Full automatic soil saturation device

A fully automatic, soil technology, applied in the field of soil saturator, can solve the problems of difficult to guarantee the accuracy of soil sample preparation, complicated operation process, low operation efficiency, etc., and achieve the effect of stable and reliable operation, high preparation precision and low labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

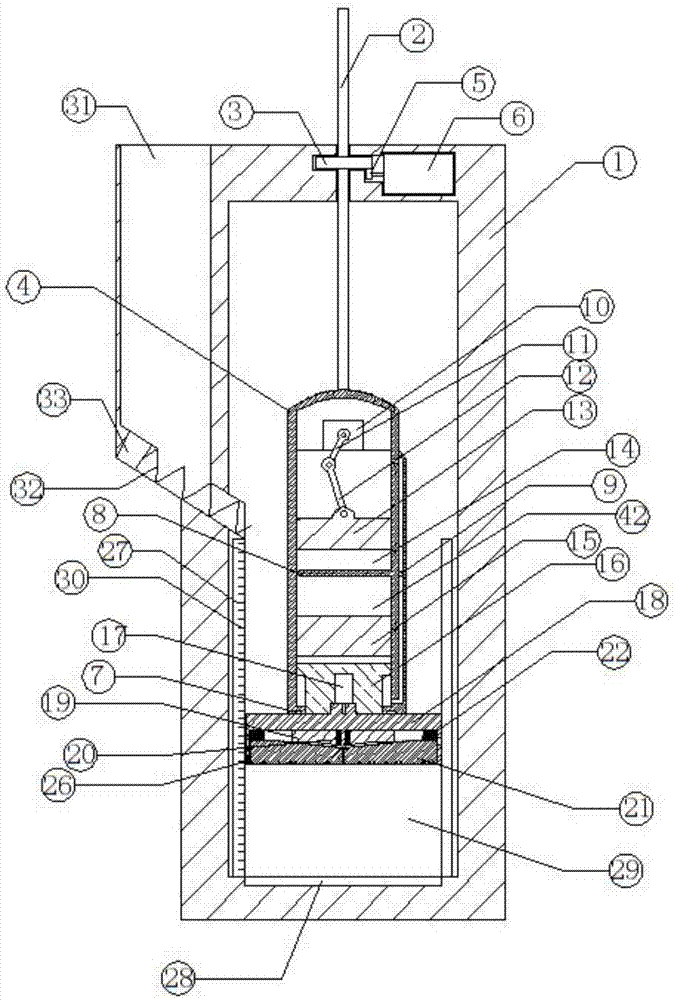

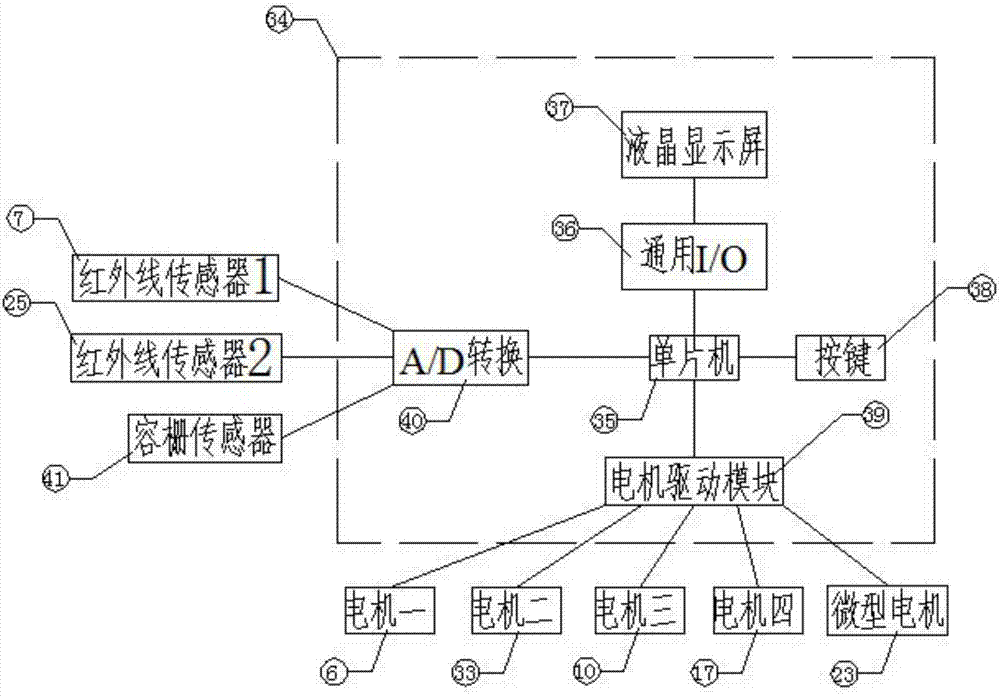

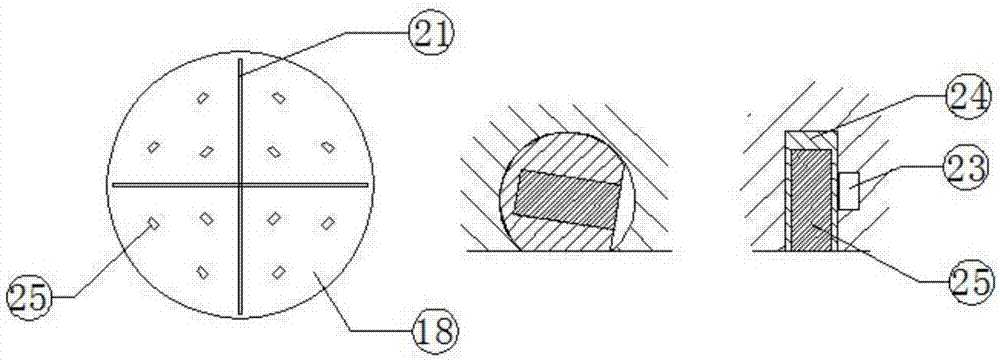

[0011] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A full-automatic soil saturator, in which a screw rod 2, a transmission wheel 3 and a cylinder housing 4 are sequentially installed on the top of the chamber of the device housing 1 from top to bottom, wherein the cylinder housing 4 and the screw rod 2 are fixed, and the The driving wheel 3 is meshed with the driving wheel 5, and the driving wheel 5 is solidified with the motor I6, and the cylinder housing 4 can be moved up and down through the screw thread on the screw rod 2 and the internal thread of the driving wheel 3, and the bottom of the cylinder housing is equipped with The infrared sensor I7 is equipped with a rotary valve I8 and a rotary valve II9 in the cylinder housing, and a motor III10, a connecting rod I11, a connecting rod II12 and a piston 13 are sequentially installed in the cylinder housing 4 from top to bottom, and the motor III10 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com