Supporting bracket of interlayer box body of lining plate mounting bearing seat of vertical type mill

A technology for vertical mills and bearing housings, applied in grain processing, etc., can solve the problems of difficult adjustment of bearing center, fast bearing wear, inconvenient maintenance, etc., and achieve the effect of convenient installation and maintenance, low manufacturing cost, and simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

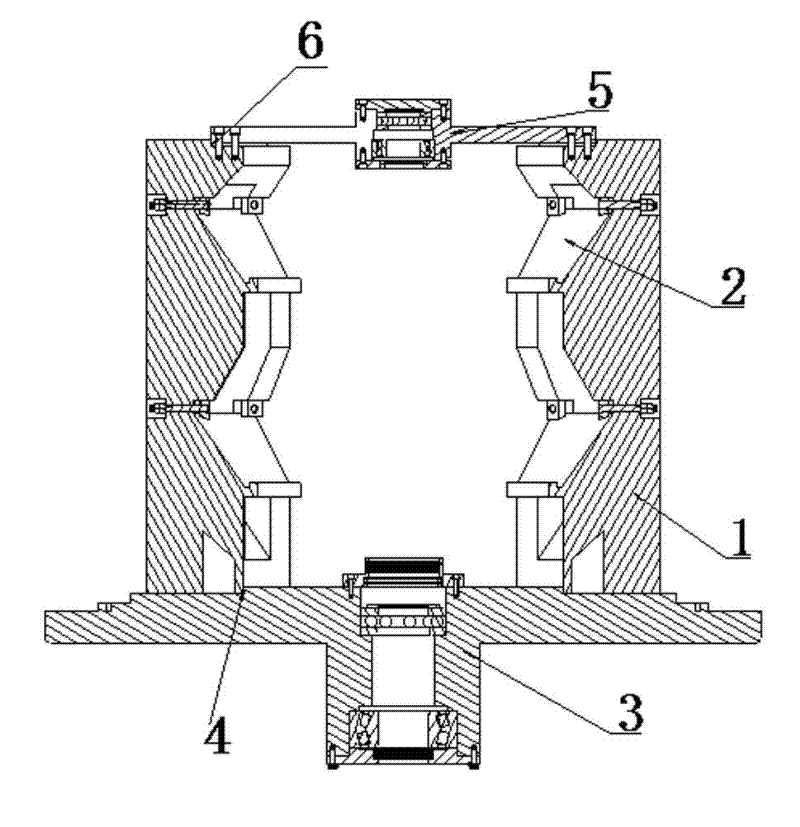

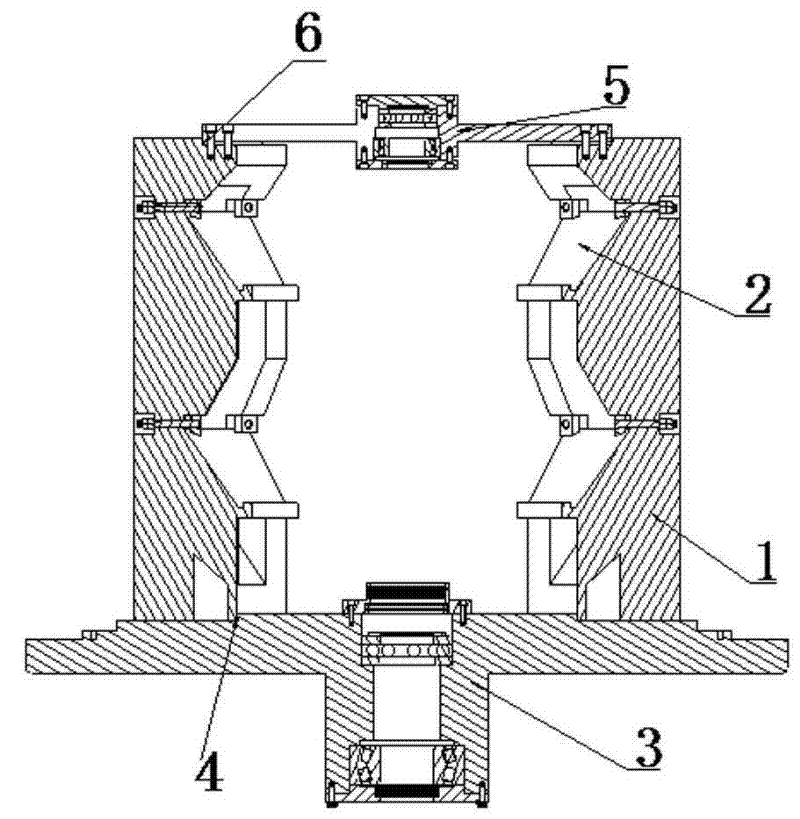

[0007] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0008] refer to figure 1 , the present embodiment includes a sub-block interlayer box body 1, and the inside of the sub-block interlayer box body 1 is provided with a liner mounting bracket 2, and the interlayer refers to an interlayer that communicates with the fine powder outlet, coarse powder outlet, and air inlet that are separated from each other. Space; the bottom end of the sub-block interlayer box 1 is placed on the positioning notch 4 on the upper end surface of the lower bearing seat 3, and the top of the sub-block interlayer box is provided with a positioning notch 6, through which the positioning notch 6 and the bottom surface of the upper bearing seat 5 Inset fixation.

[0009] The present invention can ensure that the upper bearing seat 5 and the lower bearing seat 3 of the main shaft of the mill are coaxial; because the bottom end and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com