Automatic feeder of integrated matching electric measurement machine equipment

An automatic feeding and integrated technology, applied in the direction of electrical components, electrical components, etc., can solve the problems of high labor intensity, missing test, false test, increase of unqualified products, and affecting the production of the whole line, so as to achieve stable and reliable operation and reduce labor costs. The effect of simple and reasonable quantity and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

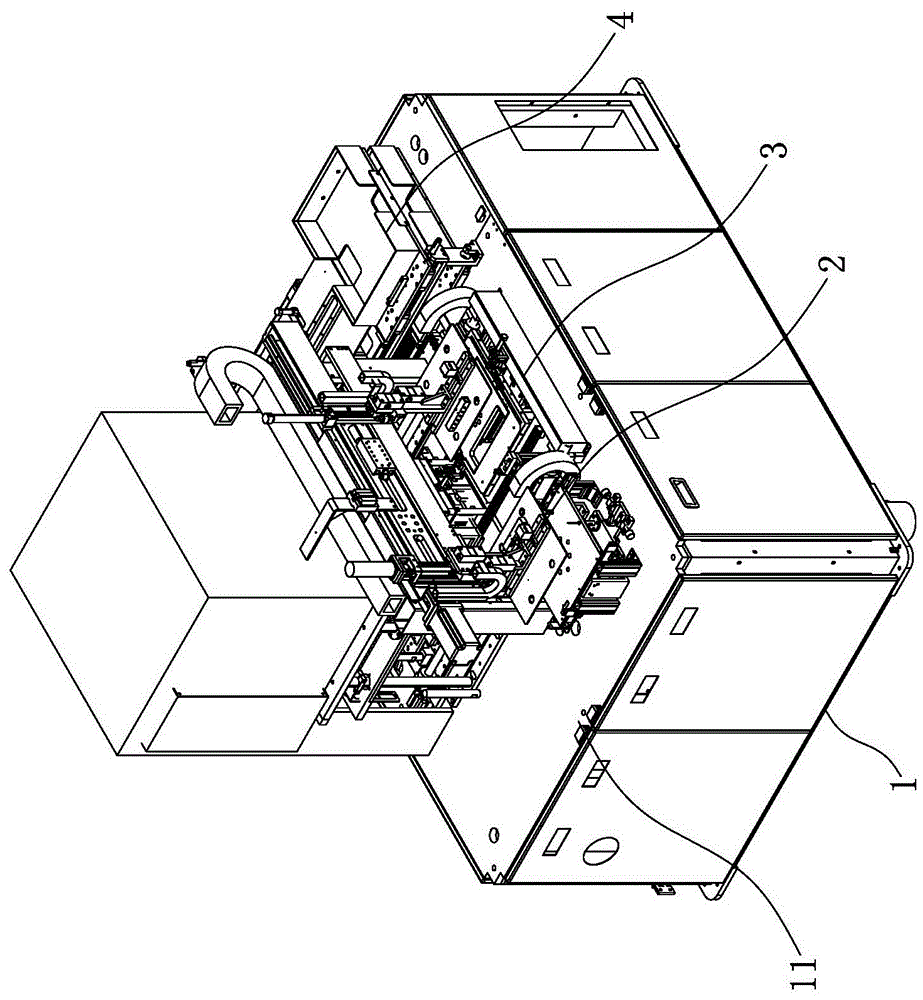

[0036] like figure 1 As shown, the present invention is an automatic feeder integrated with electrical testing equipment, including a frame 1, a loading and unloading mechanism 2, a feeding and conveying mechanism 3, a blanking mechanism 4, and a marking mechanism 5.

[0037] The described loading and unloading and conveying mechanism 2 , the feeding and conveying mechanism 3 , the unloading mechanism 4 and the marking mechanism 5 are all installed on the working platform 11 of the frame 1 .

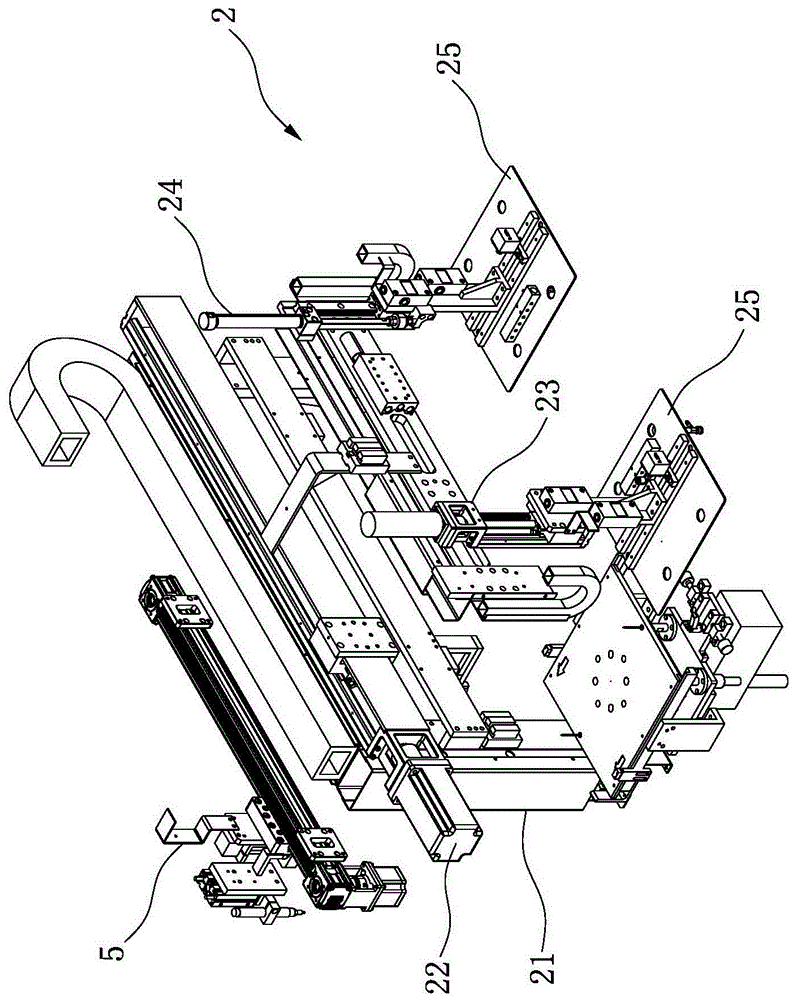

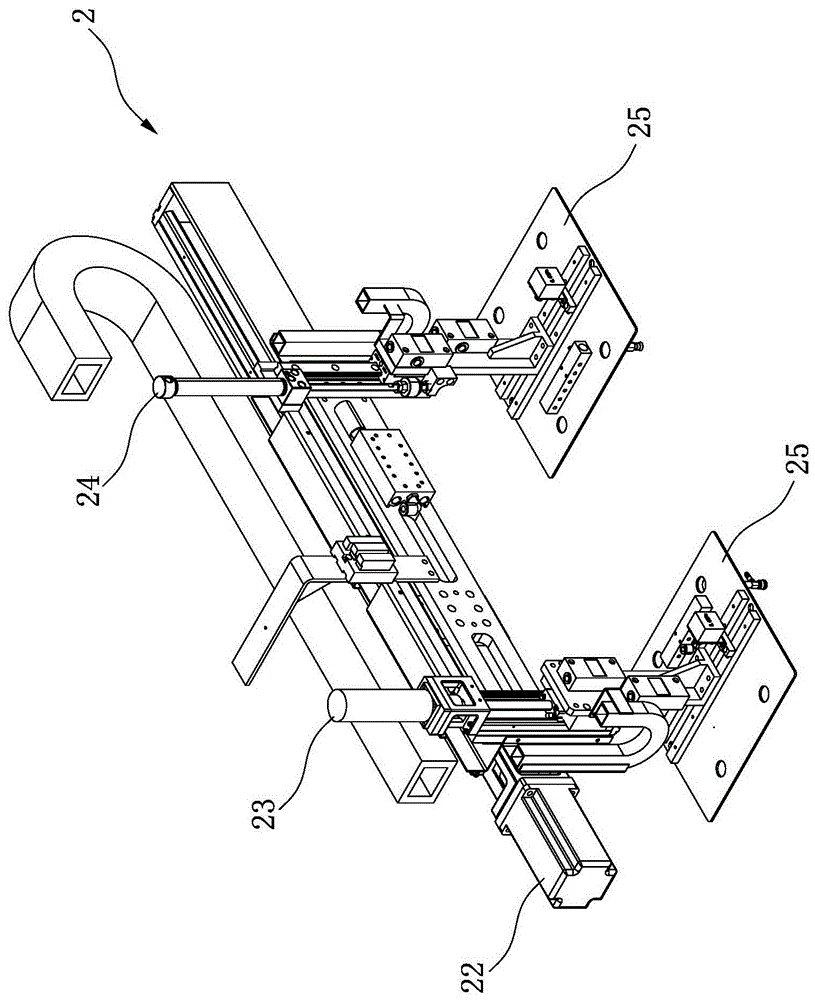

[0038] like Figure 2-Figure 5 As shown, the loading and unloading mechanism 2 includes a small gantry frame 21, an X-axis mechanism 22, a Z1-axis mechanism 23, a Z2-axis mechanism 24, and two sets of vacuum suction and placement mechanisms 25.

[0039] The X-axis mechanism 22 is mounted on the working platform 11 of the frame 1 through the small gantry 21, and the upper part of the Z1-axis mechanism 23 and the Z2-axis mechanism 24 is installed on the slide block of the X-axis mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com