Coconut picking machine

A technology for picking machines and coconuts, which is applied to picking machines, harvesters, agricultural machinery and implements, etc. It can solve the problems of high cost and achieve the effects of simple and practical operation, great market potential and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

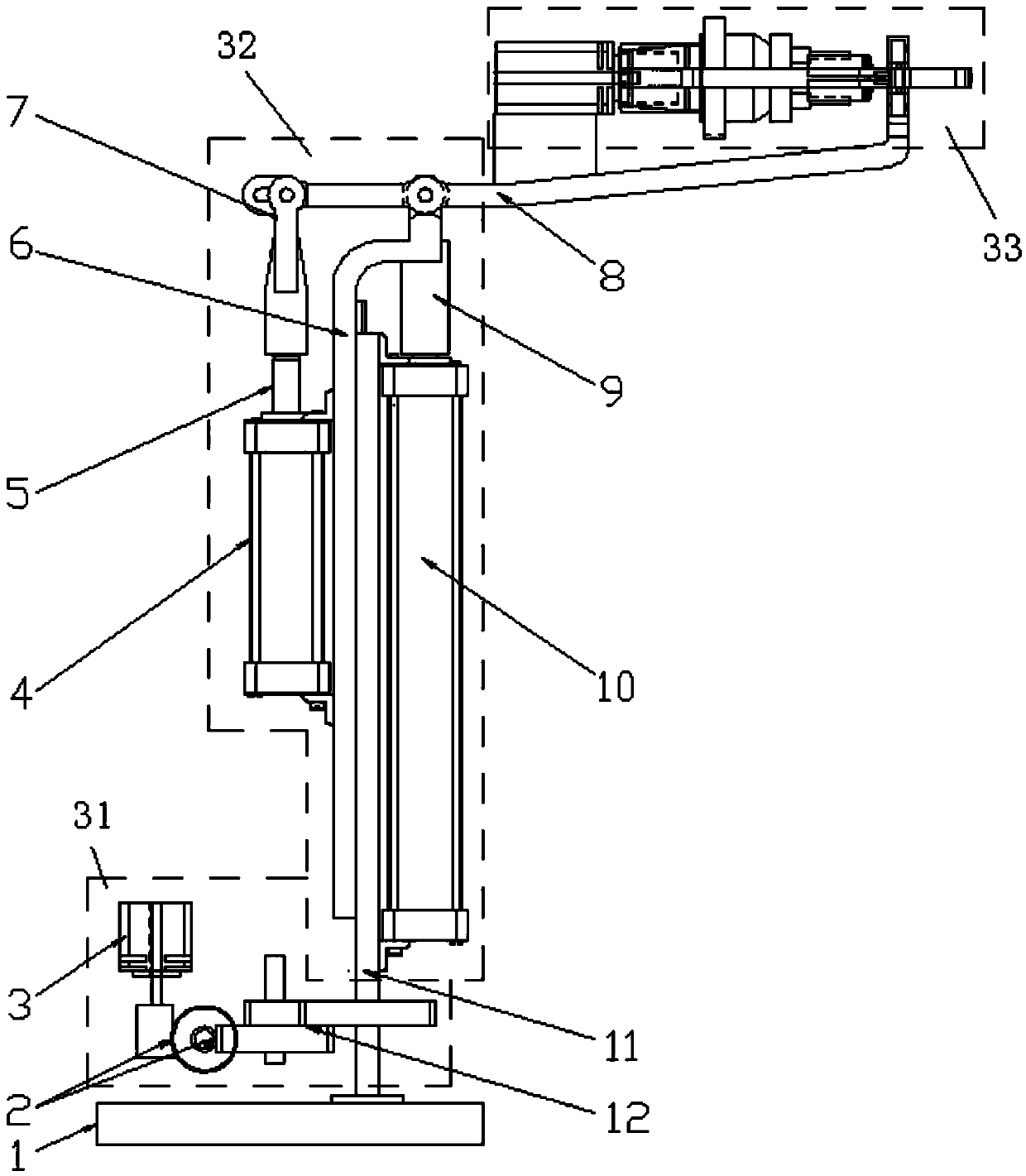

[0025] Such as figure 1 , figure 2 shown. The coconut picking machine of the present invention comprises a swing arm assembly 32, a swing arm driving assembly 31 for driving the swing arm assembly 32, and is characterized in that the coconut picking machine also includes a picking gripper 33, and the picking gripper 33 passes through the head connecting rod 9 Connected with the upper end of the swing arm assembly 32, the picking gripper 33 is installed on the front end of the head link 8;

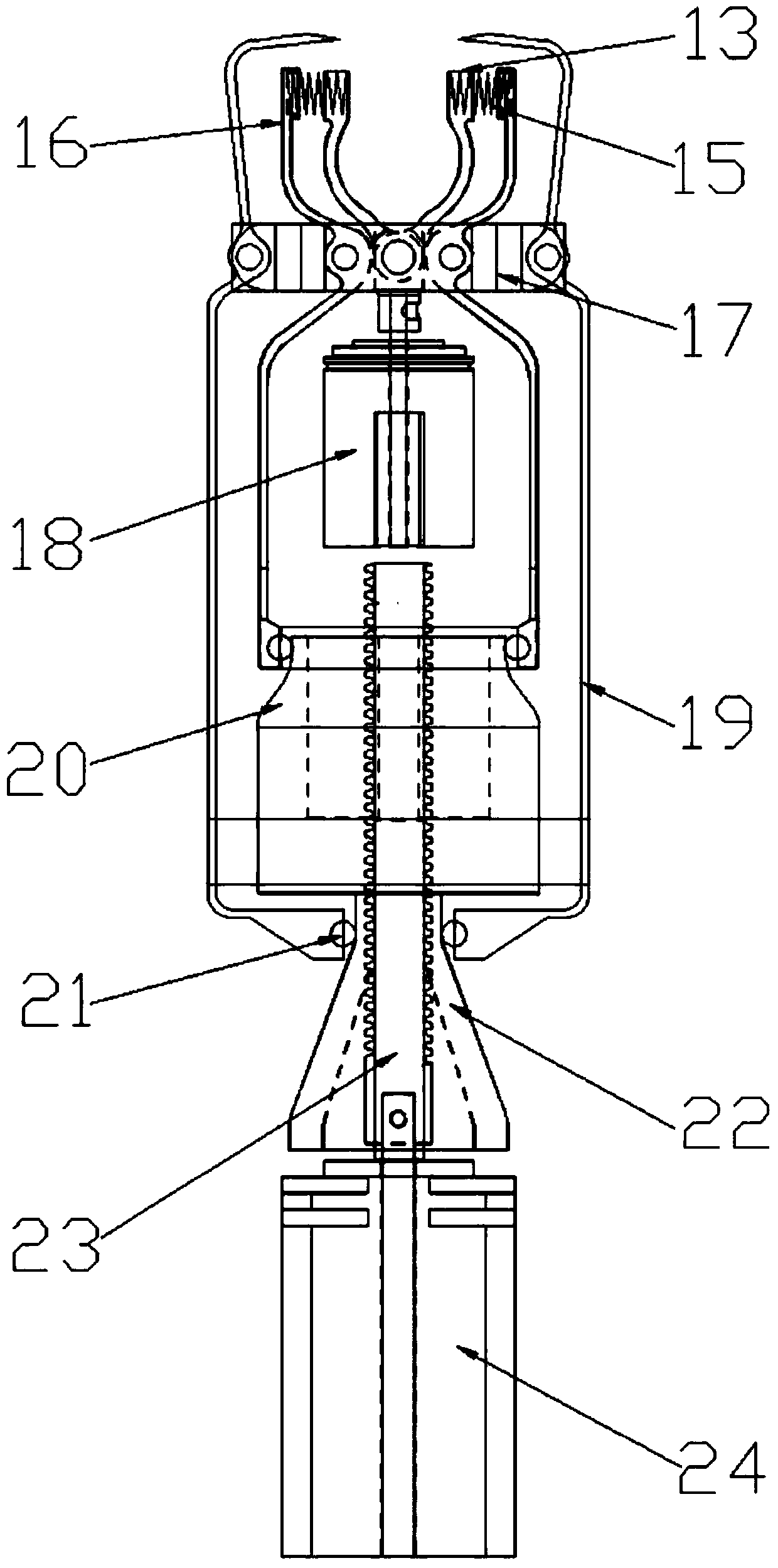

[0026] The picking grip 33 includes: a stepping motor 24, a servo motor 18, a lead screw 23, a conical sliding sleeve 22, a cylindrical step sliding sleeve 20, an inner grip 16, an outer grip 19, and a bearing 17;

[0027] One end of the leading screw 23 is connected to the rotating shaft of the stepping motor 24, and the conical sliding sleeve 22 and the cylindrical step sliding sleeve 20 are sleeved at the middle part of the leading screw 23, and the conical sliding sleeve 22 and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com