ZSM-5 molecular sieve as well as mesoporous treatment method and application thereof

A technology of ZSM-5 and treatment methods, which is applied in the field of molecular sieve performance optimization, can solve problems such as difficult control of process conditions, achieve the effects of solving durability and odor problems of polymer materials, exerting antibacterial efficacy, and improving ion exchange capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. A method for mesoporizing ZSM-5 molecular sieve at normal temperature and pressure, the specific steps are:

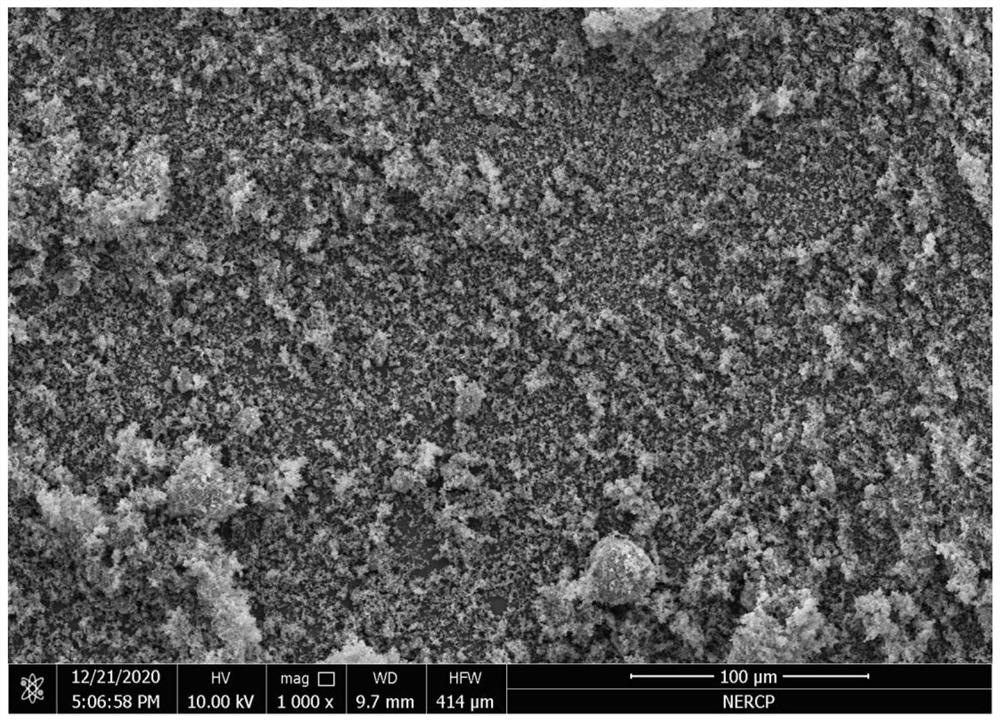

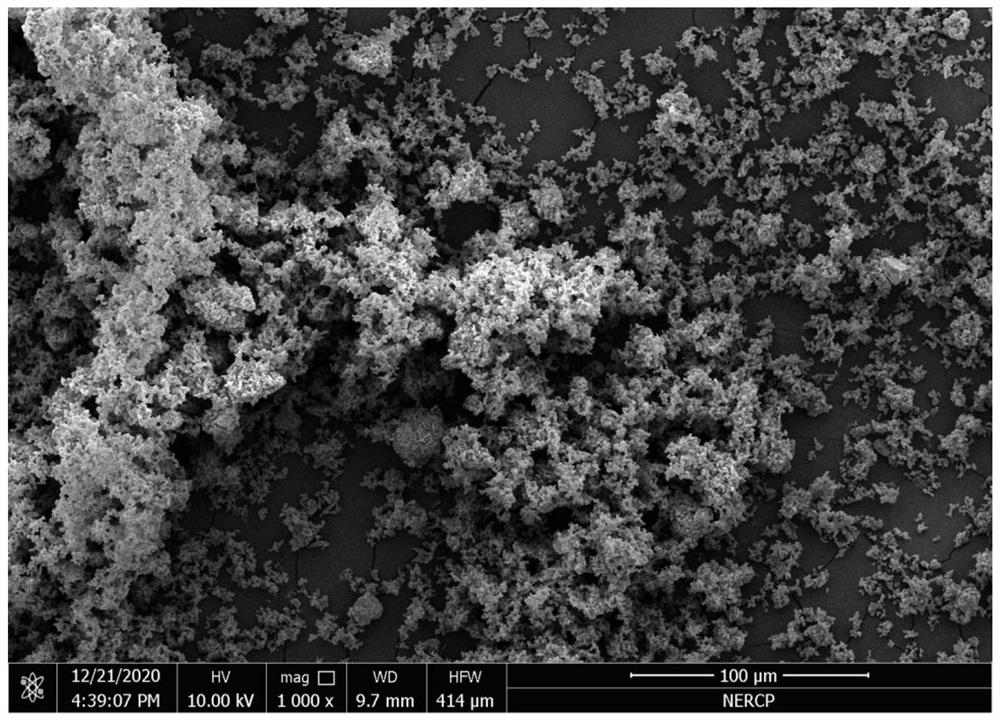

[0025] Stir 2kg of microporous ZSM-5 molecular sieve in 6L of 3mol / L sodium hydroxide solution and soak for 2 hours, filter and drain, and wash to obtain filter cake 1, and put filter cake 1 into 5L of 1mol / L tetrapropylene After being stirred in an ammonium hydroxide solution, soak for 2 hours, filter and drain to obtain filter cake 2, and obtain a wet state ZSM-5 molecular sieve with an average particle size of 7 μm and an average pore size of 30 nm.

[0026] 2. Using the above-mentioned ZSM-5 molecular sieve as a carrier to prepare a self-made silver-loaded molecular sieve, the specific steps are:

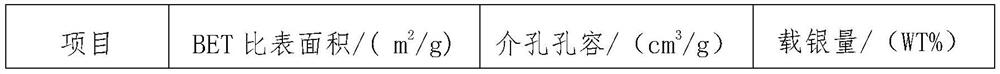

[0027] Put the wet ZSM-5 molecular sieve filter cake obtained above into 5L of 4mol / L silver nitrate solution and soak for 2 hours, take it out and dry it, and then place it in a microwave drying oven with a temperature of 40°C and dry it for 35 minutes to obta...

Embodiment 2

[0030] 1. A method for mesoporizing ZSM-5 molecular sieve at normal temperature and pressure, the specific steps are:

[0031] Stir 2kg of microporous ZSM-5 molecular sieve in 7L of 2mol / L sodium hydroxide solution and soak for 2 hours, filter and drain, and wash to obtain filter cake 1, and put filter cake 1 into 4L of 1.5mol / L sodium hydroxide solution. Stir in the propyl ammonium hydroxide solution, soak for 2 hours, filter and drain to obtain filter cake 2, and obtain a wet state ZSM-5 molecular sieve with an average particle size of 10 μm and an average pore size of 16 nm.

[0032] 2. Using the above-mentioned ZSM-5 molecular sieve as a carrier to prepare a self-made silver-loaded molecular sieve, the specific steps are:

[0033] Put the wet ZSM-5 molecular sieve filter cake obtained above into 5L of 4mol / L silver nitrate solution and soak for 2 hours, take it out and dry it, and then place it in a microwave drying oven with a temperature of 40°C and dry it for 35 minutes...

Embodiment 3

[0036] A method for treating ZSM-5 molecular sieves by mesoporization at normal temperature and pressure, the specific steps are:

[0037] Stir 2kg of microporous ZSM-5 molecular sieve in 8L of 2mol / L sodium hydroxide solution and soak for 2 hours, filter and drain, and wash to obtain filter cake 1, and put filter cake 1 into 5L of 1mol / L tetrapropylene Stir in ammonium hydroxide solution, soak for 2 hours, filter and drain to obtain filter cake 2, and obtain wet state ZSM-5 molecular sieve with an average particle size of 11 μm and an average pore size of 20 nm.

[0038] 2. Using the above-mentioned ZSM-5 molecular sieve as a carrier to prepare a self-made silver-loaded molecular sieve, the specific steps are:

[0039] Put the wet ZSM-5 molecular sieve filter cake obtained above into 6L of 3.5mol / L silver nitrate solution and soak for 2 hours, take it out and dry it, and place it in a microwave drying oven with a temperature of 40°C for 30 minutes to obtain undetermined Type...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com