Backpack type small berry picking machine

A small berry picking machine technology, applied in picking machines, harvesters, agricultural machinery and implements, etc., can solve the problems of restricting the promotion and planting of small berries, not suitable for harvesting operations, and short maturity period of small berries, and achieve weight Lightweight, compact structure, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

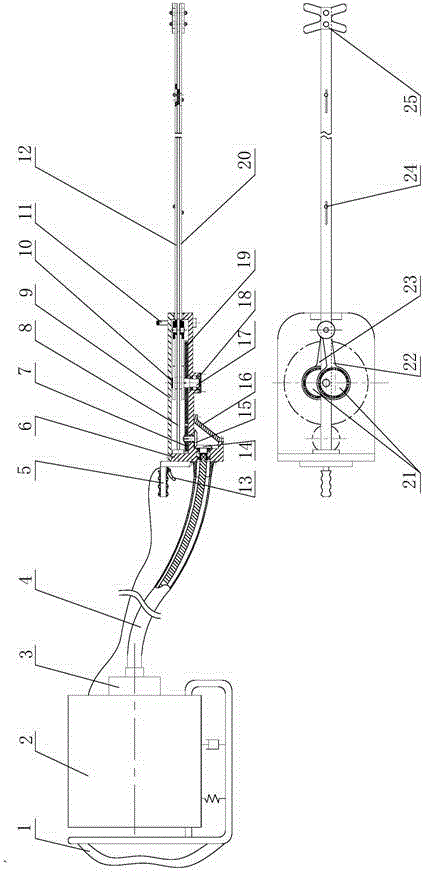

[0019] Backpack small berry picking machine, its main components include back frame 1, small gasoline engine 2, centrifugal clutch 3, wire flexible shaft 4, secondary gear transmission mechanism, eccentric vibration mechanism, eccentric adjustable camshaft 10, branch vibrator 25 , casing 6, front ring handle 11, rear handle 5 and speed regulating device 13, described knapsack type small berry picking machine is characterized in that small gasoline engine 2 is installed on the back frame 1 by vibration-isolation rubber pad, and the small gasoline engine 2 The output shaft is connected to the input end of the flexible steel shaft 4 through the centrifugal clutch 3, the square joint at the output end of the flexible steel shaft 4 is connected to the square interface of the active bevel gear shaft 14 of the secondary gear transmission mechanism, and the eccentricity of the output end of the secondary gear transmission mechanism The adjustable camshaft 10 is assembled with the large...

Embodiment 2

[0023] The eccentric adjustable camshaft 10 is assembled from a stepped shaft 17, an eccentric wheel set, a key, a bushing and a shaft end stop ring. The eccentric wheel set includes two upper and lower eccentric wheels 21 with the same shape and size. Described eccentric wheel 21 is to process an eccentric shaft hole on the circular pie-shaped steel plate, and open a keyway on the eccentric shaft hole, and its keyway is positioned at the radial line of the eccentric shaft hole perpendicular to the eccentric wheel 21 symmetrical center line, The upper and lower eccentric wheels 21 are symmetrically fitted on the stepped shaft 17 according to the forward and reverse directions, and are fixed with keys, bushings and shaft end retaining rings. Since the upper and lower eccentric wheels 21 are reversely symmetrically arranged, the The centrifugal forces of the two eccentric wheels cancel each other out, thereby effectively reducing the vibration of the handle caused by the centrifu...

Embodiment 3

[0025] The eccentric vibration mechanism includes an upper crank 22, a lower crank 23, an eccentrically adjustable camshaft 10, a double-sided guide rail 8, an upper reciprocating vibration rod 12 and a lower reciprocating vibration rod 20, and the upper crank 22 and the lower crank 23 have a large shaft The holes are respectively assembled with the upper and lower two eccentric wheels 21 of the eccentrically adjustable camshaft 10 through bearings, and the small shaft holes are respectively fitted with the shaft holes at the rear ends of the upper reciprocating vibrating rod 12 and the lower reciprocating vibrating rod 20 through pin shafts. And symmetrically arranged on the upper and lower sides of the double-sided guide rail 8, when working, the acceleration directions of the upper and lower reciprocating vibrating rods at any time are always opposite, and the generated reciprocating vibration inertial forces cancel each other out, thereby effectively reducing vibration. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com