Air-suction indent type roller seed-metering device capable of automatically clearing seeds, preventing blocking and adjusting seeding rate

An air-suction pocket type and suction pocket-type technology, which is applied in the field of air-suction seed metering devices, can solve problems such as non-adjustable and changeable, difficult to remove, narrow application range, etc., and achieve a high degree of generalization and anti-blocking effect Good, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

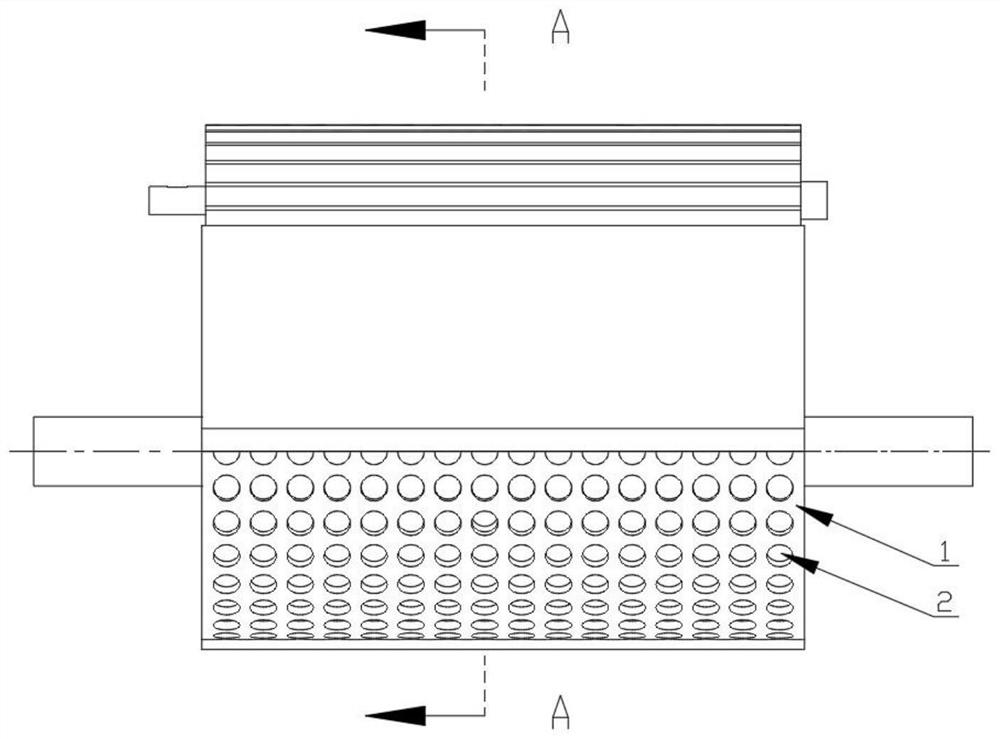

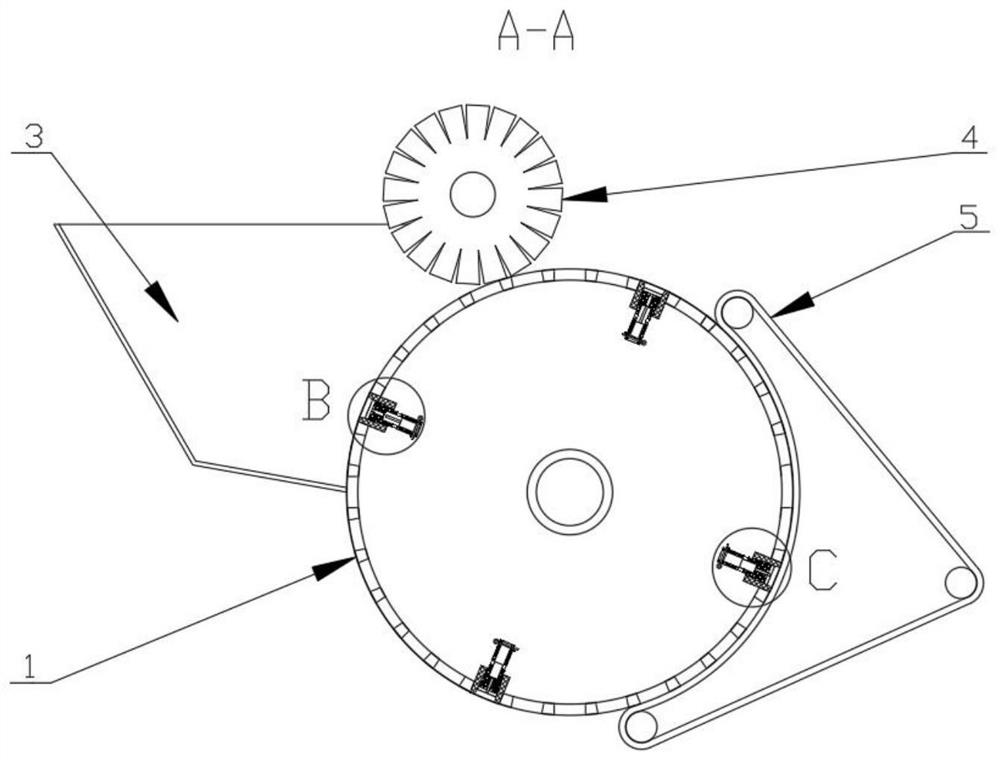

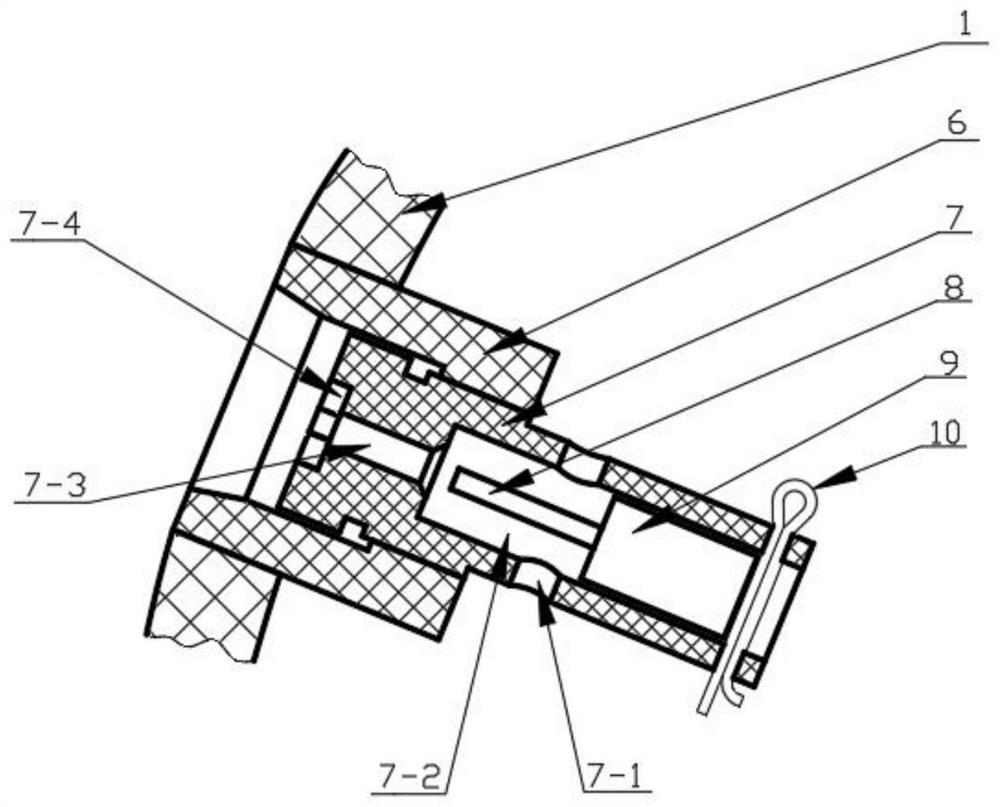

[0012] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. An air-suction socket-type roller seed metering device with automatic seed cleaning, anti-blocking and adjustable seeding rate, including an air-suction socket-type roller 1, and a plurality of sockets radially opened on the wall of the air-suction socket-type roller 1 Hole 2, on the upper part of the outer side of the cylinder wall of the air-suction socket-type cylinder 1, arrange and install the seed box 3, the cleaning brush 4 and the seed protection belt 5 in the clockwise direction of the circumference, in the socket hole 2 A cylindrical seed filling cup 6 is fixed inside, and the cylindrical seed filling cup 6 communicates with the seed box 3, and the suction nozzle body 7 is installed axially movable through threaded connection in the cup hole of the cylindrical seed filling cup 6, A suction hole 7-3 and a hollow cavity 7-2 are successively provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com