Intermittent Automatic Tray Lifting Machine for Greenhouse Seedling Trays with Mesh

An intermittent seedling tray technology, which is applied in the field of seedling raising machines in greenhouses, can solve the problems of many failures, poor starting quality, and low degree of automation, and achieve less operation failures, good starting quality, and low operating labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

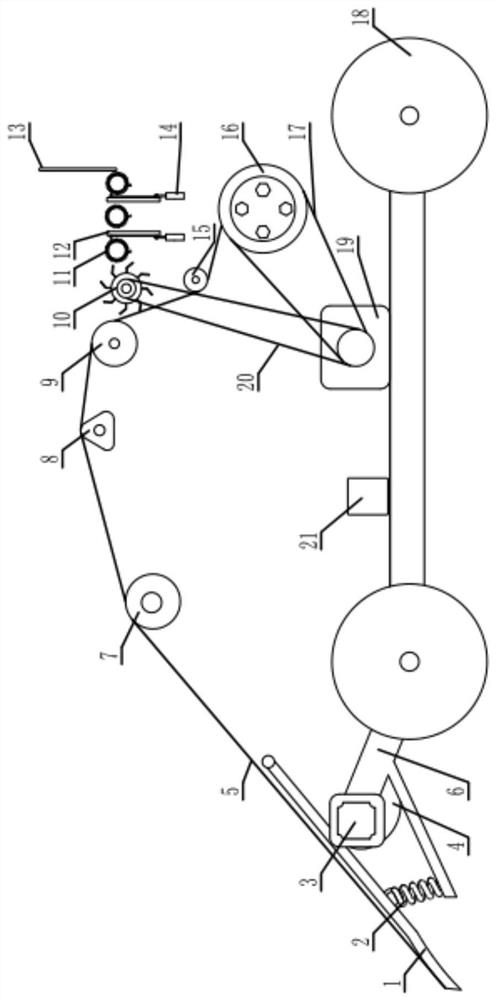

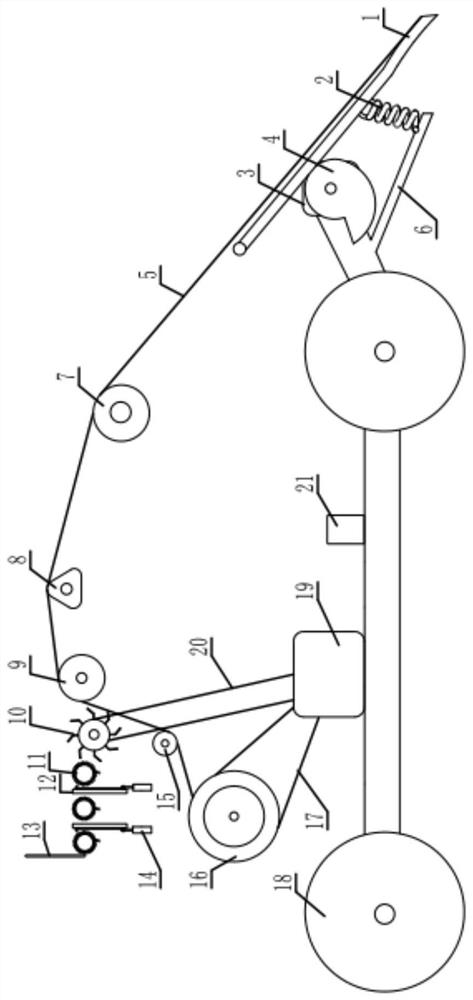

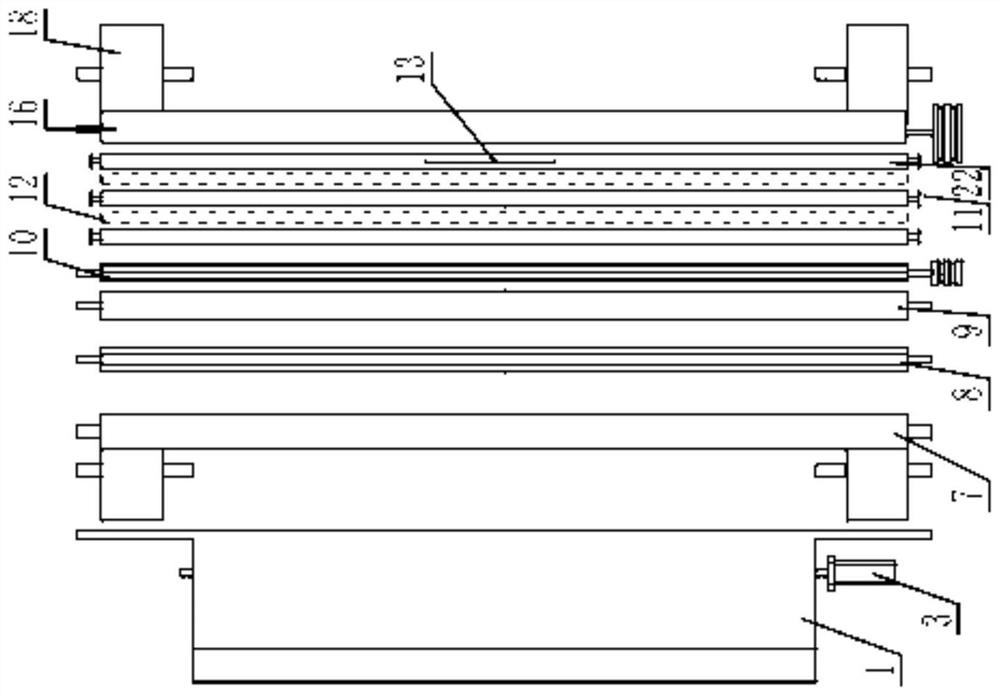

[0013] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. An intermittent automatic lifting machine for seedling trays in a mesh-distributing greenhouse. Walking wheels 18 are rotatably installed on the front, rear left, and right sides of the frame assembly 6, respectively. The automatic controller assembly 21 and the motor 19 are equipped with Installed on the frame assembly 6, a stepping motor 3 is fixed on the front end of the frame assembly 6, a snail cam 4 is fixed on the motor shaft of the stepping motor 3, and a On the front end of the assembly 6, at the upper part of the snail cam 4, there is a vibrating plate 1 that can swing up and down. The vibrating plate 1 is connected to the frame assembly 6, and on the upper side of the frame assembly 6, located at the rear side of the vibrating plate 1, the mesh belt support rollers 7, 7, Prismatic vibrating loosening roller 8, separation roller 9, finger-claw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com