Regenerated tail gas purification combined tower

A technology of exhaust gas purification and combined tower, which is applied in the direction of air quality improvement, chemical instruments and methods, and separation of dispersed particles, which can solve the problems of increasing the burden of the air blower of the regeneration tower, large equipment investment, and unfavorable production, so as to reduce energy consumption , stable and reliable operation, and the effect of saving floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

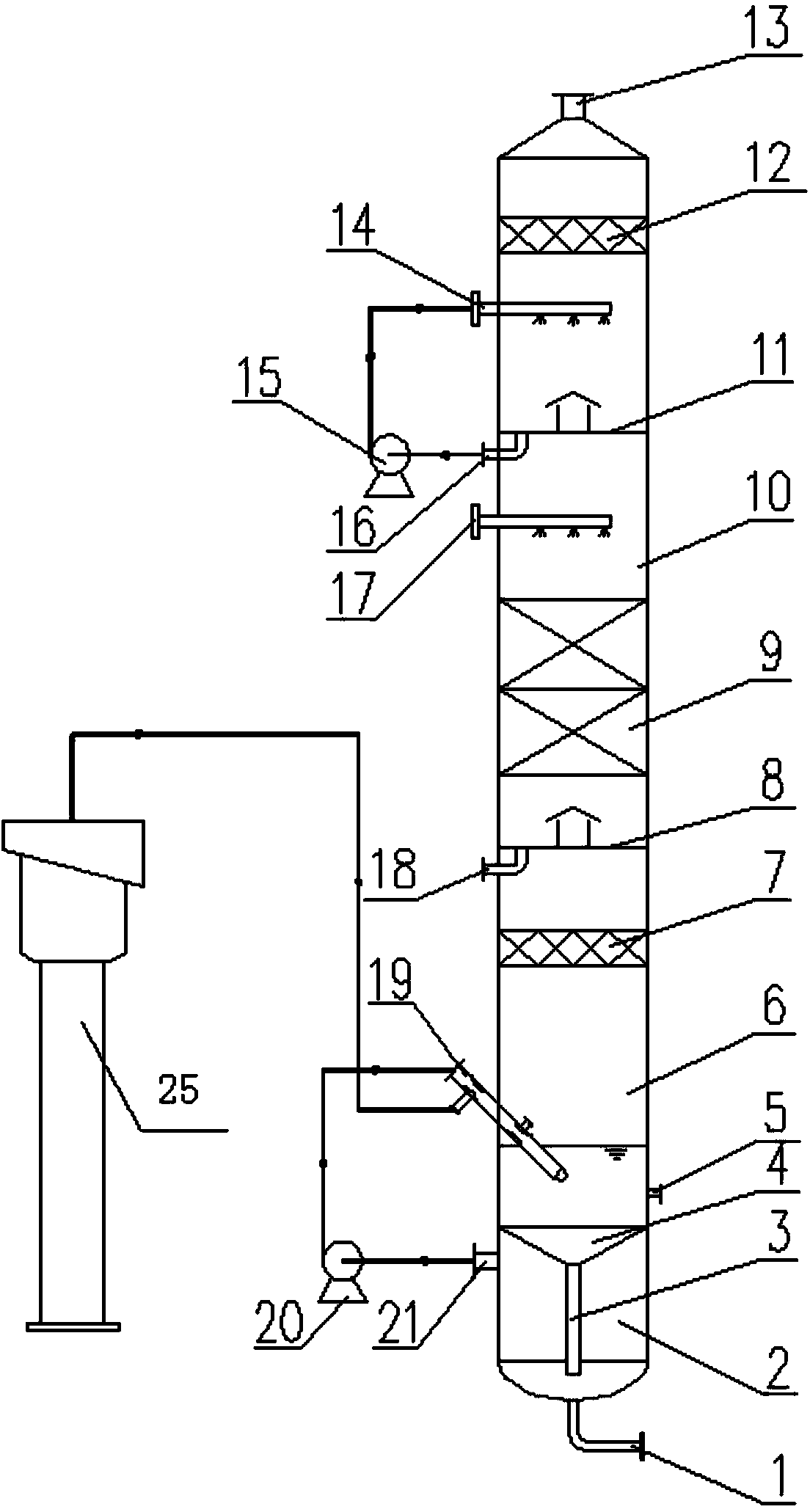

[0016] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

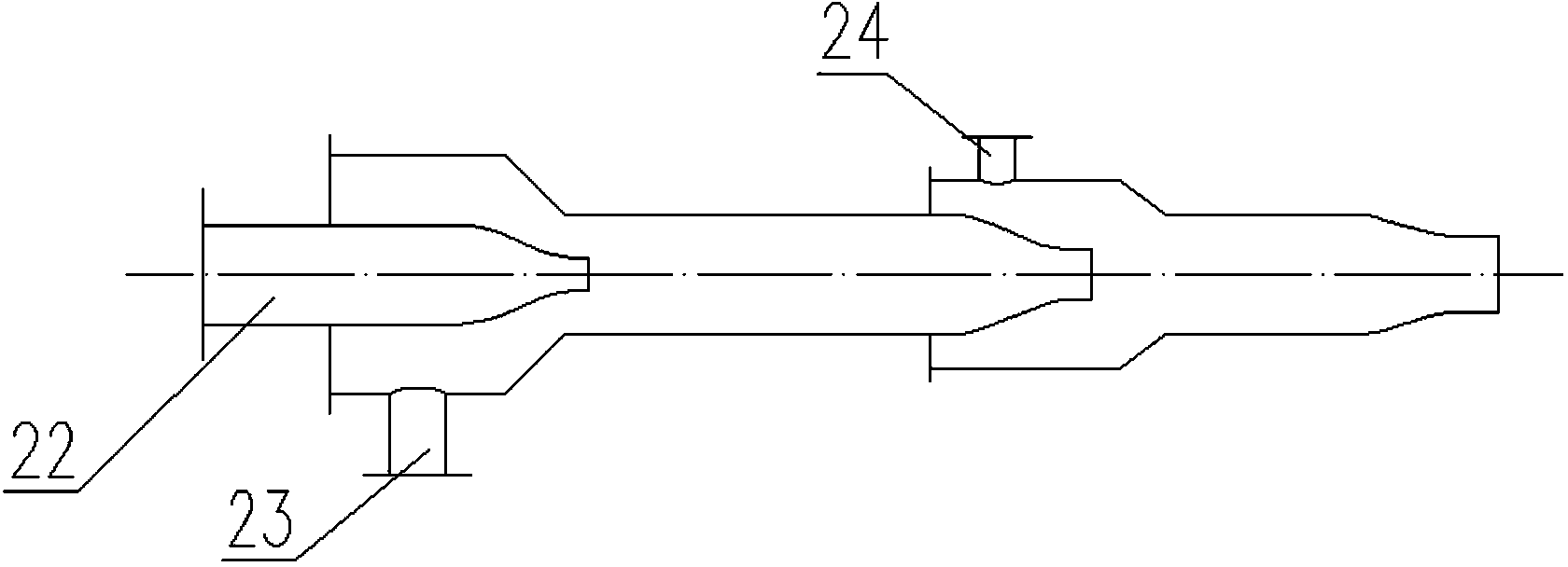

[0017] Such as figure 1 As shown, a combined regeneration tail gas purification tower is composed of a regeneration tower tail gas removal acid gas device 25 and a vertical tower, and the vertical tower is connected with the regeneration tower tail gas removal acid gas device 25 through a secondary ejector 19, The vertical tower is divided into a crystallization section 2, a deamination section 6, and an acid gas removal section 10. The acid gas removal section 10 is arranged on the upper part of the deamination section 6 and is connected with the deamination section 6 through a liquid breaker 8, and the crystallization section 2 is arranged in The lower part of the deamination section 6, the deamination section 6 is connected with the crystallization section 2 through the conical head 4;

[0018] The crystallization section 2 includes a crystallizati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com