Composition brake shoe for railway freight car, and method for manufacturing same

A technology for synthesizing brake shoes and trucks, applied in the field of brake pad materials, to achieve the effects of high bonding strength, no smoke and dust noise, and safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in combination with specific embodiments.

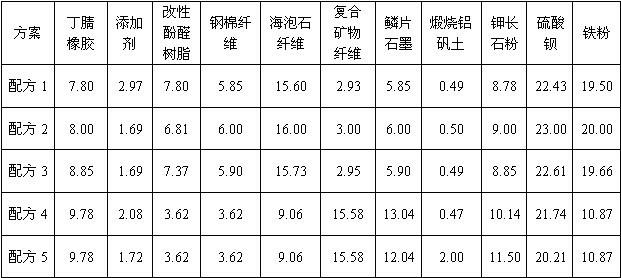

[0032] 1. The composite brake shoe for railway freight cars provided by the present invention includes a steel back and a brake shoe body, and the brake shoe body is fixed on the steel back. The brake shoe body is prepared from synthetic materials with the following weight ratios (refer to the following table for the formulations of the examples, which are not intended to limit the present invention).

[0033]

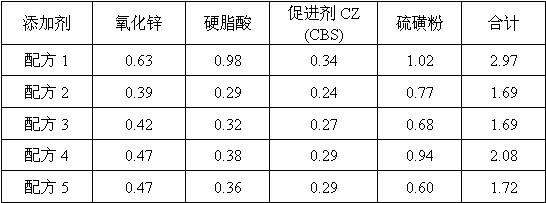

[0034] Additives are prepared according to the following formula:

[0035]

[0036] The raw materials and additives used in the present invention are all industrial-grade conventional products, all of which are sold on the market.

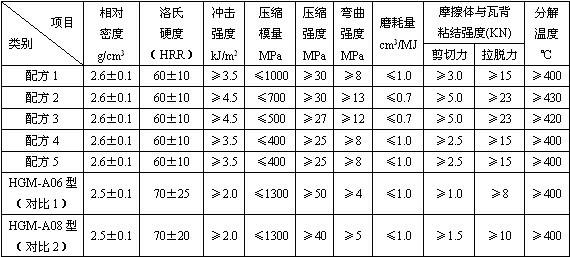

[0037] The formula design of the invention is scientific and reasonable, and the synthetic brake shoe can better meet various performance indexes required in the railway industry standard TB / T 2403-2010 of the People's R...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com