Material self-cleaning and recovery device of grain tubular dryer

A dryer and tube-type technology, which is applied in grain drying, drying solid materials, drying, etc., can solve the problems of falling outside the tube dryer, easy damage of seed materials, and long feeding time , to achieve good self-cleaning recovery effect, avoid grains from being broken, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

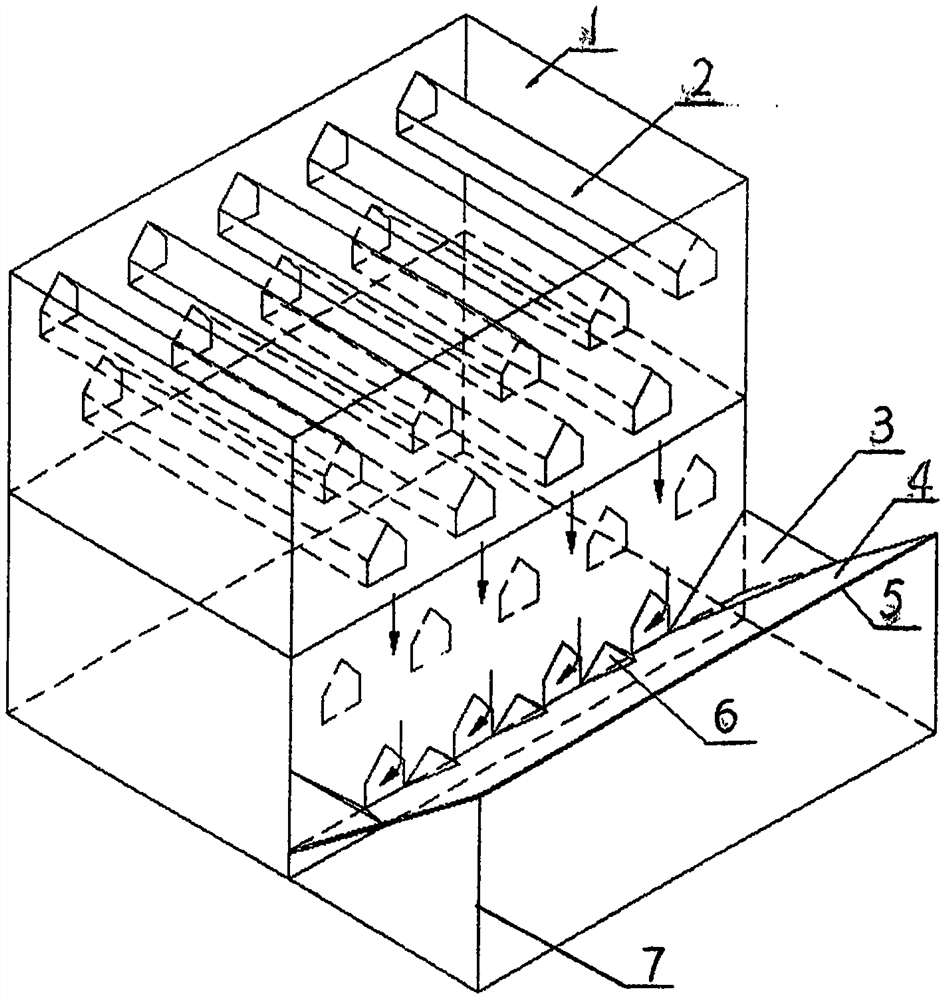

[0012] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A material self-cleaning and recovery device for a grain tube dryer, comprising a grain tube dryer 1 with multi-layer angular tubes 2 arranged crosswise from top to bottom, and a side wall plate of the grain tube dryer 1 Outside, the angled tube 2 that is located at the bottom of the outer part of one end of the nozzle is equipped with a tilting frame 7, and the self-cleaning recovery plate 5 is installed on the upper inclined position of the tilting frame 7, and the inner lower end of the self-cleaning recovery plate 5 Located below the port of the angular tube 2 at the bottom, triangular cone-shaped partitions are respectively installed on the two side ends of the self-cleaning recovery plate 5 and between the side wall plates of the grain tube dryer 1 for recovery. The plate 3 is equipped with a triangular cone on the part between the middle part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com