Ribbed guardrail plate

A technology for guardrails and ribs, which is applied to layered products, buildings, and metal layered products. It can solve problems such as poor impact energy absorption, easy corrosion, and small elastic modulus of all-plastic materials, and achieve overall strength improvement. The effect of prolonging the contact time and reducing the impact peak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

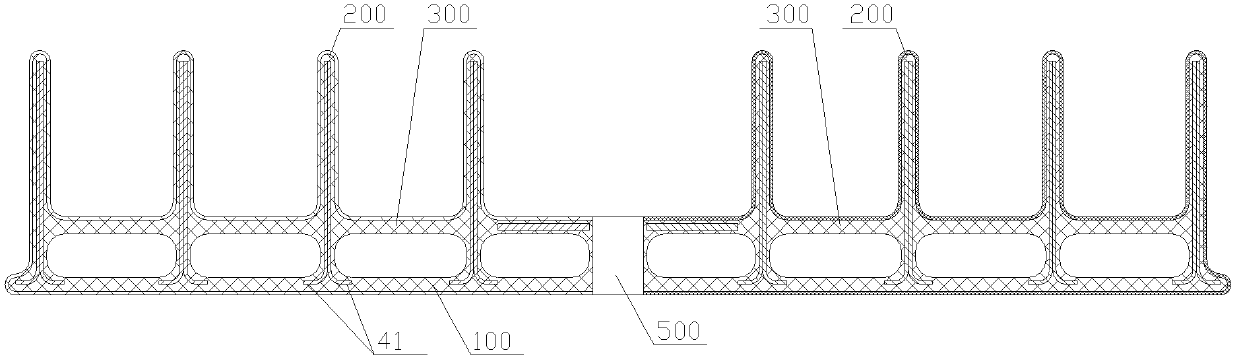

[0077] Embodiment 1, as figure 1 In the shown guardrail board, the beam plate 100 is a flat thermoplastic material plate, and a plurality of installation holes 500 are spaced apart on the central axis of the beam plate 100. Eight rib plates 200 are arranged in parallel longitudinally along the beam plate 100, two of which are It is arranged on the edges of both sides of the beam slab 100, and the others are evenly distributed in the direction of the center of the beam slab 100, and the eight ribs 200 are symmetrical about the longitudinal central axis of the beam slab 100, and connecting ribs 300 are respectively arranged between adjacent ribs 200 , the connecting rib 300 is a plate structure, and connects the adjacent ribs 200 from the beginning to the end. The connecting ribs 300 are perpendicular or substantially perpendicular to the ribs 200 , and the positions of the connecting ribs 300 are the same, they are all close to the beam slab 100 , about one-third of the ribs 20...

Embodiment 2

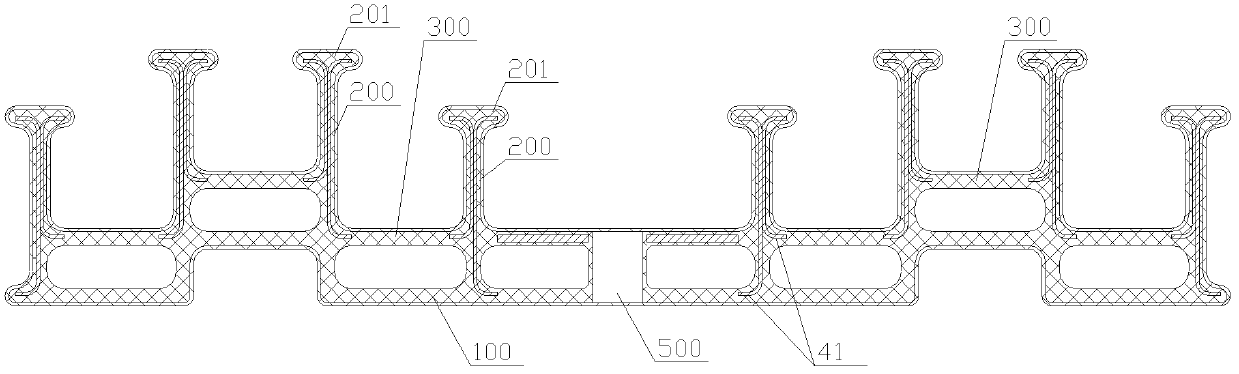

[0078] Embodiment 2, as figure 2 The guardrail shown is an improvement made on the basis of Embodiment 1, wherein the beam plate 100 is a special-shaped plate obtained by bending a flat plate, and two square ribs are formed along the longitudinal direction, among which there are four ribs 200 located on the convex side. The edges of the ribs, two of which are located at the edge of the beam slab 100. A flange is provided on the top of the rib 200 . The flanges extend to both sides of the rib 200 and are parallel to the beam 100 . The cross-section of the rib 200 forms a T-shaped structure. Both sides of the reinforcing frame 4 are provided with flanges that are folded to both sides respectively, the flanges of the reinforcing frame 4 at the top of the rib plate 200 are respectively arranged on both sides of the flange, and the flanges of the reinforcing frame 4 at the bottom of the rib plate 200 Fold into the beam panels 100 on both sides respectively. The rest of the struc...

Embodiment 3

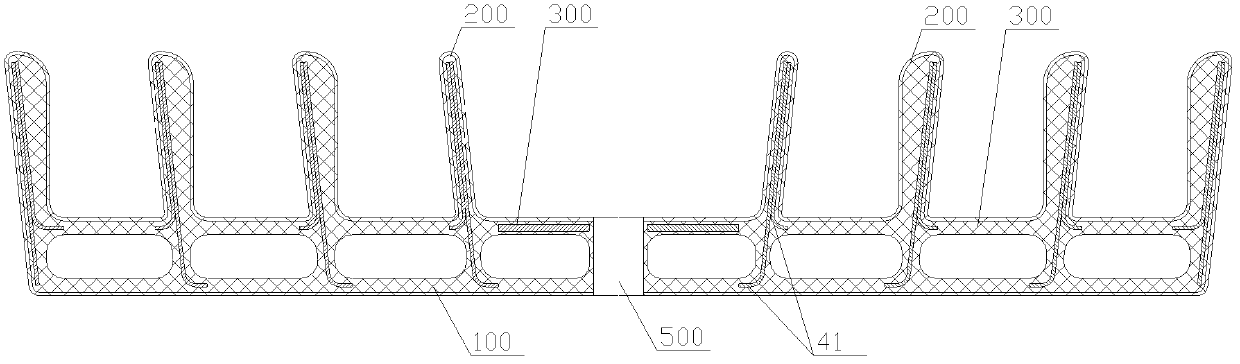

[0079] Embodiment 3, as image 3 The shown guardrail is an improvement on the basis of Example 1, the beam 100 remains unchanged, and the ribs 200 are respectively inclined to the two sides of the beam 100, and the inclination angle is 70-85°. Among them, the ribs 200 The section is wedge-shaped, and the thickness of the top of the wedge is greater than that of the bottom. The thickened and raised top is conducive to buffering and absorbing energy; adjusting the length of the flange of the reinforced skeleton, as well as the number and position of the connecting ribs 300 can adjust the flexibility of the guardrail. Good for cushioning under different protection levels. The rest of the structure is the same as that of Embodiment 1 and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com