Patents

Literature

32results about How to "No impact resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite phase-change energy storage material for microcapsule and preparation method thereof

InactiveCN101824307ANo leaksPlay the role of self-control temperature controlHeat-exchange elementsMicroballoon preparationCrack resistanceSolvent

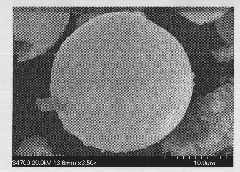

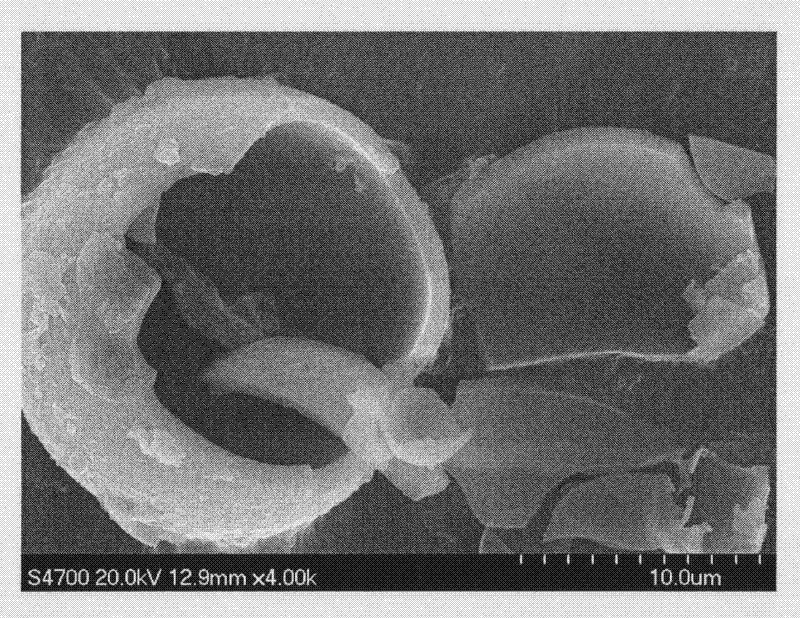

The invention discloses a composite phase-change energy storage material for microcapsules and a preparation method thereof. The coating of the microcapsule is made of silicon dioxide, and the core of the microcapsule is made of a phase-change energy storage material, wherein the phase-change energy storage material is a paraffin organic solid-liquid phase-change energy storage material. 0.2 to 0.5 wt.% of dispersed emulsifier, 52.5 to 62.5 wt.% of solvent water, 18.75 to 31.5 wt.% of phase-change energy storage material and 15.5 to 18.75 wt.% of inorganic silica source are matched and put into a reactor for stirring for 5 to 8 hours; the mixture is uniformly dispersed and emulsified at the temperature 3 to 8 DEG C higher than that for solid-liquid phase change; hydrochloric acid aqueous solution catalyst with the pH value of 0.93 to 4.07 or sodium hydroxide aqueous solution catalyst with the pH value of 8.0 to 12.0 is added into the emulsion; the reacting solution is naturally cooled to room temperature and precipitation solution is obtained; the precipitate is washed with the combination of water and petroleum ether, wherein the mass percent of the petroleum ether is 30 wt.%; then the precipitate is washed with deionized water and is filtered, and the product is naturally aired. The invention improves the technology of phase-change energy storage and conservation, and has the function of automatic temperature regulation, favorable physical and chemical stability, crack resistance, flame retardancy, wear resistance and high thermal conductivity.

Owner:BEIJING UNIV OF CHEM TECH

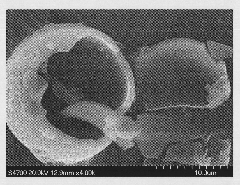

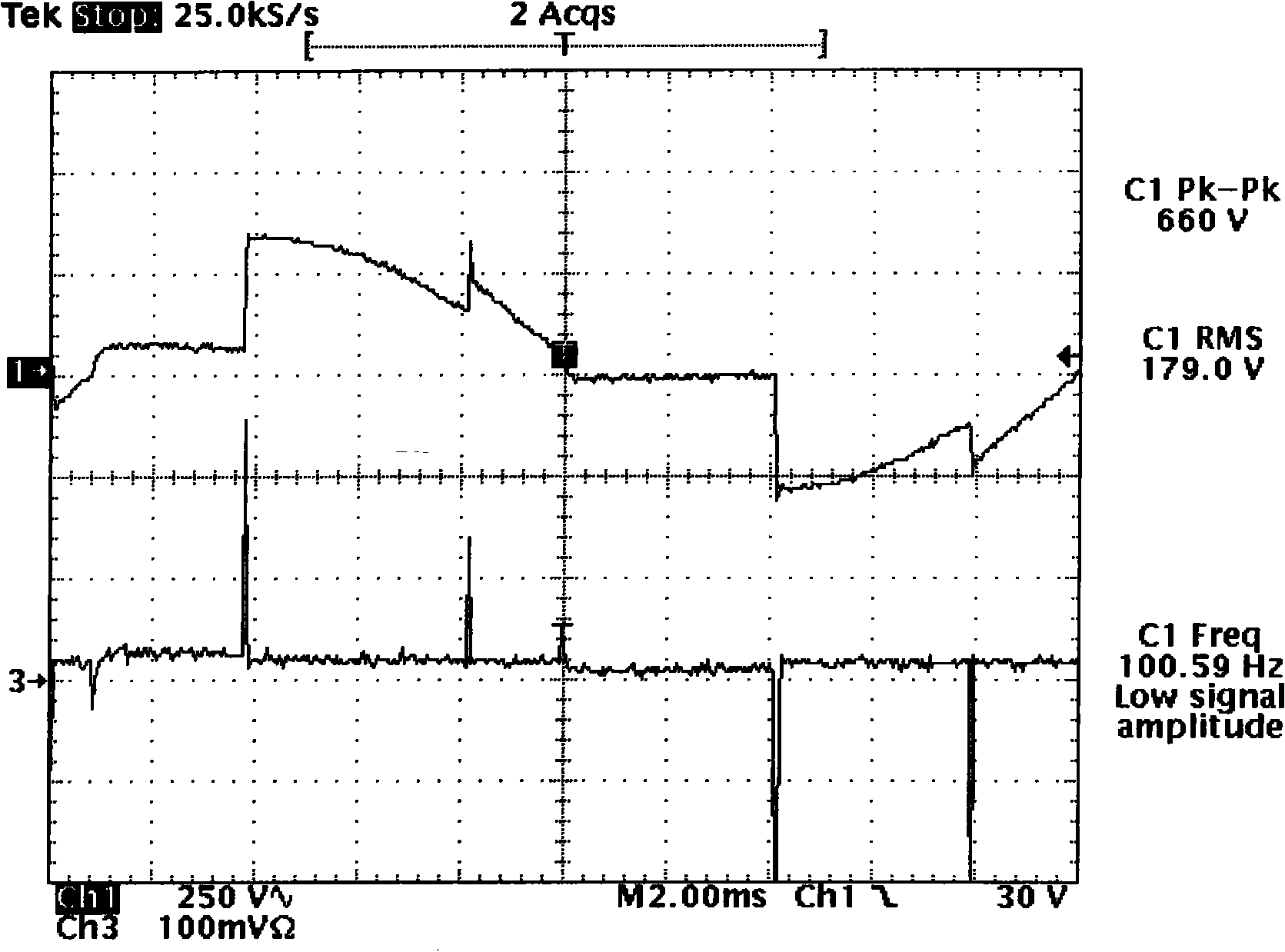

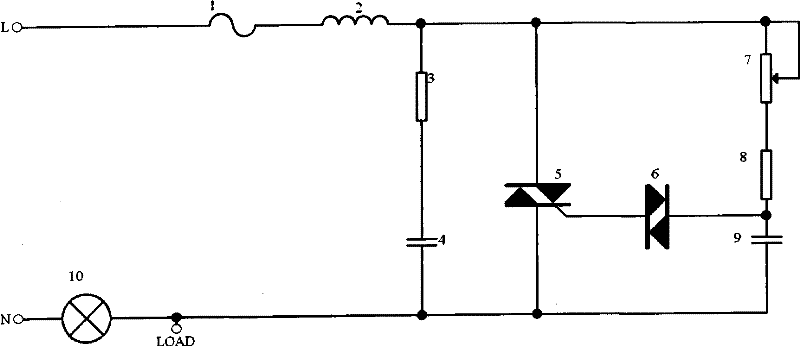

LED light modulation apparatus suitable for controlled silicon dimmer

InactiveCN101404844AReduce lossBrightness adjustableElectric light circuit arrangementElectric variable regulationLoad circuitTransformer

The invention relates to an LED dimming device which is applicable to a controllable silicon dimmer. The LED dimming device comprises a rectifier, a fictitious load circuit, a zero-crossing detection circuit, a high frequency transformer, a main power supply drive integrated circuit, a secondary rectification and filter circuit, a secondary power supply drive integrated circuit and an average voltage detection circuit. The invention has the beneficial effect that the LED dimming device is capable of realizing the brightness adjustment of an LED lamp by the controllable silicon dimmer and has the advantages of good dimming effect, long service life, simple structure and environmental protection and energy saving.

Owner:CIVILIGHT SHENZHEN SEMICON LIGHTING

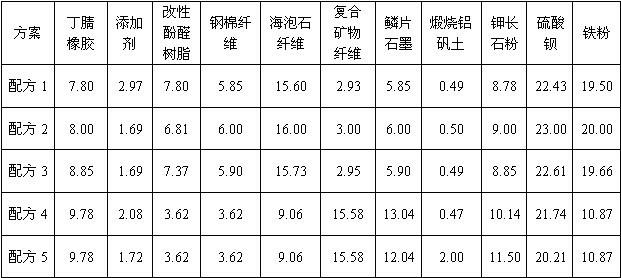

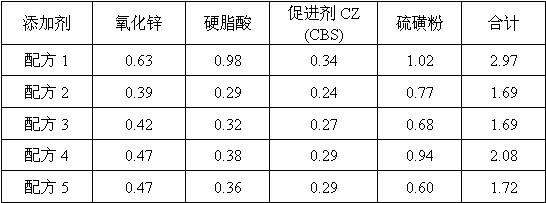

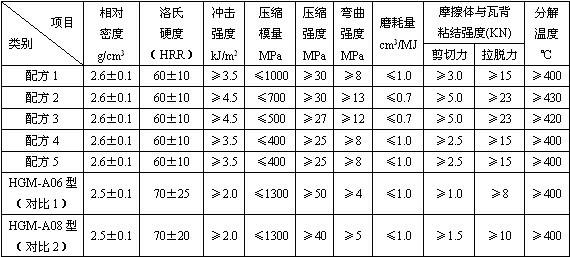

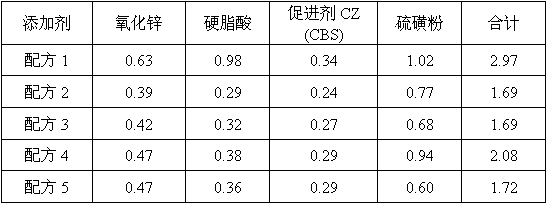

Composition brake shoe for railway freight car, and method for manufacturing same

ActiveCN102661340AHigh bonding strengthReduce wearOther chemical processesBraking membersCrazingSlag

The invention discloses a composition brake shoe for a railway freight car, and a method for manufacturing the same. A friction piece of the composition brake shoe for the railway freight car is synthetised by using following materials by weight parts: 6-10 parts of nitrile rubber, 2-8 parts of modified phenolic resin, 3-6 parts of steel wool fibers, 9-16 parts of sepiolite fibers, 2-16 parts of composite mineral fibers, 5-13 parts of graphite, 0.4-2 parts of calcined bauxite, 20-24 parts of barium sulfate, 8-12 parts of potassium feldspar powder, 10-20 parts of iron powder, and 1-3 parts of additives. The friction piece of the composition brake shoe is formed through the steps of dosing, banburying or mixing, crashing, hot press molding and curing forming, and thermal processing. The composition brake shoe is capable of well satisfying various performance indexes requested in PRC (People's Republic of China) railway industrial standard TB / T2403-2010, and can be applied to railway freight cars traveling at the highest speed of 120km / h and axle load of the composition brake shoe is not greater than 25 tons; besides, the composition brake shoe has stable friction properties and excellent friction resistance, and is low in attrition to wheels and low in braking noise; and as a result, potential quality hazards ( such as brake shoe body breakage, slag and block dropping, metal inlaying and hot cracks) endangering traveling safety are fundamentally solved.

Owner:CHONGQING YUHONG RAIL CAR ACCESSORIES CO LTD

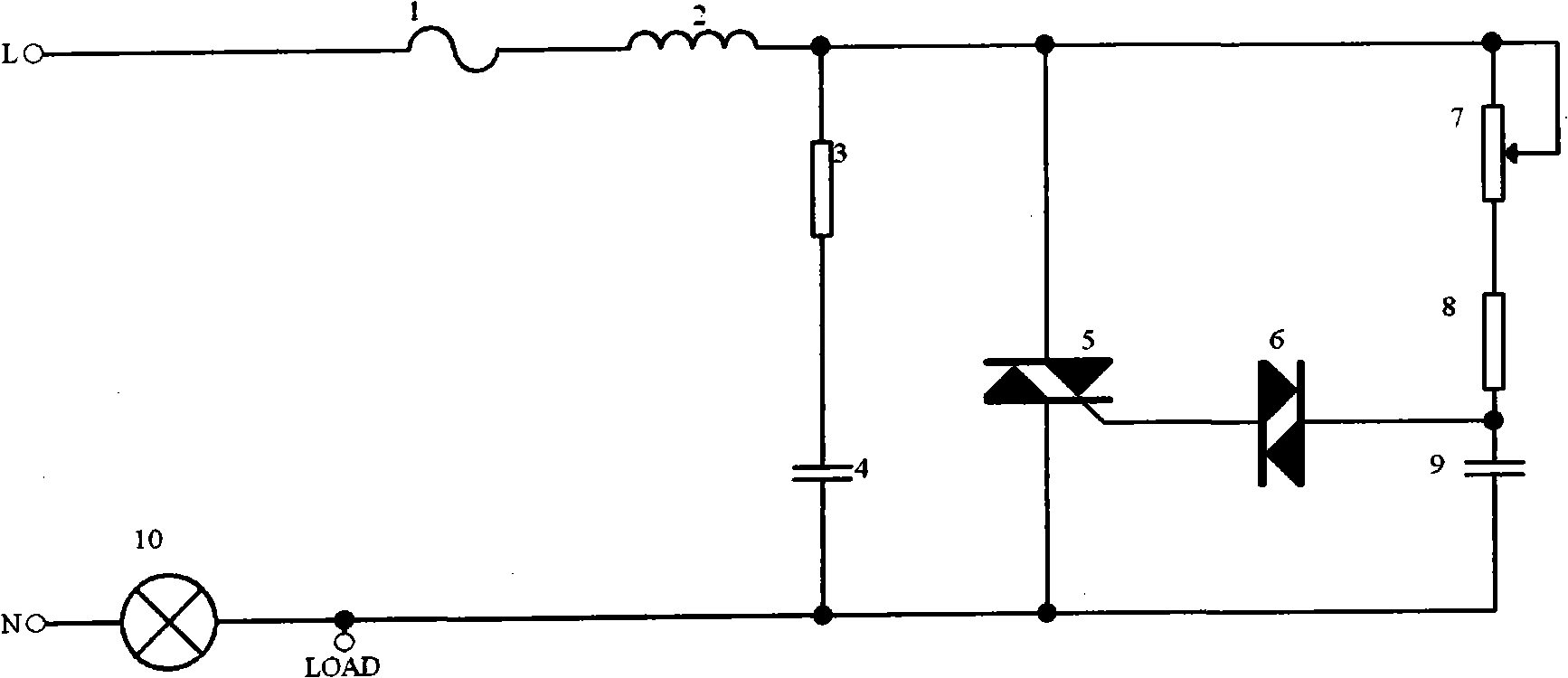

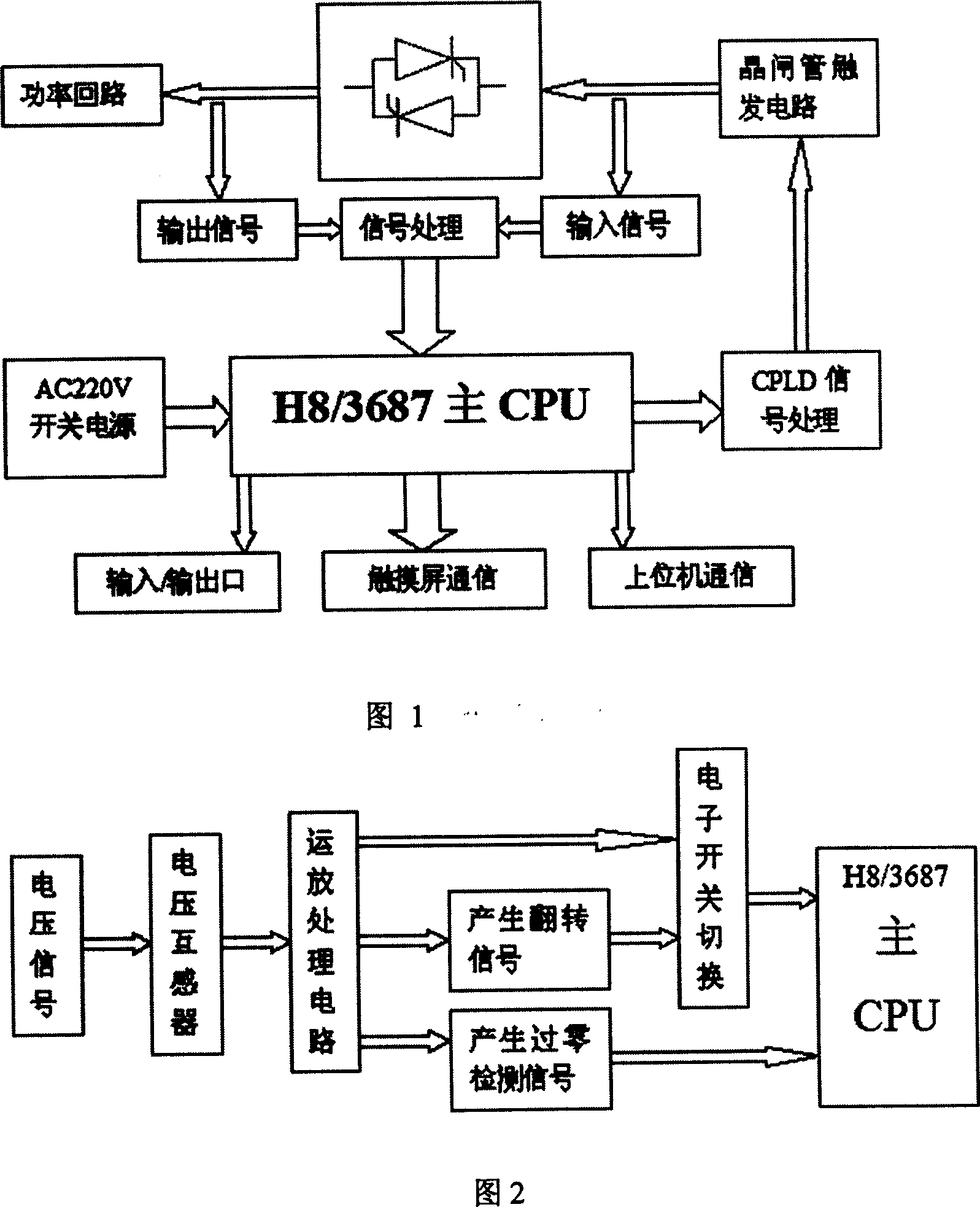

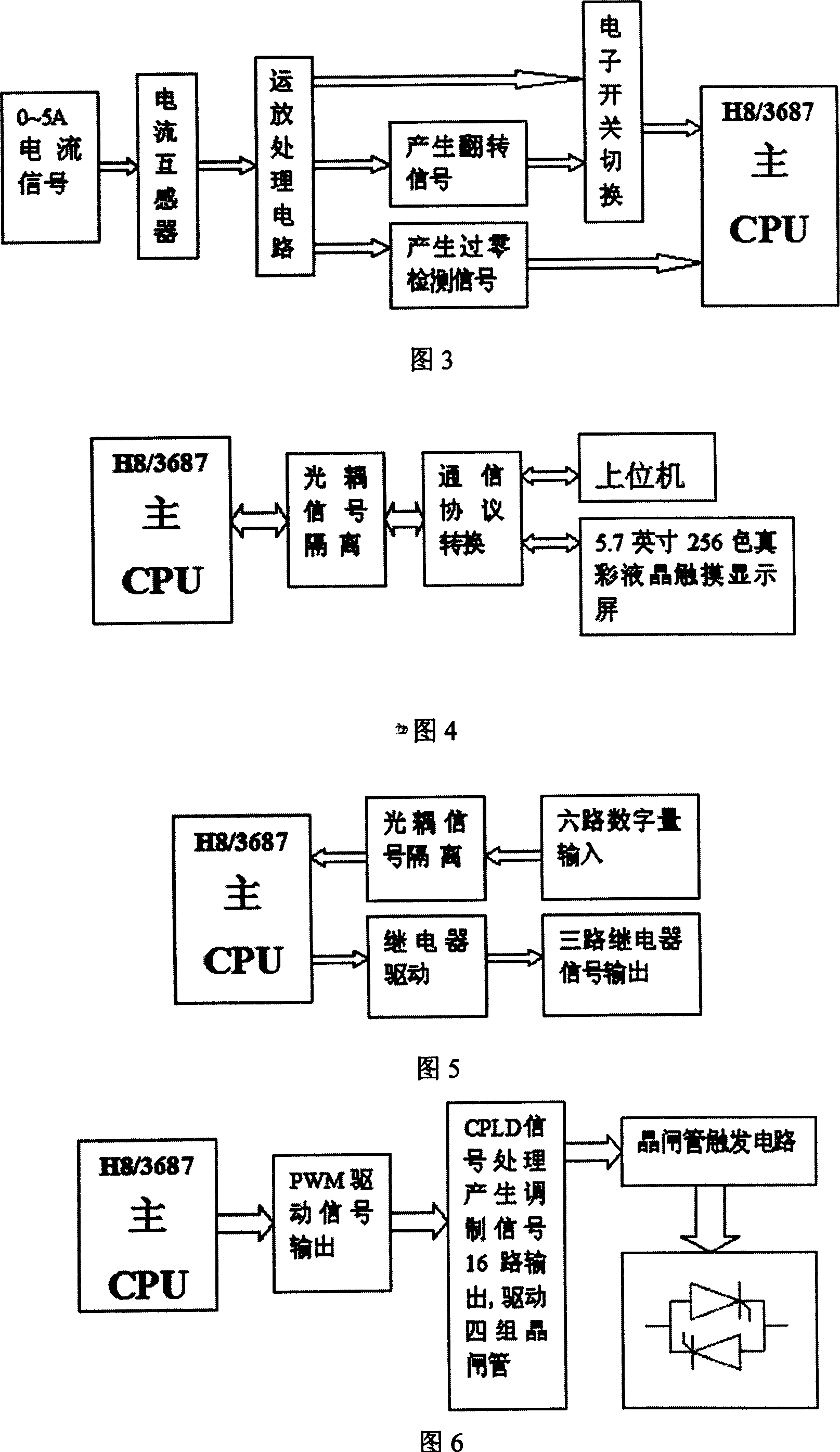

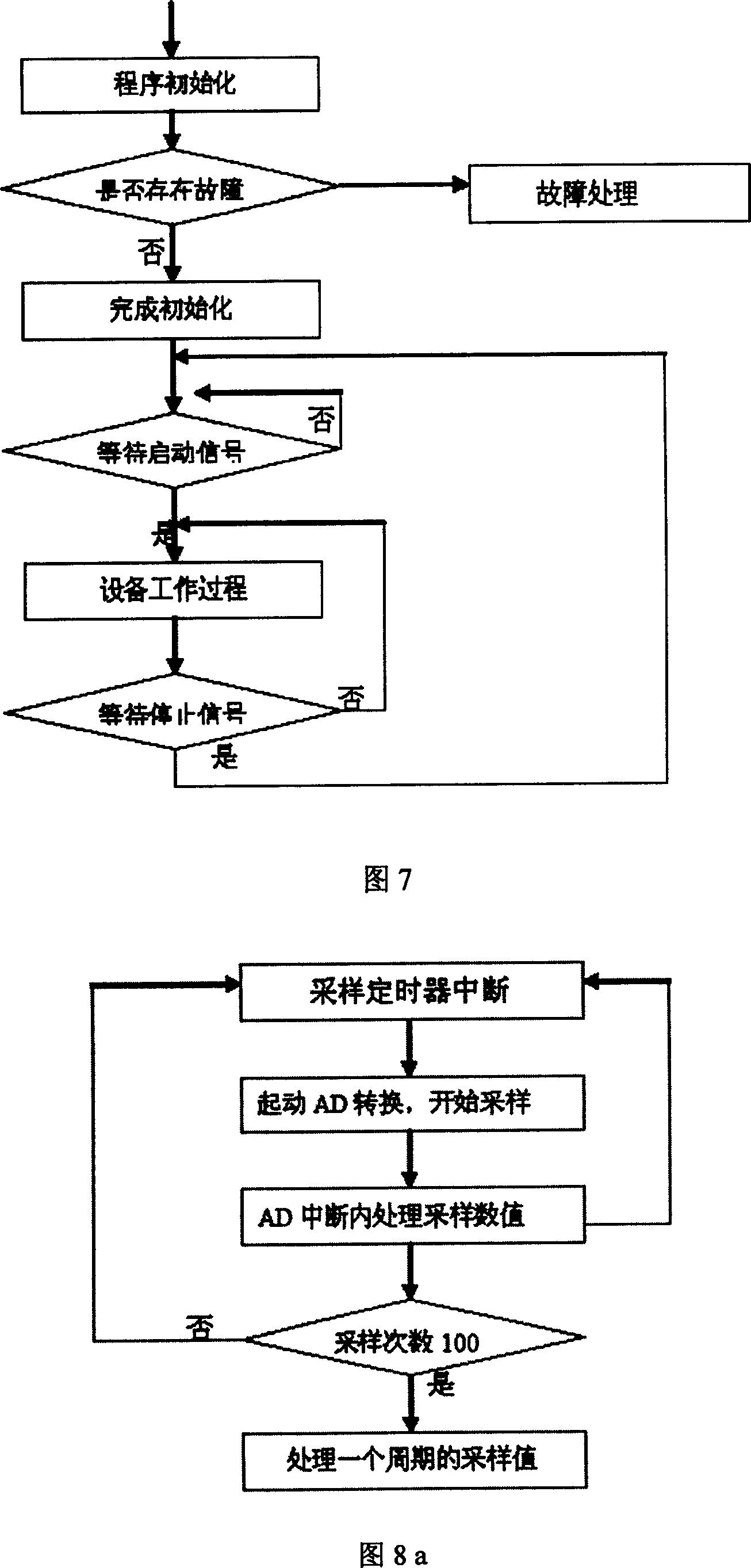

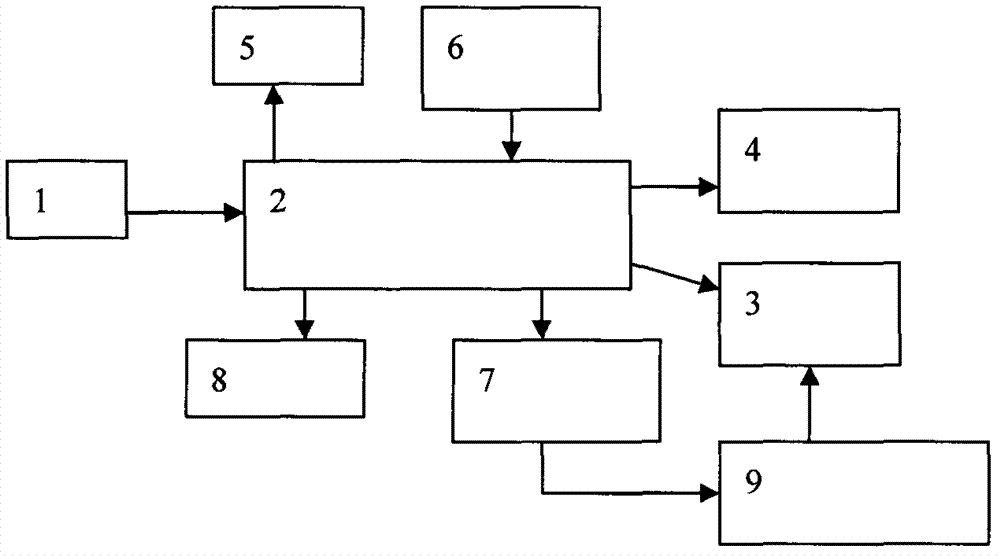

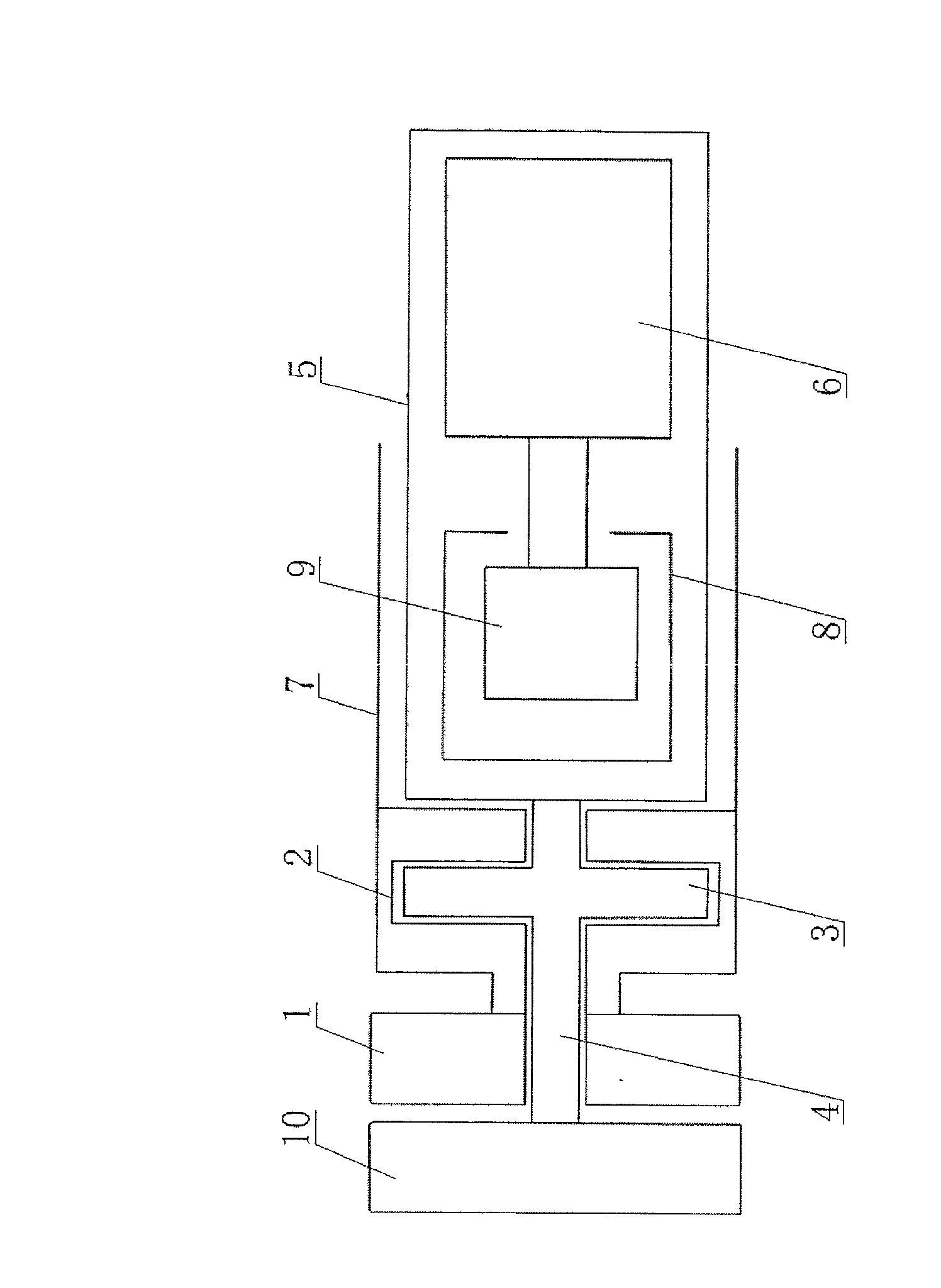

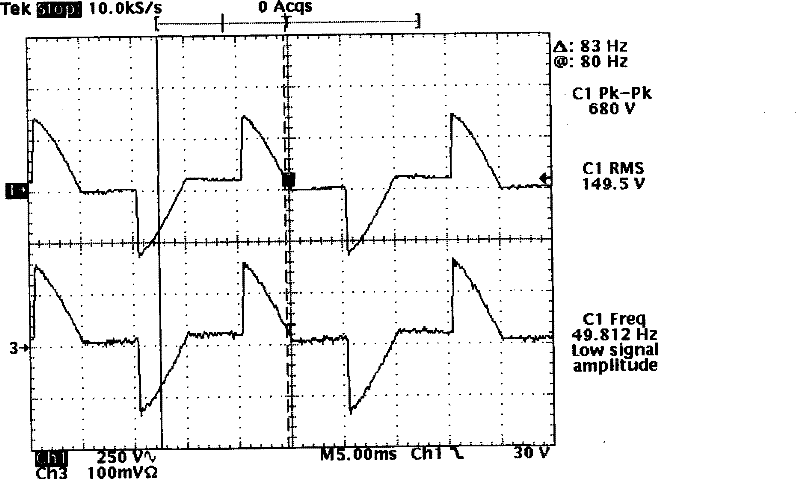

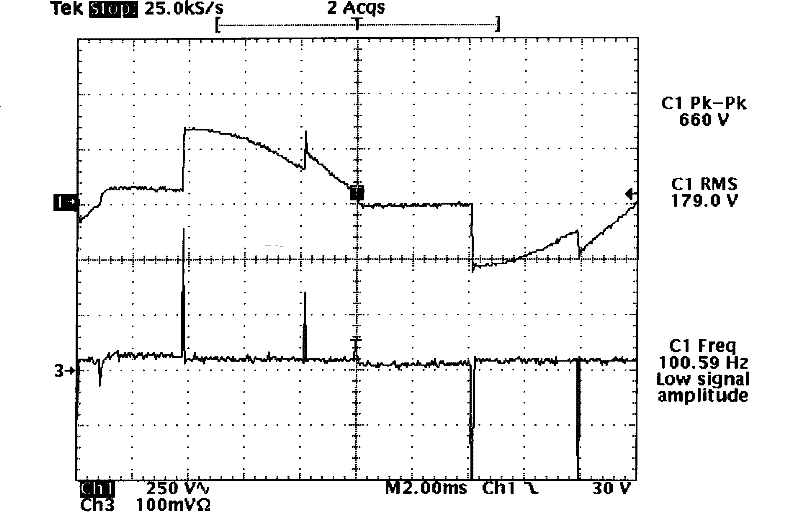

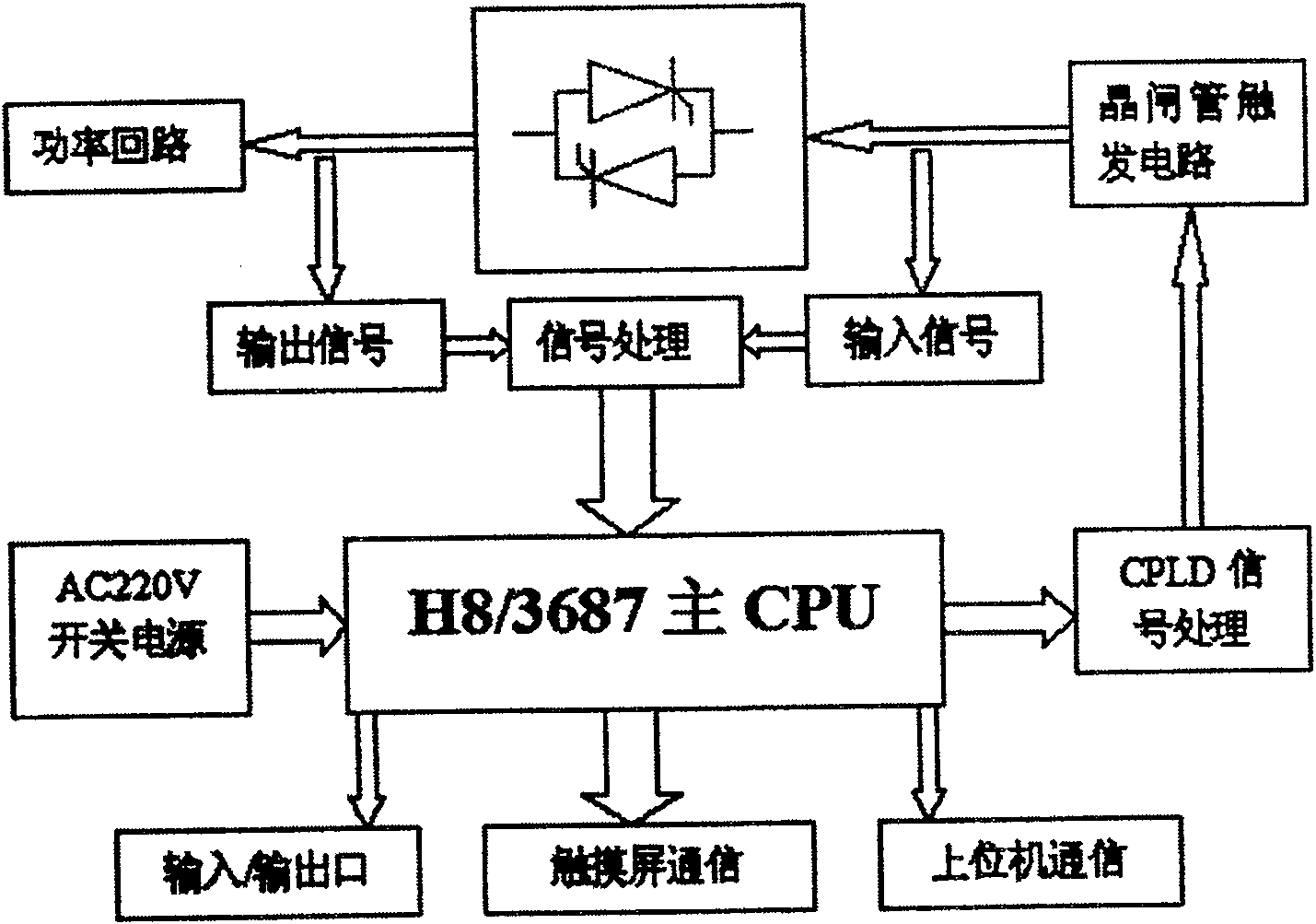

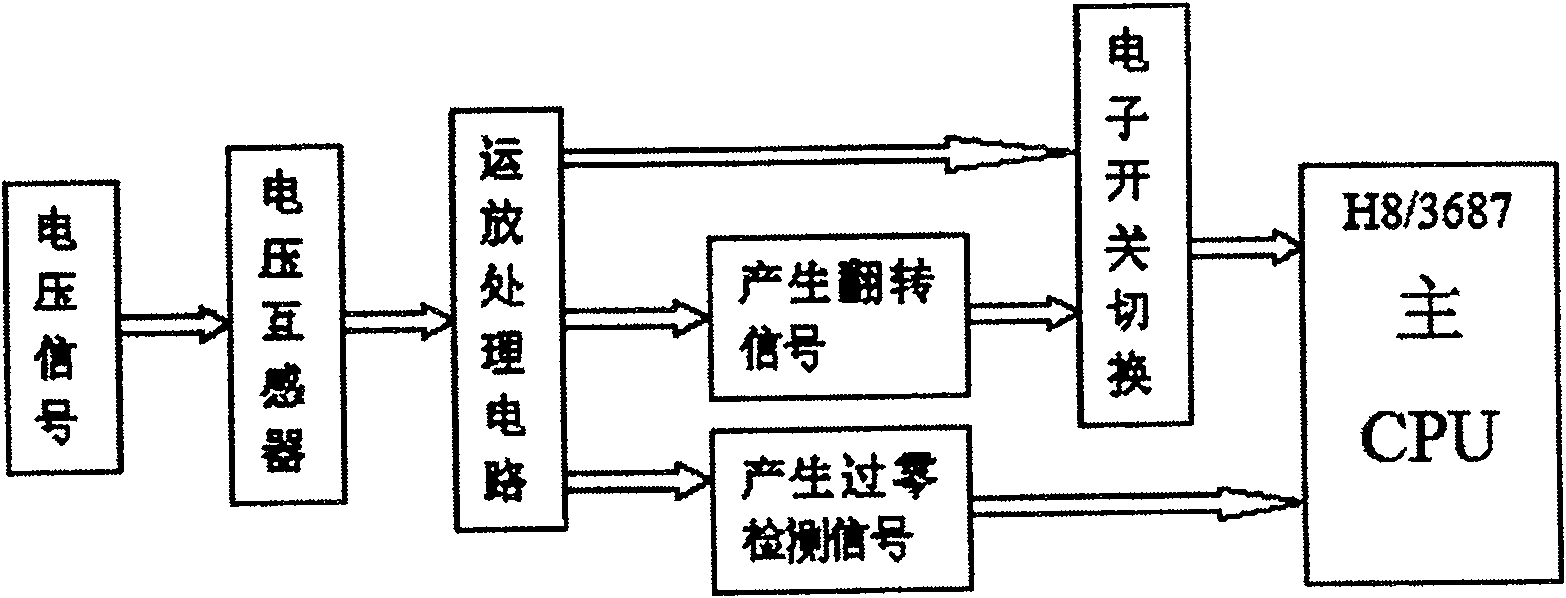

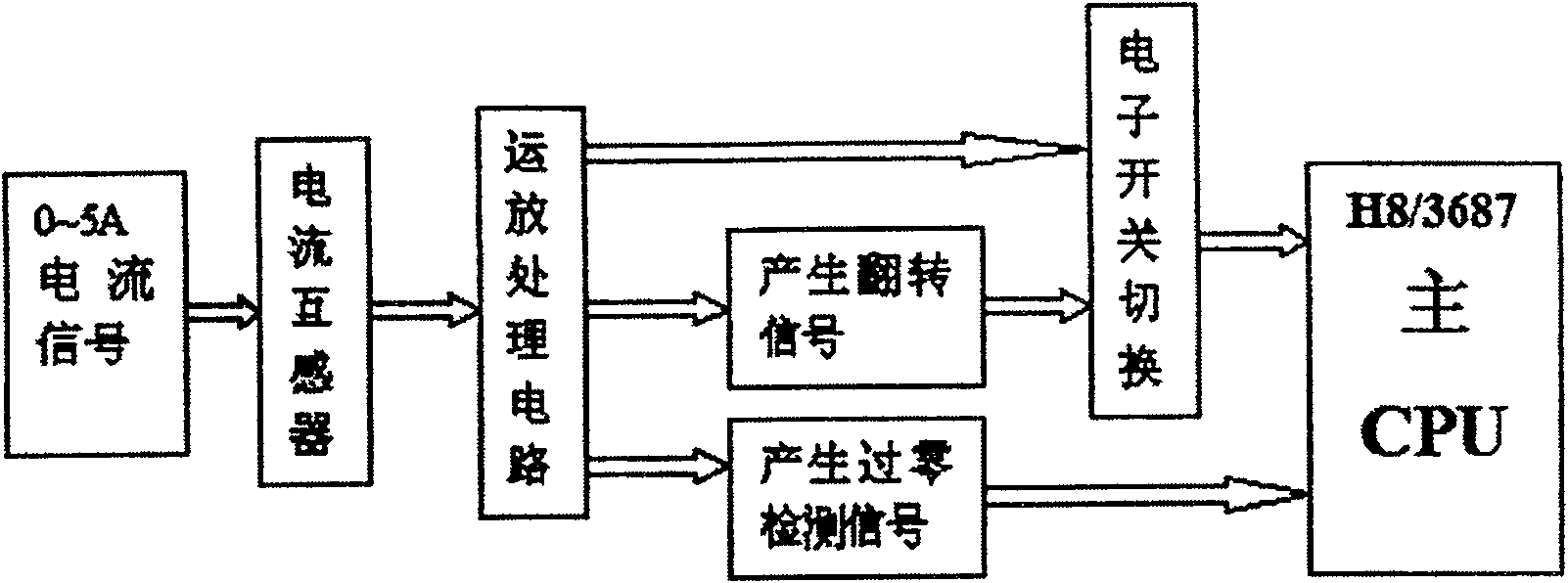

Thyristor phase-selecting switch experiment device

ActiveCN1971298AReduce volumeReduce weightElectrical testingElectronic switchingSignal processing circuitsThyratron

The invention relates to a thyristor phase switch testing device, the comprehensive microprocessor and thyristor technique are used in the device; the projection angle of switch is operated by the drive pulse phase of the thyristor. The device includes: host CPU, acquisition circuit of input-output signal, switch power supply, input-output interface, touching screen communication, upper machine communication, CPLD signal processing circuit, thyristor trigger circuit, power return circuit and thyristor; the electrical signal transitive relation is: the thyristor trigger circuit triggers the thyristor, the signal is transmitted to the acquisition circuit, processed by the host CPU, and separately transmitted to the touching screen communication, the upper machine communication and the input-output interface, the CPLD signal processing circuit and switch power supply provide power for the host CPU, thyristor and power return circuit, and the signal is output.

Owner:SHANGHAI ELECTRICAL APPLIANCES RES INSTGROUP

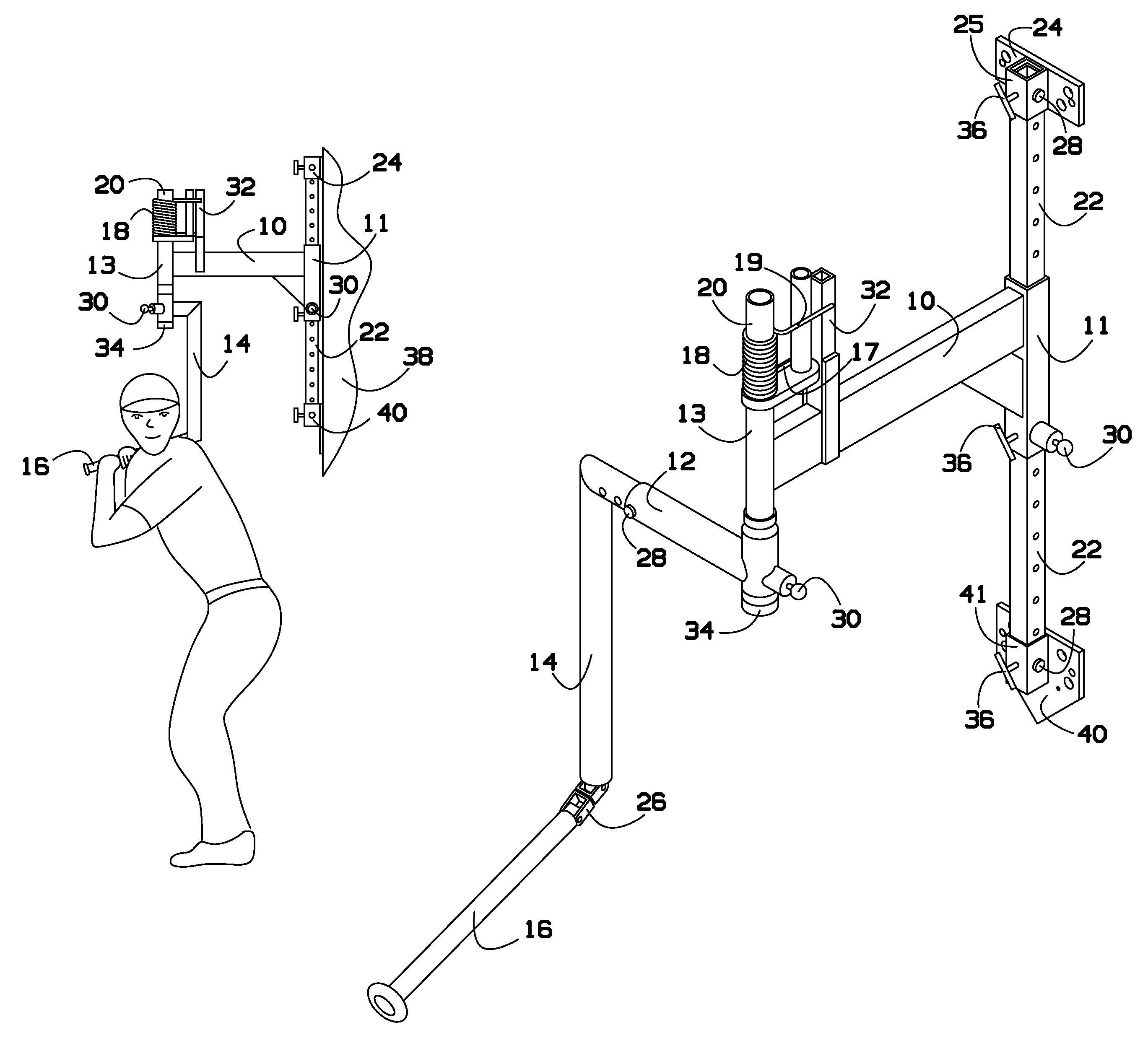

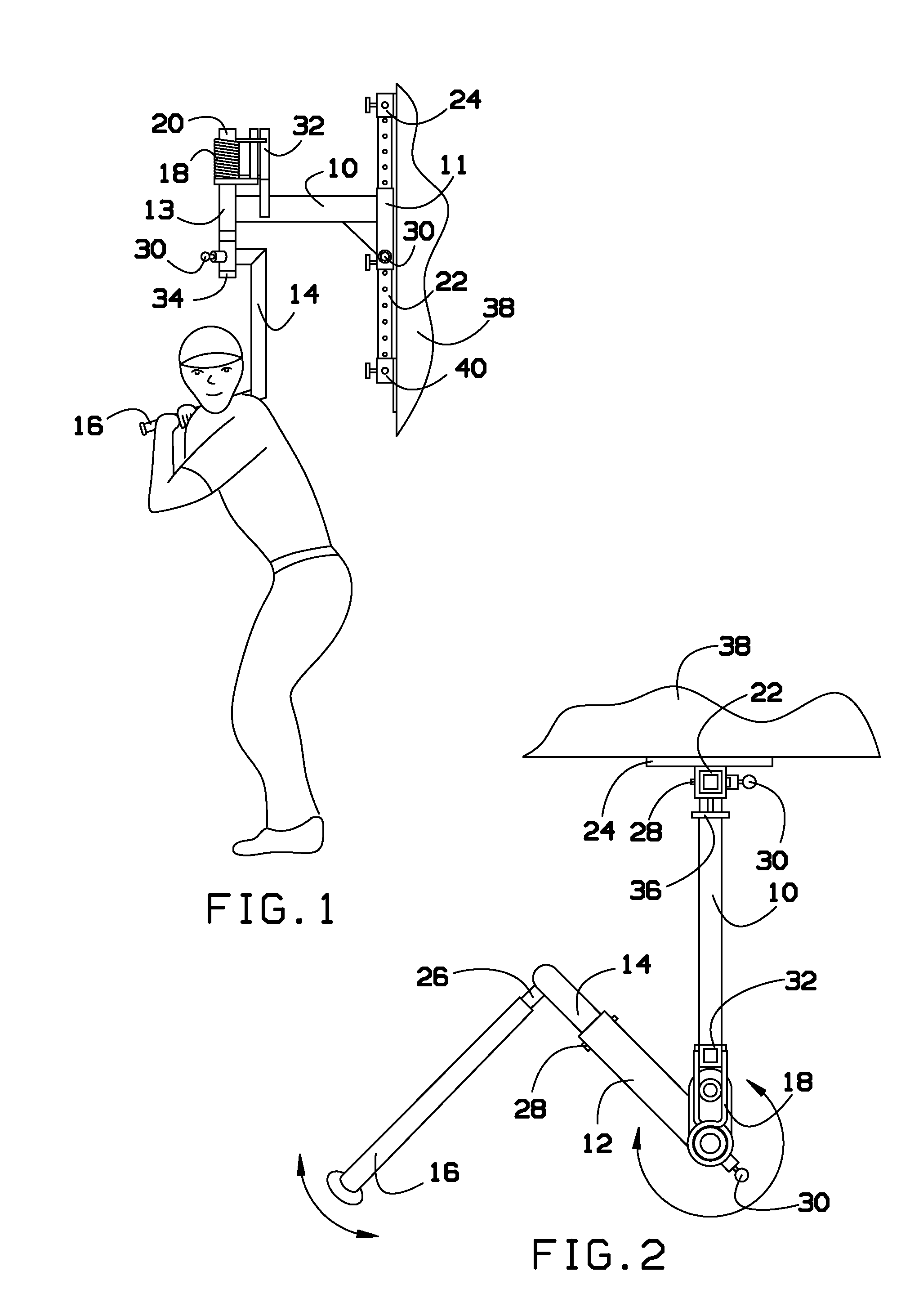

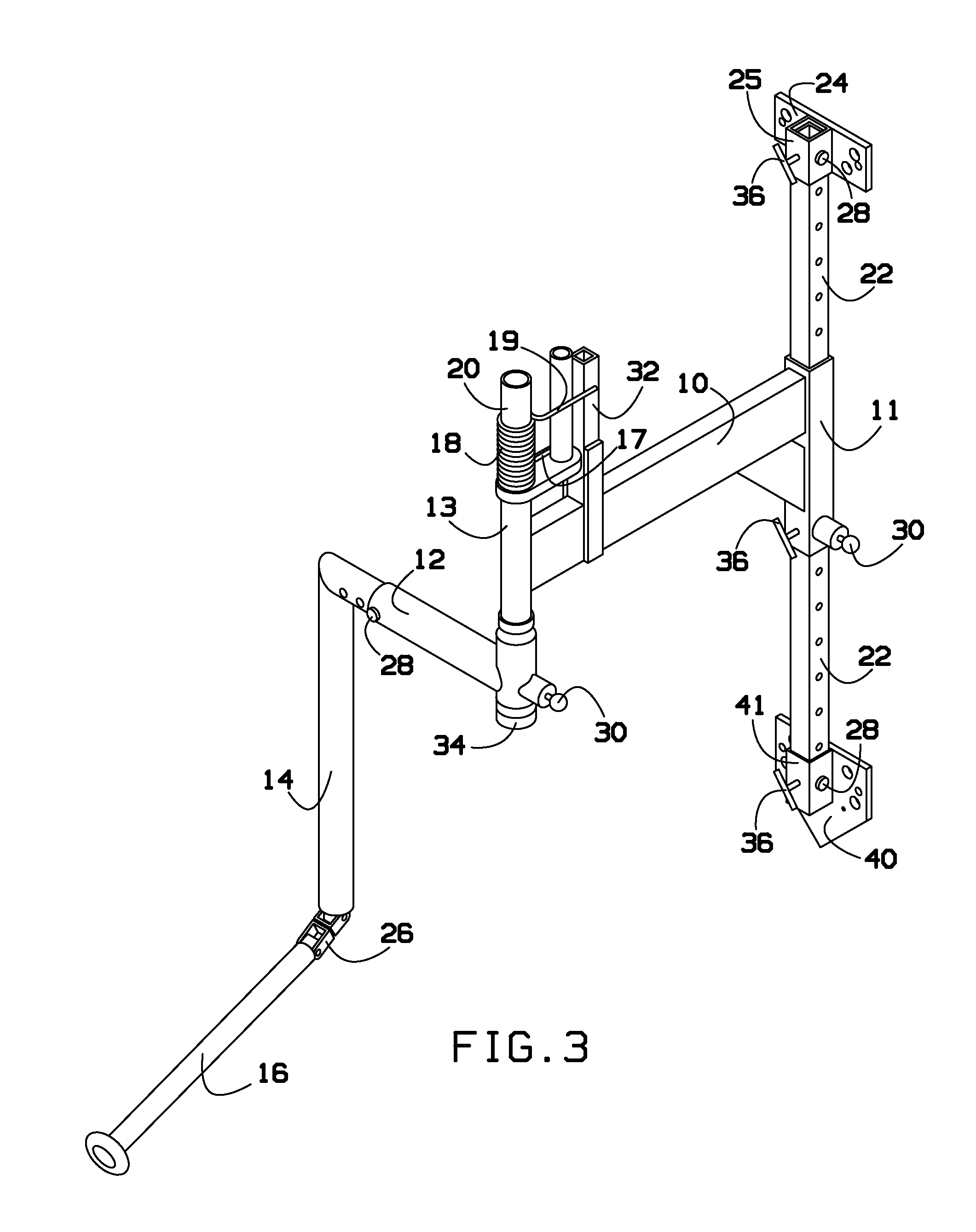

Bat swing training machine

InactiveUS8852032B1Precise position controlEasy to transportMuscle exercising devicesRacket sportsMicrochiropteraMuscle strength

A bat swing training machine for improving a user's bat swing technique and developing muscular strength includes a frame carried by an adjustable post for height adjustment and two mounting brackets for installation in various locations. The machine also includes a torsion spring, a swing arm with swivel linkage and a bat handle. The machine provides torsional resistance with precise positional control throughout the swing motion and does so equally for right and left handed swings. Backswing is relatively un-resisted thereby allowing the athlete or trainee to stay in position and continuously repeat the swing motion.

Owner:BARNES JERRY

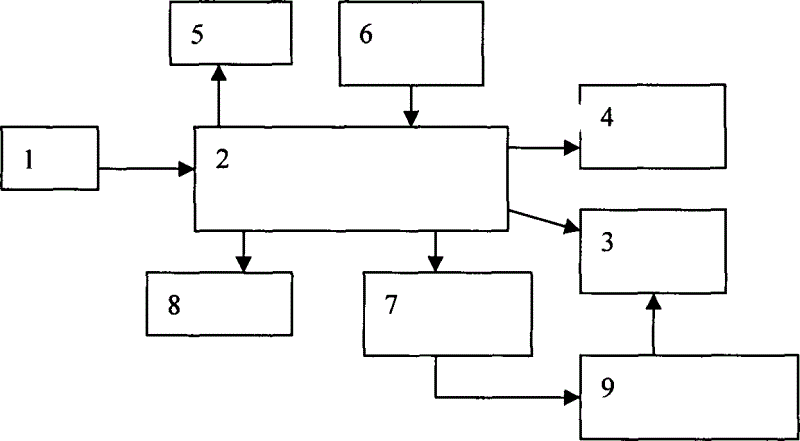

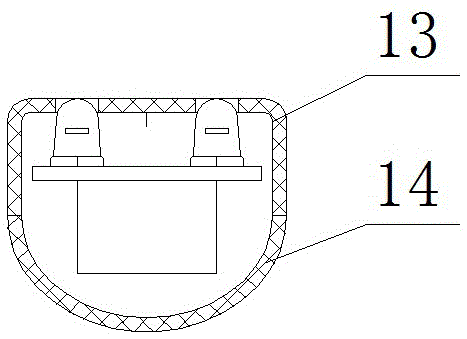

Light source system of integral reflection LED (light emitting diode) shadowless operating lamp

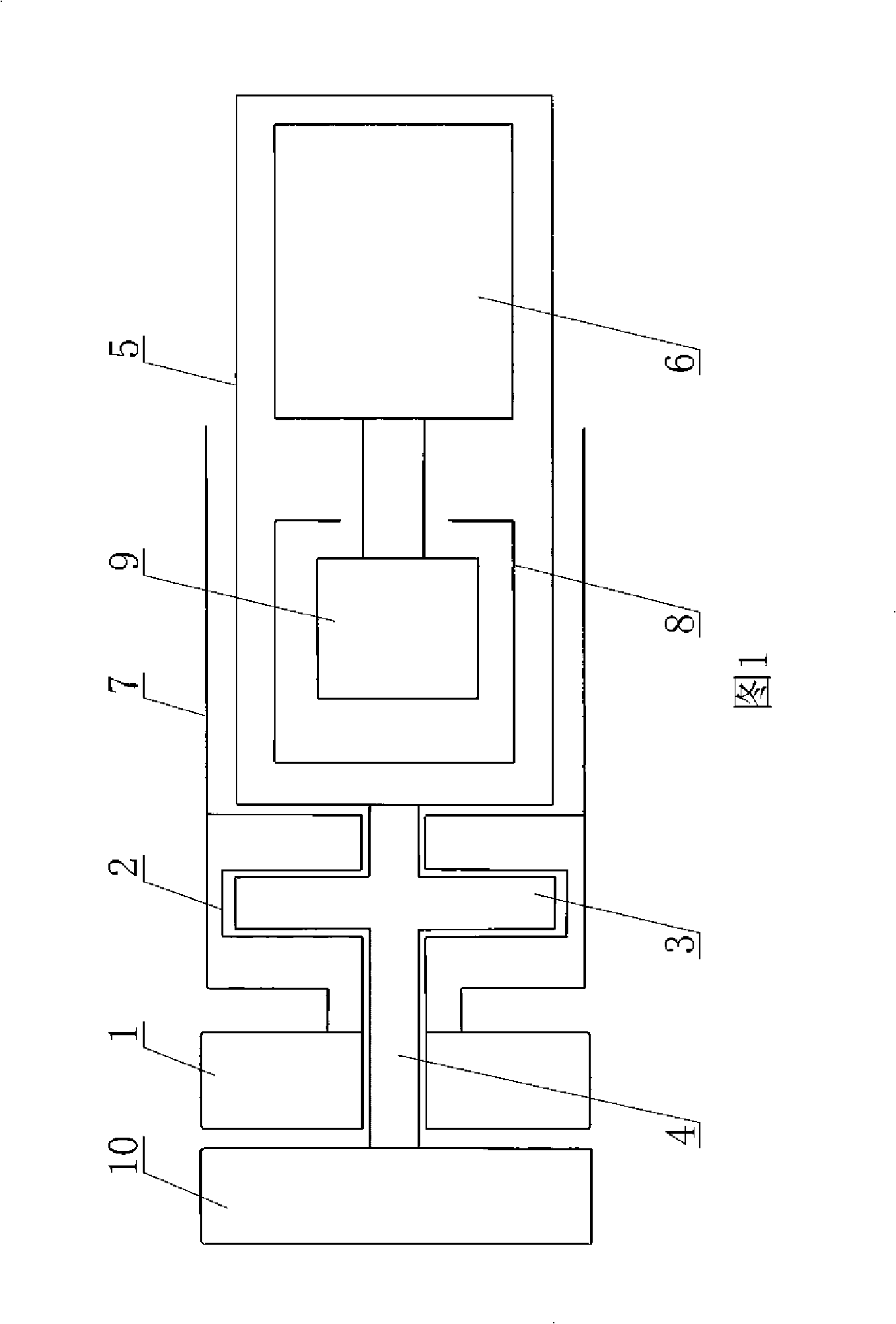

InactiveCN102711344AGood shadowless effectIncrease illuminationElectric light circuit arrangementEnergy saving control techniquesEngineeringAlternating current

The invention relates to a light source system of an integral reflection LED (light emitting diode) shadowless operating lamp. The light source system takes advantages to offset disadvantages, integrates the technical advantages of integral reflection and an LED and overcomes defects. The light source system comprises a light source (1), a control board (2), a main lamp (3), an assistant lamp (4), a display panel (5), a control panel (6), a charging battery (7), a conversion circuit (8) of the main lamp (3) and the assistant lamp (4), and an emergency (switch) circuit (9). A pillar LED lamp is used as a light source for meeting the requirement of integral reflection for the light source, achieving the purposes of energy saving, environment-friendly performance, small thermal generation and long service life. The energy consumption is low, and the battery can be adopted for power supply. The emergency performance of the integral reflection LED shadowless operating lamp is increased by an alternating current and direct current conversion circuit, the conversion circuit of the main lamp and the assistant lamp, and the emergency (switch) circuit.

Owner:YANGZHOU NO 1 PEOPLES HOSPITAL +2

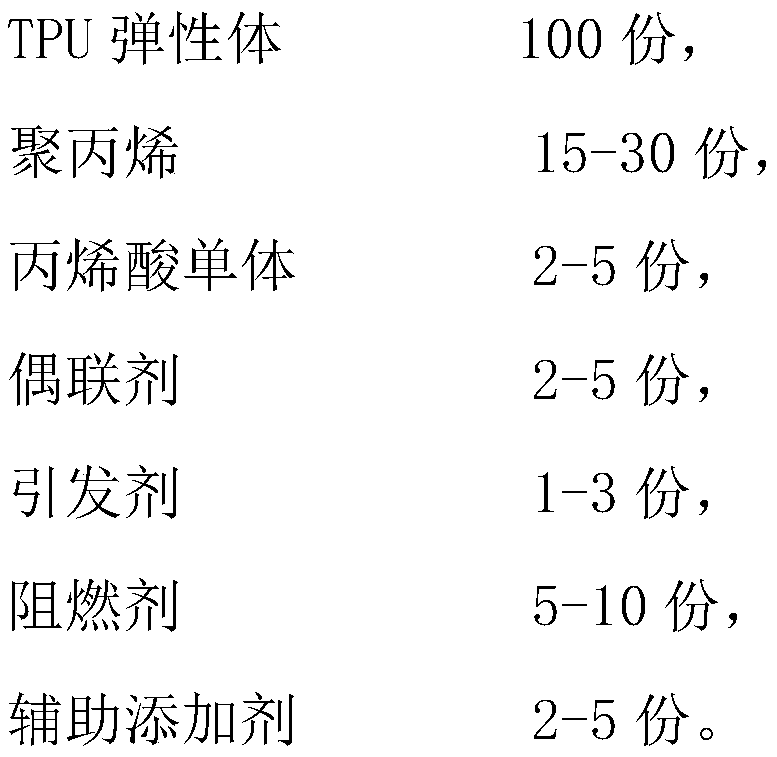

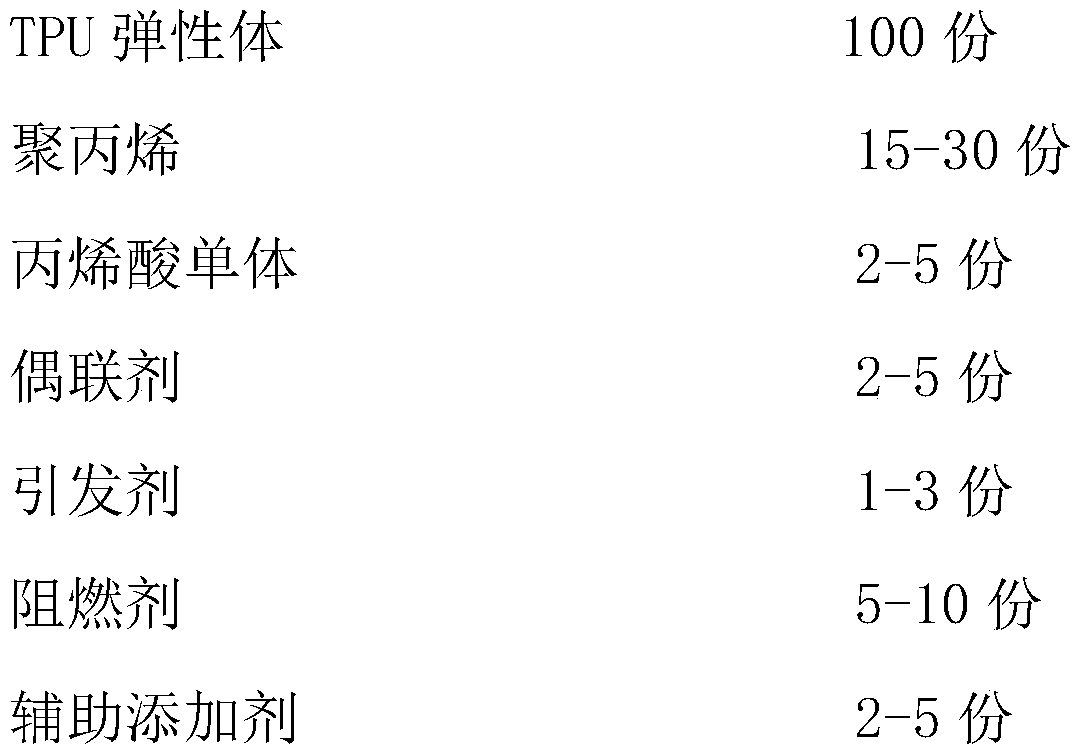

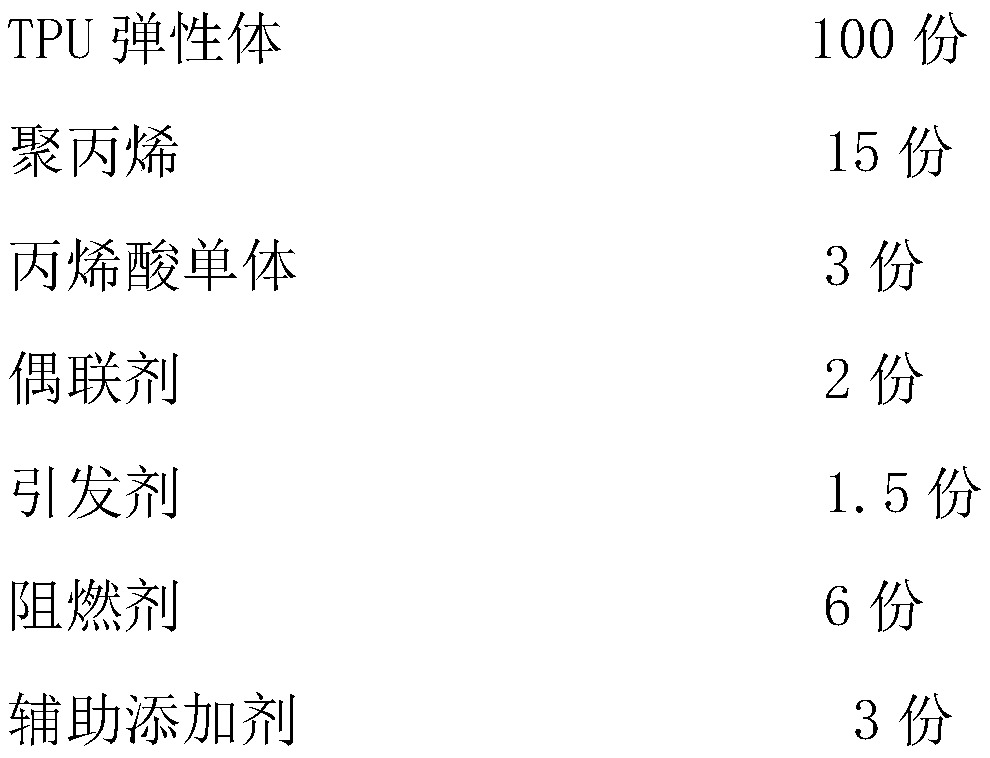

Thermoplastic polyurethane optical film and coating method thereof

InactiveCN109735240ARigid and flexible performanceNo impact resistanceOrganic non-macromolecular adhesiveFilm/foil adhesives without carriersRubber materialMass ratio

The invention provides a thermoplastic polyurethane optical film. The thermoplastic polyurethane optical film is obtained by mixing thermoplastic polyurethane (TPU) and polypropylene (PP) according toa mass ratio to obtain a basic material and preparing from acrylic monomers, coupling agents, initiators, fire retardants and auxiliary additives. The thermoplastic polyurethane optical film has hightransparency, excellent mechanical properties, high weather and chemical resistance, high-and-low temperature resistance and good bonding properties, and can be melted, flowable, transparent, and extremely-low initially viscous under a certain temperature, thereby being capable of serving as an optical coating rubber material for touch display screens; touch display screen components bonded by the thermoplastic polyurethane optical film have the advantages of simplicity and convenience in process, convenience in bubble elimination, easiness in rework, high production efficiency, low cost andthe like, and touch display screen components coated with the thermoplastic polyurethane optical film have the advantages of good optical performance, excellent mechanical property, high chemical andweather resistance and good environmental performance, so that the thermoplastic polyurethane optical film is an excellent optical rubber material.

Owner:SHENZHEN GAOREN ELECTRONICS NEW MATERIAL

Powder anti-corrosion coatings for submarine pipelines

PendingCN106147505AImprove waterproof performanceStrong adhesionAnti-corrosive paintsPowdery paintsPolyvinyl butyralEpoxy

The invention discloses a powder anticorrosion coating for submarine pipelines, which is composed of the following raw materials in parts by weight: 20-50 parts of epoxy resin, 20-50 parts of novolak epoxy resin, 5-30 parts of titanium dioxide, trimethyl 4‑10 parts of hexamethylenediamine, 1‑2 parts of polyvinyl butyral, 3‑4 parts of defoamer, 0.1‑0.2 parts of dimethylimidazole, 1‑2 parts of antioxidant DNP, aminopropyl 1-3 parts of triethoxysilane, 5-26 parts of barium sulfate, 2-10 parts of thickener, 0.5-5 parts of graphene, and 0-4 parts of colorant. The powder anticorrosion coating for submarine pipelines of the present invention can protect steel structures from corrosion of various corrosive media for a long time, is non-toxic, non-polluting, resistant to salt spray, strong in adhesion, strong in impact resistance, and low in cost, and is an environmentally friendly coating with excellent comprehensive performance. coating.

Owner:西安烨森电子科技有限责任公司

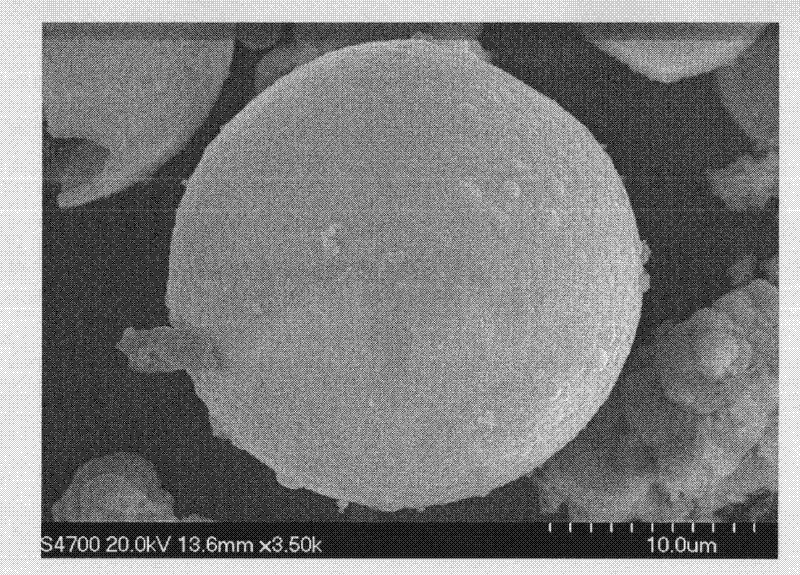

Composite phase-change energy storage material for microcapsule and preparation method thereof

InactiveCN101824307BImprove phase change energy storage technologyWith the ability of automatic temperature adjustmentHeat-exchange elementsMicroballoon preparationCrack resistanceSolvent

The invention discloses a composite phase-change energy storage material for microcapsules and a preparation method thereof. The coating of the microcapsule is made of silicon dioxide, and the core of the microcapsule is made of a phase-change energy storage material, wherein the phase-change energy storage material is a paraffin organic solid-liquid phase-change energy storage material. 0.2 to 0.5 wt.% of dispersed emulsifier, 52.5 to 62.5 wt.% of solvent water, 18.75 to 31.5 wt.% of phase-change energy storage material and 15.5 to 18.75 wt.% of inorganic silica source are matched and put into a reactor for stirring for 5 to 8 hours; the mixture is uniformly dispersed and emulsified at the temperature 3 to 8 DEG C higher than that for solid-liquid phase change; hydrochloric acid aqueous solution catalyst with the pH value of 0.93 to 4.07 or sodium hydroxide aqueous solution catalyst with the pH value of 8.0 to 12.0 is added into the emulsion; the reacting solution is naturally cooledto room temperature and precipitation solution is obtained; the precipitate is washed with the combination of water and petroleum ether, wherein the mass percent of the petroleum ether is 30 wt.%; then the precipitate is washed with deionized water and is filtered, and the product is naturally aired. The invention improves the technology of phase-change energy storage and conservation, and has the function of automatic temperature regulation, favorable physical and chemical stability, crack resistance, flame retardancy, wear resistance and high thermal conductivity.

Owner:BEIJING UNIV OF CHEM TECH

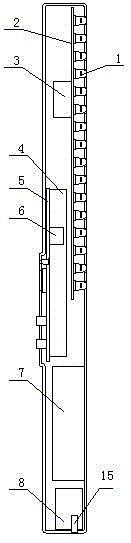

Down-hole slurry generator

InactiveCN101251077AExtend product lifeStable and reliable operationDynamo-electric gearsMachines/enginesStatorElectricity

The invention relates to an underground mud generator, the main structure of which is as follows: a turbine is connected to an outer magnetic rotor of a magnetic coupling through a cushion double wall sleeve; an annular groove is arranged in the middle part of the inside wall of the cushion double wall sleeve; a buffer plunger is contained in the annular groove; one of the buffer plunger and the cushion double wall sleeve is a magnet; the center of the buffer plunger is connected to two ends of a stator plunger rod; one end of the stator plunger rod is connected to a seal housing of the generator, while the other end passes through the center of the turbine and is connected to a supporter; an inner magnetic rotor of the magnetic coupling is positioned in an outer magnetic rotor drum of the magnetic coupling, and the both are isolated by the seal housing; the inner magnetic rotor is provided with a necking cavity; one end of a suspended shaft is arranged in the necking cavity, while the other end is connected to the rotor of the generator body; and the seal housing encloses the generator body, the inner magnetic rotor of the magnetic coupling and the suspended shaft. The underground mud generator has the advantages of no-sealing, zero leakage and shock proof, and supplies steady electricity for logging-while-drilling instruments underground in a high temperature and high pressure environment.

Owner:BEIJING TIANXING JINGZUAN TECH DEV

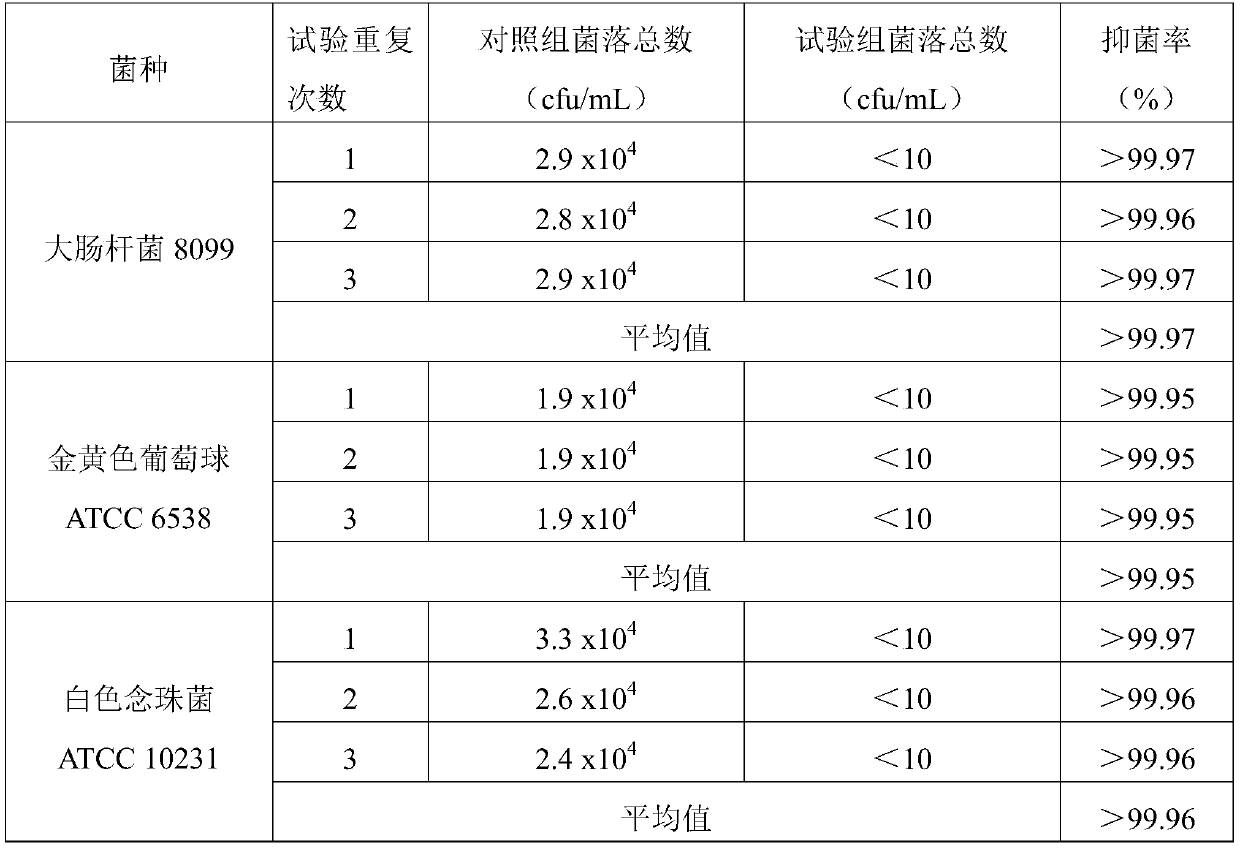

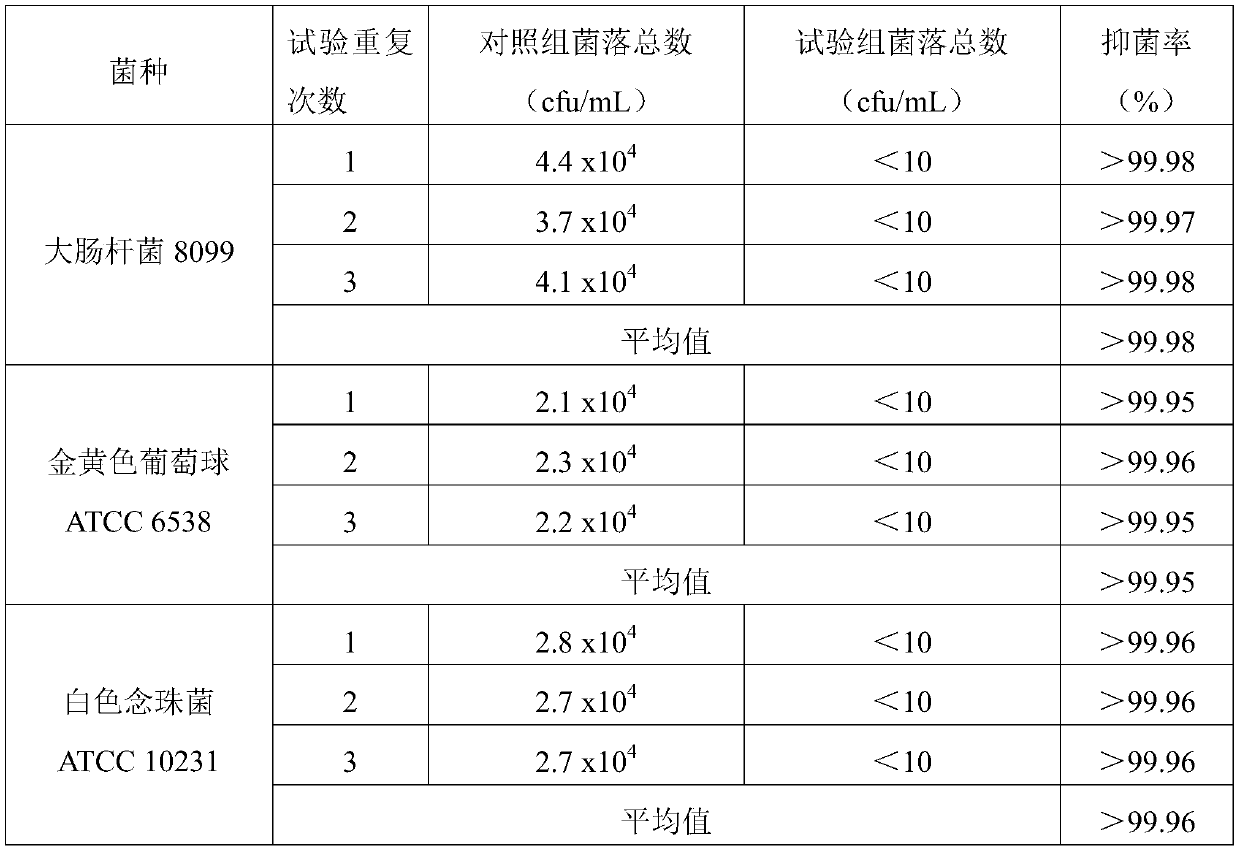

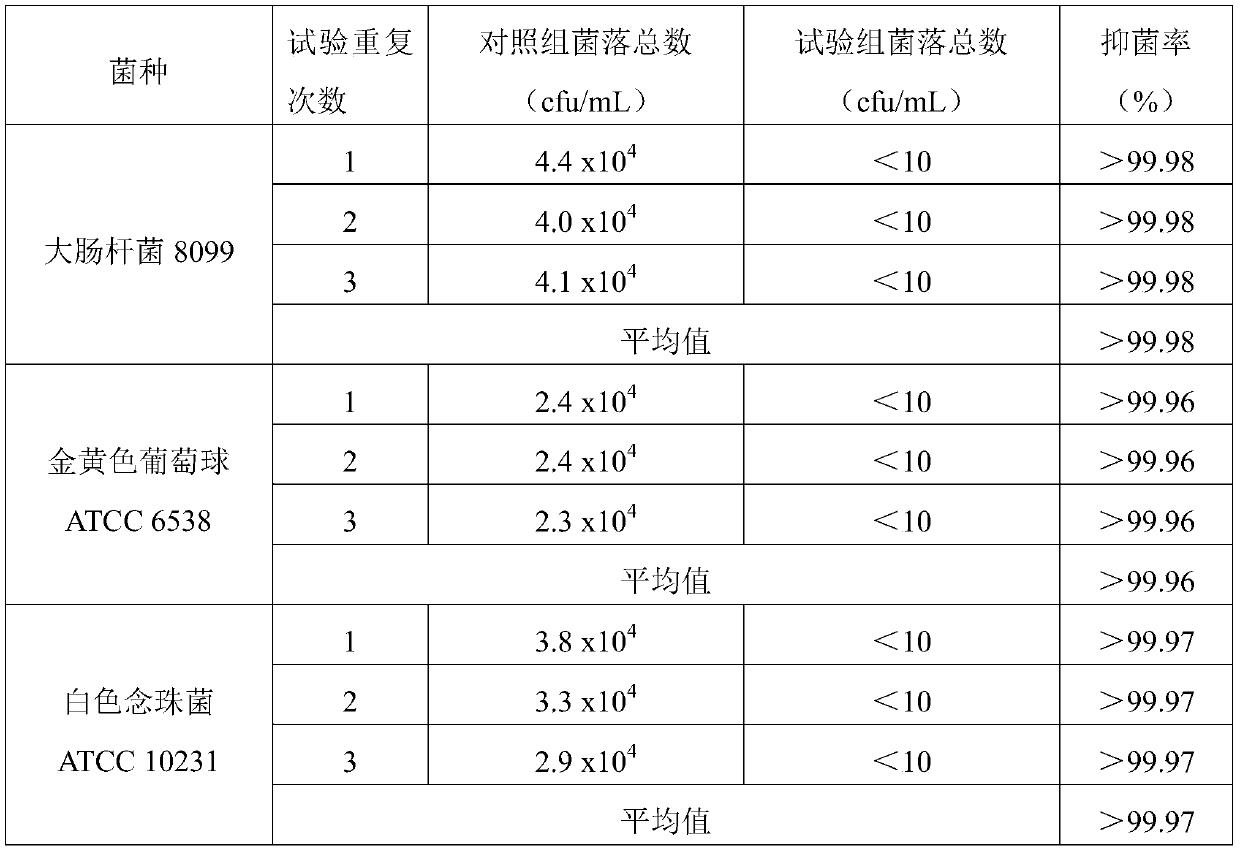

Long-acting antibacterial and virus-killing hygienic protection article spray and application thereof

ActiveCN111226993AImprove breathabilityImprove the efficiency of sand-killing virusBiocideDisinfectantsMethyl palmoxiratePropanediol

The invention belongs to the technical field of antibiosis and disinfection of hygiene protection articles. The invention relates to a spray, and particularly discloses a long-acting antibacterial andvirus-killing hygienic protection article spray and application thereof. The formula of the spray comprises the following components in percentage by silver concentration: 0.01 to 1.0 percent of polyhexamethylene biguanide hydrochloride, 0.001 to 0.1 percent of nano-silver gel, 0.5 to 5 percent of quaternary ammonium salt, 0.0001 to 0.001 percent of melaleuca alternifolia oil, 2 to 15 percent oforganic silicon, 1 to 10 percent of propylene glycol and the balance of water. The spray for the protective articles is lasting in antibacterial effect, the spray is uniformly sprayed on the surfacesof the used sanitary protective articles until the sanitary protective articles are wet, and the sanitary protective articles can be reused after being dried. After the mask treated by the protectivearticle spray is washed with water for three times, the antibacterial rate is kept at 95% or above under the condition of keeping good air permeability.

Owner:SOUTH CHINA UNIV OF TECH +1

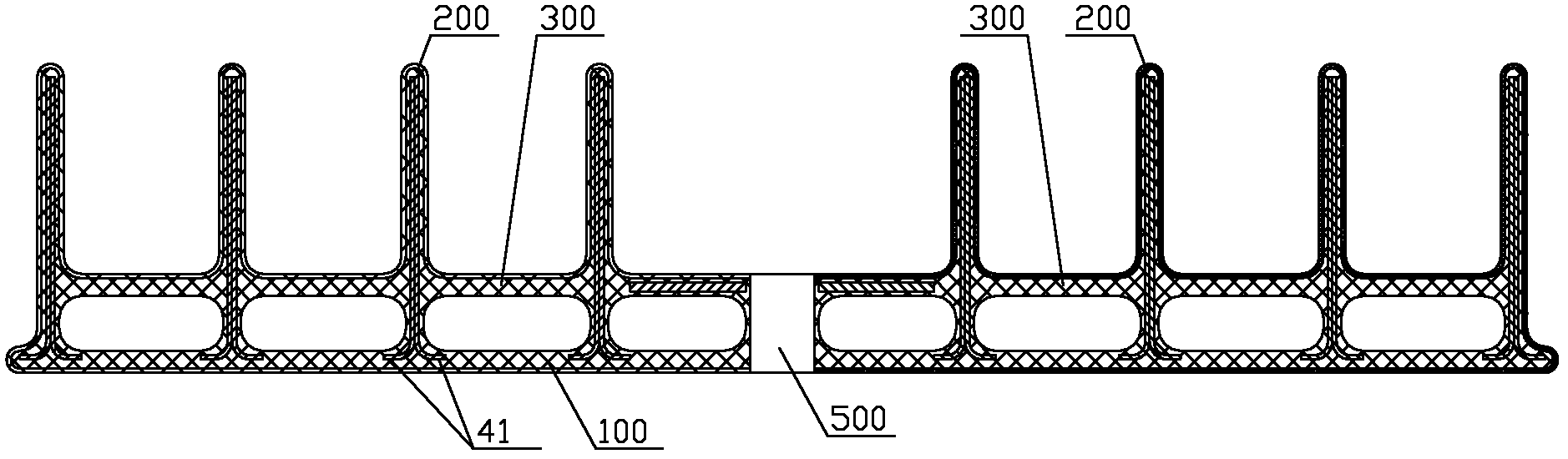

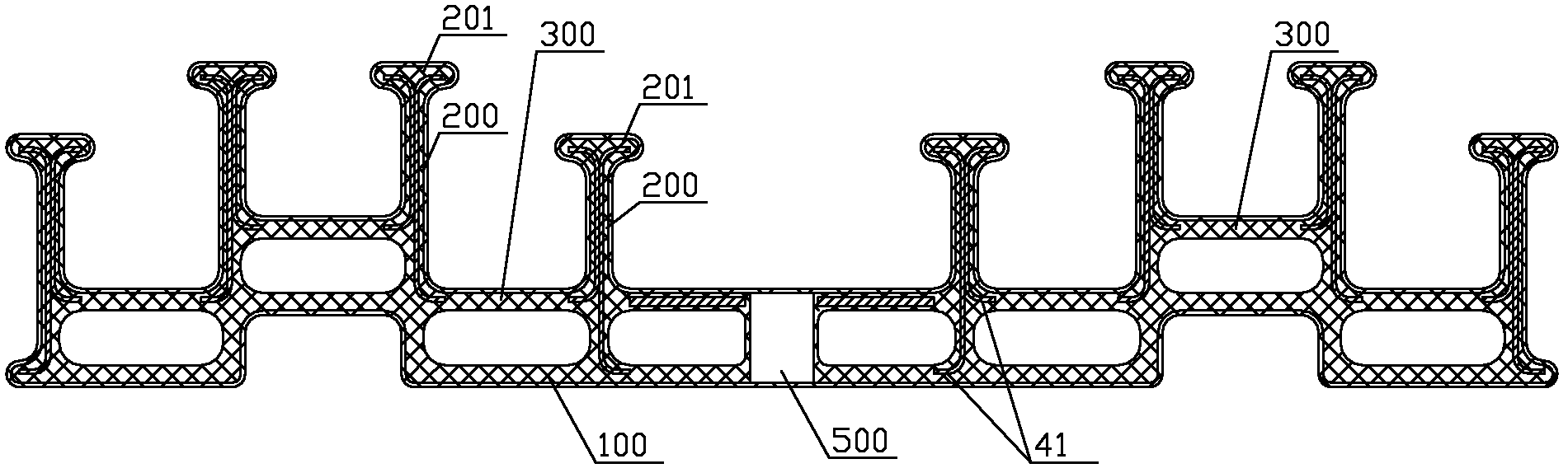

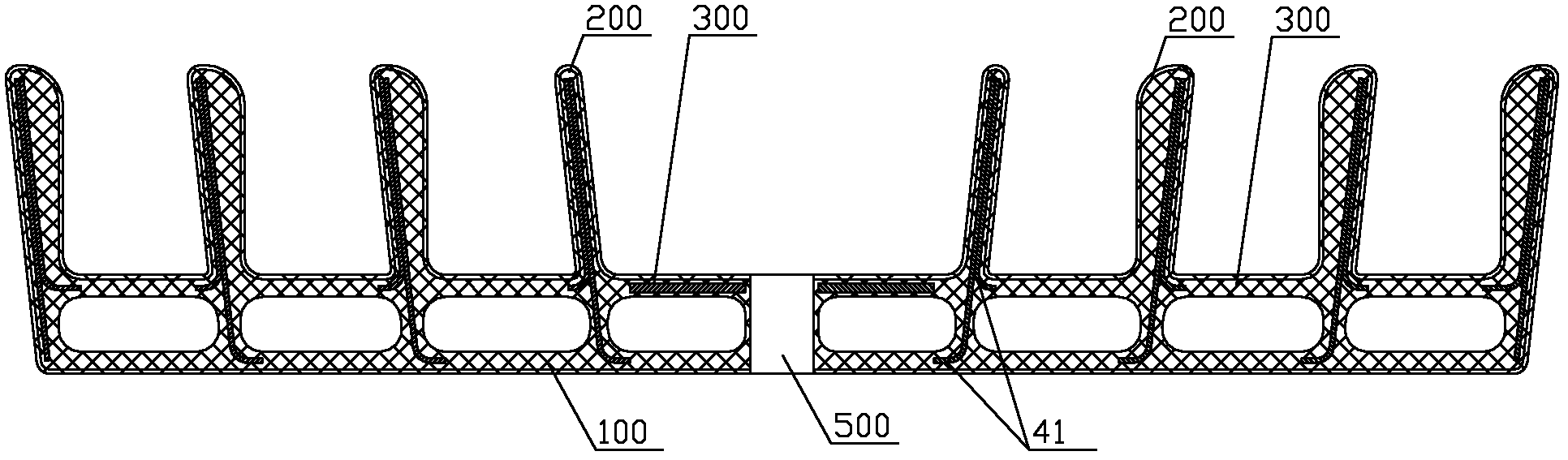

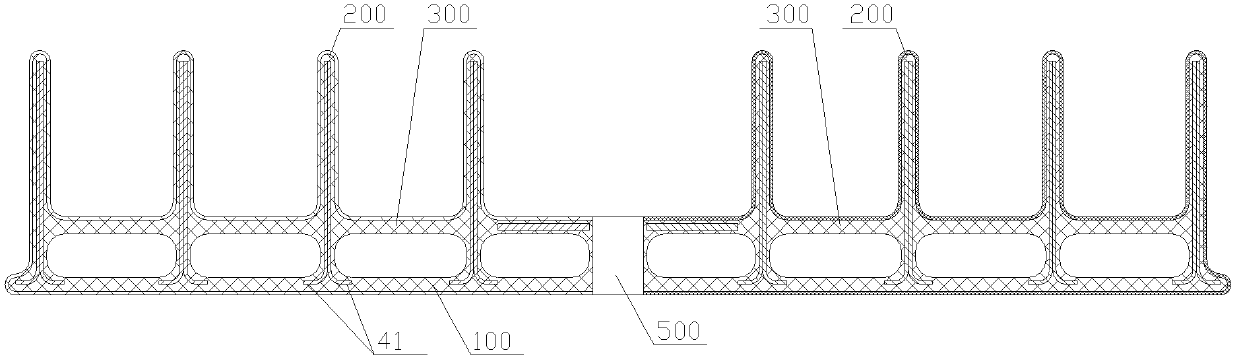

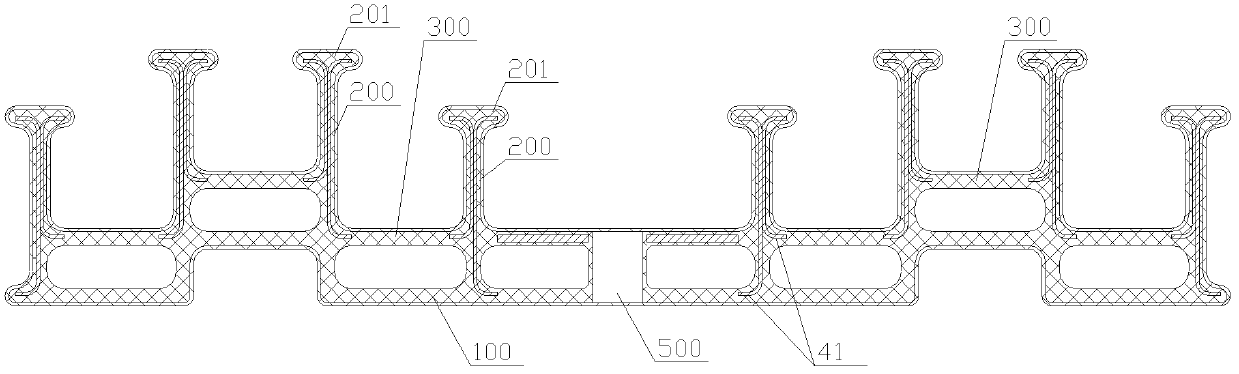

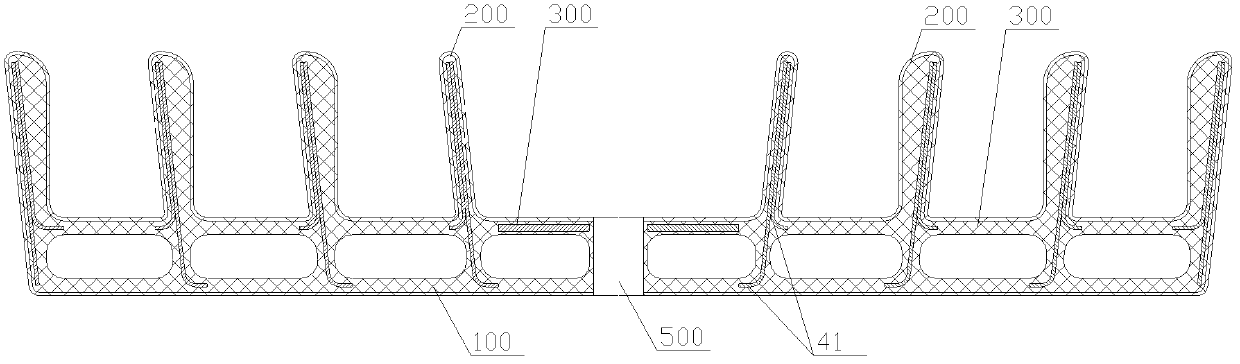

Ribbed guardrail plate

InactiveCN102535367AReduce impact forceGood flexibilitySynthetic resin layered productsMetal layered productsManufacturing technologyEnergy absorption

The invention discloses a ribbed guardrail plate comprising a beam plate, wherein a plurality of rib plates integrated with the beam plate are arranged on the plate face of the beam plate; the beam plate and the rib plates extend in the length direction of the guardrail plate; the beam plate is a thermoplastic composite plate or a thermoplastic material plate; the rib plates are thermoplastic composite plates; and each thermoplastic composite plate comprises a reinforcing frame wrapped in a thermoplastic material layer. Aiming to overcome the defects of high probability of corrosion, high rigidity and poor collision energy absorption of a steel guardrail plate, small elastic modulus, large size and high cost of the all-plastic material of an all-plastic guardrail plate, and complex manufacturing technology and worse collision energy absorption of a plastic-steel guardrail plate, the invention provides the ribbed guardrail plate, which has the advantages of corrosion resistance and lower maintenance difficulty and can excellently absorb collision energy to reduce harm to a vehicle and personnel.

Owner:HUNAN JINHONG TECH CO LTD

Process for producing roof water-proof paint

InactiveCN101113263ANo pollution in the processNo impact resistanceUnspecified rubber coatingsEmulsion paintsEthylenediamineEmulsion

The invention relates to a production process of a roof waterproof coating. 1. 5kg polyvinyl alcohol is taken, 95kg water is added, the temperature is raised to 80 DEG C to be continued to 13min, solution with 5 percent of polyvinyl alcohol is prepared untill the mixture is fully dissolved; 2. crumb rubber is taken to be sieved and about 20kg is reserved; 3. 0.4kg surfactant and 0.6kg diethylenetriamine are added in the material produced in 1 and 2 and evenly stirred to be reserved; 4. the material produced in 1 is evenly stirred with 20kg white emulsion and 0.6kg ethylenediamine to be reserved; 5. 100kg polyether type end NCO prepolymer, 40kg dioctyl phthalate and 5kg PAPI are evenly stirred to be reserved; 6. 50kg material produced in 3 and 20kg material produced in 5 are evenly stirred to produce bottom material; 7. 50kg material produced in 4 and 20kg material produced in 5 are evenly stirred to produce the coating. The invention has the advantages of strong adhesion, impact resistance and aging resistance.

Owner:ZHONGHONG (TIANJIN) IND CO LTD

Down-hole slurry generator

The invention relates to an underground mud generator, the main structure of which is as follows: a turbine is connected to an outer magnetic rotor of a magnetic coupling through a cushion double wallsleeve; an annular groove is arranged in the middle part of the inside wall of the cushion double wall sleeve; a buffer plunger is contained in the annular groove; one of the buffer plunger and the cushion double wall sleeve is a magnet; the center of the buffer plunger is connected to two ends of a stator plunger rod; one end of the stator plunger rod is connected to a seal housing of the generator, while the other end passes through the center of the turbine and is connected to a supporter; an inner magnetic rotor of the magnetic coupling is positioned in an outer magnetic rotor drum of themagnetic coupling, and the both are isolated by the seal housing; the inner magnetic rotor is provided with a necking cavity; one end of a suspended shaft is arranged in the necking cavity, while theother end is connected to the rotor of the generator body; and the seal housing encloses the generator body, the inner magnetic rotor of the magnetic coupling and the suspended shaft. The undergroundmud generator has the advantages of no-sealing, zero leakage and shock proof, and supplies steady electricity for logging-while-drilling instruments underground in a high temperature and high pressure environment.

Owner:BEIJING TIANXING JINGZUAN TECH DEV

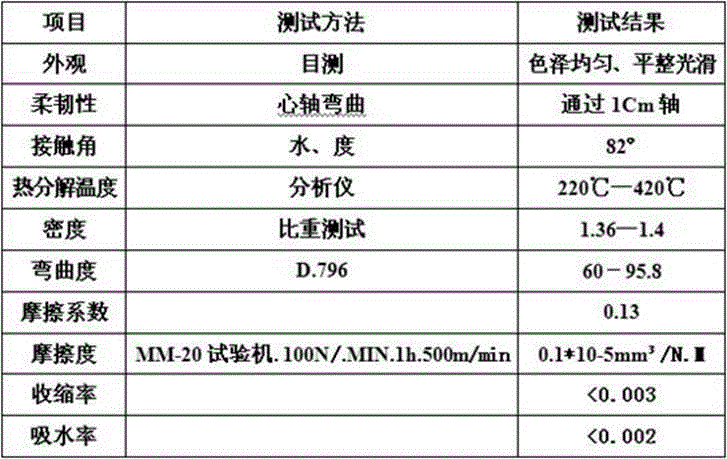

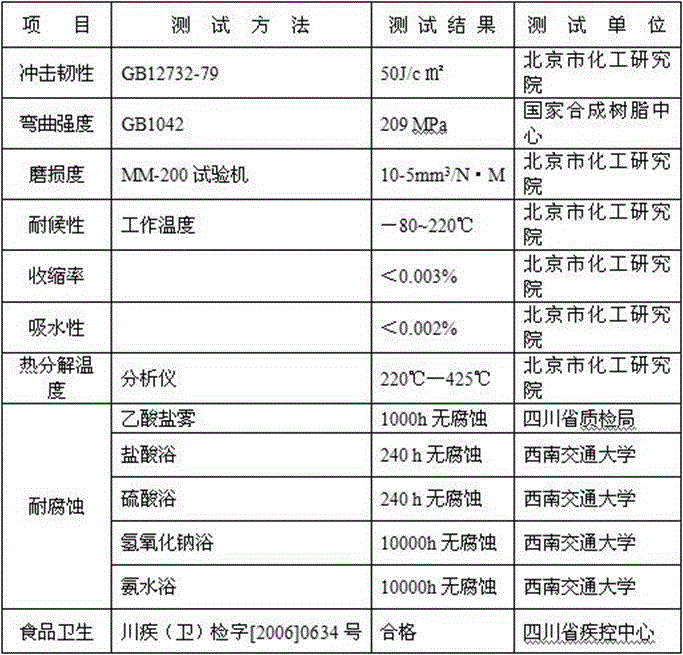

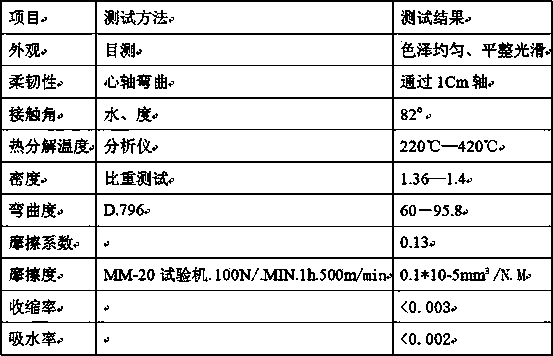

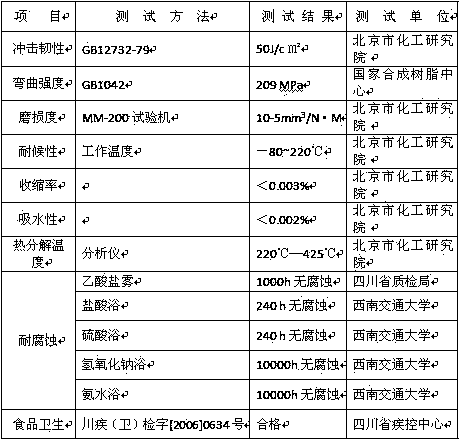

Polymer alloy composite cement water supply pipe and manufacture method thereof

The invention provides a polymer alloy composite cement water supply pipe which sequentially comprises a cement layer, a bonding layer, an interface compatible layer and an overflowing layer from outside to inside. The bonding layer adopts fibers to serve as polyamide modified epoxide resin composite materials of a reinforcing material, the overflowing layer is a resin modified polymer alloy material layer, and the interface compatible layer is a coupling reagent connecting the bonding layer and the overflowing layer. A manufacture method particularly comprises the following steps of prefabricating the cement layer, enabling the fibers to be soaked by liquid state polyamide modified epoxide resin, bonding the fiber on an inner wall of the cement layer, and solidifying for 4 hours at the temperature of 80-100 DEG C or conducting normal temperature solidification for 240 hours; spraying the liquid state polyamide modified epoxide resin on an inner surface of the bonding layer, evenly pasting resin modified polymer alloy material sheets of soaked by the liquid state coupling reagent, and solidifying for 4 hours at the temperature of 100 DEG C or conducting normal temperature solidification for 240 hours. The polymer alloy composite cement water supply pipe has performance such as corrosion resistance, aging resistance, impact resistance, zero poison, innocuity, zero pollution, wear resistance, high strength and the like.

Owner:宋广山 +1

Polymer alloy composite cement water supply pipe and manufacture method thereof

The invention provides a polymer alloy composite cement water supply pipe which sequentially comprises a cement layer, a bonding layer, an interface compatible layer and an overflowing layer from outside to inside. The bonding layer adopts fibers to serve as polyamide modified epoxide resin composite materials of a reinforcing material, the overflowing layer is a resin modified polymer alloy material layer, and the interface compatible layer is a coupling reagent connecting the bonding layer and the overflowing layer. A manufacture method particularly comprises the following steps of prefabricating the cement layer, enabling the fibers to be soaked by liquid state polyamide modified epoxide resin, bonding the fiber on an inner wall of the cement layer, and solidifying for 4 hours at the temperature of 80-100 DEG C or conducting normal temperature solidification for 240 hours; spraying the liquid state polyamide modified epoxide resin on an inner surface of the bonding layer, evenly pasting resin modified polymer alloy material sheets of soaked by the liquid state coupling reagent, and solidifying for 4 hours at the temperature of 100 DEG C or conducting normal temperature solidification for 240 hours. The polymer alloy composite cement water supply pipe has performance such as corrosion resistance, aging resistance, impact resistance, zero poison, innocuity, zero pollution, wear resistance, high strength and the like.

Owner:宋广山 +1

LED light modulation apparatus suitable for controlled silicon dimmer

InactiveCN101404844BBrightness adjustableSolution to short lifeElectric light circuit arrangementElectric variable regulationLoad circuitSilicon-controlled rectifier

Owner:CIVILIGHT SHENZHEN SEMICON LIGHTING

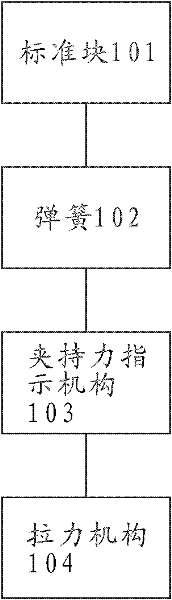

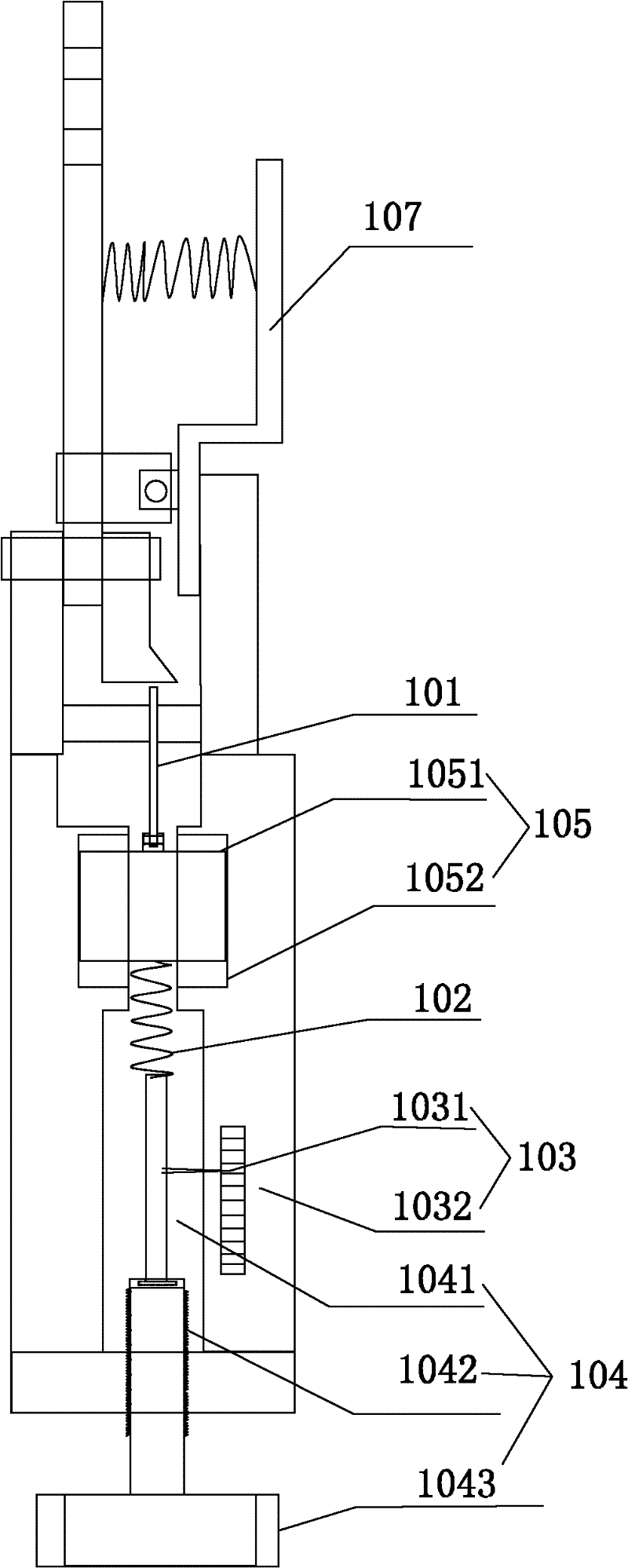

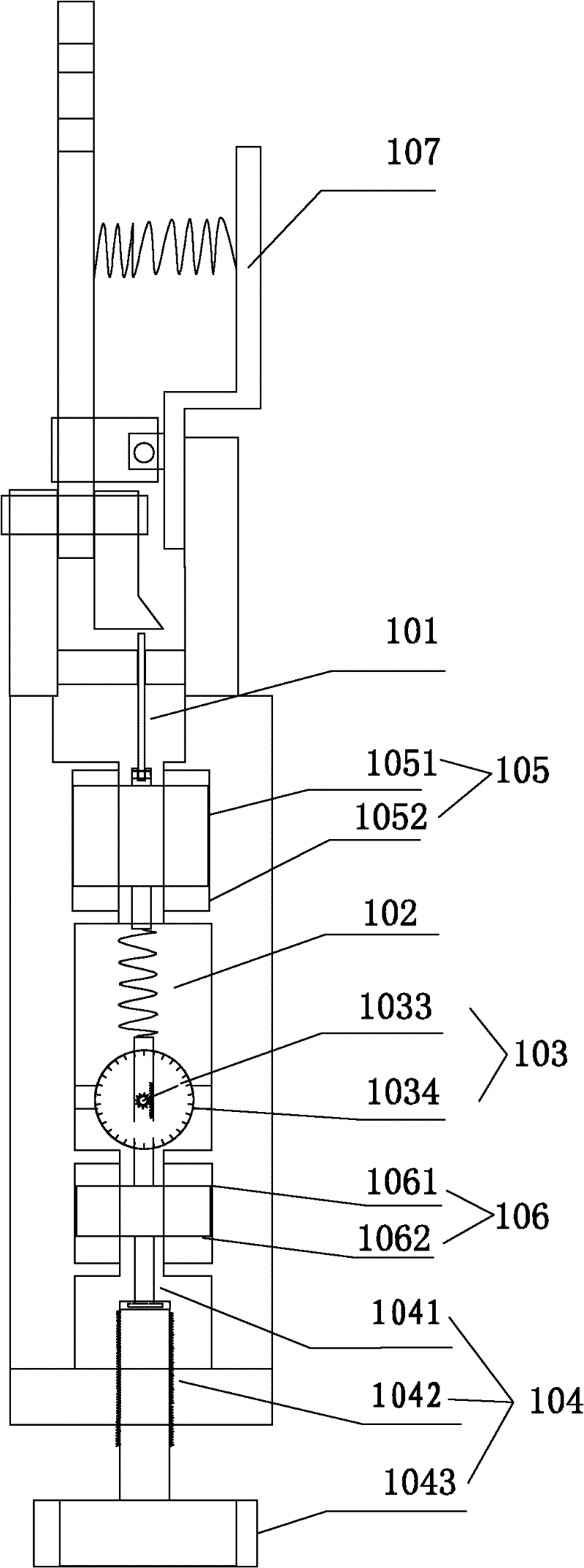

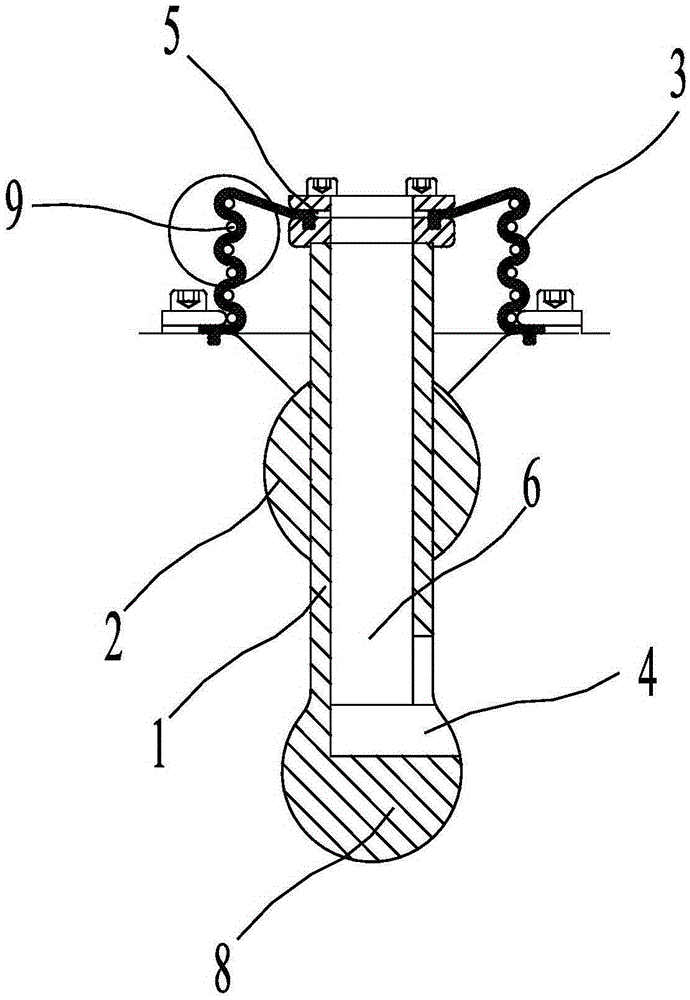

Clamping force measuring instrument and clamping force measuring method

ActiveCN102183321BAccurate measurementNo impact resistanceForce measurement by elastic gauge deformationPull forceMeasuring instrument

The invention discloses a clamping force measuring instrument and a clamping force measuring method, which are used for measuring clamping force of a clamp. The clamping force measuring instrument comprises a replaceable standard block, a spring, a clamping force indicating mechanism and a tension mechanism, wherein the standard block is suitable to be clamped by different clamps; the clamping force indicating mechanism is used for displaying magnitude of the clamping force; the tension mechanism is used for producing tension; the standard block is fixedly connected with the spring; the spring is fixedly connected with the clamping force indicating mechanism; the clamping force indicating mechanism is fixedly connected with the tension mechanism; and an indicated numerical value of the clamping force indicating mechanism is directly proportional to deformation of the spring. The invention provides a pure mechanical clamping force measuring instrument; force for pulling the standard block which is clamped in the clamp out is produced through the tension mechanism; the tension produced by the tension mechanism is intuitively indicated in the indicating mechanism through the deformation of the spring; an accurate measuring result of the clamping force of the clamp is achieved; and the instrument and the method are suitable for maintaining various clamps in a printed circuit board(PCB) industry.

Owner:SHENNAN CIRCUITS

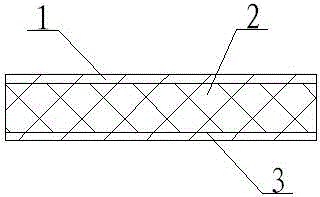

A preparation method for a new type of marine cold storage composite plate

The invention relates to a method for preparing a novel cold storage installation composite board for ships. The method comprises the following steps: manufacturing an upper protective layer and a lower base material layer according to the dimension of the composite board, heating and mixing an expandable modified phenolic resin, a surfactant, a foaming agent, a curing agent and an auxiliary at the temperature of 25-60 DEG C, spraying the mixture between the upper protective layer and the lower base material layer through a high-pressure spray gun, emulsifying, forming and holding the temperature for 24 hours through equipment of a continuous production line, and demoulding, thereby obtaining the composite tube, wherein the mass ratio of expandable modified phenolic resin to the surfactant to the foaming agent to the curing agent to the auxiliary is 100:4:5:25:5; the surfactant is a general surfactant of silicane and tween series; the foaming agent is a NaCO or metal powder general solid foaming agent; the curing agent is hydrochloric acid or sulfuric acid or phosphoric acid; the auxiliary is boracic acid or urea or antimony oxide.

Owner:JIANGSU HENGSHENGDA ENVIRONMENTAL PROTECTION SCI & TECH

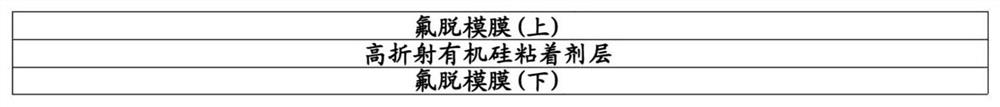

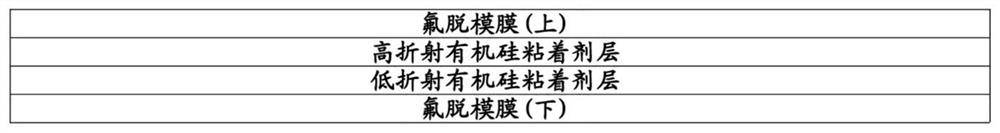

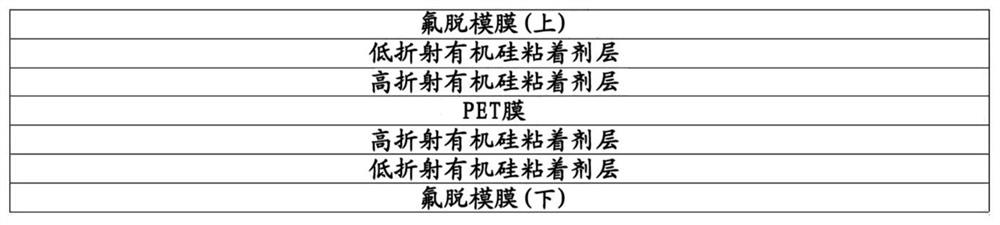

Silicone adhesive, silicone film and backlight unit

PendingCN114672280AImprove heat resistanceHigh transparencyFilm/foil adhesive release linersIdentification meansOrganosiliconSolvent free

The present invention provides a highly functional silicone adhesive, a silicone film, and a backlight unit, and more particularly, to a functional silicone adhesive which has high transparency, high heat resistance, low reflectance, vibration resistance, no yellowing, impact resistance, and high adhesion of 3,000 gf / inch or more, can be used in a solvent-free manner, and can be used in a non-solvent manner. The present invention relates to an adhesive composition which exhibits uniform and excellent adhesion even when the thickness is 500 [mu] m or more, facilitates both-side adhesion, has a high refractive index of 1.5 or more, facilitates functional lamination with a high adhesion equal to or greater than that of acrylic or urethane when formed into a film, and has high visibility characteristics at the same time.

Owner:湖南宇矿融合科技有限公司 +5

Thyristor phase-selecting switch experiment device

ActiveCN1971298BReduce volumeReduce weightElectrical testingElectronic switchingSignal processing circuitsThyratron

The invention relates to a thyristor phase switch testing device, the comprehensive microprocessor and thyristor technique are used in the device; the projection angle of switch is operated by the drive pulse phase of the thyristor. The device includes: host CPU, acquisition circuit of input-output signal, switch power supply, input-output interface, touching screen communication, upper machine communication, CPLD signal processing circuit, thyristor trigger circuit, power return circuit and thyristor; the electrical signal transitive relation is: the thyristor trigger circuit triggers the thyristor, the signal is transmitted to the acquisition circuit, processed by the host CPU, and separately transmitted to the touching screen communication, the upper machine communication and the input-output interface, the CPLD signal processing circuit and switch power supply provide power for the host CPU, thyristor and power return circuit, and the signal is output.

Owner:SHANGHAI ELECTRICAL APPLIANCES RES INSTGROUP

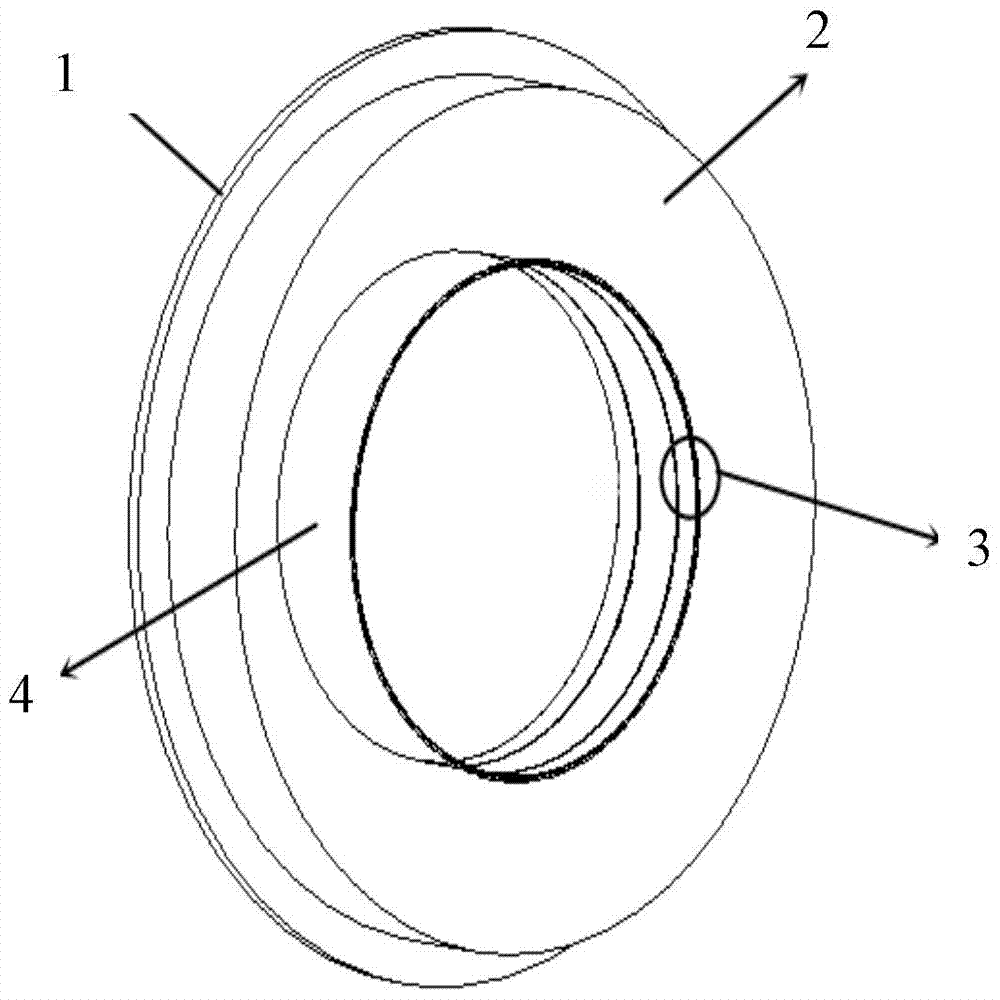

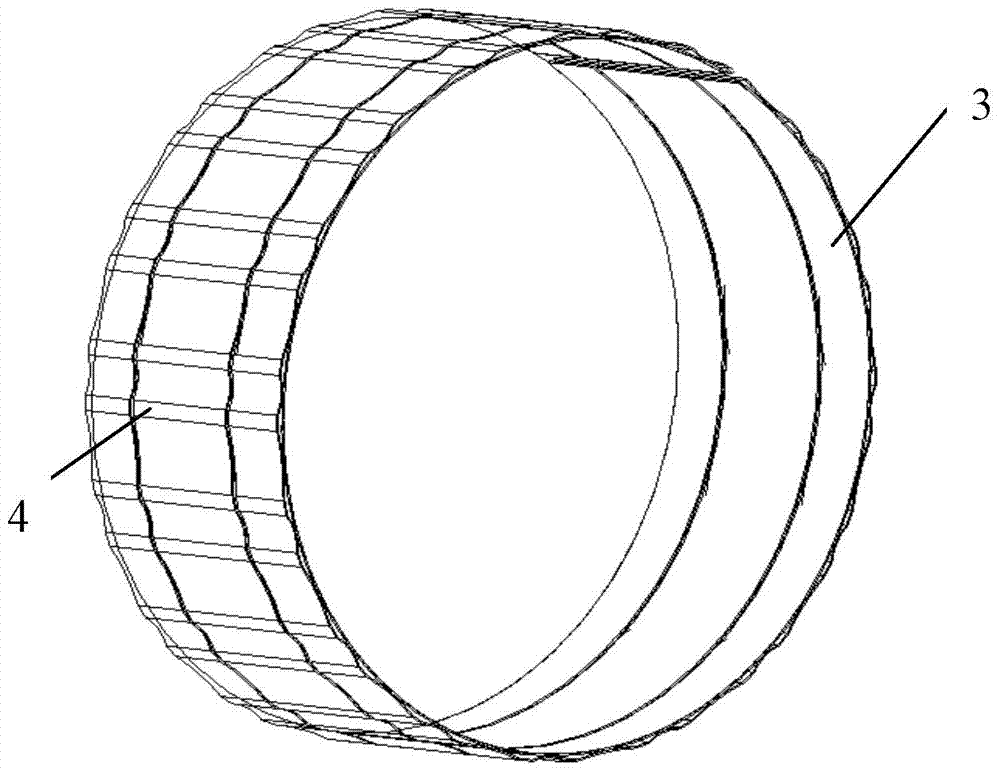

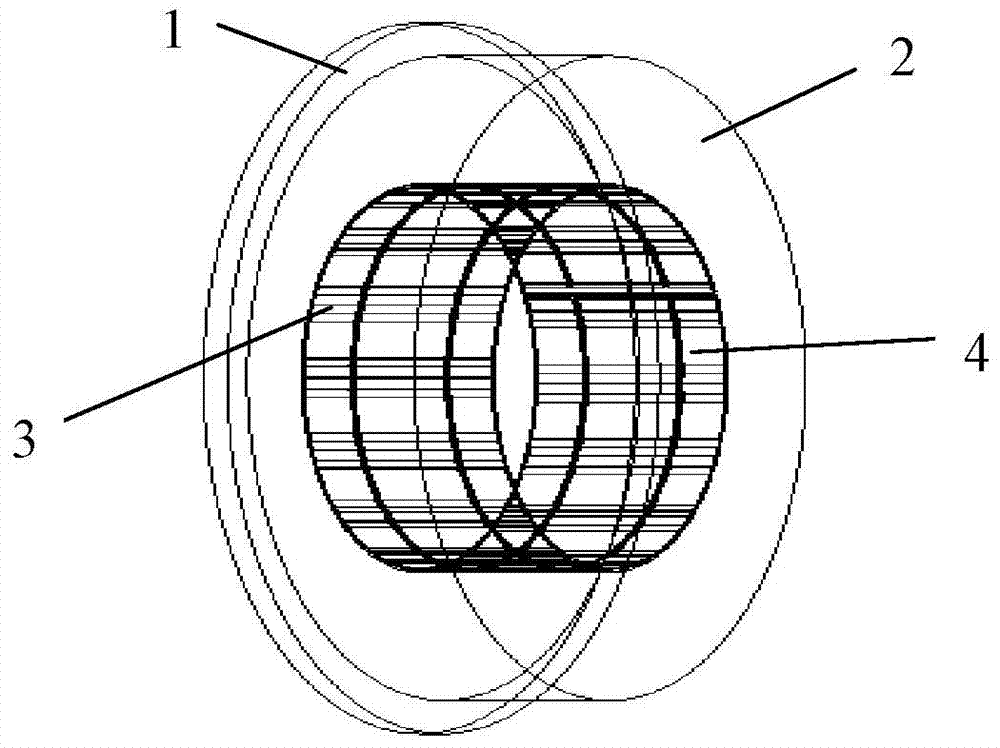

A corrugated foil type air dynamic pressure bearing

A corrugated foil type air dynamic pressure bearing. It includes a shoulder, a bearing shell, a flat foil and multiple corrugated foils; the shoulder is formed by extending radially outward from one end edge of the bearing shell; multiple flat foils are arranged side by side, and two adjacent flat foils The side edges overlap each other; the corrugated foils are provided with two kinds of corrugations alternately arranged with different radii of curvature, one side is attached to the outer surface of all flat foils, and the other side is fixed on the inner circumferential surface of the bearing housing On the top, one end of the flat foil and multiple corrugated foils is fixed on the inner circumferential surface of the bearing housing at the same time, and the other end is a free end. The invention can replace the ball bearings on small commercial aircraft, reduce the weight of the engine, and can replace the traditional lubricating oil lubrication with gas lubrication. When the engine is in the working state, because the upper wedge gap is small and the dynamic pressure effect is strong, it can provide The bearing capacity is equivalent to the rigid surface gas dynamic pressure bearing, which can greatly reduce the friction force, resistance and vibration of the bearing, and increase the working stability of the engine.

Owner:CIVIL AVIATION UNIV OF CHINA

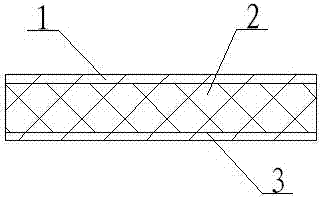

Ribbed guardrail plate

InactiveCN102535367BReduce impact forceGood flexibilitySynthetic resin layered productsMetal layered productsEngineeringThermoplastic composites

A rib-shaped guiderail panel comprising a beam panel (100) and a rib panel (200). The rib panel (200) is arranged on a panel face of the beam panel (100) and is arranged integrally with the beam panel (100). The beam panel (100) and the rib panel (200) extend along the lengthwise direction of the guiderail panel. The beam panel (100) is a thermoplastic composite panel or a thermoplastic material panel. The rib panel (200) is a thermoplastic composite panel. The thermoplastic composite panel comprises a reinforced skeleton (4), while the reinforced skeleton (4) is covered thereout with a thermoplastic material layer. The rib-shaped guiderail panel is corrosion-resistant, has a simplified manufacturing process, and ensures vehicle and personnel safety by adsorbing impact energies.

Owner:HUNAN JINHONG TECH CO LTD

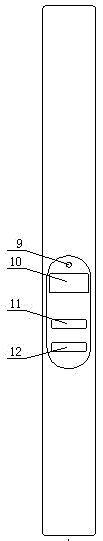

led ultraviolet sterilization stick

InactiveCN103353719BNo noiseNo impact resistanceProgramme control in sequence/logic controllersLithiumLiquid-crystal display

The invention discloses an LED ultraviolet sterilization rod which comprises a housing, at least one ultraviolet LED light source, a light source circuit board, a light source constant current source, a control circuit, a control circuit board, a time controller, a charging lithium cell, a charging controller, a work indicating lamp, a liquid crystal display, a time control switch, a pause / switch, a front cover and a DC charger jack. The front cover, the light source circuit board, the control circuit board, the charging lithium cell and the charging controller are sequentially installed on the housing from top to bottom. The ultraviolet LED light source and the light source constant current source are disposed on the light source circuit board, wherein the light source constant current source is arranged on one side of the ultraviolet LED light source. The control circuit, the time controller, the work indicating lamp, the liquid crystal display, the time control switch and the pause / switch are sequentially arranged on the control circuit board from top to bottom. The DC charger jack is disposed in the charging controller. The beneficial effects are that the LED ultraviolet sterilization rod generates no noise, is high in stability, safe, environmentally friendly and energy-saving, and is suitable for use on all occasions.

Owner:DALIAN ZHONGSHENG ZIGUANG TECH

Combined non-spill drain baffle

InactiveCN103615390BImprove inhalation performanceEliminates momentary backflowOscillating piston pumpsOscillating piston liquid enginesEngineering

Owner:ZHEJIANG UNIV

Ultra-high molecular weight polyethylene pipe and modified additive for producing same

The invention provides an ultra-high molecular weight polyethylene pipe and a modified additive for producing the same, belongs to the technical field of pipe production, and aims to solve the technical problems that the molecular weight of the produced ultra-high molecular weight polyethylene pipe is reduced, abrasion resistance, impact resistance, lubrication, impact absorption and the like of the produced ultra-high molecular weight polyethylene pipe do not reach indexes and the like as common polyethylene powder is added when an ultra-high molecular weight polyethylene pipe is produced in the current. The modified additive is prepared from, by weight, 600-800 parts of bright lubrication dispersing agents, 100-200 parts of stearic acid, 100-200 parts of ultra-high molecular polysiloxane, 90-150 parts of zinc stearate, 80-150 parts of calcium stearate and 50-150 parts of antioxidants. The ultra-high molecular weight polyethylene pipe prepared by the modified additive is prepared from, by weight, 30-50 parts of ultra-high molecular weight polyethylene, 1-2 parts of macromolecule wax and 0.8-1.5 parts of modified additive for producing the ultra-high molecular weight polyethylene pipe.

Owner:山西华星管业科技有限公司

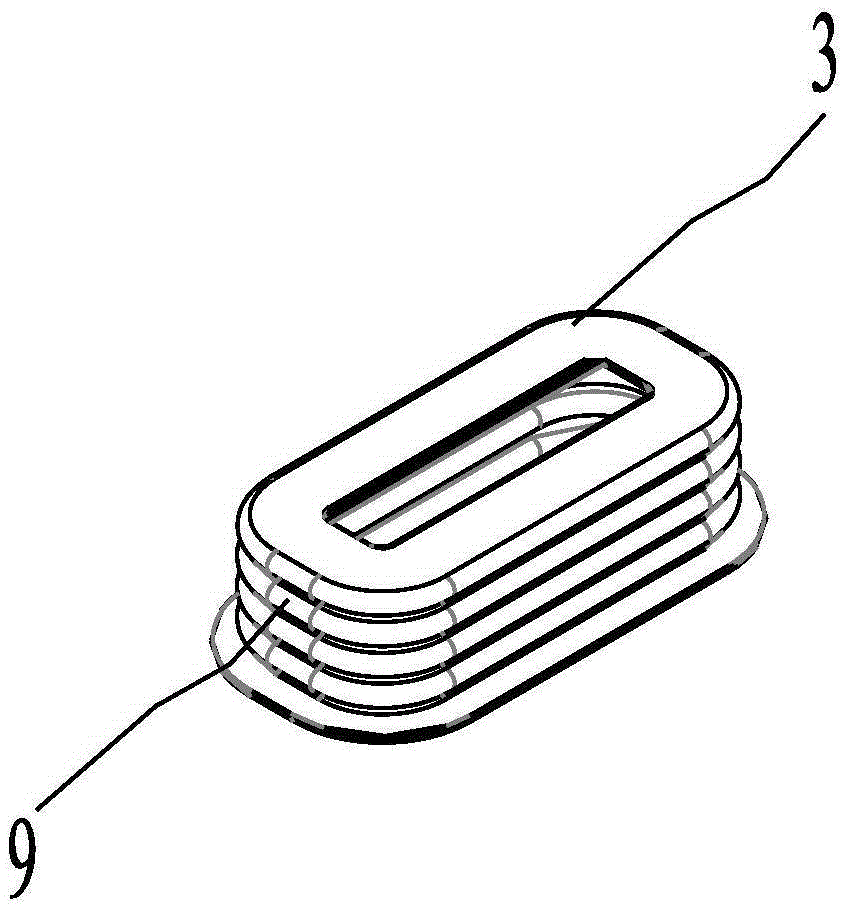

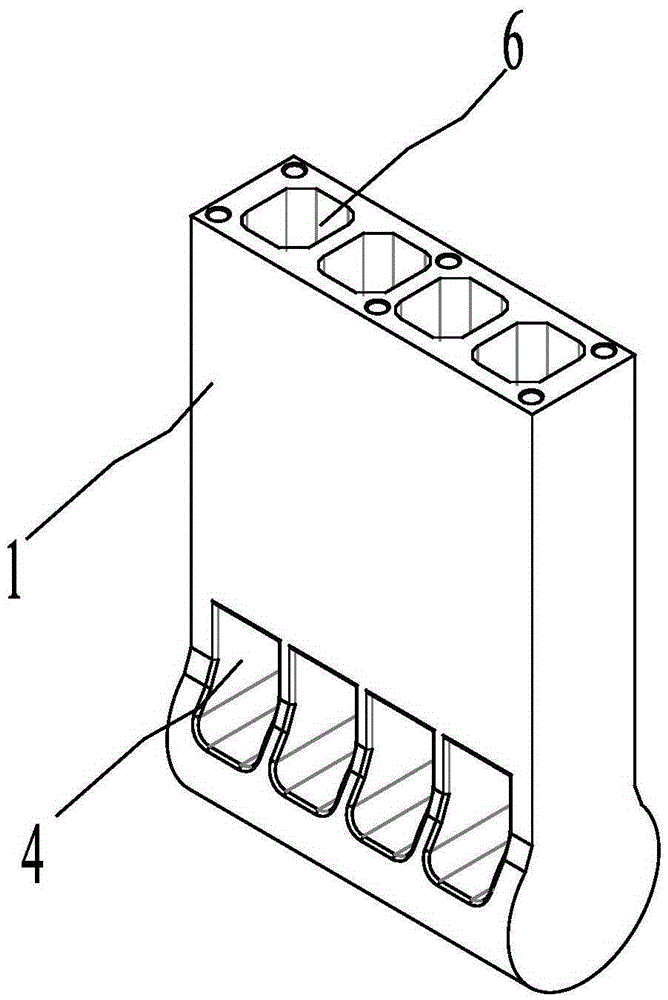

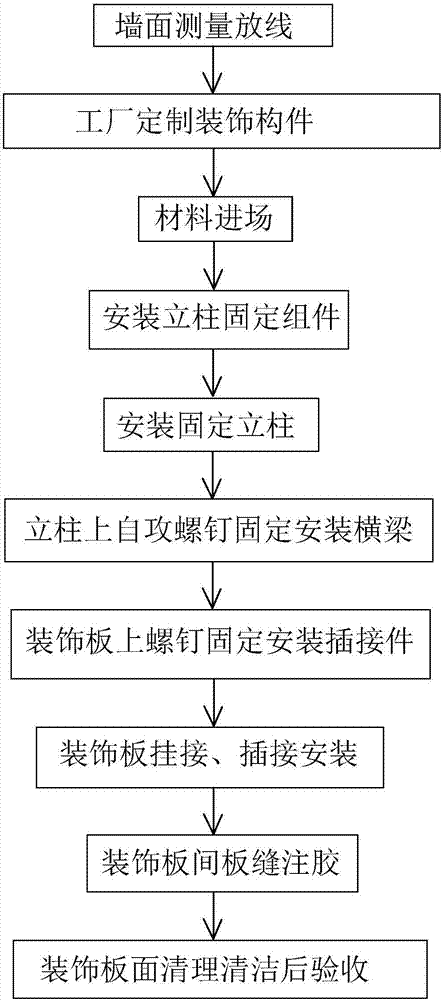

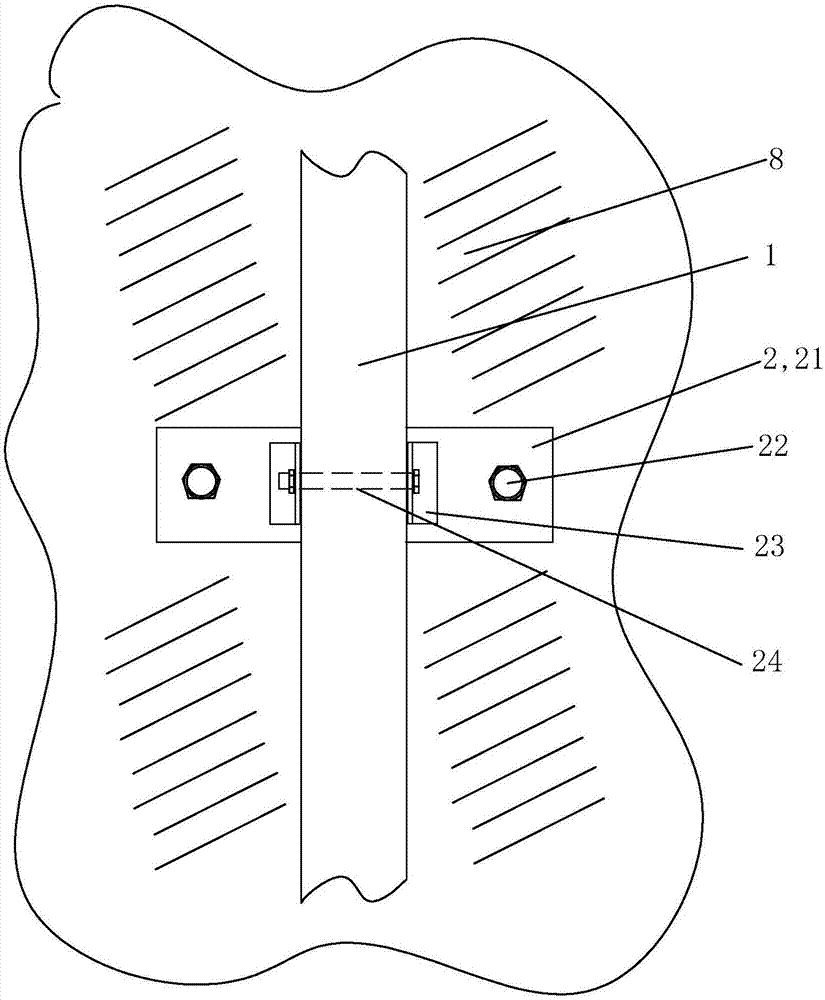

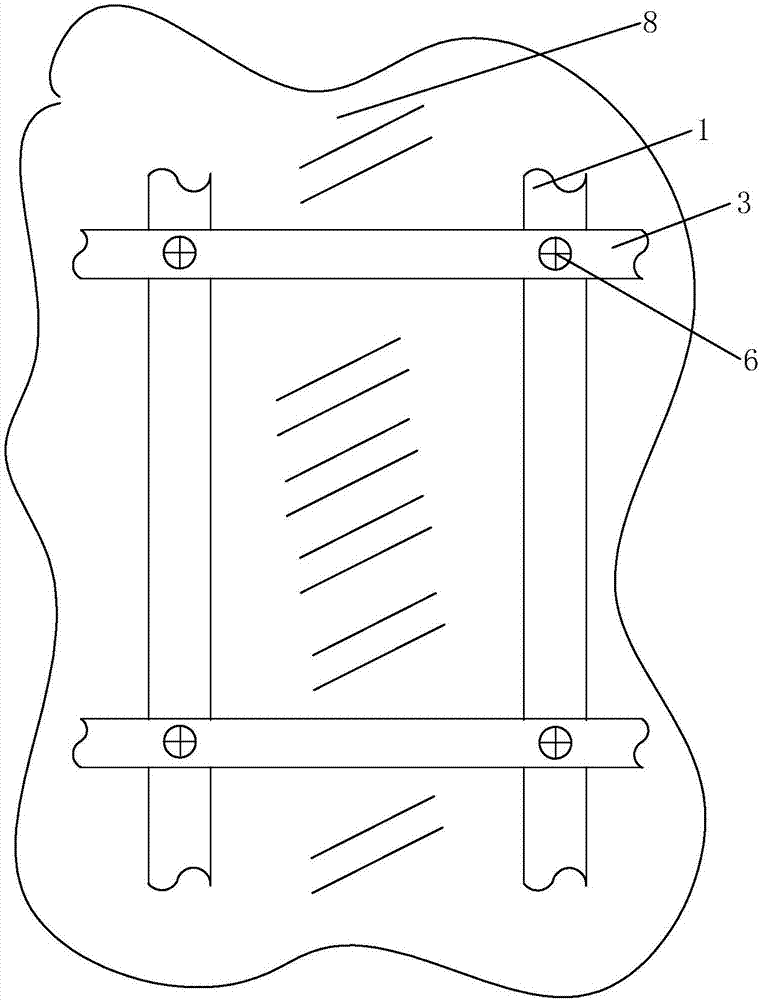

Cutting-free inserting-connection-type mounting construction method of wall surface decoration boards

ActiveCN107989381AHas radiationDirt-resistantBuilding material handlingConnection typeSurface measurement

The invention provides a cutting-free inserting-connection-type mounting construction method of wall surface decoration boards. The cutting-free inserting-connection-type mounting construction methodmainly adopts vertical columns, vertical column mounting assemblies, cross beams, the decoration boards, Z-shaped inserting-connection pieces, tapping screws and screws to implement, the cutting-freeinserting-connection-type mounting construction method comprises the steps that (1) wall surface measurement and paying off are conducted, and a mounting construction scheme is determined; (2) components required by decoration is custom-made at a factory; (3) materials are transported to a site; (4) vertical column fixing assemblies are mounted; (5) the vertical columns are mounted and fixed; (6)the cross beams are mounted and fixed; (7) the Z-shaped inserting-connection pieces are fixedly arranged on the decoration boards; (8) the decoration boards are mounted in inserted-connection and hung-connection modes; (9) glue are injected into board seams; and (10) clearing and cleaning of the decoration board surfaces and acceptance are conducted. According to the cutting-free inserting-connection-type mounting construction method of the wall surface decoration boards, the decoration boards are mounted by utilizing the inserting-connection pieces, site cutting-free operation is achieved, noise and dust pollution are less, construction is simple, convenient and fast, cost performance is high, and the used materials during secondary decoration can be recycled.

Owner:CHANGZHOU NO 1 CONSTR GRP

Method for preparing novel cold storage installation composite board for ships

The invention relates to a method for preparing a novel cold storage installation composite board for ships. The method comprises the following steps: manufacturing an upper protective layer and a lower base material layer according to the dimension of the composite board, heating and mixing an expandable modified phenolic resin, a surfactant, a foaming agent, a curing agent and an auxiliary at the temperature of 25-60 DEG C, spraying the mixture between the upper protective layer and the lower base material layer through a high-pressure spray gun, emulsifying, forming and holding the temperature for 24 hours through equipment of a continuous production line, and demoulding, thereby obtaining the composite tube, wherein the mass ratio of expandable modified phenolic resin to the surfactant to the foaming agent to the curing agent to the auxiliary is 100:4:5:25:5; the surfactant is a general surfactant of silicane and tween series; the foaming agent is a NaCO or metal powder general solid foaming agent; the curing agent is hydrochloric acid or sulfuric acid or phosphoric acid; the auxiliary is boracic acid or urea or antimony oxide.

Owner:JIANGSU HENGSHENGDA ENVIRONMENTAL PROTECTION SCI & TECH

Method for machining yoga mat

InactiveCN106273878AHigh affinityIncreased durabilityLamination ancillary operationsPolyureas/polyurethane adhesivesFiberMaterials science

The invention discloses a method for machining a yoga mat, relating to the technical field of sports goods. The method mainly comprises the following steps: (1) taking a cork wood coiled material or leather as a core layer and carrying out dust removing and heating treatment on the core layer; (2) coating the upper surface of the core material with an environment-friendly adhesive layer; (3) selecting ultrafine fibers, soft cow leather or PU leather as a surface material layer, and carrying out heating treatment on the core layer; applying the weight of 0.3kg / cm<3> to 2.0kg / cm<3> and sticking and compounding the surface material layer, the adhesive layer and the core layer; (4) coating the surface of the surface material layer with a wear-resisting layer; and (5) repeating the step (1) to the step (4), and sequentially forming the adhesive layer, the surface material layer and the wear-resisting layer on the lower surface of the core material, so as to prepare the yoga mat which has high air permeability, high strength and high environmental friendliness.

Owner:苏州市新南湾材料科技有限公司

Composition brake shoe for railway freight car, and method for manufacturing same

The invention discloses a composition brake shoe for a railway freight car, and a method for manufacturing the same. A friction piece of the composition brake shoe for the railway freight car is synthetised by using following materials by weight parts: 6-10 parts of nitrile rubber, 2-8 parts of modified phenolic resin, 3-6 parts of steel wool fibers, 9-16 parts of sepiolite fibers, 2-16 parts of composite mineral fibers, 5-13 parts of graphite, 0.4-2 parts of calcined bauxite, 20-24 parts of barium sulfate, 8-12 parts of potassium feldspar powder, 10-20 parts of iron powder, and 1-3 parts of additives. The friction piece of the composition brake shoe is formed through the steps of dosing, banburying or mixing, crashing, hot press molding and curing forming, and thermal processing. The composition brake shoe is capable of well satisfying various performance indexes requested in PRC (People's Republic of China) railway industrial standard TB / T2403-2010, and can be applied to railway freight cars traveling at the highest speed of 120km / h and axle load of the composition brake shoe is not greater than 25 tons; besides, the composition brake shoe has stable friction properties and excellent friction resistance, and is low in attrition to wheels and low in braking noise; and as a result, potential quality hazards ( such as brake shoe body breakage, slag and block dropping, metal inlaying and hot cracks) endangering traveling safety are fundamentally solved.

Owner:CHONGQING YUHONG RAIL CAR ACCESSORIES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com