Thermoplastic polyurethane optical film and coating method thereof

A thermoplastic polyurethane and optical adhesive technology, which is used in adhesives, films/sheets without carriers, non-polymer organic compound adhesives, etc. glue and other problems, to achieve good curing effect, improve production efficiency, and good optical performance.

Inactive Publication Date: 2019-05-10

SHENZHEN GAOREN ELECTRONICS NEW MATERIAL

View PDF7 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Solid optical adhesive OCA has a sticky surface, which is easy to contaminate, difficult to align, difficult to remove bubbles, and difficult to remove during lamination, especially for medium and large-sized touch screens. It is difficult to operate; liquid LOCA is easy to Adhesive overflow, bubbles are difficult to remove, and difficult to clean, especially for medium and large-sized touch screens. In addition, these two materials are difficult to operate, low in production efficiency, and low in production costs in the application of bonding touch screens. High and difficult to meet higher requirements in physical performance, which poses challenges and constraints to the development of the industry

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

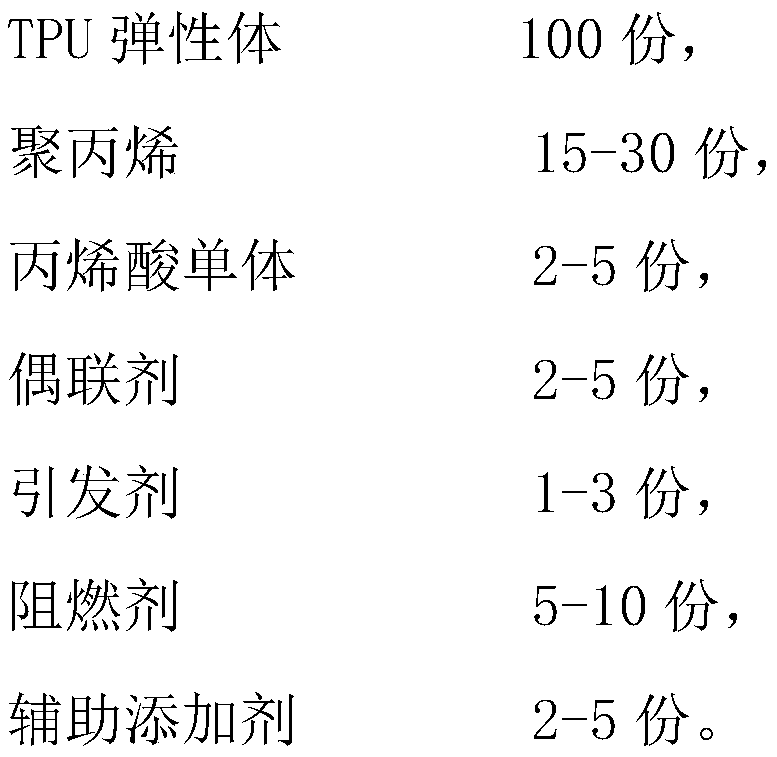

Embodiment 1

[0042] Thermoplastic polyurethane optical adhesive film consists of the following components:

[0043]

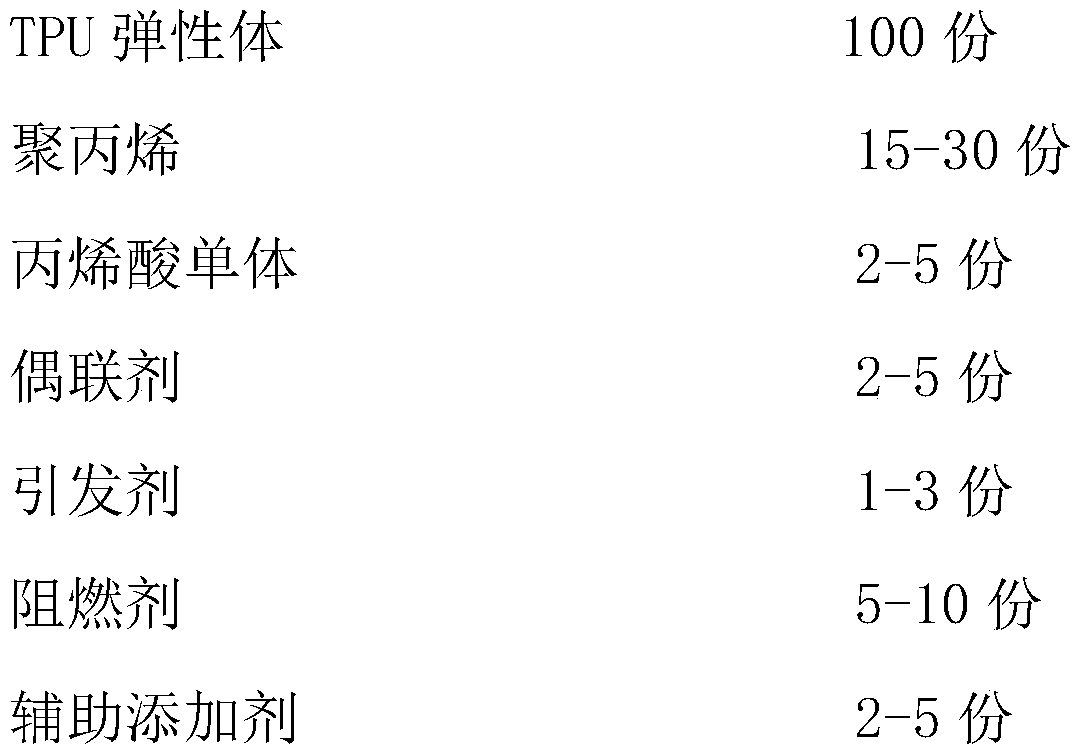

Embodiment 2

[0045]

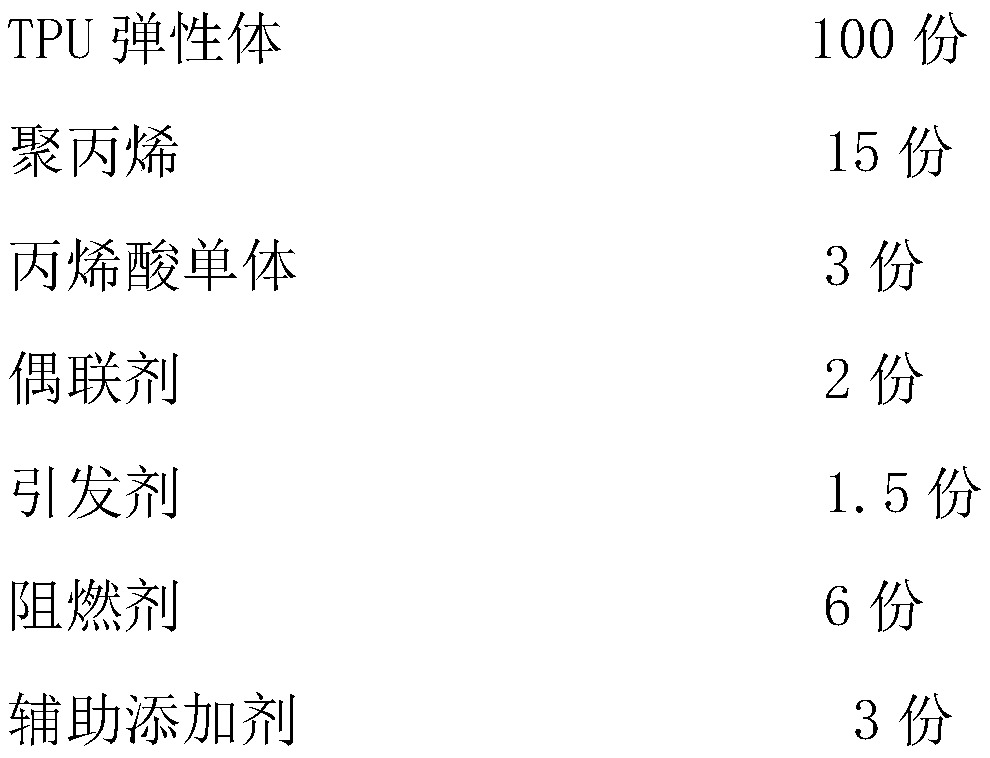

Embodiment 3

[0047]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides a thermoplastic polyurethane optical film. The thermoplastic polyurethane optical film is obtained by mixing thermoplastic polyurethane (TPU) and polypropylene (PP) according toa mass ratio to obtain a basic material and preparing from acrylic monomers, coupling agents, initiators, fire retardants and auxiliary additives. The thermoplastic polyurethane optical film has hightransparency, excellent mechanical properties, high weather and chemical resistance, high-and-low temperature resistance and good bonding properties, and can be melted, flowable, transparent, and extremely-low initially viscous under a certain temperature, thereby being capable of serving as an optical coating rubber material for touch display screens; touch display screen components bonded by the thermoplastic polyurethane optical film have the advantages of simplicity and convenience in process, convenience in bubble elimination, easiness in rework, high production efficiency, low cost andthe like, and touch display screen components coated with the thermoplastic polyurethane optical film have the advantages of good optical performance, excellent mechanical property, high chemical andweather resistance and good environmental performance, so that the thermoplastic polyurethane optical film is an excellent optical rubber material.

Description

technical field [0001] The invention relates to the technical field of optical adhesive films, in particular to a thermoplastic polyurethane optical adhesive film and a bonding method thereof. Background technique [0002] In the field of touch screen display, the development of touch technology is directly related to and affects the application and development of touch display. At present, touch technology is in a stage of rapid development, and it is also facing challenges and a period of technical research. The industry has higher and higher requirements for the overall performance of the touch display screen, and correspondingly higher requirements for the bonding process and technology. [0003] At present, the optical materials used for bonding touch screens in the market are still mainly solid OCA optical glue and liquid LOCA optical glue. Solid optical adhesive OCA has a sticky surface, which is easy to contaminate, difficult to align, difficult to remove bubbles, ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09J7/10C09J4/02C09J4/06G06F3/041

Inventor 陆志胆孙仕兵顾孔胜

Owner SHENZHEN GAOREN ELECTRONICS NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com