Small folding suction roller device for handkerchief paper folding machine

A folding machine and handkerchief paper technology, which is applied in packaging, papermaking, transportation and packaging, etc., can solve the problems of poor paper horizontal folding effect and easy flying paper, and achieve the goal of improving production efficiency, no radial runout, and ensuring folding effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

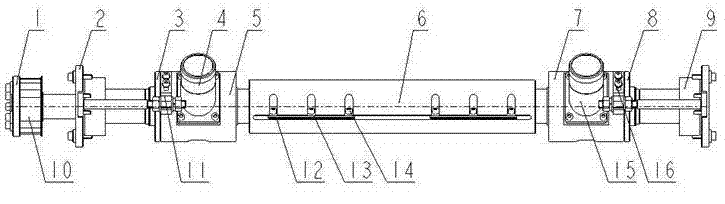

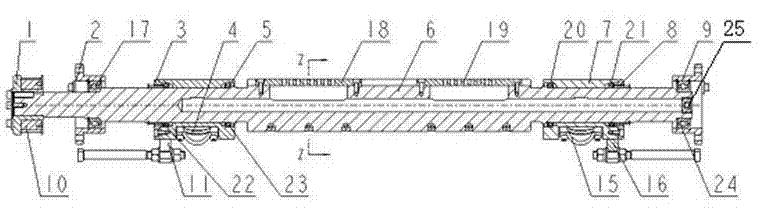

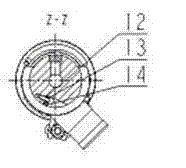

[0011] Below in conjunction with accompanying drawing, describe in detail as follows:

[0012] exist figure 1 , figure 2 and image 3 Among them, the small folding suction roller device of this handkerchief paper folding machine includes a suction roller 6, one end of the suction roller 6 is fixed with a cover plate 1 and a pulley 10, and the rest of the suction roller 6 has a symmetrical structure, and the suction roller 6 passes through the method at both ends. The flange 2 and the flange 9 are connected with the folder body, and the flange 2 and the flange 9 are connected with the suction roller 6 through the bearing 17 and the bearing 24; the pipe joint 4 and the pipe joint 15 are respectively connected with the gas distribution sleeve 5 and the matching The air sleeve 7 is connected; there are two radial square holes at both ends of the suction roller 6, which communicate with the air distribution sleeve 5 and the air distribution sleeve 7 at both ends respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com