Ultralow-temperature-resistant ozone-resistant modified rubber

A modified rubber and ozone-resistant technology, applied in the field of rubber processing, can solve the problems of poor insulation performance, poor low temperature resistance, low elasticity, etc., and achieve the effect of prolonging the life of the product and expanding the field of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A modified rubber with ultra-low temperature resistance and ozone resistance provided in this example includes the following components in parts by mass:

[0034] 95 parts of nitrile rubber,

[0035] 15 parts of polyvinyl chloride,

[0036] 60 parts of carbon black,

[0037] 5 parts of silicon dioxide,

[0038] Dioctyl sebacate 10 parts,

[0040] 0.5 parts of stearic acid,

[0041] 0.5 parts of sulfur,

[0042] Thiourea antioxidant 1.5 parts,

[0043] Microcrystalline paraffin 3.0 parts,

[0044] 1.2 parts of N-cyclohexyl-2-benzothiazole sulfenamide.

[0045] The above mass parts of nitrile rubber, polyvinyl chloride, and plasticizer were blended in an internal mixer to 160°C to prepare a modified rubber. Modified rubber, carbon black, plasticizer, anti-aging agent, vulcanizing agent, etc. are blended in the internal mixer, rubber, carbon black, etc. are mixed in the internal mixer for 40 seconds before adding plasticizer, cleaning ...

Embodiment 2

[0047] A modified rubber with ultra-low temperature resistance and ozone resistance provided in this example includes the following components in parts by mass:

[0048] 105 parts of nitrile rubber,

[0049] 30 parts of polyvinyl chloride,

[0050] 90 parts of carbon black,

[0051] 15 parts of silicon dioxide,

[0052] Dioctyl sebacate 20 parts,

[0054] 2 parts stearic acid,

[0055] 1..5 parts of sulfur,

[0056] Thiourea antioxidant 3.0 parts,

[0057] Microcrystalline paraffin 5.0 parts,

[0058] 2.5 parts of N-cyclohexyl-2-benzothiazole sulfenamide.

[0059] Mixing method is with embodiment one.

Embodiment 3

[0061] A modified rubber with ultra-low temperature resistance and ozone resistance provided in this example includes the following components in parts by mass:

[0062] 100 parts of nitrile rubber,

[0063] 20 parts polyvinyl chloride

[0064] 70 parts of carbon black

[0065] 10 parts of silicon dioxide

[0066] Dioctyl sebacate 20 parts

[0067] Zinc oxide 5 parts

[0068] 0.5 parts of stearic acid

[0069] 1 part sulfur

[0070] Thiourea antioxidant 3 parts

[0071] Microcrystalline paraffin 3.5 parts

[0072] 1.5 parts of N-cyclohexyl-2-benzothiazole sulfenamide.

[0073] Mixing method is with embodiment one.

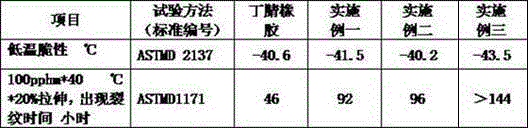

[0074] The rubber material that above-mentioned embodiment provides is resistant to low temperature ozone resistance test result as shown in table 1:

[0075] Table 1

[0076]

[0077] From the above experimental data, it can be seen that the low temperature and ozone resistance of Examples 1 to 3 are significantly better than those of the comparative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com