Integrated hydraulic oil testing system

A technology of comprehensive testing and hydraulic oil, applied in the field of testing, can solve the problems of increased internal leakage, economic losses, and reduced system response speed, so as to reduce failures and improve production life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

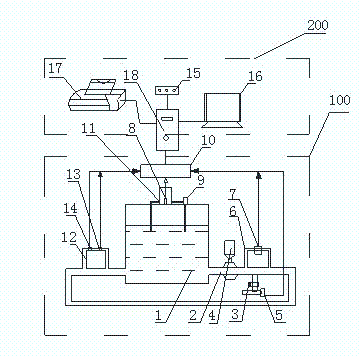

[0014] The present invention will be further described below in conjunction with accompanying drawing:

[0015] Such as figure 1 As shown, the present invention includes a data acquisition device 100 and a monitoring device 200, and the data acquisition device 100 includes a sampling oil tank 1, an oil delivery pump 4, a turbidity detector 7, an oil pressure detector 5, a viscosity detector 8, and micro-water detection device 13, oil temperature detector 14 and acquisition data converter 10, the outlet of the circuit oil pipe 2 of the sampling oil tank 1 is provided with an oil delivery pump 4, and the outlet end of the oil delivery pump 4 is provided with a first oil pipe branch 6 and a second Two oil pipe branches 12, the first oil pipe branch 6 is provided with a turbidity detector 7, the second oil pipe branch 12 is provided with a micro water detector 13 and an oil temperature detector 14, and the oil pressure detector 5 is arranged in the circuit On the oil pipe 2, a sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com