Down-hole slurry generator

A generator and mud technology, applied in the direction of engine components, machines/engines, electrical components, etc., can solve the problems of short product life, easy leakage, poor sealing, etc., and achieve the effect of long product life, reliable and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

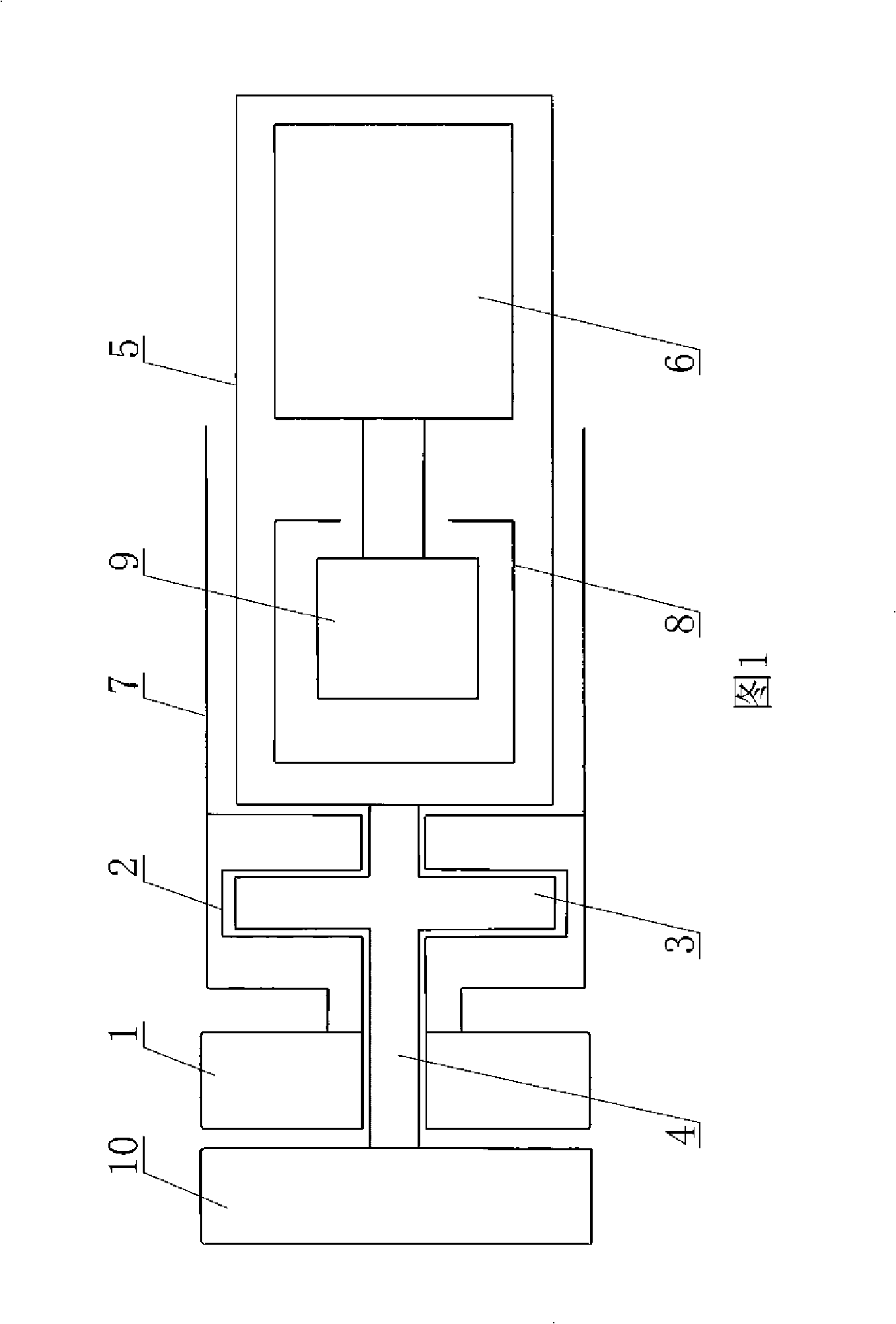

[0018] The embodiment is shown in Figure 1. In this downhole mud generator, the power is transmitted by a magnetic coupling between the turbine 1 driven by the mud and the generator body 6. The turbine 1 is connected to the magnetic coupling through a buffer clamping wall sleeve 2 The outer magnetic rotor 7 is connected, and the middle section of the inner wall of the buffer clamping wall sleeve 2 has an annular groove sunken toward the outer wall. The buffer plug 3 is accommodated in the annular groove, and there is a buffer gap between the buffer plug 3 and the buffer clamping wall sleeve 2. Either one of the buffer plug 3 and the buffer clamp wall cover 2 is a permanent magnet or an electromagnet. The center of the buffer plug 3 is connected to the stator plug rod 4 to both ends, one end of the stator plug rod 4 is connected to the generator sealing cover 5, and the other end passes through the center of the turbine 1 and is connected to the support body 10, and the connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com