Intensive bus duct

A busway, intensive technology, applied in the direction of cooling busbar devices, semi-closed busbar devices, etc., can solve the problem that the heat dissipation effect of the joint part does not reach the ideal effect, affects the conductivity of the busbar of the busway product, and is unfavorable for the dynamic and thermal stability of the busbar and other problems, to achieve the effect of heat dissipation, fewer parts and simple product structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

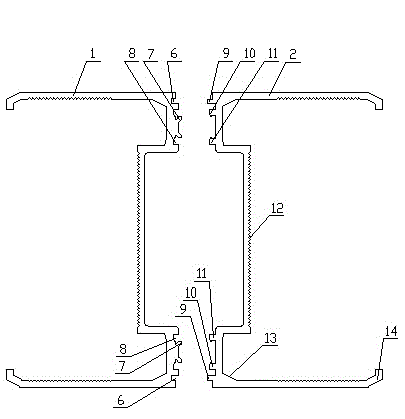

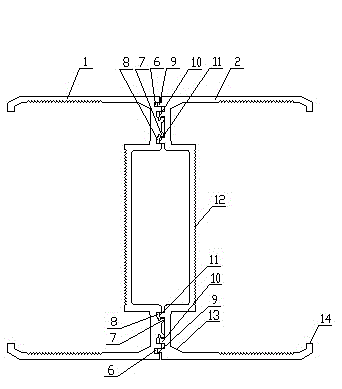

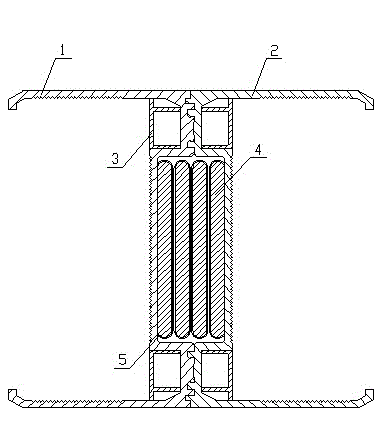

[0016] As shown in the figure, the dense busway of the present invention is composed of a left conjoined side cover plate 1, a right conjoined side cover plate 2, a reinforcing rib sealing plate 3, a bus bar 4 and an insulating layer 5, and the bus bar 4 is covered The insulating layer 5 is then placed in the middle of the left conjoined side cover 1 and the right conjoined side cover 2. The left conjoined side cover 1 and the right conjoined side cover 2 are rolled and riveted by special riveting equipment to form intensive The overall busway, the reinforcing rib sealing plate 3 is fixed on the upper and lower necks of the dense busway integral body composed of the left conjoined side cover plate 1 and the right conjoined side cover plate 2.

[0017] In the dense busway of the present invention, the riveting contact surface of the left conjoined side cover plate 1 has riveting grooves 6, riveting claws 7, and riveting hook grooves 8, and the riveting surface of the right conjo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com