Automatic soilless culture production line

A technology of soilless cultivation and production line, which is applied in the direction of soilless cultivation, cultivation, agricultural machinery and tools, etc. It can solve the problems of inconvenient use, low degree of automation, and damage to vegetable appearance, so as to avoid damage, facilitate recycling, and improve work efficiency. The effect of efficiency and degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

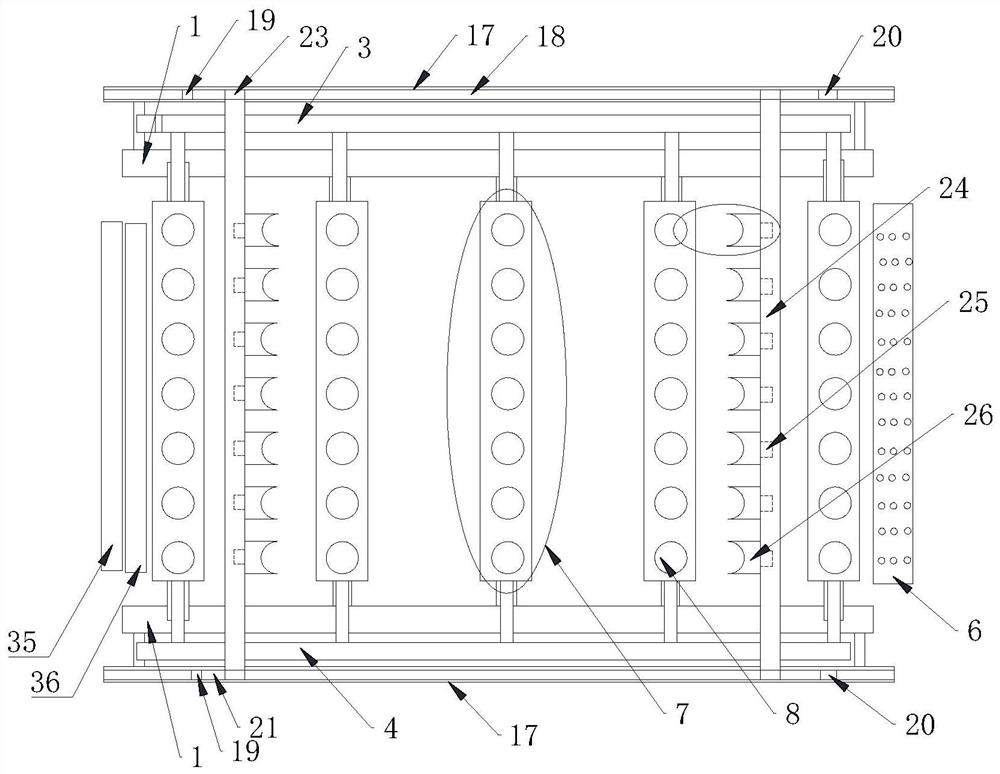

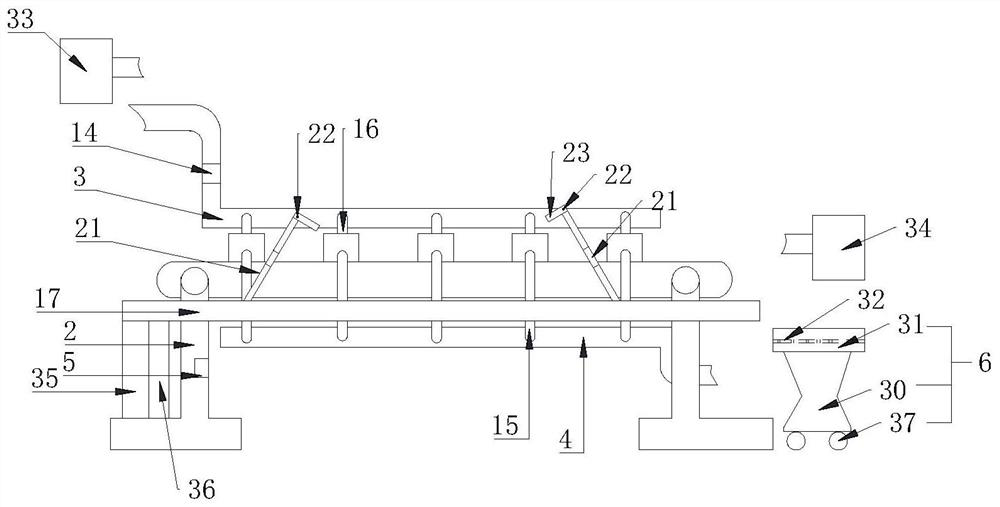

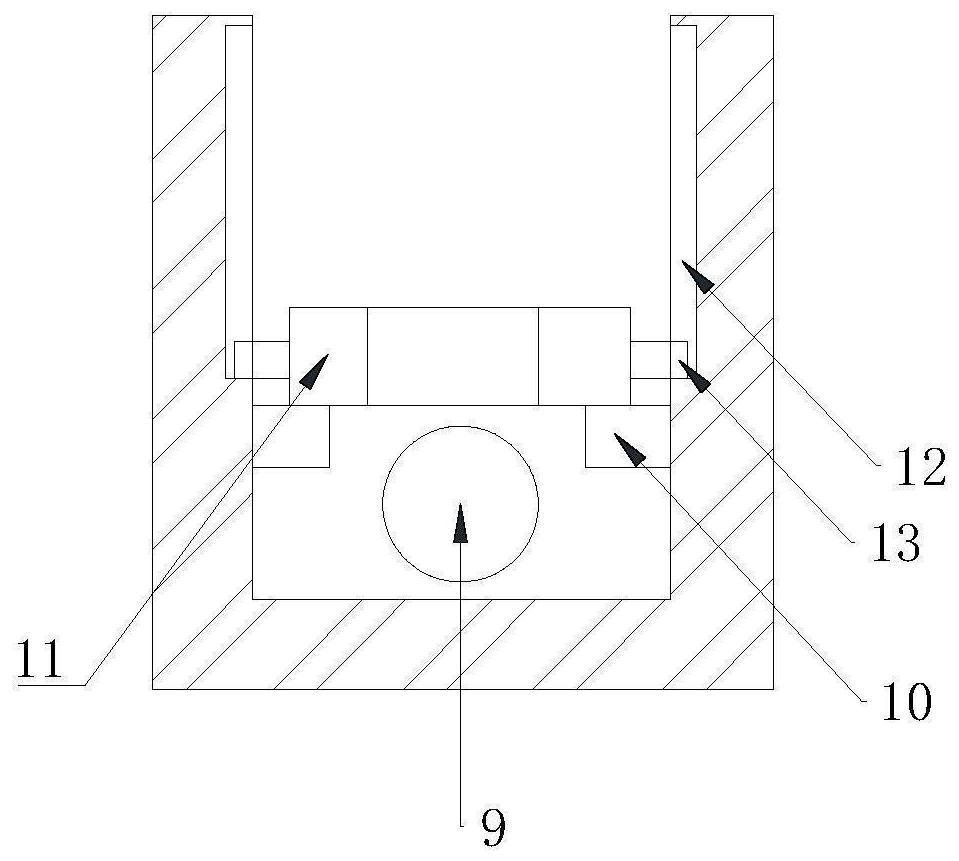

[0032] Embodiment: a kind of automatic soilless cultivation production line, as Figure 1 to Figure 5As shown, it includes two conveyor belt groups 1 arranged in parallel, a support frame 2 connected to the ends of the rotating shafts of the two conveyor belt groups 1, a liquid inlet main pipe 3, a liquid discharge main pipe 4, a controller 5 and a vegetable collection device 6. The conveyor belt group 1 helps to fix the soilless cultivation device 7, so that the soilless cultivation of vegetables can be realized; the support frame 2 helps to support the conveyor belt group 1 and the support horizontal version, so that the implantation, cultivation and cultivation of vegetable seedlings can be completed. Picking; Utilizing the liquid inlet main pipe 3 helps to input nutrient solution in the cultivation tank 8; Utilizing the liquid discharge main pipe 4 helps to discharge the nutrient solution in the cultivation tank 8 for easy picking; Utilize the controller 5 to help Send con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com