Hydraulic control system for hydraulic boarding ladder

A technology of hydraulic control system and boarding ladder, which is applied to ship accessories, fluid pressure actuating devices, ships, etc., can solve the problems of insufficient compact structure, low degree of automation of the boarding ladder, and inability to adapt to the movement of the hull. Stable and reliable, improve the effect of security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

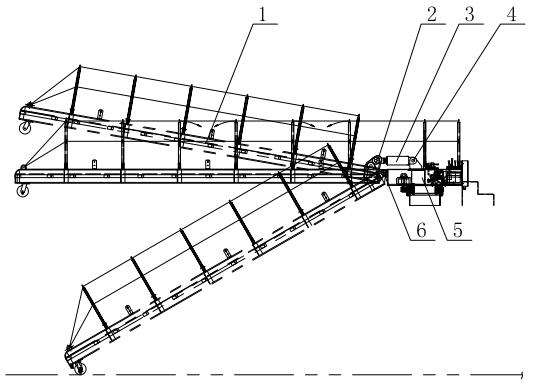

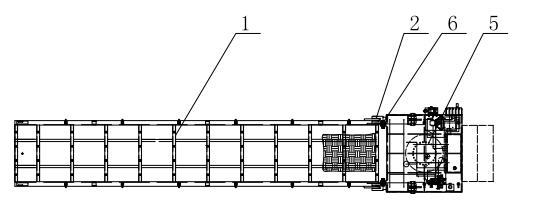

[0017] Such as figure 1 , figure 2 As shown, the ladder 1 of the hydraulic boarding ladder is connected to the slewing base 5 through the rotation axis 5, and can rotate around the rotation axis 6; at the same time, it is connected with the piston 2 of the lifting hydraulic cylinder 3 at the connecting part, and the lifting hydraulic cylinder 3 The pivot 4 is rotatably connected to the top surface of the slewing base 5; the telescopic action of the lifting hydraulic cylinder 3 can realize the rising and falling swing of the ladder 1.

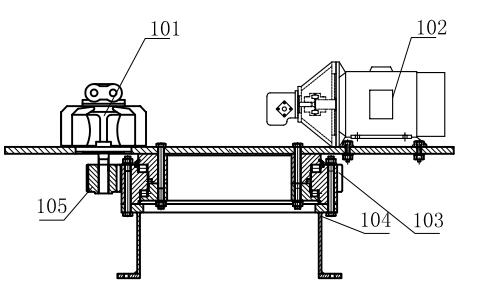

[0018] Such as image 3 , Figure 4 As shown, an oil tank 102 and a pump station are arranged in the rotary base 5, and the rotary gear 103 is fixed on the base frame 104. The output shafts of the two hydraulic motors 101 are provided with a pinion 105, and the pinion 105 is meshed with the rotary gear 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com