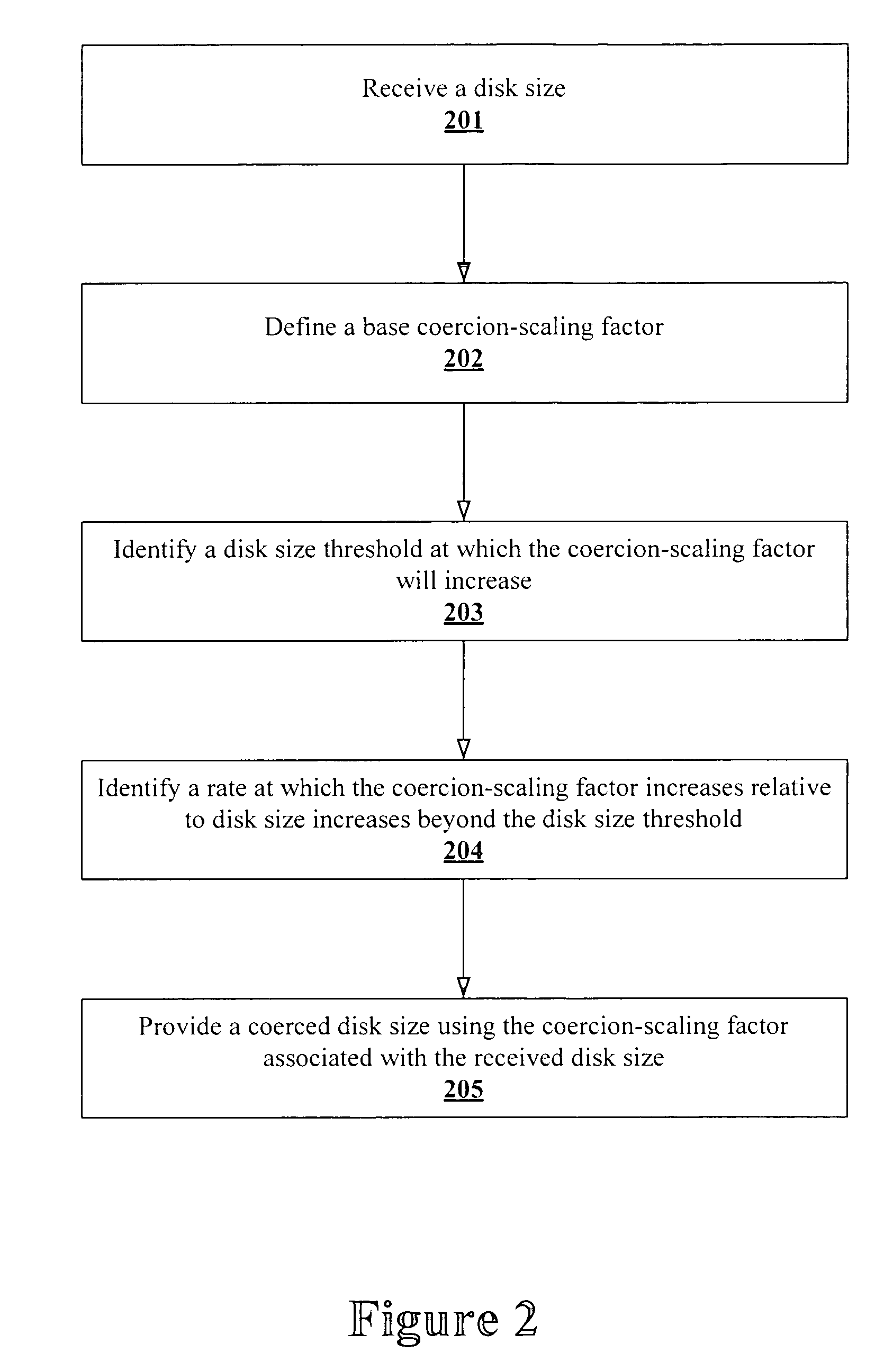

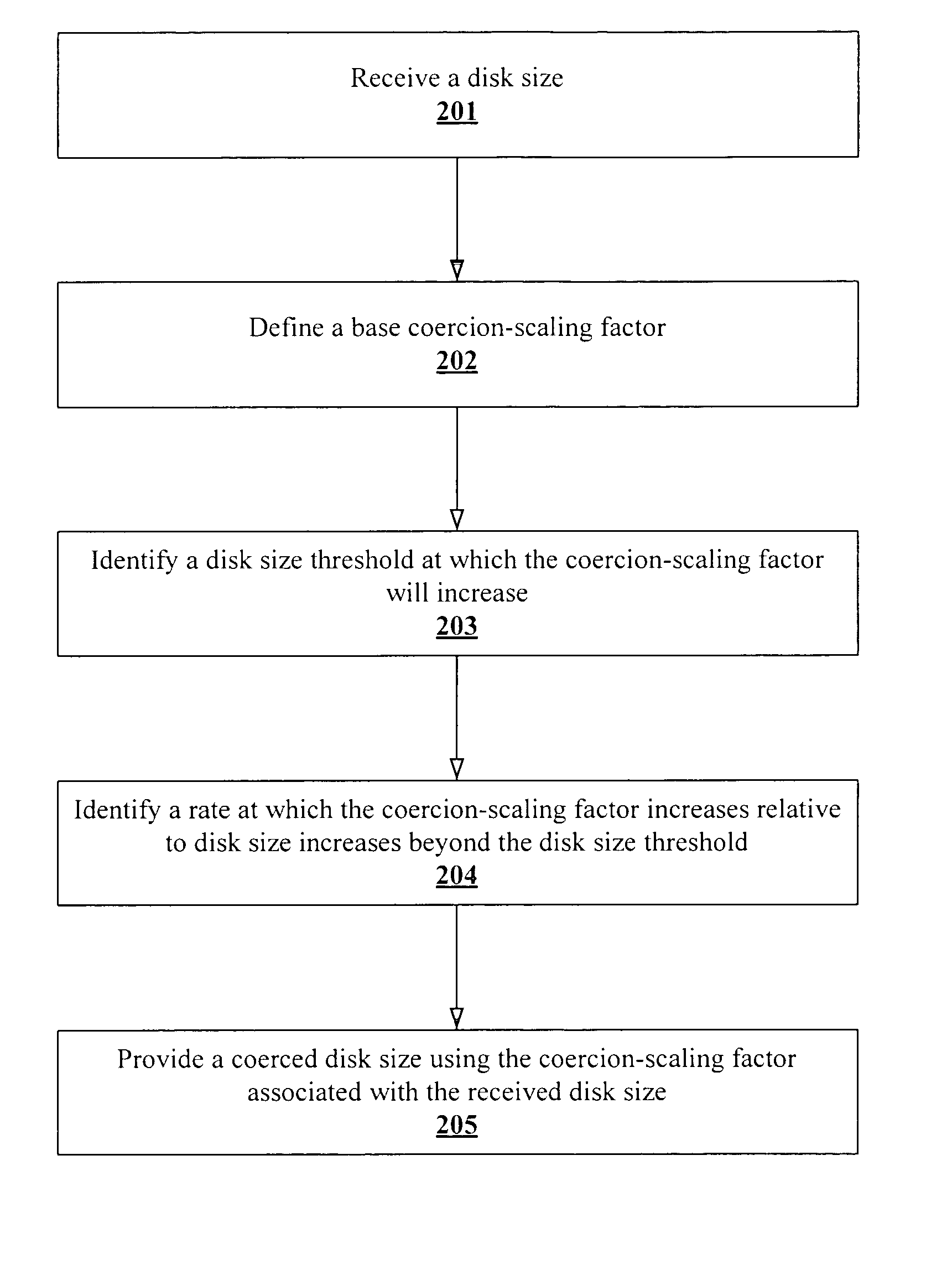

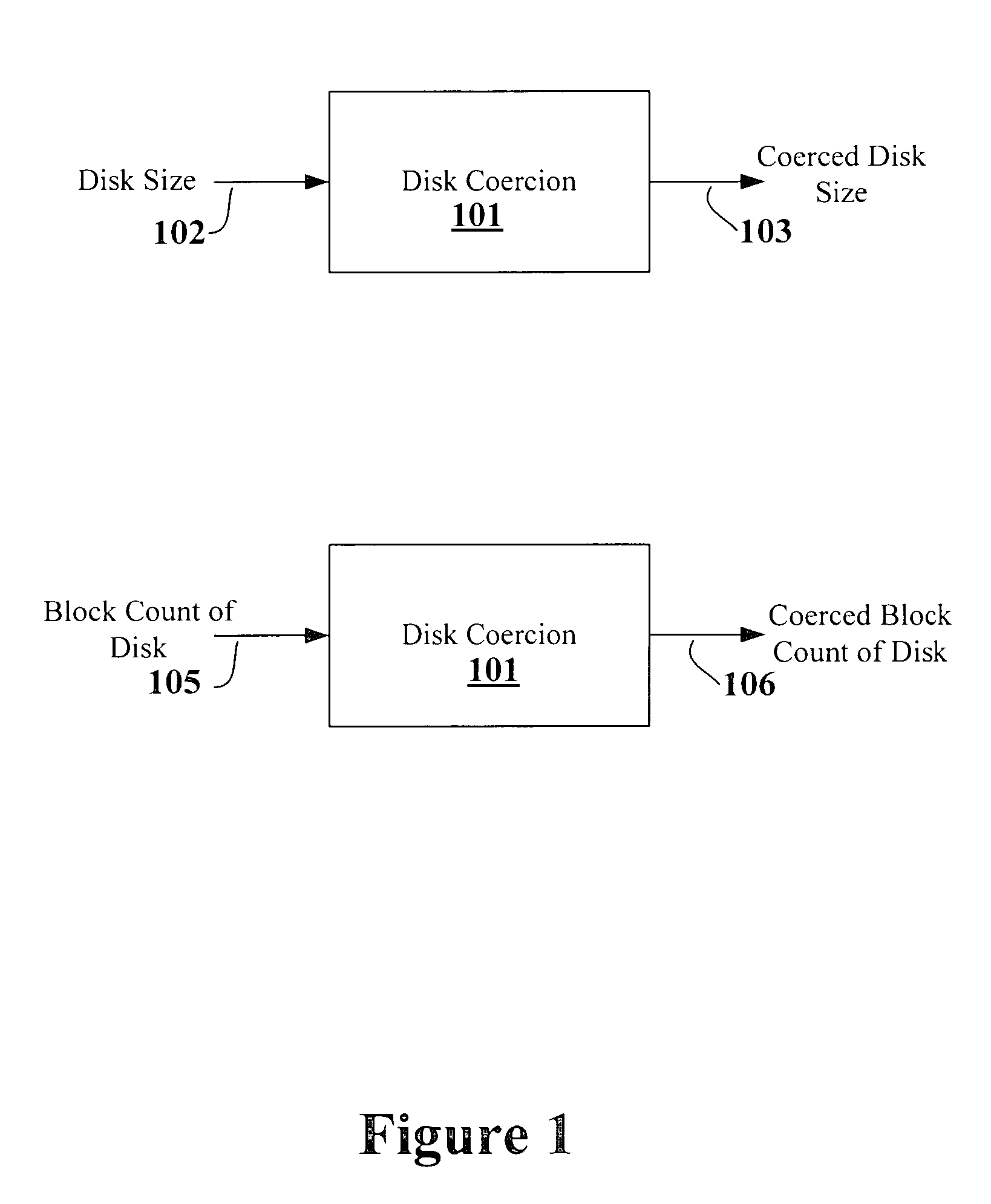

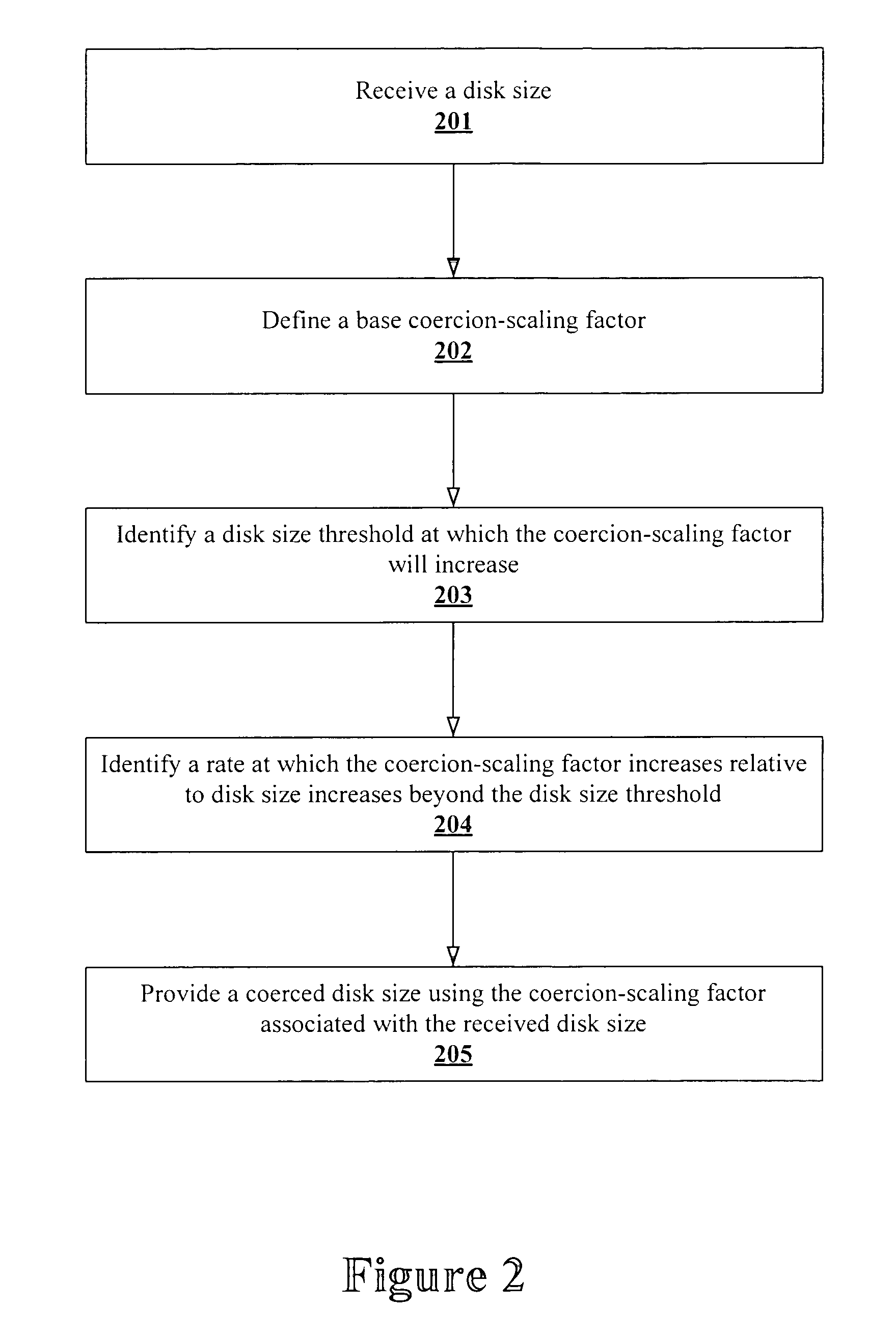

Scaled coercion of disk drive capacity

The present invention provides disk coercion by generating coercion percentages or values that can be used to coerce various disks according to each disk's particular labeled size or capacity. In one embodiment, a disk size is received and a base coercion scaling factor is provided such that the received disk size is coerced according to the base coercion scaling factor if the labeled disk capacity is below a disk size threshold. The coercion scaling factor increases for labeled disk capacity above the disk threshold. If the labeled disk capacity is above the disk size threshold, then a coercion scaling factor is provided according to the rate of increase of coercion scaling factors and the labeled disk capacity.

Owner:AVAGO TECH WIRELESS IP SINGAPORE PTE +1

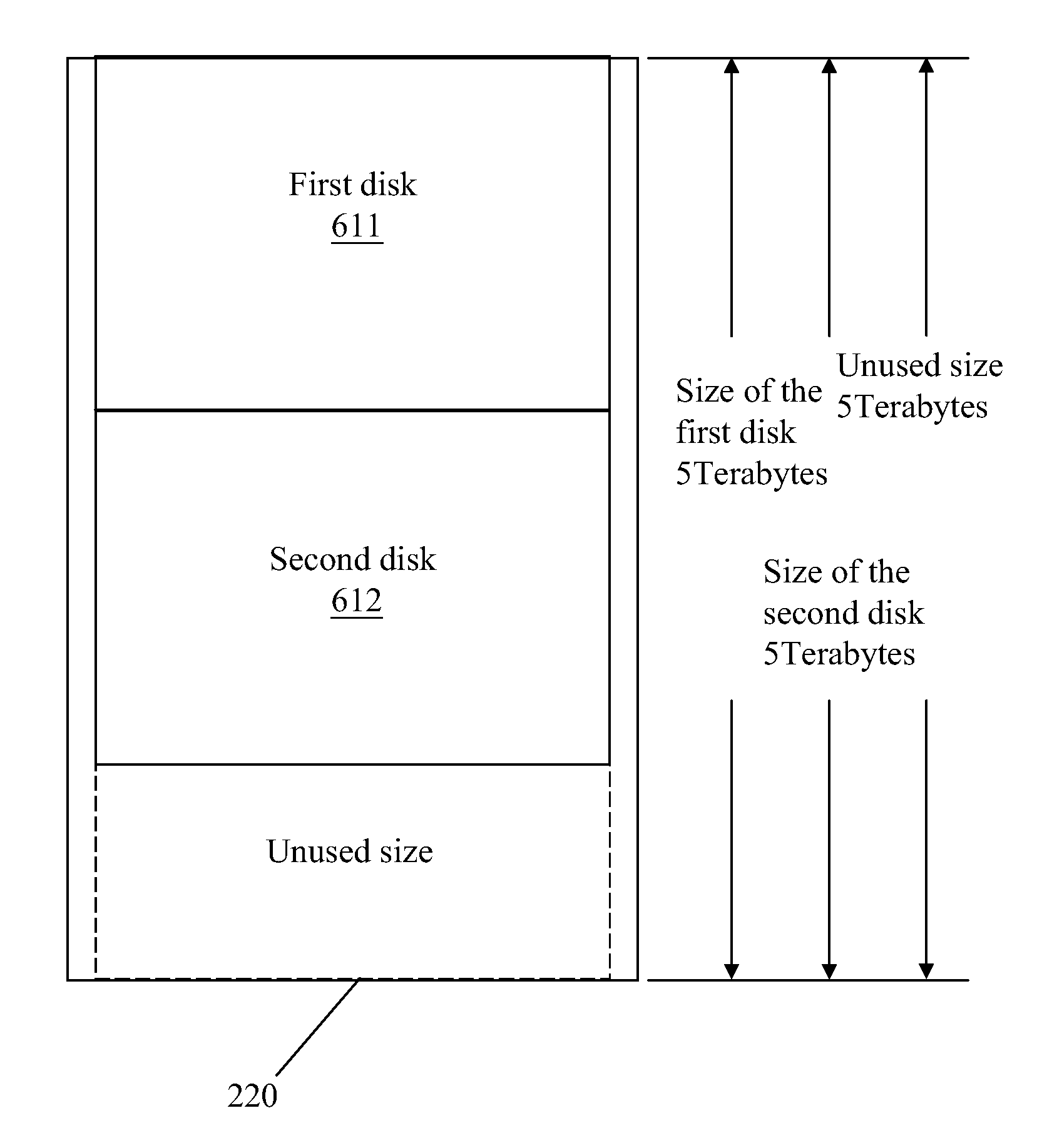

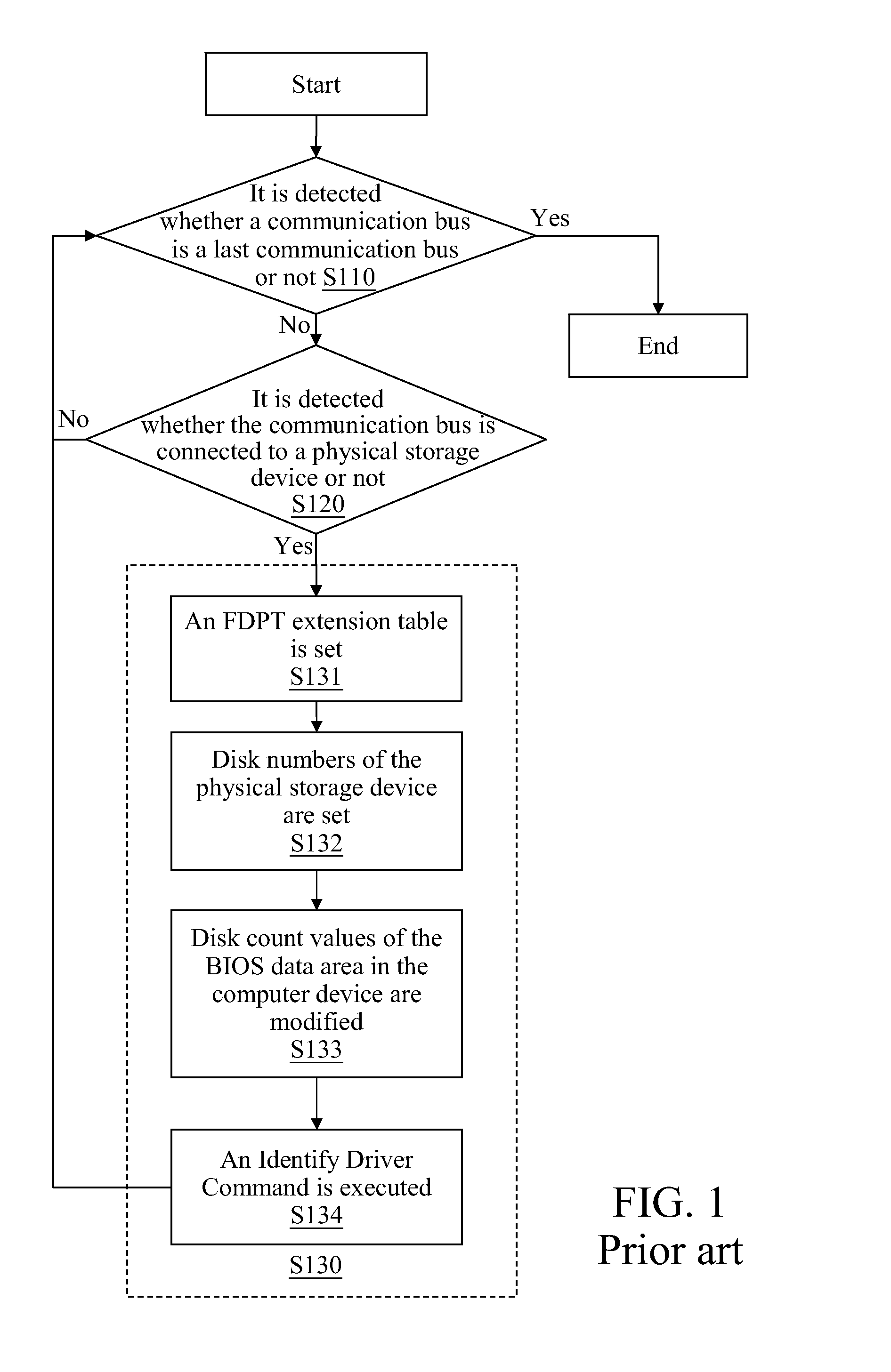

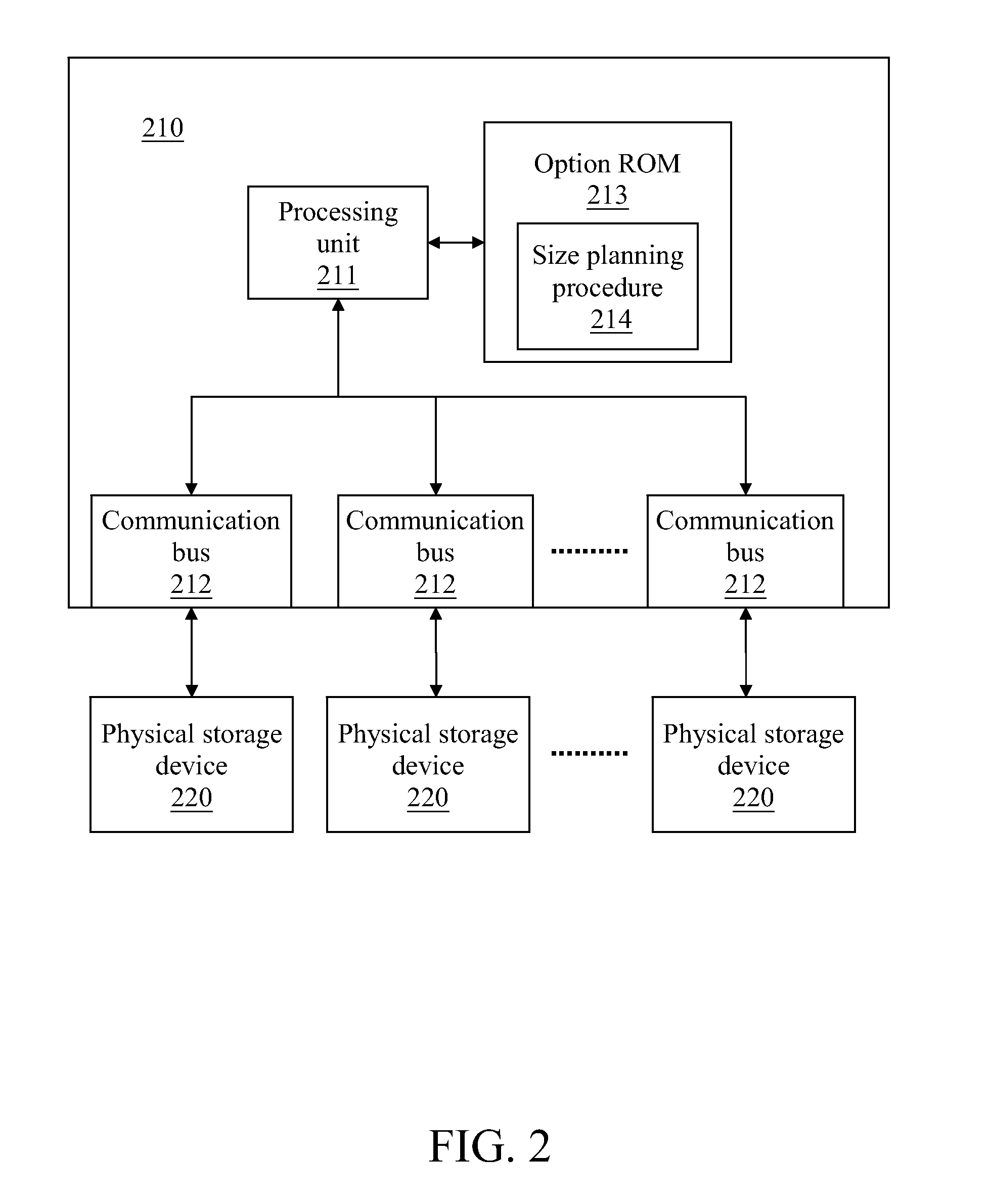

Size planning method for storage device, and read and access correcting methods thereof

InactiveUS20110047328A1Avoid sizeMemory adressing/allocation/relocationInput/output processes for data processingDisk sizePlanning method

A size planning method for a storage device, and read and access correcting methods thereof are described. When a computer device is booted, a size of a physical storage device is managed. The management method includes the following steps. A physical storage device connected to a computer device is searched. When a size of the physical storage device is larger than a maximum disk size, a current disk having a specified size is partitioned from the physical storage device. Various parameters of a logical fixed disk parameter table (FDPT) extension table of the current disk are set. A residual size of the physical storage device is partitioned into several disks having the specified size, and the corresponding logical FDPT extension tables are set until the residual size is smaller than the maximum disk size.

Owner:INVENTEC CORP

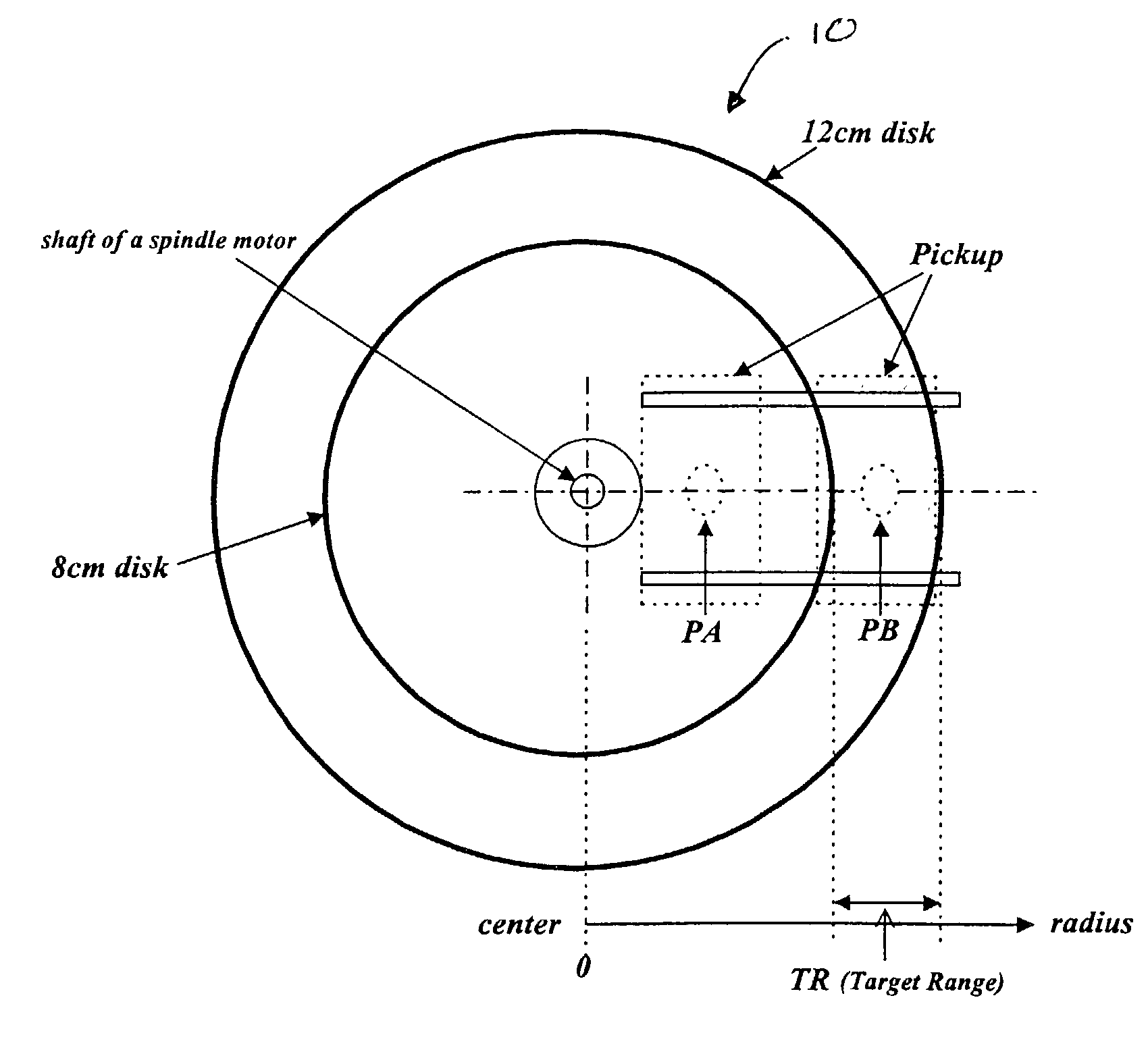

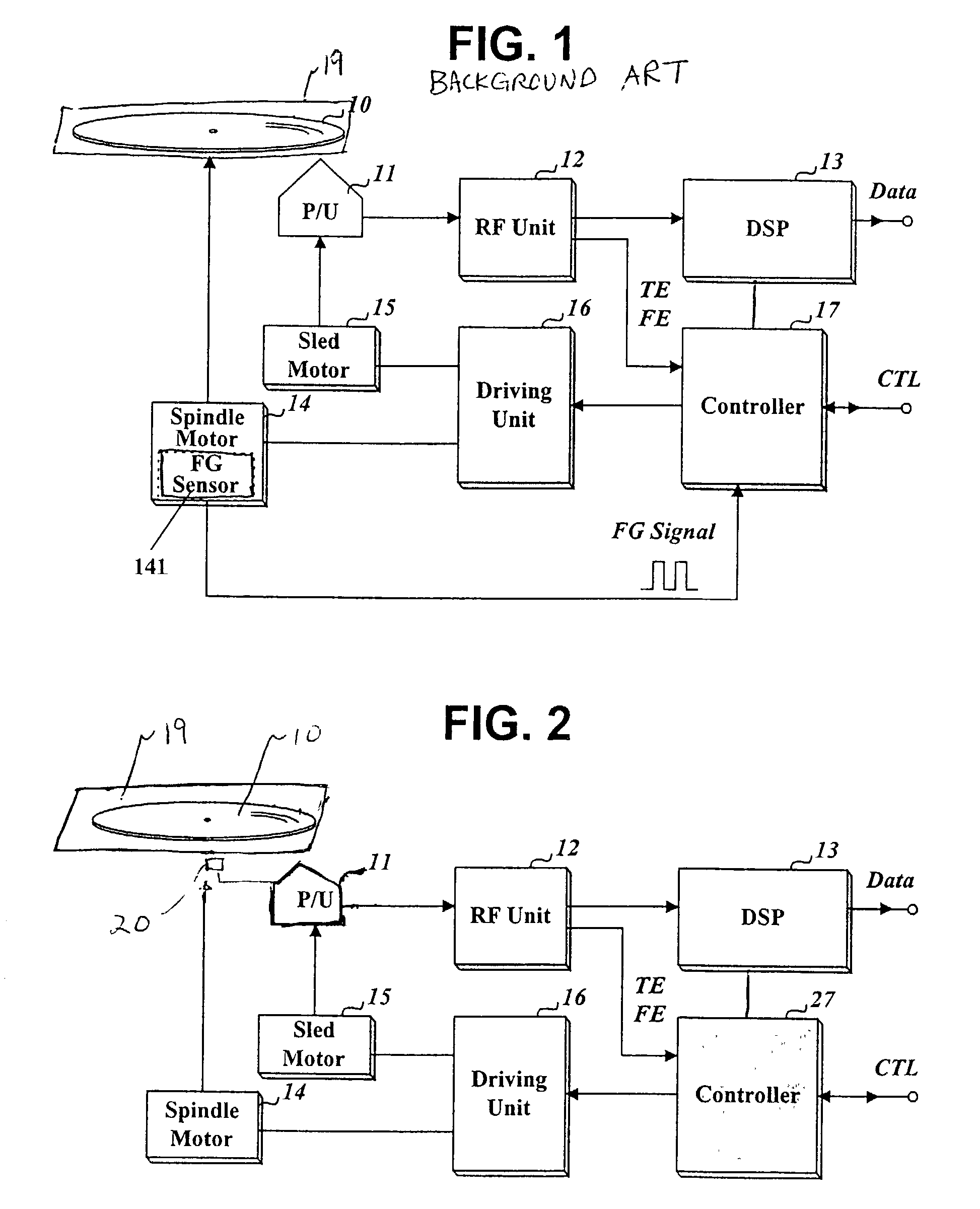

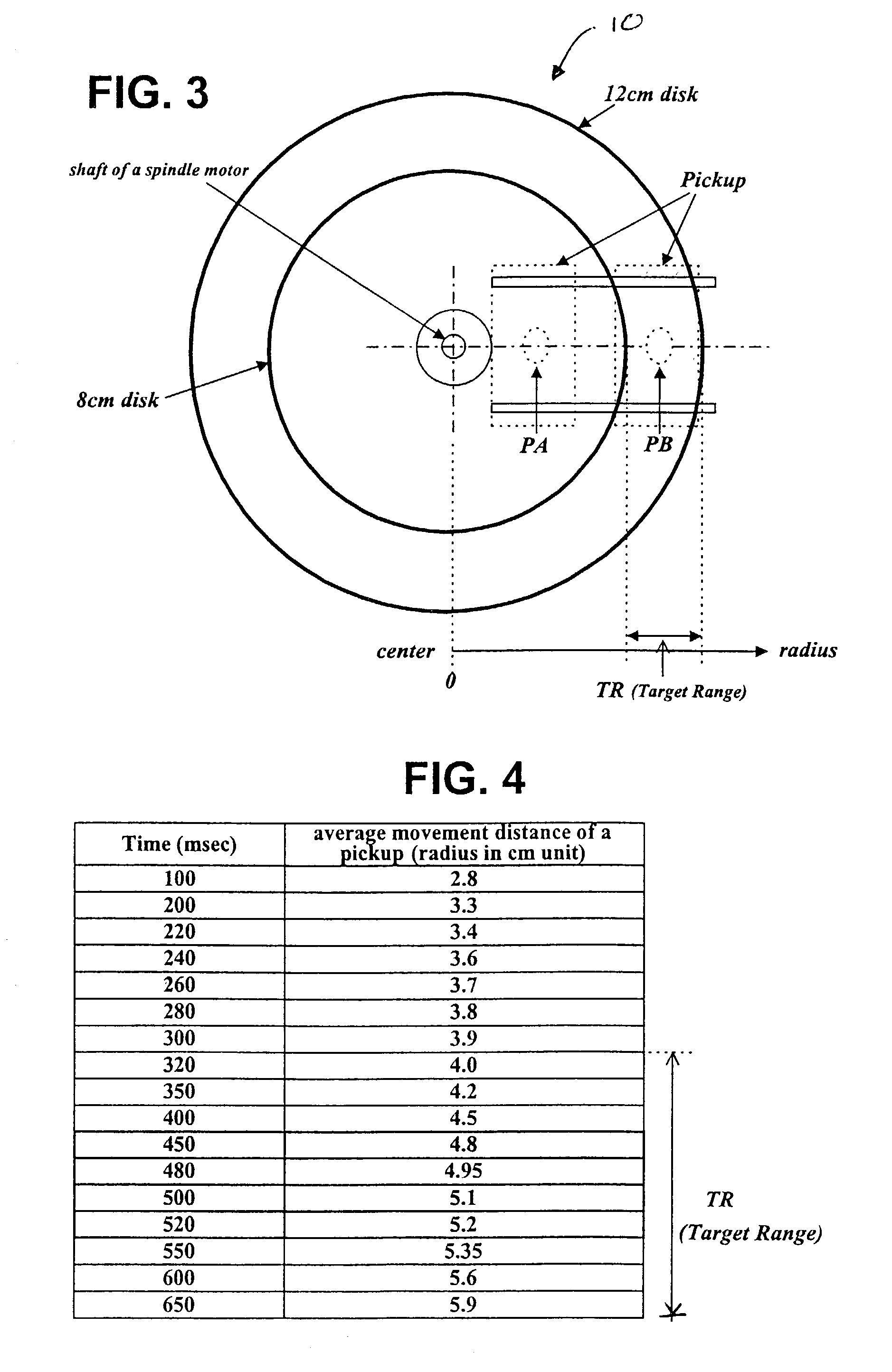

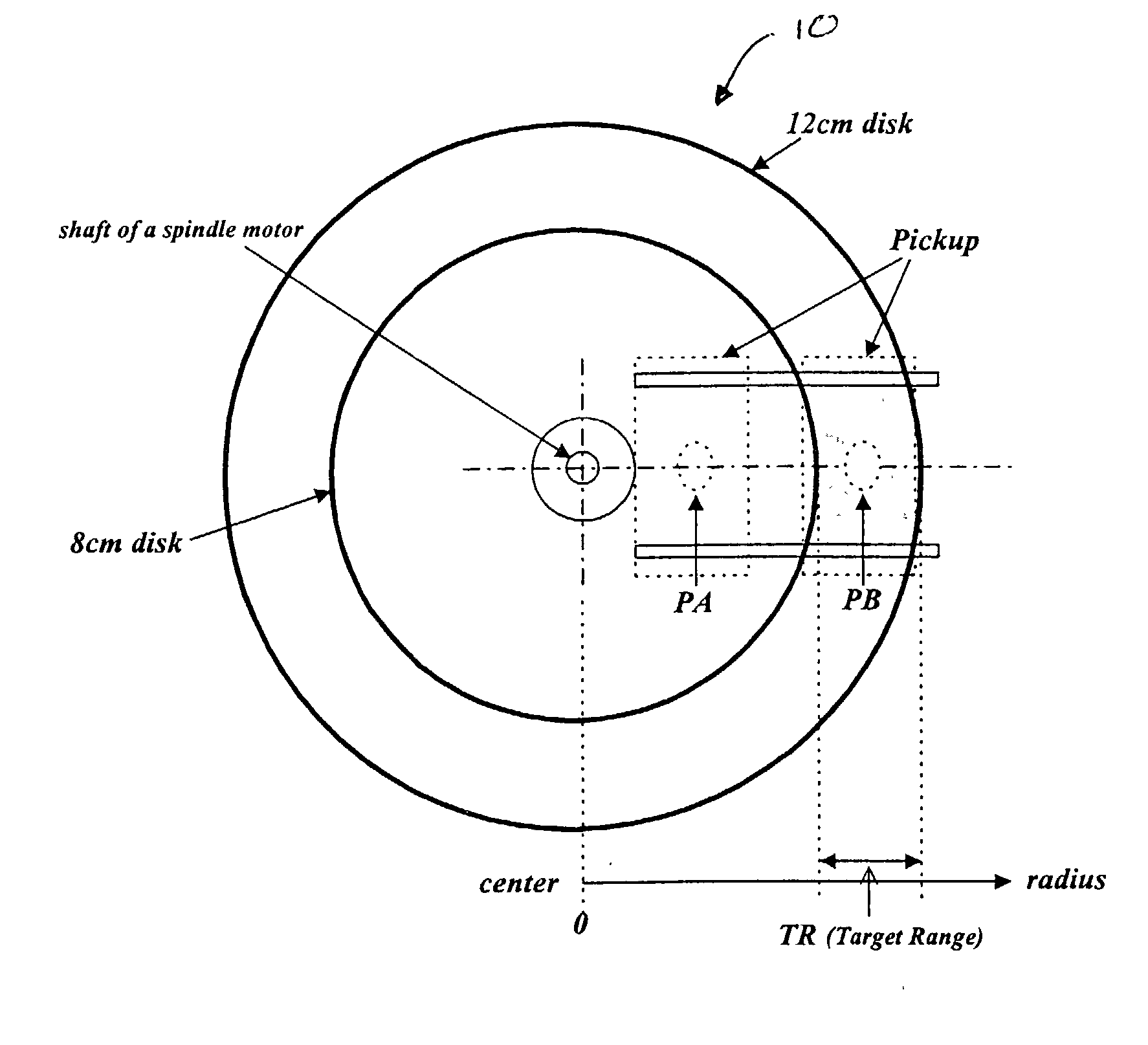

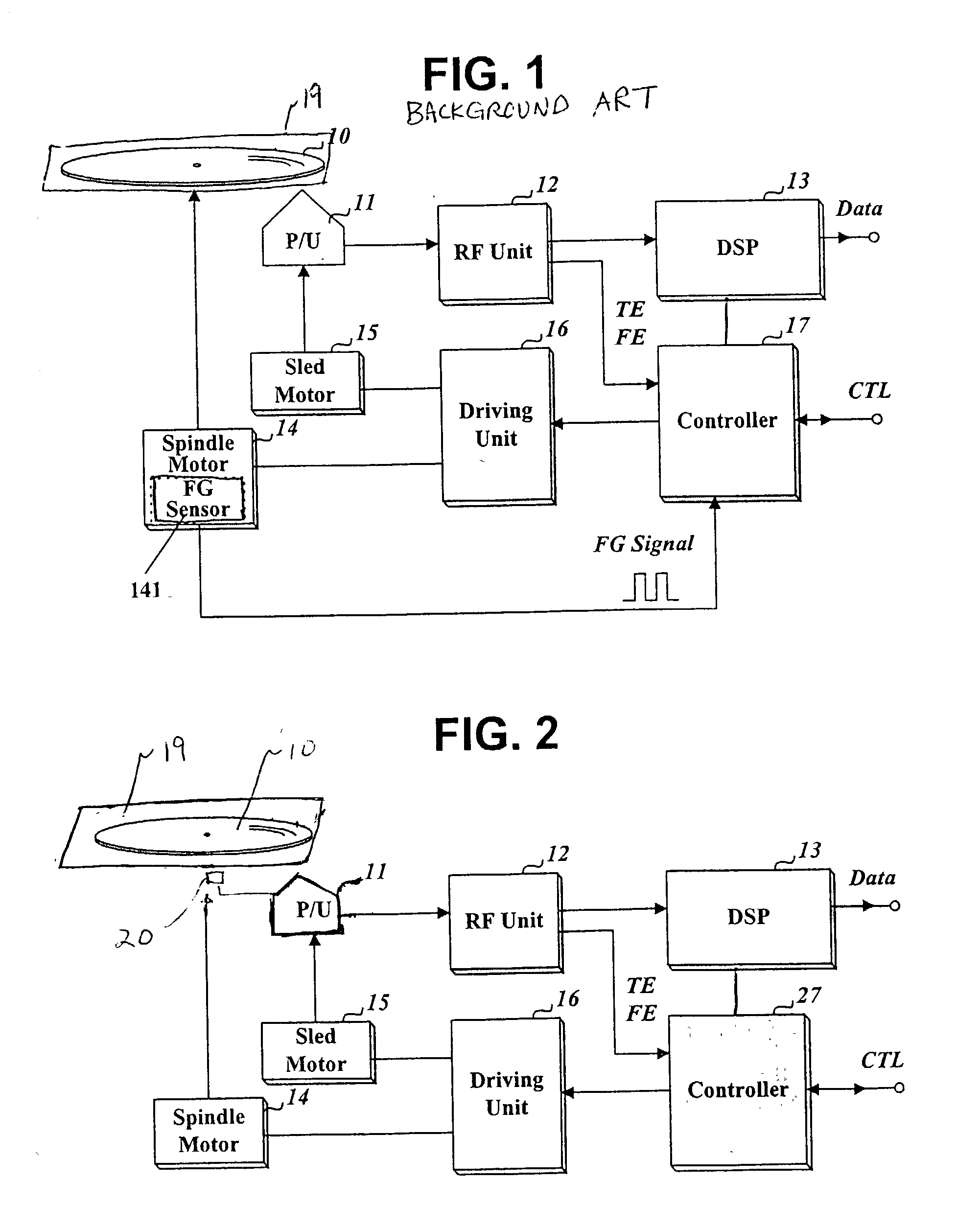

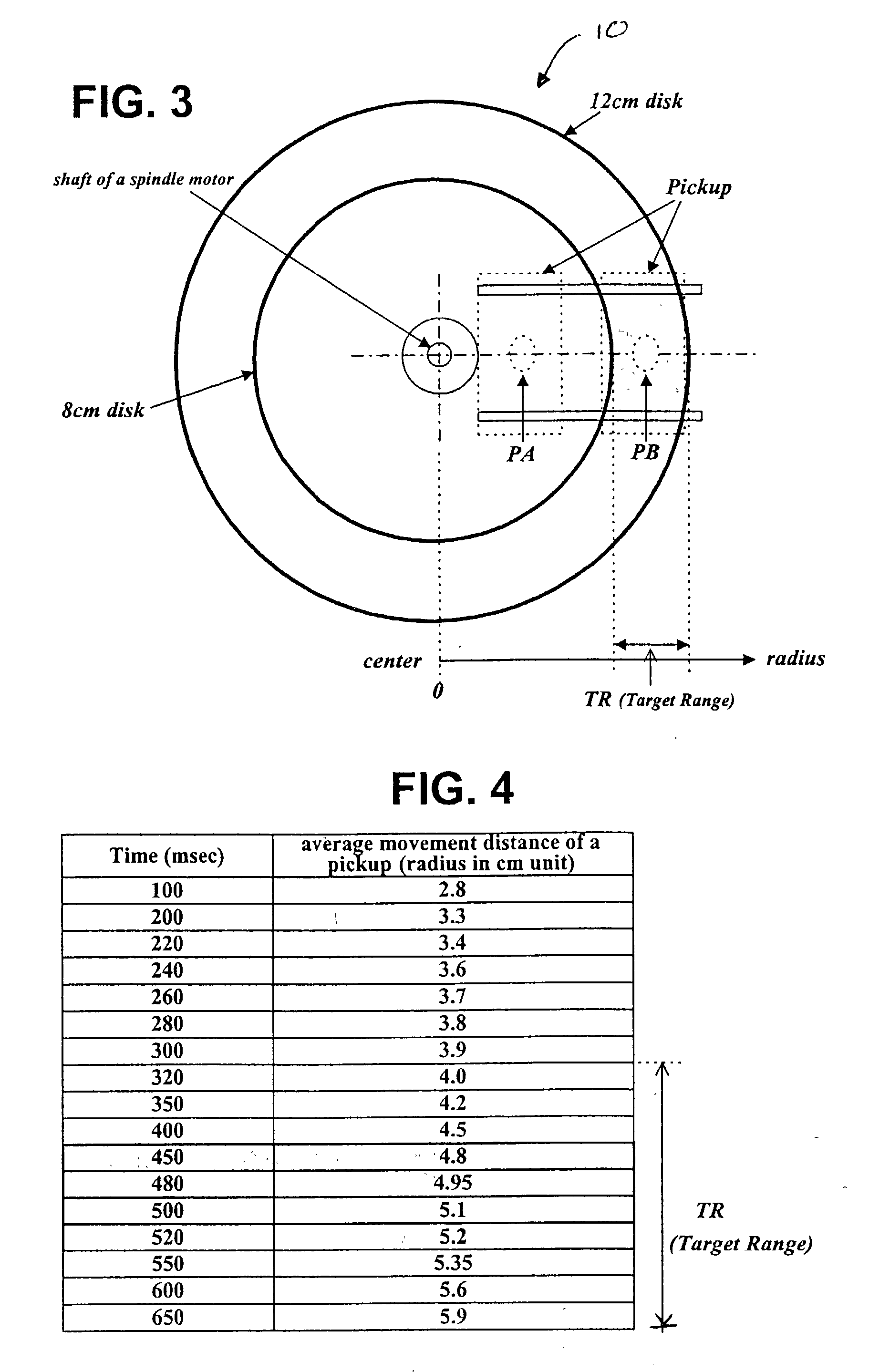

Method and device for determining disk size and stopping a rotating disk without using FG signals

InactiveUS7110337B2Small sizeLow costCombination recordingRecord information storageDisk sizeLight beam

A method and device for determining the presence or absence of a disk and / or a disk size without using FG signals, are provided. The method includes placing a pickup at a first zone on the optical recording medium, the first zone located between an outer radius of a first recording medium type and an outer radius of a second recording medium type, where the outer radius of the second recording medium type is larger than the outer radius of the first recording medium type; detecting a reflected signal based on a returned beam from the first zone of the optical recording medium; and determining at least one of a size and an absence of the optical recording medium based on the detected reflected signal. Therefore, an FG sensor that is provided in a general disk device can be eliminated, thereby reducing the size and cost of a disk device.

Owner:LG ELECTRONICS INC

Method and device for determining disk size and stopping a rotating disk without using FG signals

InactiveUS20030103430A1Small sizeLow costCombination recordingOptical beam sourcesDisks (device)Disk size

A method and device for stopping a rotating optical recording medium without the use of an FG sensor, are provided. The method includes determining position information on a current position of a pickup on a rotating optical recording medium when a recording medium rotation stop request is received; determining a break voltage applying time based on the determined position information; and applying a break voltage to a motor for a duration of the determined break voltage applying time to stop the rotating recording medium. Therefore, an FG sensor that is provided in general disk devices can be eliminated to reduce the size and cost of a disk device.

Owner:LG ELECTRONICS INC

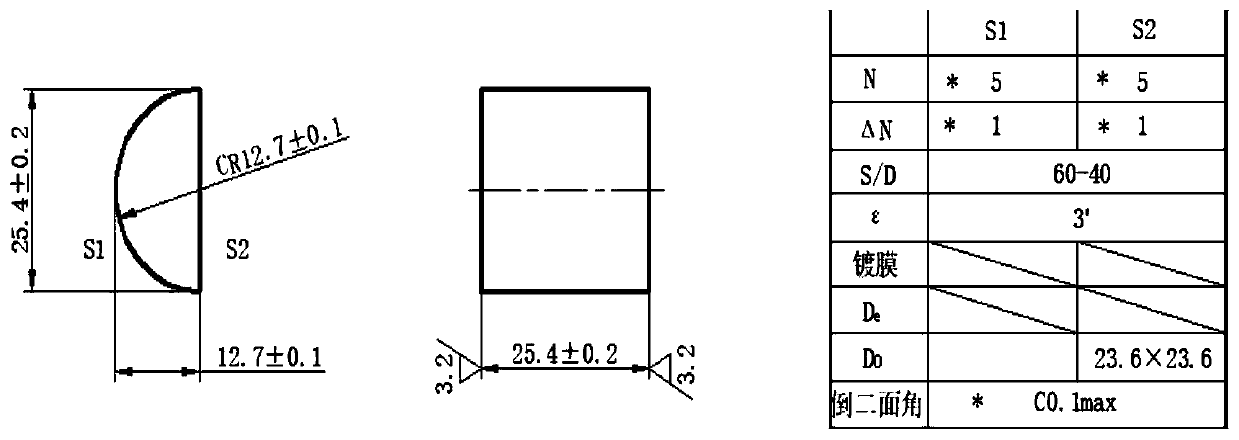

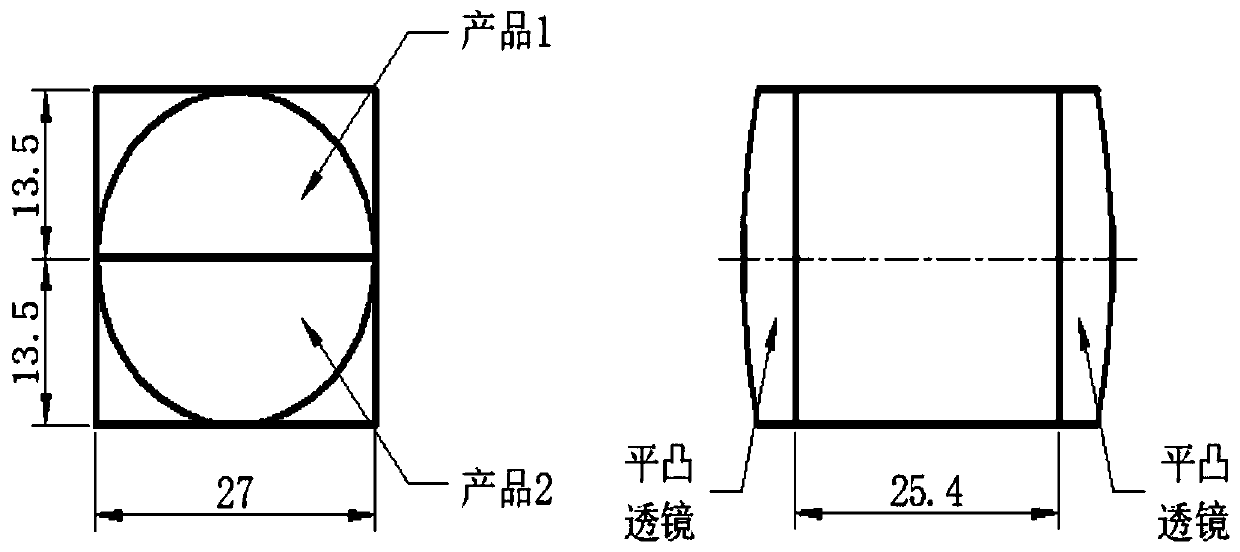

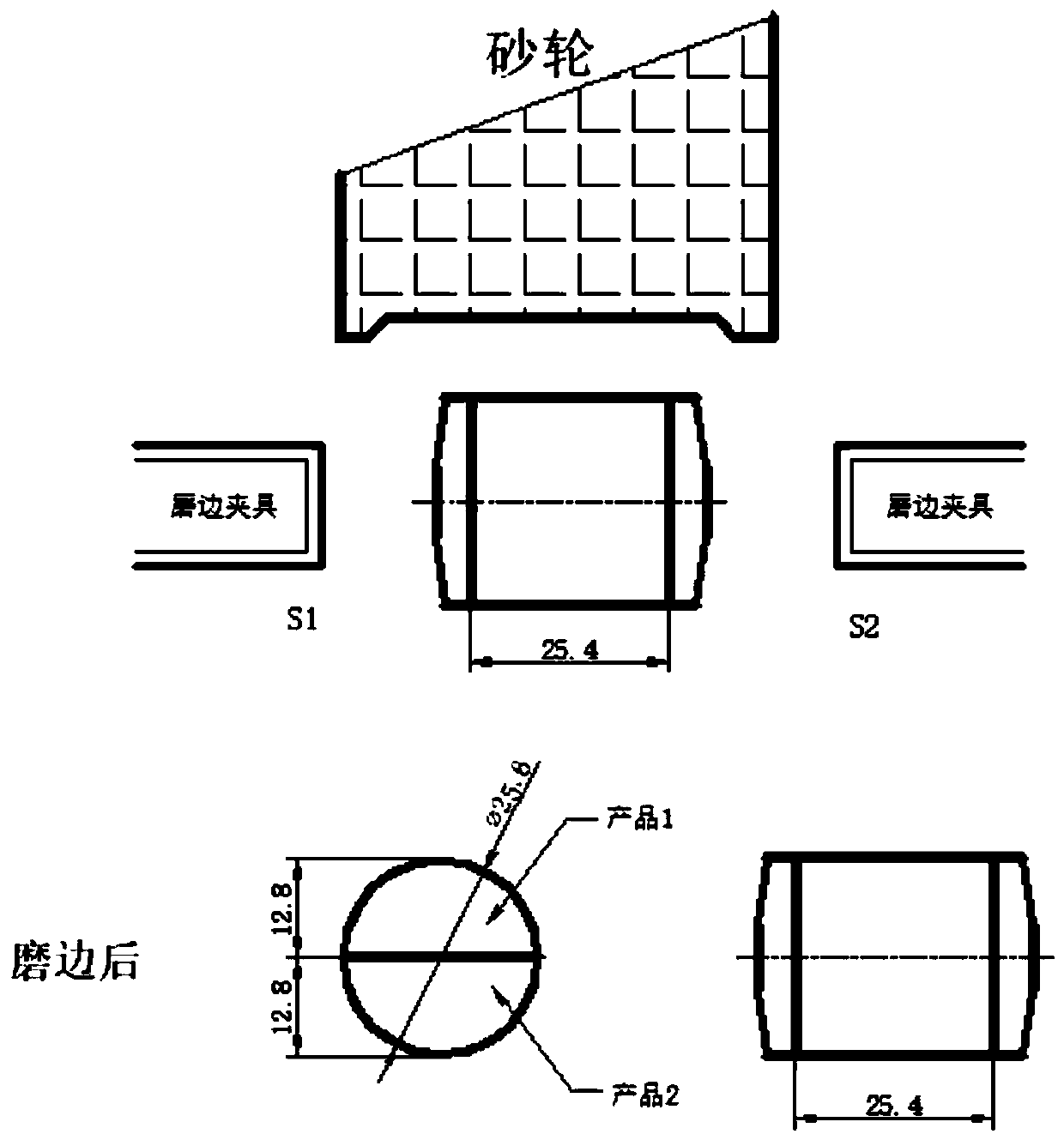

ZnSe semi-cylindrical mirror development process

The invention discloses a ZnSe semi-cylindrical mirror development process. The invention provides the ZnSe semi-cylindrical mirror development process in order to overcome the defects existing in theprior art. The ZnSe semi-cylindrical mirror development process includes the following steps that S1, according to the product size (R12.7*12.7*25.4), a corresponding face mirror base material is selected for use, and the size is 28*27*14; S2, disk forming for machining the base material is performed, the whole disk size consistency can be guaranteed well due to ring grinding machining, and six surfaces are machined; S3, ring polishing of the 27*25.4 face is performed till the size is 27*25.4*13.5(0 / -0.005); S4, two semi-finished products where ring polishing is completed are taken, the two polished faces (27*25.4) are glued with photosensitive glue, the plane finish degree is guaranteed well, and the size of the semi-finished products after being glued is 27*27*25.4, edge grinding is performed, and edge grinding is performed till the outer diameter D25.6(0 / -0.02) size is achieved; and S7, the two products are dismantled, the plane photosensitive glue is removed, disk feeding is performed, low polishing machining of a product cylindrical face is performed, and the client requirement is met; and the product consumption size is consistent before polishing, and the polishing machining size consumption is about 0.02; and S8, disk discharging is performed, cleaning is performed, edge chamfering is performed, and a product is completed. The ZnSe semi-cylindrical mirror development process utilizes a conventional cuboid base material, and cost is effectively saved.

Owner:合肥嘉东光学股份有限公司

A Method of Rapid Horizontal Expansion of Database

ActiveCN102930062BImprove the speed of expansionEasy to monitorSpecial data processing applicationsIn-memory databaseData segment

Owner:NANJING FUJITSU NANDA SOFTWARE TECH

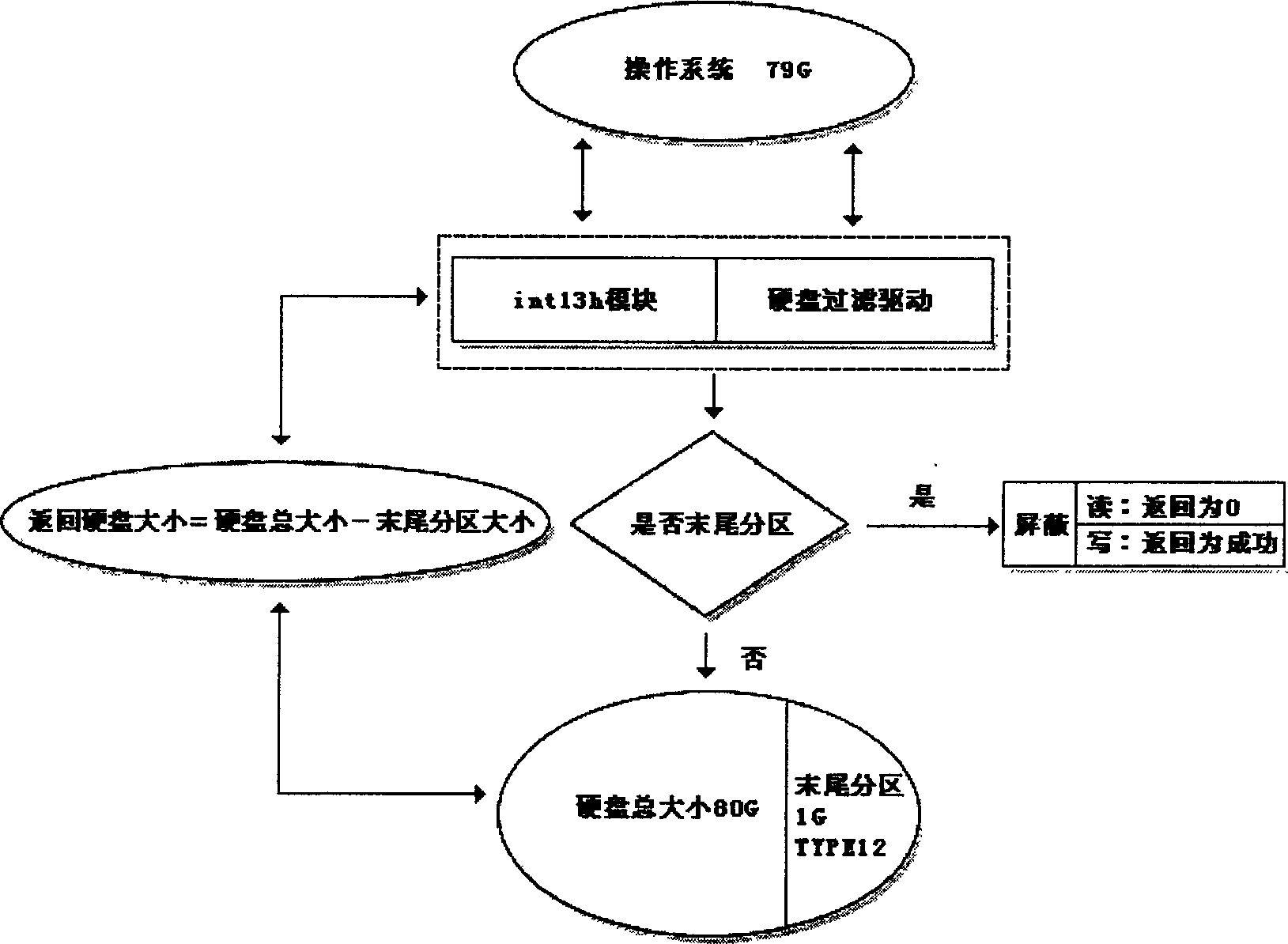

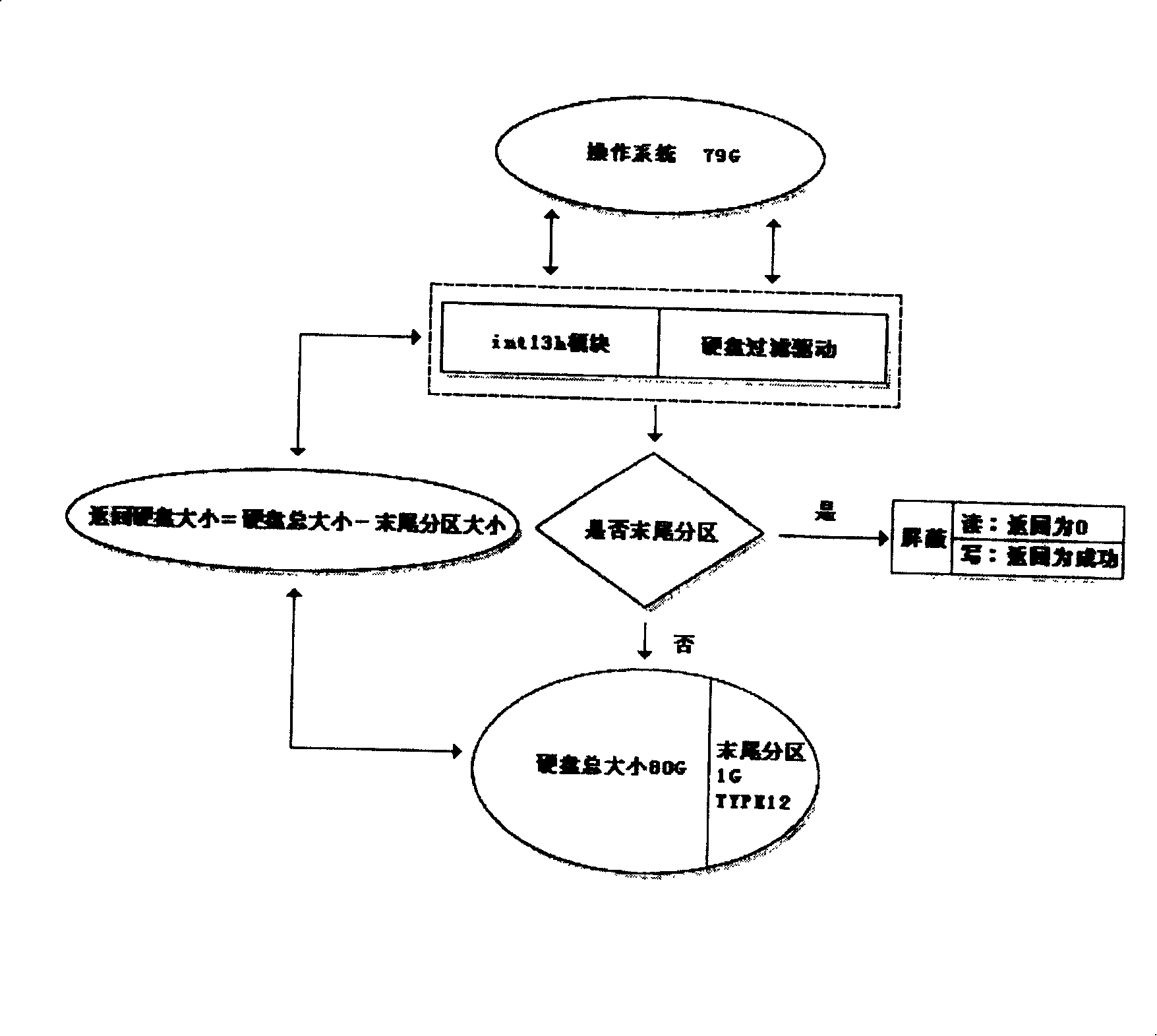

Method for protecting hard disk last partition

InactiveCN1845073AHas practical application effectProtect last partitionUnauthorized memory use protectionProgram loading/initiatingDisk sizeBIOS

The invention relates to a method for protecting the tail zone of hard disk. Wherein, in the process of starting the computer, first using BIOS to load in one INT13H filter module; then starting the WINDOWS operating system; and loading hard disk filter driving module; with the driving of INT14H module and the hard disk filter driving, the hard disk size feedback to the operating system is equal to the value that actual hard disk reduced by the size of tail zone; the operating system will not actively access the tail zone, but actively stop the read and write operation on the tail zone; the operating system and the application program can not access and modify the tail zone; the hard disk filter driving program can be added into the mounding program when leaving factory and be automatically mounted. The invention also checks the zone list of tail zone before starting the operating system in each computer starts, and automatically builds a main zone lift for the tail zone as TYPE12, with which the new mounted operating system can destroy said zone.

Owner:张健

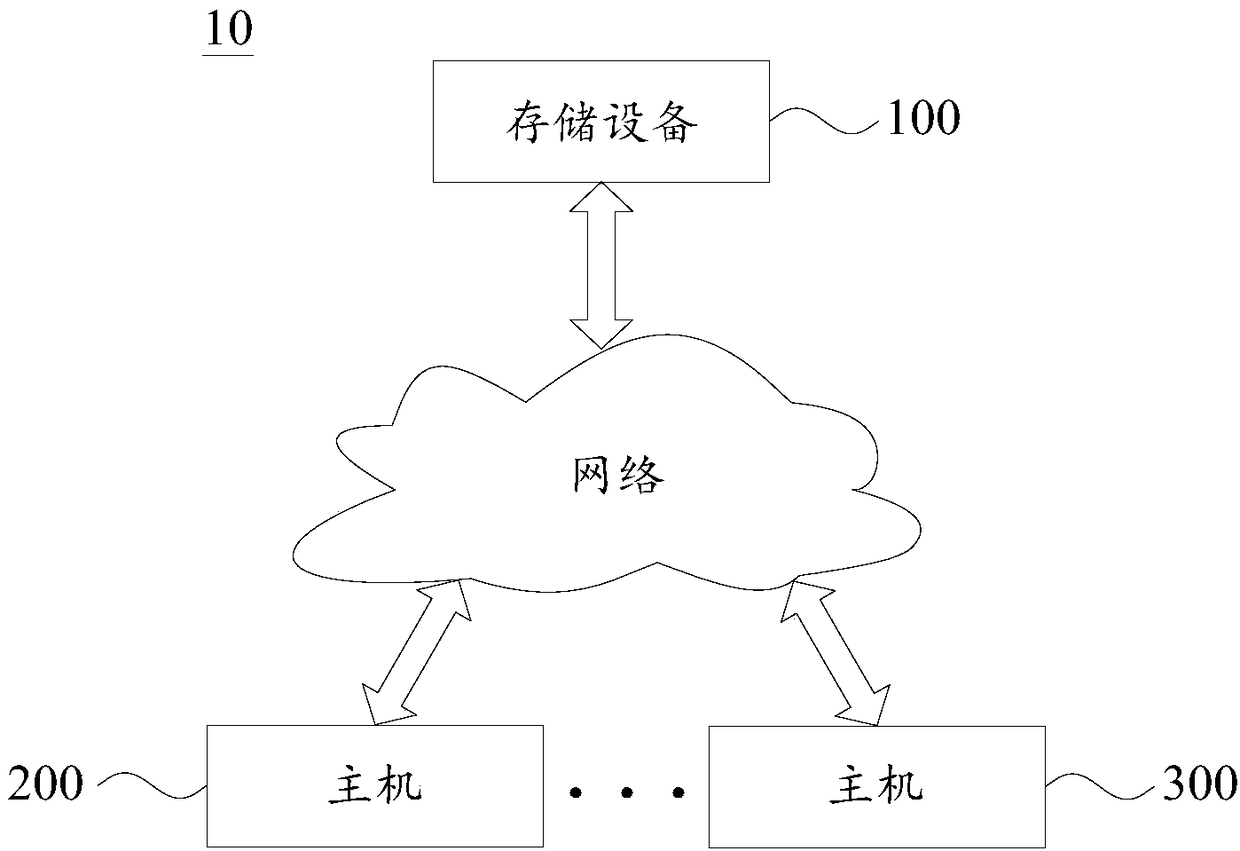

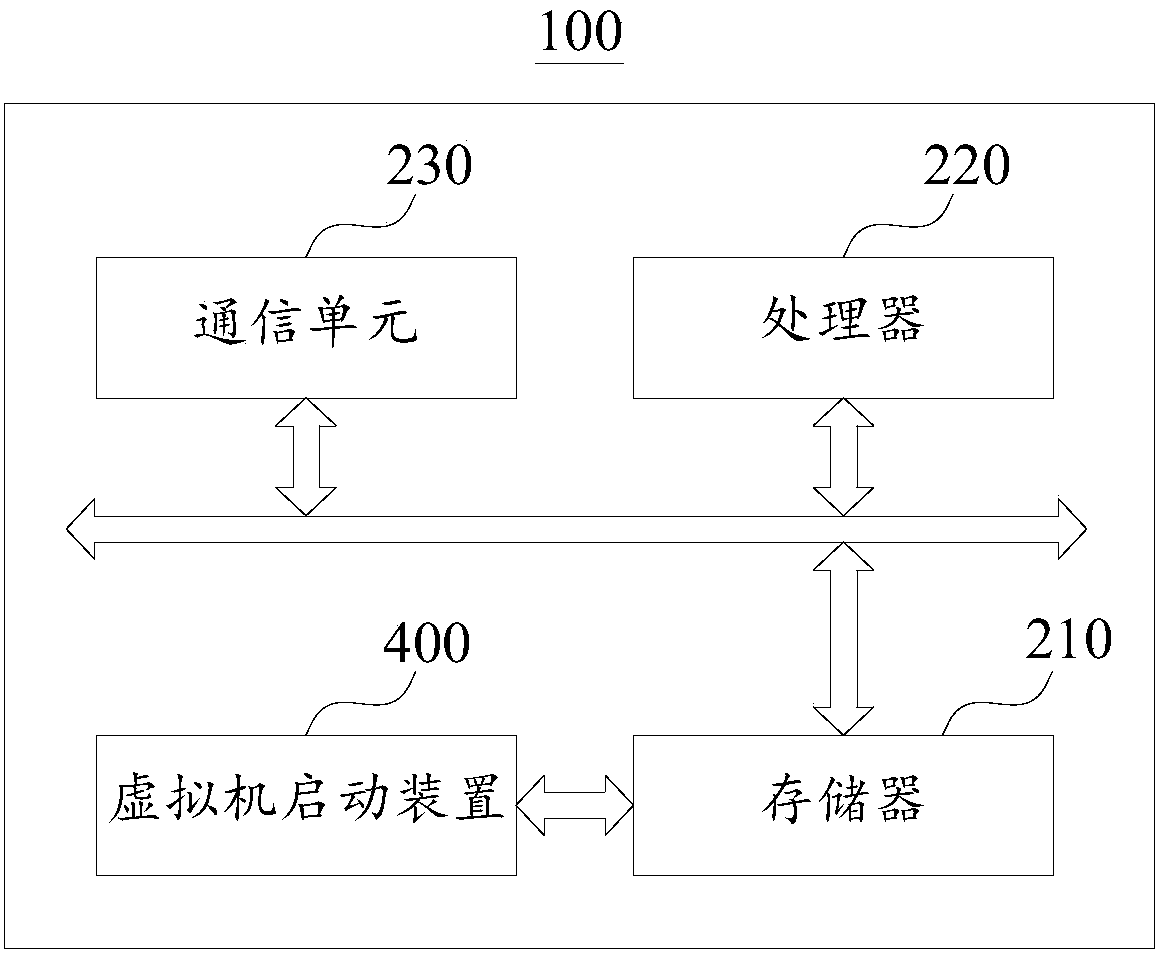

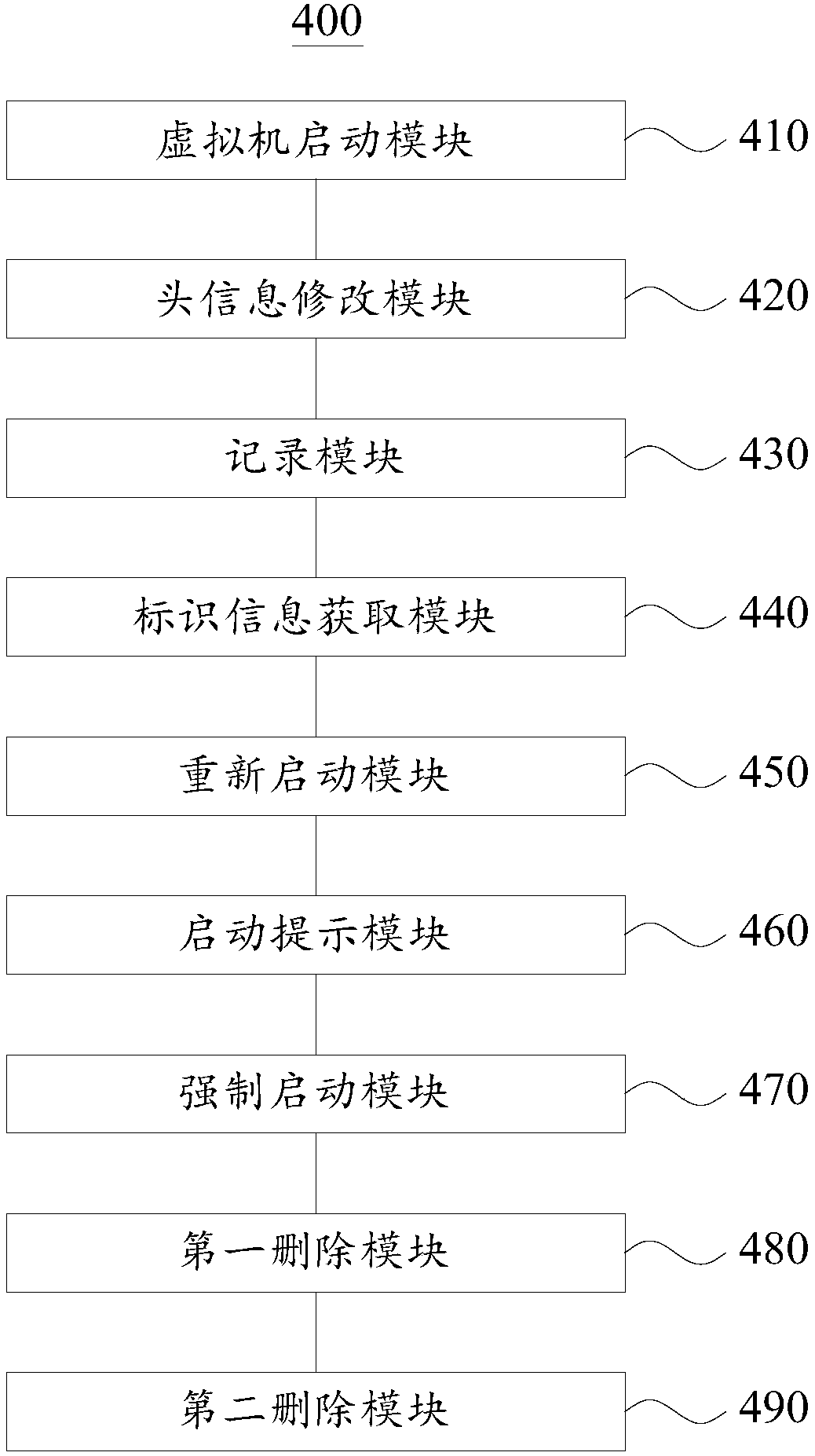

Virtual machine starting apparatus and method, and host

ActiveCN108509252AAvoid startingAvoid damageInput/output to record carriersSoftware simulation/interpretation/emulationDisk sizeSize value

The invention provides a virtual machine starting apparatus and method, and a host. The apparatus and the method are applied to each host in communication connection with a storage device; at least one virtual machine is deployed in each host; and virtual disk files used for starting the virtual machines are stored in the storage device. The apparatus comprises a virtual machine starting module used for obtaining a virtual disk size value recorded in header information of a target virtual disk file when a starting instruction for starting any virtual machine through the target virtual disk file is executed, and starting the virtual machine through the target virtual disk file when the virtual disk size value is greater than a preset threshold value, and a header information modification module used for modifying the virtual disk size value recorded in the header information of the target virtual disk file to a preset size value when the virtual machine is started successfully through the target virtual disk file, thereby preventing other virtual machines from being started through the target virtual disk file.

Owner:NEW H3C CLOUD TECH CO LTD

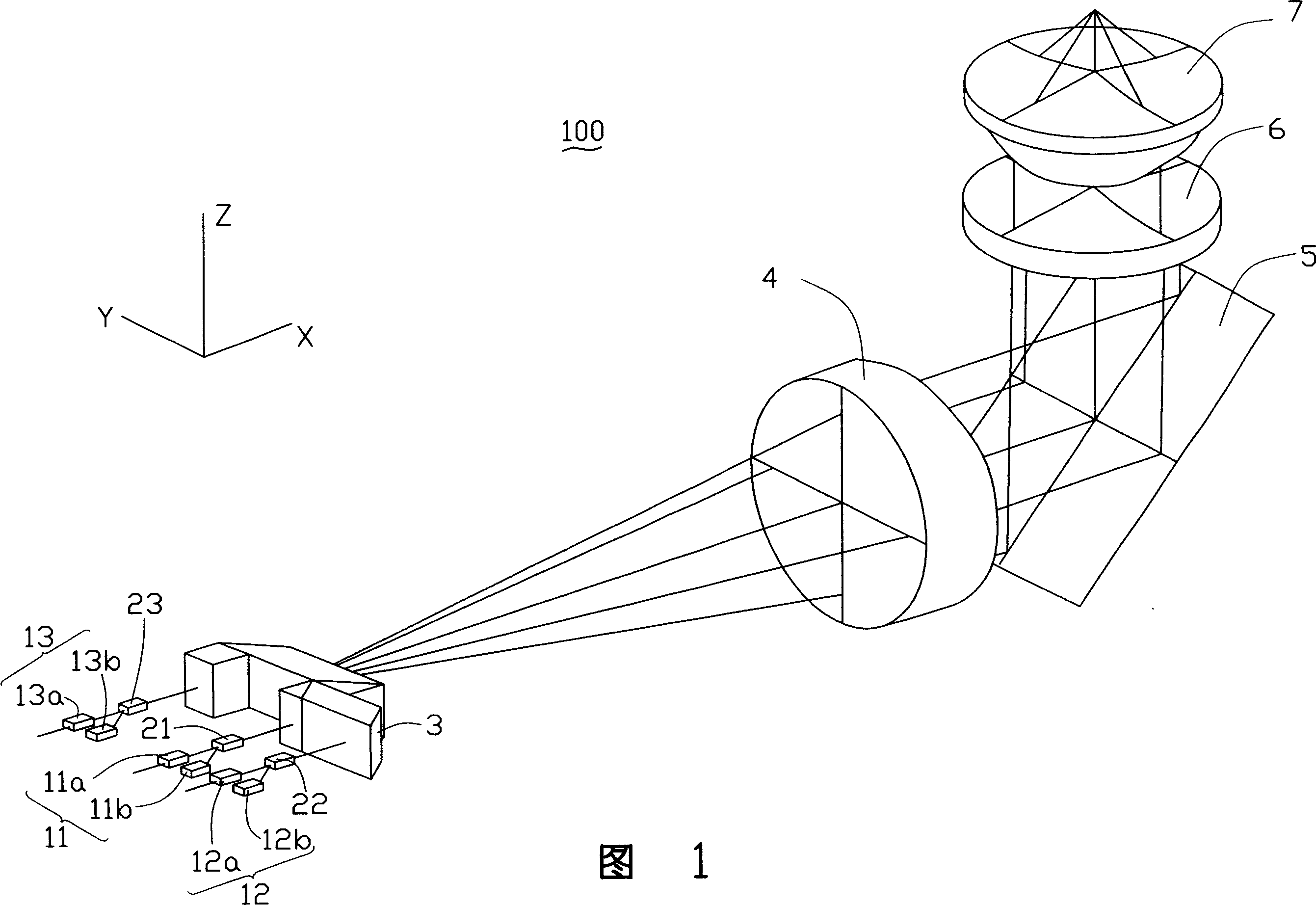

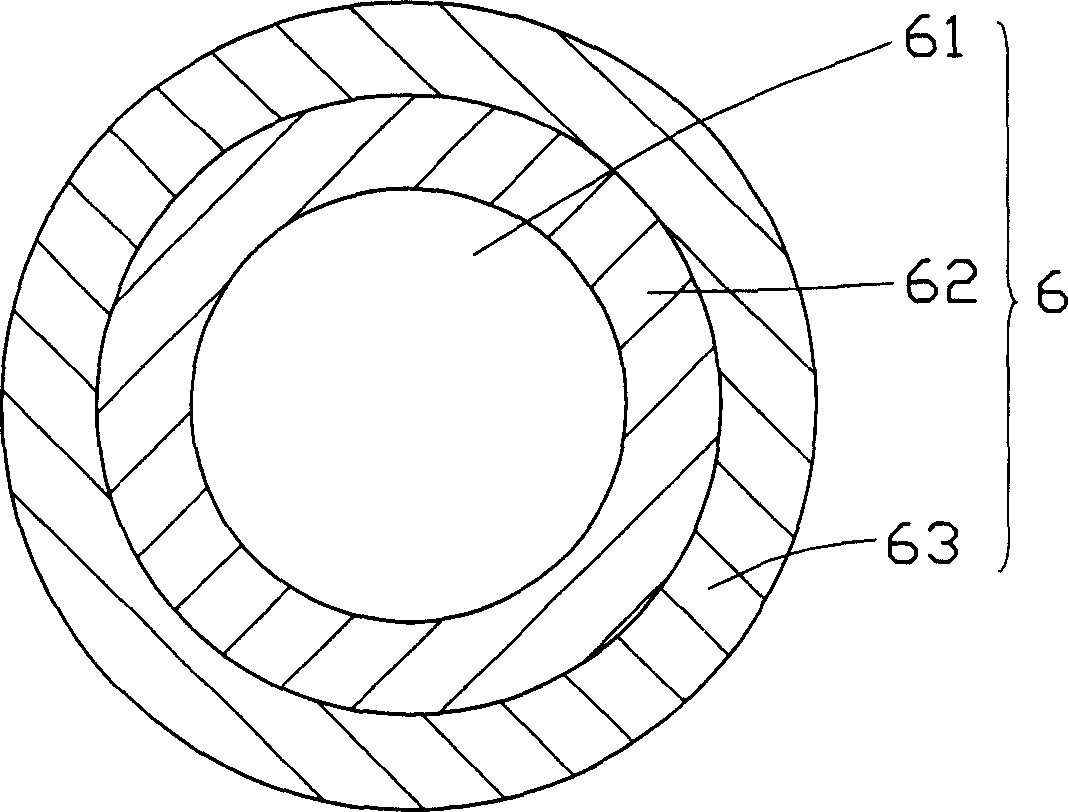

Optical read/write system

InactiveCN1722258AReduce package sizeLow costOptical beam sourcesRecord information storageDisk sizeLight beam

The invention relates to an optical read-write system, which can record / inactivates first, second and third disk size signal. The storage density of the disk size in turn reduces; the optical read-write system comprises a first, second and third light source which can emit first, second and third incident beam of first, second and third wavelength, a prism unit, a collimation lens and an object lens, wherein second wavelength is longer than first wavelength; third wavelength is longer than second wavelength; the prism unit comprises a first incident light side, an aspheric surface structure inputted to second incident light side of third incident beam and an outlet light side of first, second and third incident beam on the same place, wherein first incident light side comprises first and second incident light area which are separately opposed with first and second light transmitting-receiving unit; second incident light area is aspheric surface structure; the collimation lens is on the light path of one outlet light side of prism lens and has the matched optical parameter of first disk size with the object lens.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Method for protecting hard disk last partition

InactiveCN100392593CEasy to modifyHas practical application effectUnauthorized memory use protectionProgram loading/initiatingDisk sizeBIOS

The invention relates to a method for protecting the tail zone of hard disk. Wherein, in the process of starting the computer, first using BIOS to load in one INT13H filter module; then starting the WINDOWS operating system; and loading hard disk filter driving module; with the driving of INT14H module and the hard disk filter driving, the hard disk size feedback to the operating system is equal to the value that actual hard disk reduced by the size of tail zone; the operating system will not actively access the tail zone, but actively stop the read and write operation on the tail zone; the operating system and the application program can not access and modify the tail zone; the hard disk filter driving program can be added into the mounding program when leaving factory and be automatically mounted. The invention also checks the zone list of tail zone before starting the operating system in each computer starts, and automatically builds a main zone lift for the tail zone as TYPE12, with which the new mounted operating system can destroy said zone.

Owner:张健

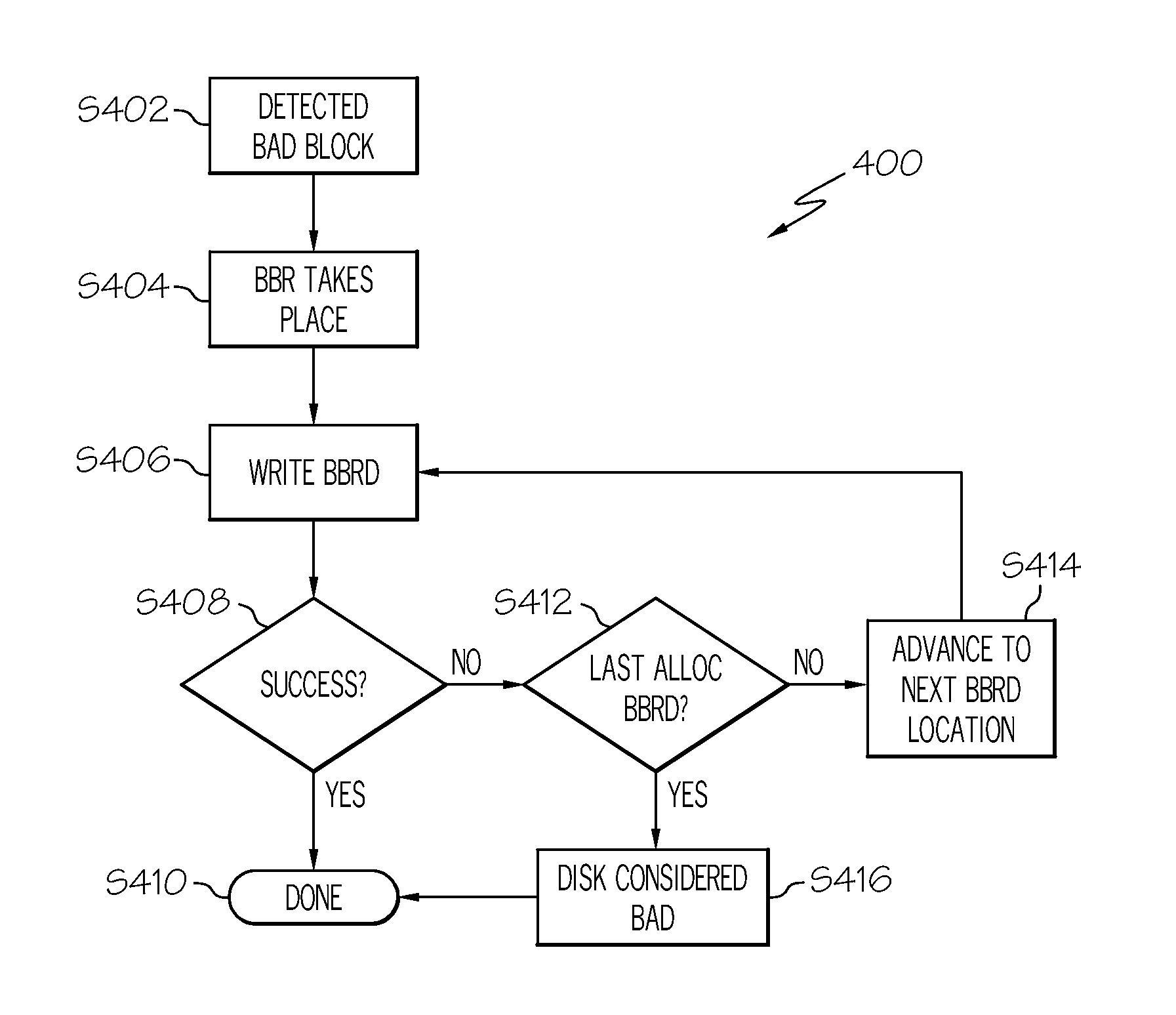

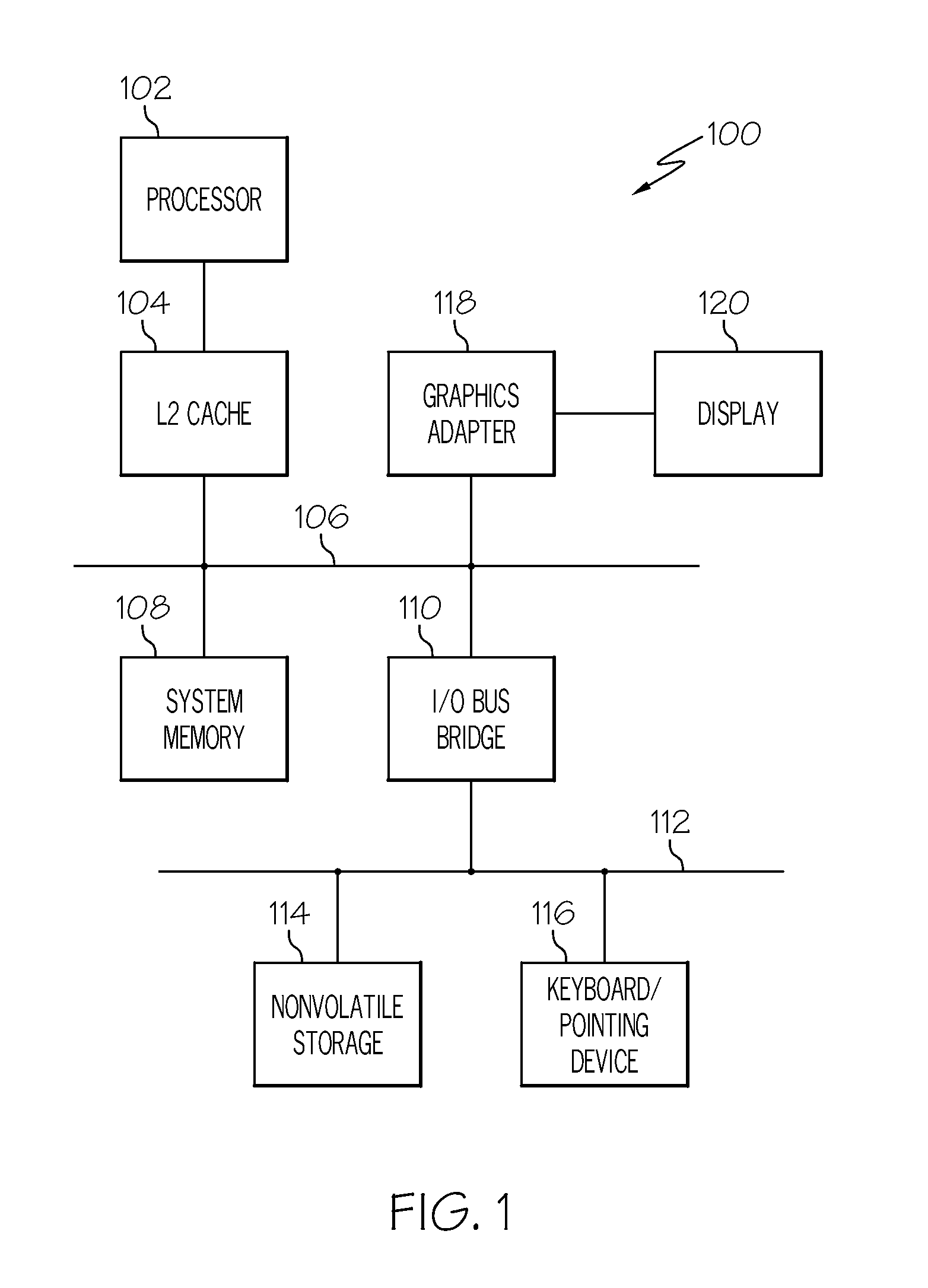

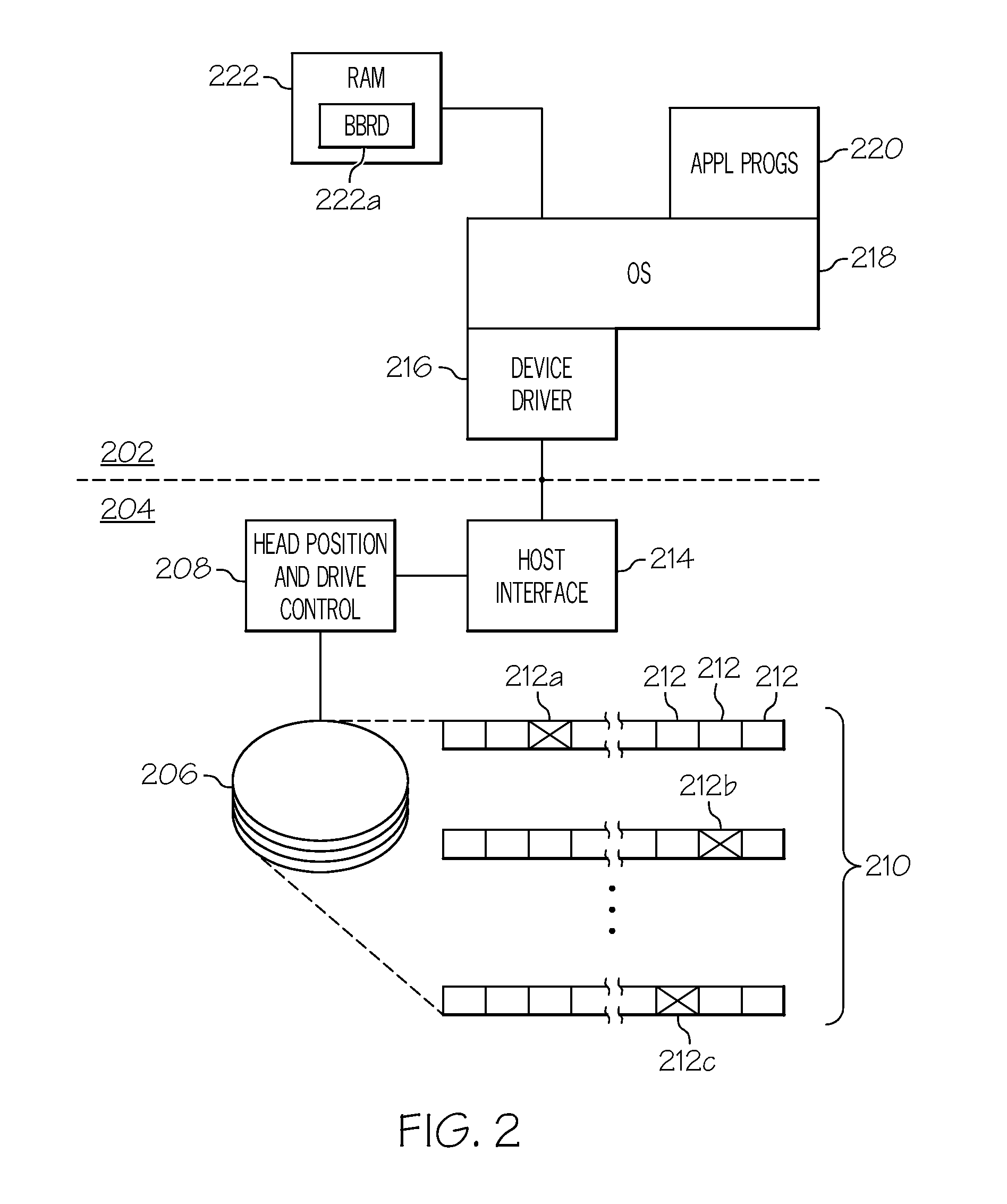

Relocating bad block relocation (BBR) directory upon encountering physical media defect on a disk

Apparatus, method and program product for relocating Bad Block Relocation Directory (BBRD) on a disk storage pre-allocate a number of areas for BBRD in different locations of the disk storage. The locations for the BBRD are calculated based upon the size of the disk and BBRD count. If the update of BBRD fails due to defective media at the location to be updated, that location is abandon and the next pre-allocated location is used. A copy of the BBRD is stored in RAM and maintained by the kernel. By so doing, when a bad block in the BBRD is detected the kernel causes the BBRD to be written in a good one of the locations reserved for BBRD. When the number of alternate BBRD locations used hits a pre-defined threshold, this indicates a situation where many sections of the disk are going bad and the disk needs replacement. If all BBRD locations are used, the disk is presumed bad and all future I / O activities to the disk is suspended. An administrator may be notified that the disk is going bad and needs to be replaced.

Owner:INT BUSINESS MASCH CORP

Appropriate conversion of small-panel storage pools to large-panel storage pools

PendingCN114365076AReduce storage consumptionImprove operational efficiencyInput/output to record carriersComputational scienceDisk size

A computer-implemented method includes identifying a request to translate an existing storage pool having a smaller first chunk size to an expected storage pool having a larger second chunk size. Reels in an existing storage pool are reordered such that boundaries between physical tile disks of a volume and tile disks of an intended storage pool are aligned. Each of the blocks in the existing storage pool is transitioned from the first block disk size to a second block disk size. Thereafter, for each of the volumes: a temporary pause / lock is performed on the VST entry corresponding to the given volume, and an existing structure associated with the VST entry corresponding to the first block disk size is removed. In addition, the VST entry is populated with a new structure corresponding to the second block disk size.

Owner:IBM CORP

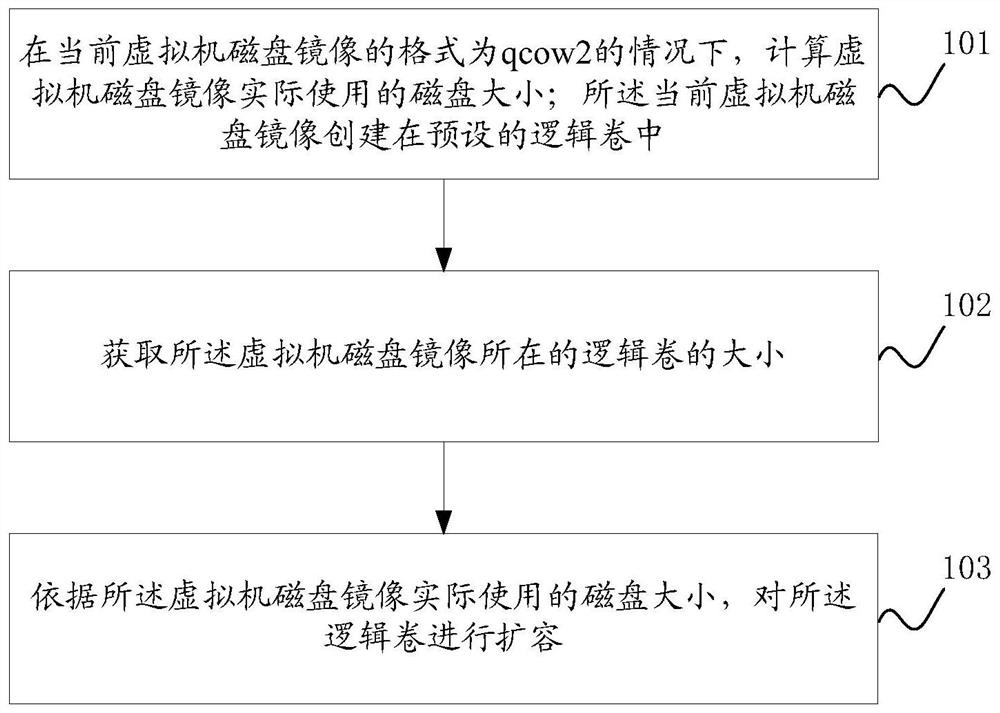

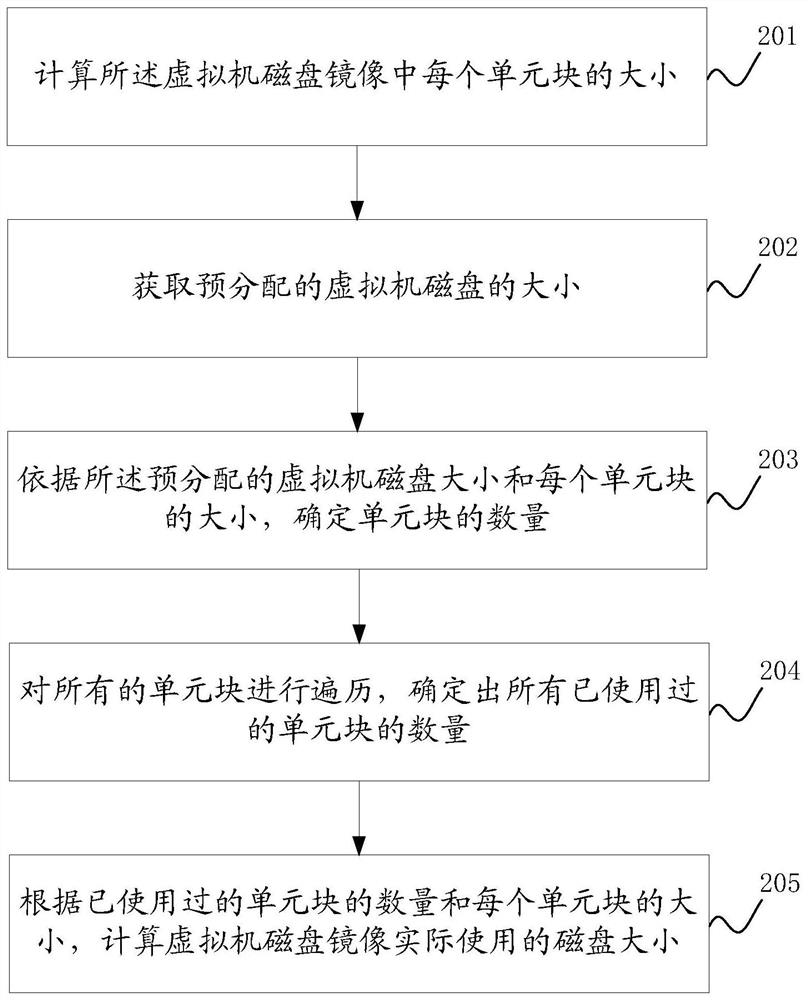

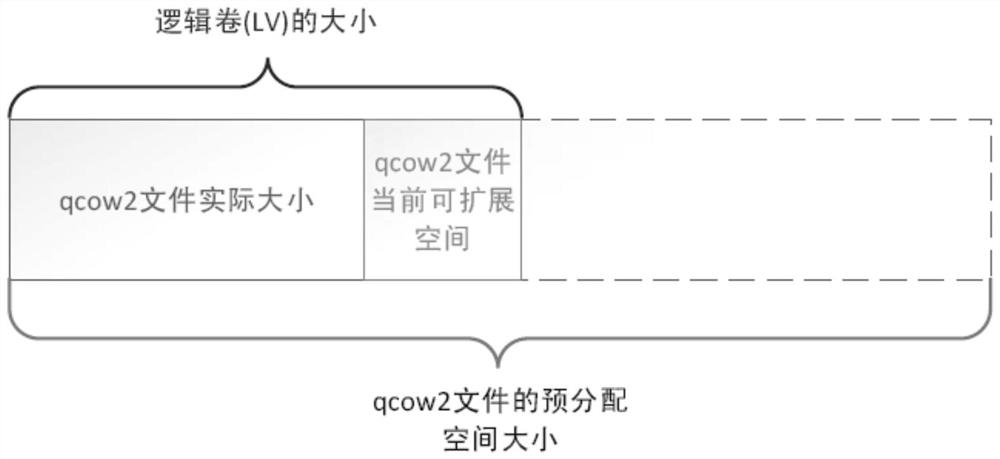

Method and device for thinning virtual machine disk

The invention discloses a method and device for streamlining a virtual machine disk, comprising: creating a virtual machine disk image in a preset logical volume, and calculating the actual volume in the virtual machine disk image when the current virtual machine disk image is qcow2 The size of the used disk; obtaining the size of the logical volume where the virtual machine disk image is located; and expanding the capacity of the logical volume according to the actual size of the disk used by the virtual machine disk image. It can be seen from this that the storage space is expanded according to the actual size of the disk used, thus improving the utilization rate of the disk space.

Owner:SICHUAN ZHONGDIAN AOSTAR INFORMATION TECHNOLOGIES CO LTD +1

Scaled coercion of disk drive capacity

InactiveUS20070208909A1Quantity minimizationSignificant differenceError detection/correctionMemory systemsDisk sizeComputer engineering

The present invention provides disk coercion by generating coercion percentages or values that can be used to coerce various disks according to each disk's particular labeled size or capacity. In one embodiment, a disk size is received and a base coercion scaling factor is provided such that the received disk size is coerced according to the base coercion scaling factor if the labeled disk capacity is below a disk size threshold. The coercion scaling factor increases for labeled disk capacity above the disk threshold. If the labeled disk capacity is above the disk size threshold, then a coercion scaling factor is provided according to the rate of increase of coercion scaling factors and the labeled disk capacity.

Owner:AVAGO TECH WIRELESS IP SINGAPORE PTE +1

Hard disk size self-adaptive auxiliary equipment for artificial intelligence software development recording

InactiveCN113421596AAchieve adjustable fixationProtection from damageReconditioning/cleaning record carriersRecord information storageDisk sizeProtection mechanism

The invention relates to the technical field of artificial intelligence software development, and discloses hard disk size self-adaptive auxiliary equipment for artificial intelligence software development recording, the equipment comprises a fastening mechanism, a protective shell is movably connected to the outside of the fastening mechanism, and a mounting base is movably connected to one end, away from the protective shell, of the fastening mechanism. A connecting groove is movably connected to the interior of the mounting base, protection mechanisms are movably connected to the upper side and the lower side of the fastening mechanism correspondingly, and the sides, away from the fastening mechanism, of the protection mechanisms are movably connected with a maintenance mechanism. The connecting frame is driven to rotate by manual rotation of the manual runner, and the connecting frame rotates to drive the rotation screw, the pressing frame is driven to slide, then the pressing walls are driven to move, the two pressing walls move oppositely, the clamping range can be adjusted according to the hard disks of different sizes, and when the hard disks are recorded, the effects of adjustably fixing the hard disks and protecting the hard disks from being damaged in multiple directions are achieved.

Owner:杭州星舞科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com