Flag hoisting and lowering mechanism of flag pole

A flagpole and drive mechanism technology, applied in the field of flagpoles, can solve problems affecting the effect of flag flying, twisted or entangled coils, delays in the flag-raising process, etc., to achieve the effects of increased decoration, stable and reliable operation, and a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following examples are further supplements and illustrations of the present invention, and do not constitute any limitation to the present invention.

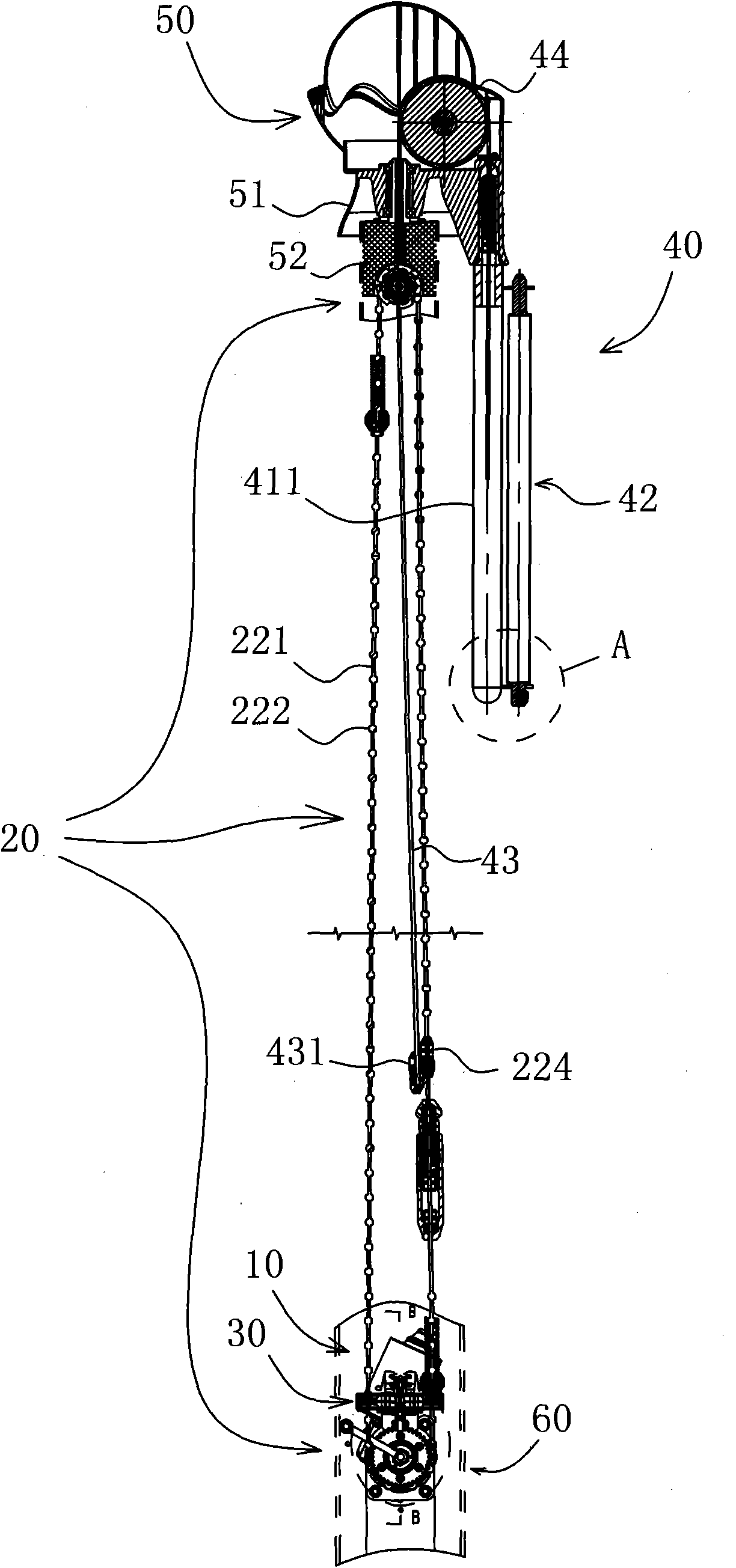

[0026] refer to figure 1 , The lifting flag mechanism of the flagpole of the present invention includes a driving mechanism 10 , a transmission mechanism 20 , a lifting flag positioning mechanism 30 , a flag hanging assembly 40 , a spherical crown assembly 50 and a flagpole 60 .

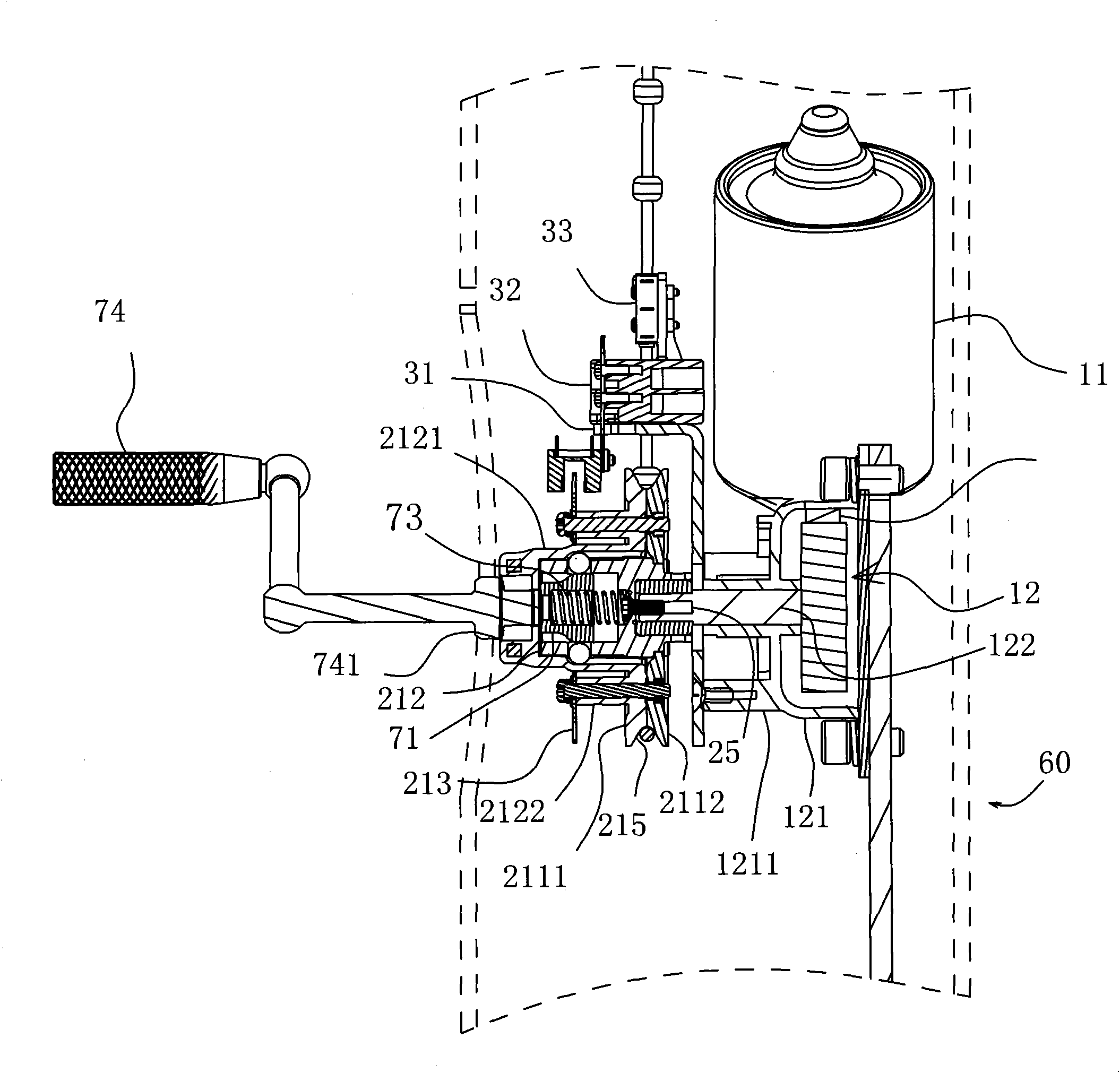

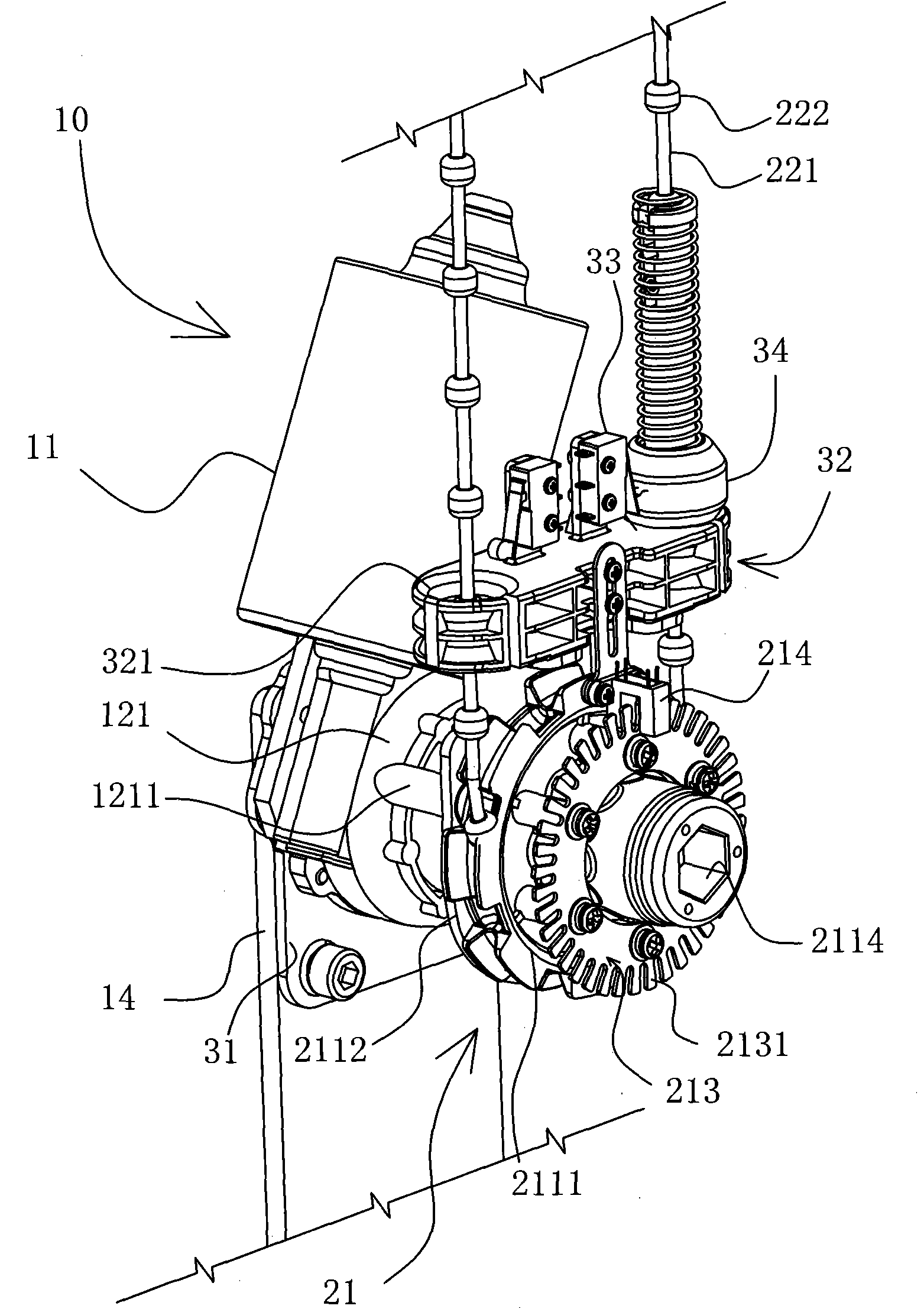

[0027] Described drive mechanism 10 structures such as Figure 2A ~ Figure 2C As shown, the driving mechanism 10 is mounted on the inner bottom of the flagpole 60 , which includes a motor 11 , a worm gear 12 and a worm 13 , wherein the motor 11 is a columnar reversible motor, which is arranged along the axial direction of the flagpole 60 . The worm 13 is integrated with the motor shaft and meshes with the worm gear 12. The motor 11, the worm gear 12 and the worm 13 are selected from a commercially available integrated worm gear reduction m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com