Patents

Literature

42results about How to "Easy combined installation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

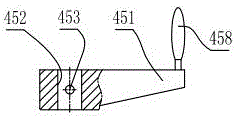

Inclined-plane turn angle arbitrary four-side engineering rubber fixing rest pliers

InactiveCN105547820AAchieve fixationAvoid stickingStrength propertiesIsosceles trapezoidInterference fit

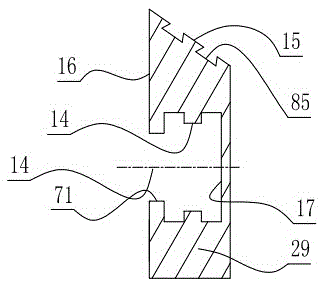

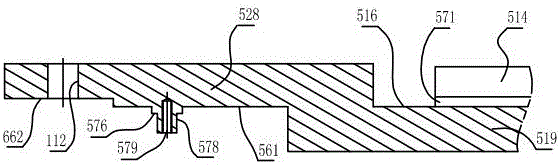

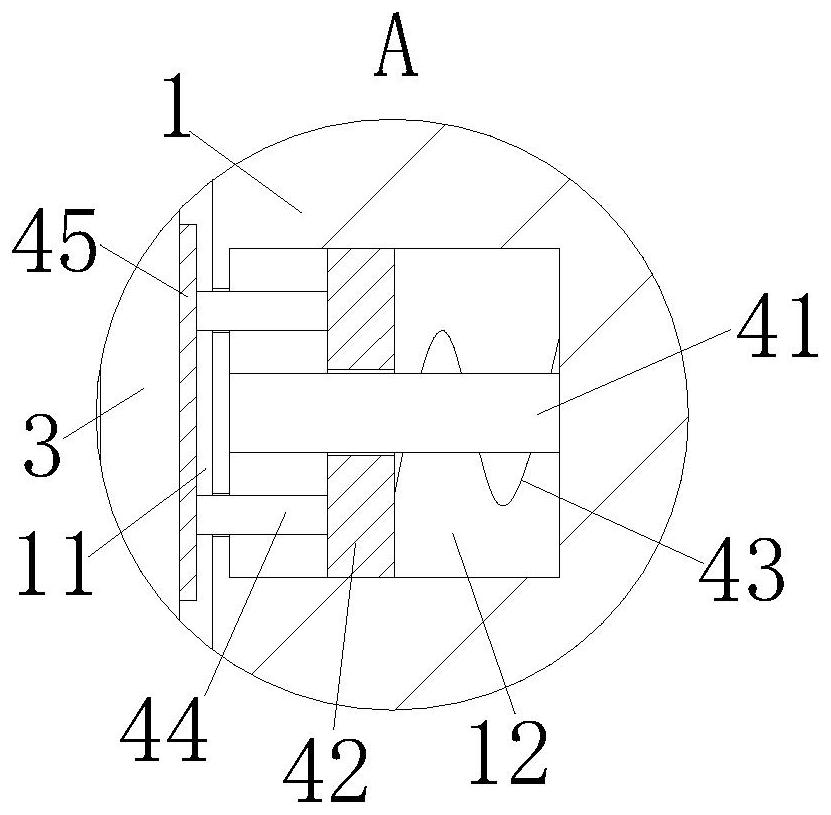

The invention relates to fixing rest pliers for glass detection, and in particular relates to a pair of inclined-plane turn angle arbitrary four-side engineering rubber fixing rest pliers. The pair of inclined-plane turn angle arbitrary four-side engineering rubber fixing rest pliers has following improvement: one end of an upper clamping plane is provided with an inclined-plane groove the bottom surface of which is provided with a bottom plane of the groove; the cross section of the inclined-plane groove is isosceles trapezoid; a lower slipping plane is provided with a rotary through hole; a rotary plate chamber arc surface is arranged at one side of the rotary through hole; the turn angle chamber arc surface is provided with a turn angle arc surface protruding pointer; an inclined-plane convex rail is positioned on the lower slipping plane; the cross section of the inclined-plane convex rail is also isosceles trapezoid; the lower slipping plane is provided with two plane screw holes; the inclined-angle convex rail is also provided with two convex rail stepped holes; convex rail screws pass through the convex rail stepped holes and are fit with the plane screw holes in a spirally fastening mode so as to fix the convex rail contact surface on the lower slipping plane; inclined planes at two sides of anti-falling raised lines and inclined planes at two sides of anti-falling grooves are in interference fit so as to generate extrusion and expansion force and prevent falling accidents caused by glue aging; heights of the anti-falling raised lines and depths of the anti-falling grooves are in clearance fit for the convenience of installation and binding.

Owner:张志雄

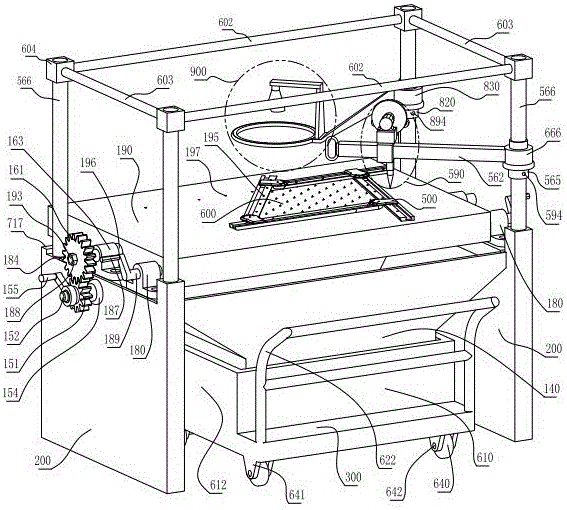

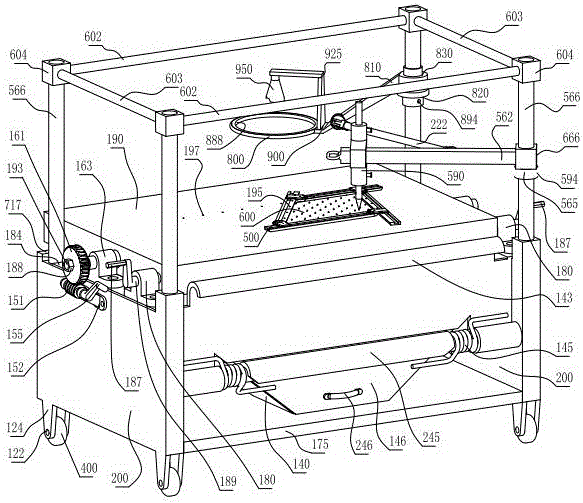

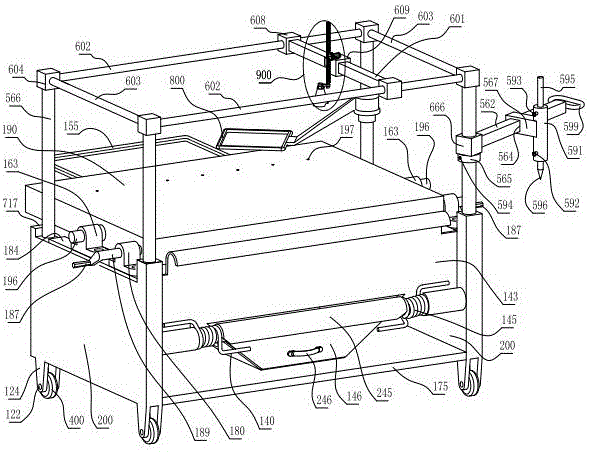

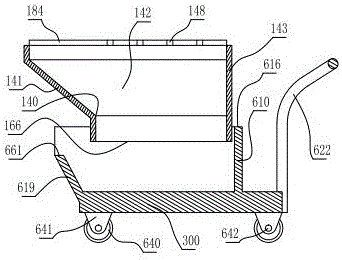

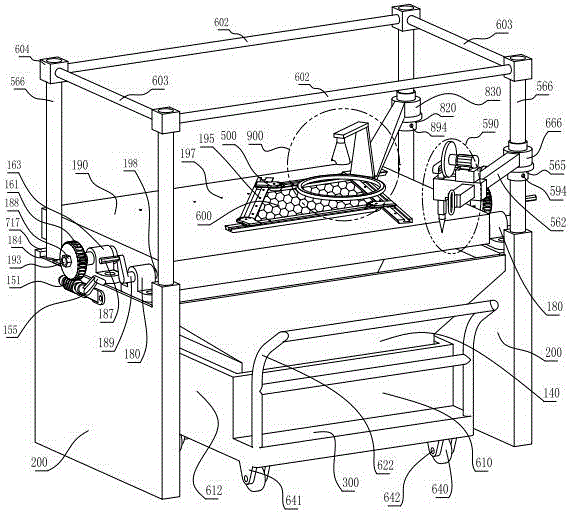

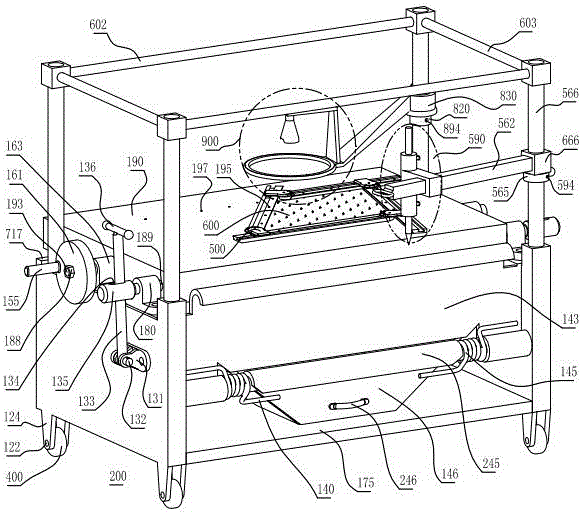

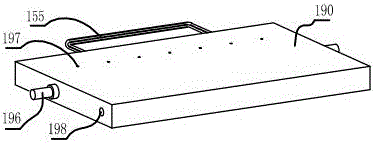

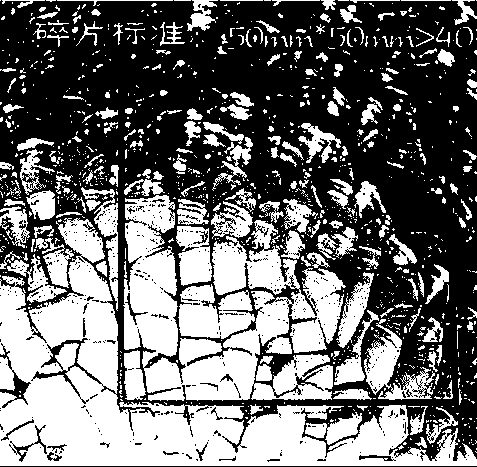

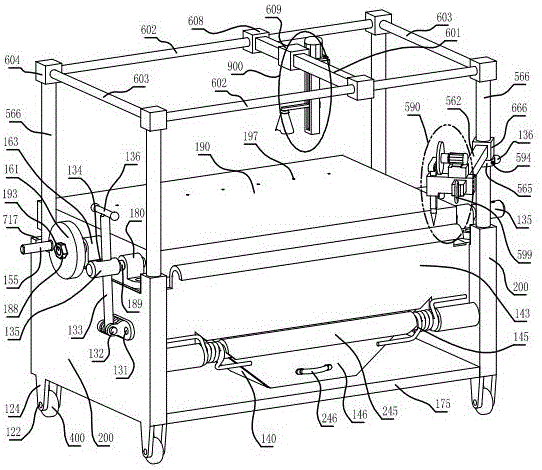

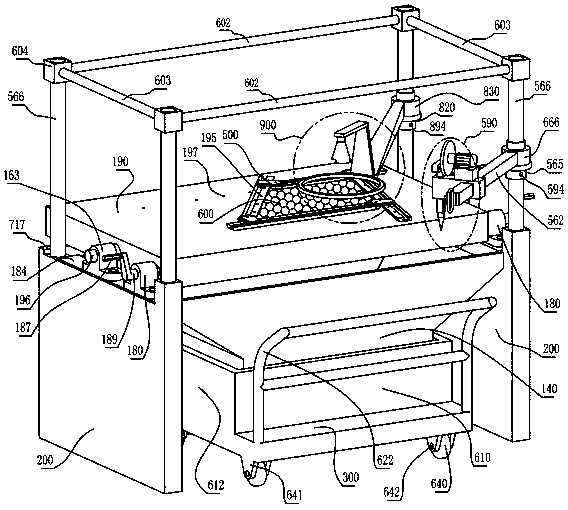

Method for testing glass by using worm wheel turntable rack photography and circular corner clamp plates

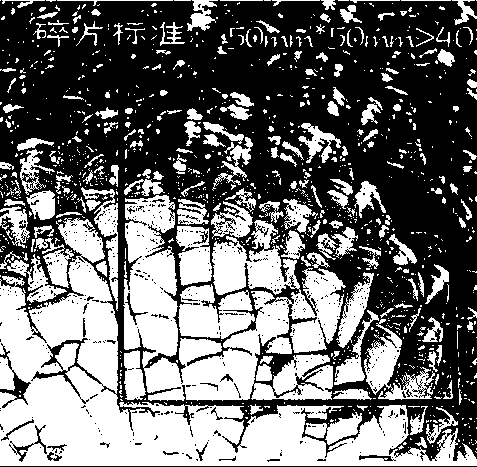

InactiveCN105651629AChange labor intensityAvoid accidental splash damageStrength propertiesEngineeringGlass fragment

The invention relates to a tempered glass testing method, in particular to a method for testing glass by using worm wheel turntable rack photography and circular corner clamp plates. Modifications include: one, an assembly process includes a clamp plate assembly process and a machine assembly process; two, a tempered glass fragmentation test includes the following steps: (one), a worm cranking handle at one end of a worm shaft is cranked by hand so that a test top plate is horizontal; (two), first, second, third and fourth clamp plates equal in structural size are placed on the test top plate; (three), a trapezoidal glass plate to be tested is placed on the test top plate within a surrounded space; (four), an impact motor is started to break the trapezoidal glass plate; (five), a photography motor is started to take photos and send fragment photos to a computer processing center; (six), the second and third clamp plates are moved so that tempered glass fragments can be conveniently cleared and dropped into a glass fragment recycling container.

Owner:WENZHOU ECONOMIC TECH DEV ZONE BINHAI XIONGJIE ELECTROMECHANICAL RES & DEV STUDIO

Arbitrary quadrilateral butadiene styrene rubber wheel corner fixed clamp

InactiveCN105547821AAchieve fixationInhibit sheddingStrength propertiesInterference fitButadiene-styrene rubber

The invention relates to a glass detection fixed clamp, and particularly relates to an arbitrary quadrilateral butadiene styrene rubber wheel corner fixed clamp. As the improvement, a rotary through hole is formed in a lower slippage plane; the other side of the rotary through hole is provided with a rotary table chamfering arc surface; the rotary table chamfering arc surface is located on a back plane of the lower slippage plane; a corner arc surface convex pointer is arranged on the rotary table chamfering arc surface; a step shaft pin is arranged on the other side of the rotary through hole; a wheel hole matching section is arranged on the step shaft pin; the outer end of the wheel hole matching section is a shaft pin outer end; a shaft pin screw hole is formed in the center of the shaft pin outer end; the outer circle of the wheel hole matching section is matched with a wheel inner hole in a rotatable manner; the shaft pin screw hole is matched with a wheel screw; a screw head of the wheel screw simultaneously shields a wheel step surface; a wheel slide groove is formed in one end of an upper clamping plane; a transition notch is formed between the wheel slide groove and the upper clamping plane; an anti-releasing groove is formed in a clamping inclined slope; an anti-releasing convex strip is arranged on a rubber pressing sheet; and the anti-releasing convex strip and the anti-releasing groove are in embedded type interference fit, so that quadrilateral glass with arbitrary included angles is fixed.

Owner:张志雄

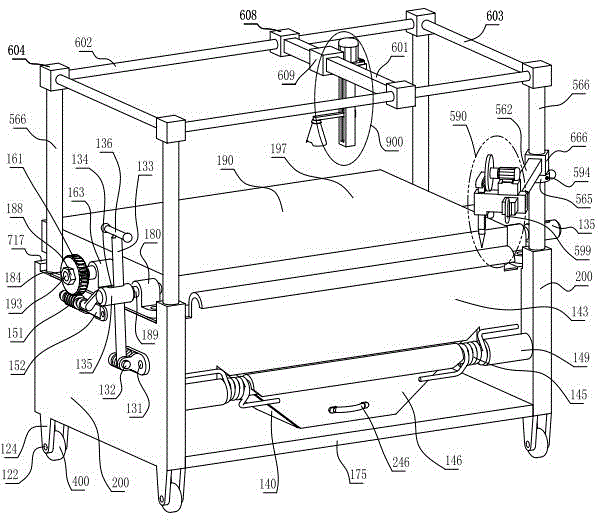

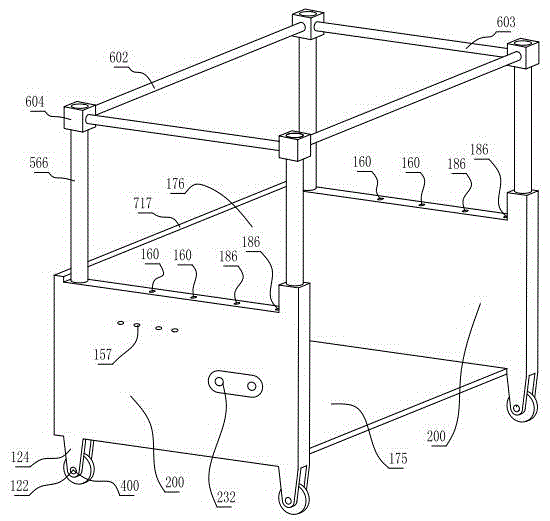

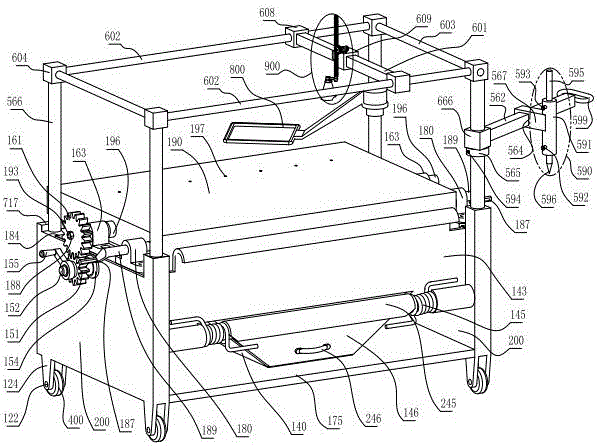

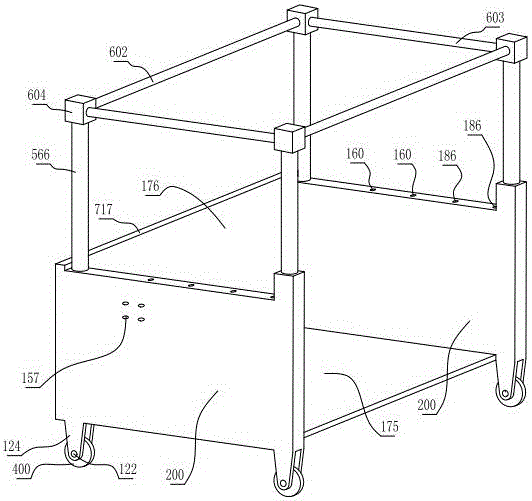

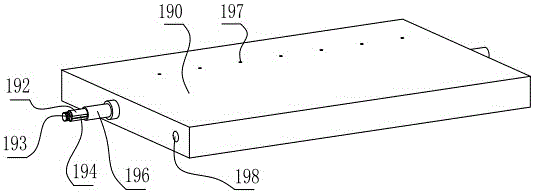

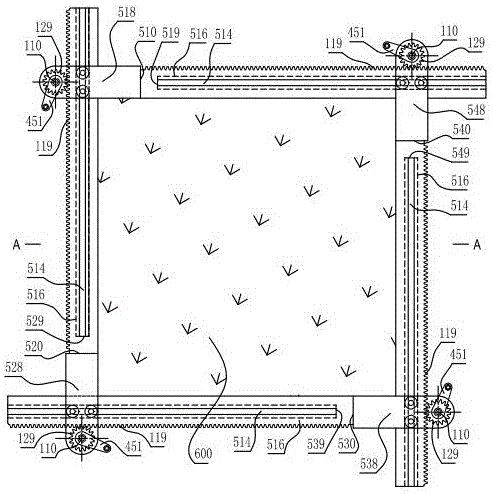

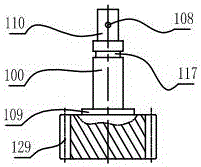

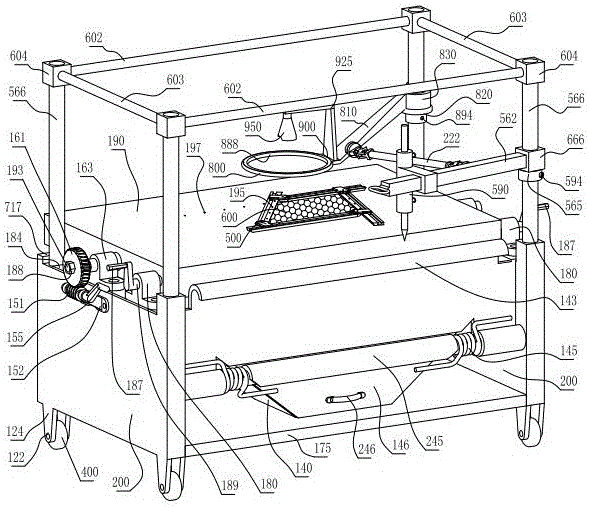

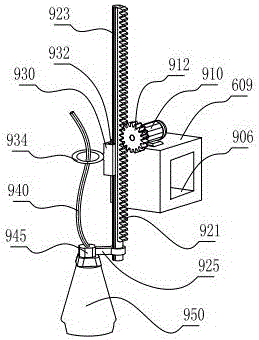

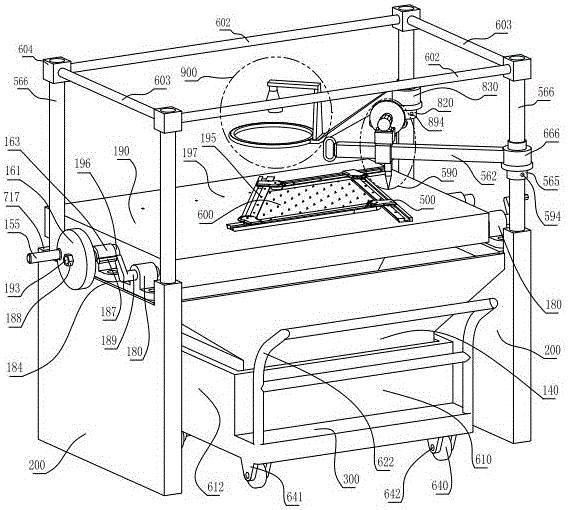

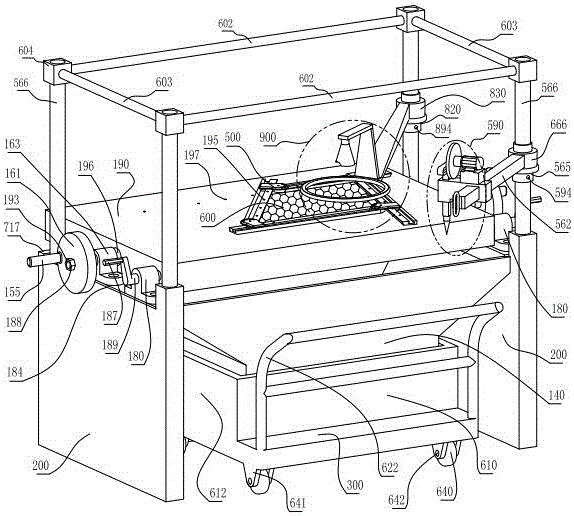

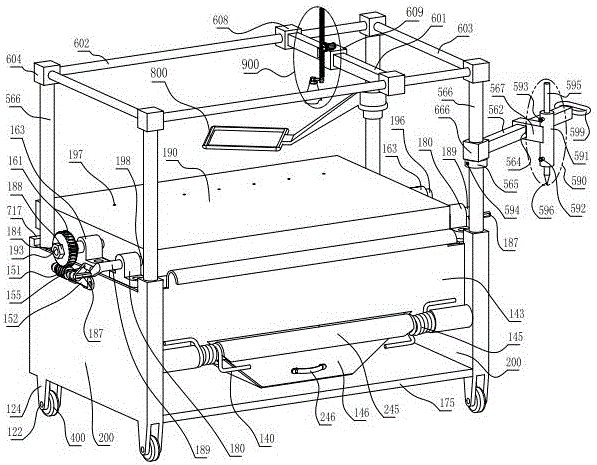

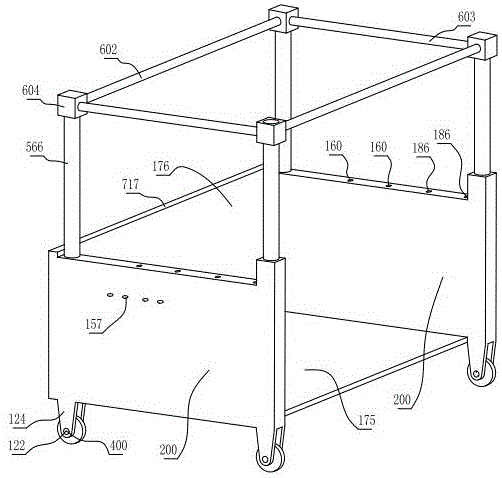

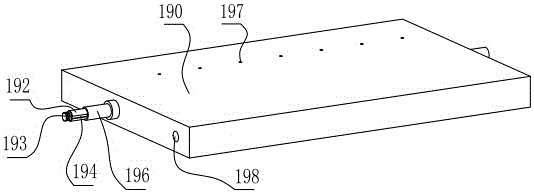

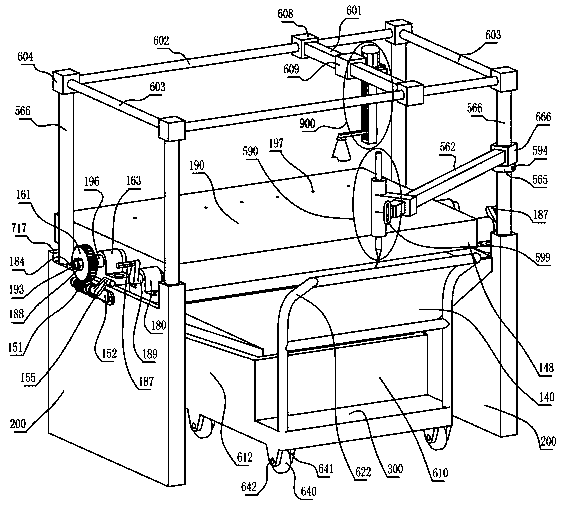

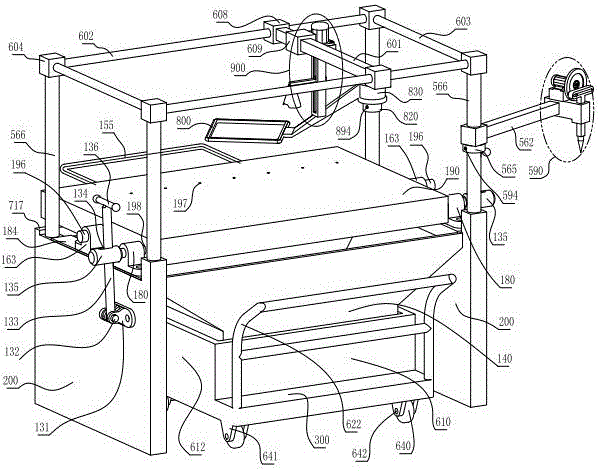

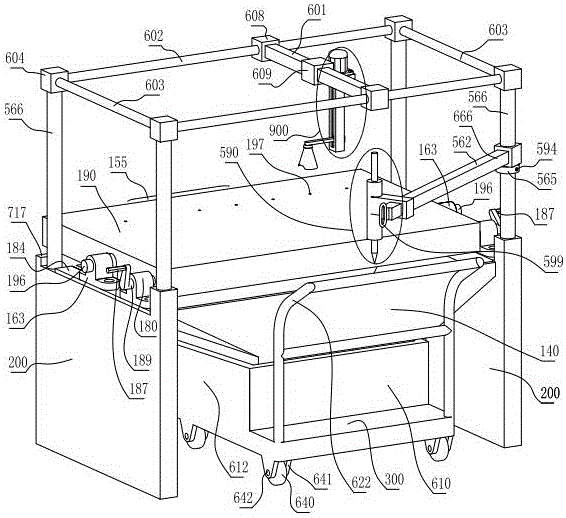

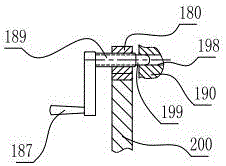

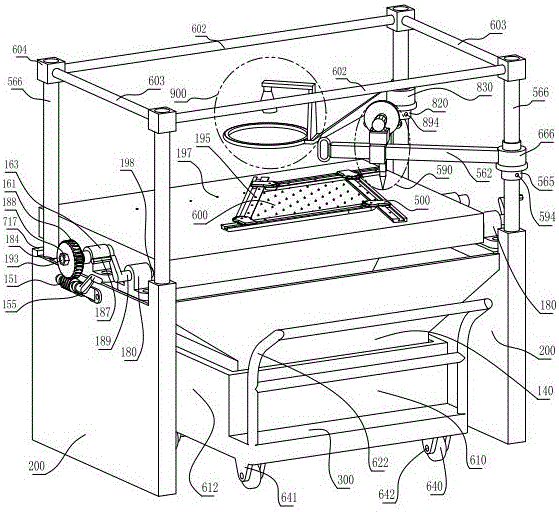

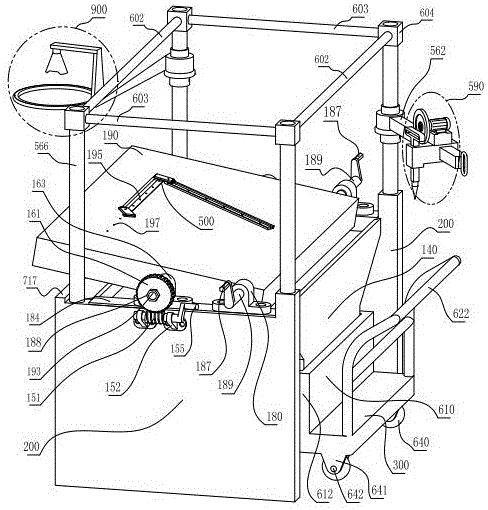

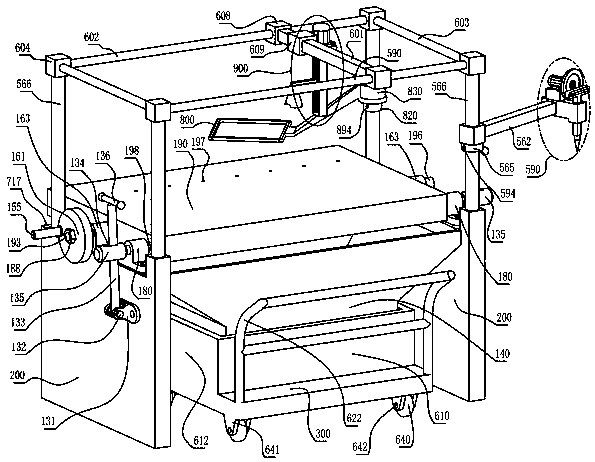

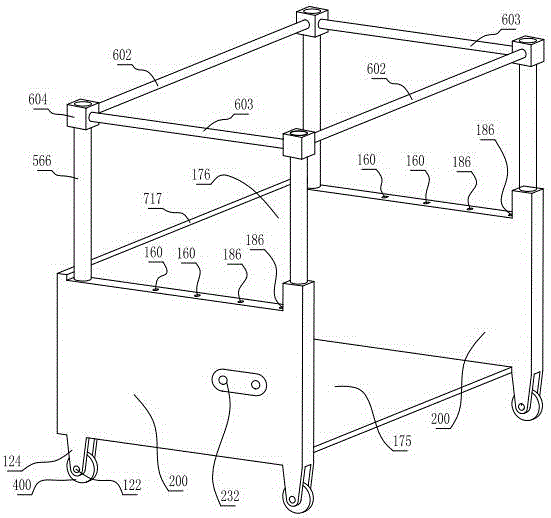

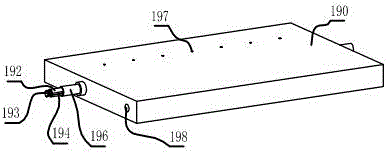

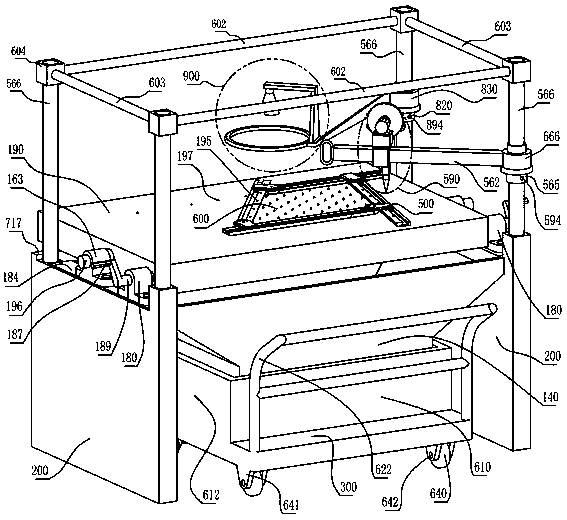

Glass detecting rack and method for carrying out glass detection by using glass detecting rack

InactiveCN105758750AEasy to removeReduce frictional resistanceMaterial analysis by optical meansMaterial strength using repeated/pulsating forcesTest specificationUltimate tensile strength

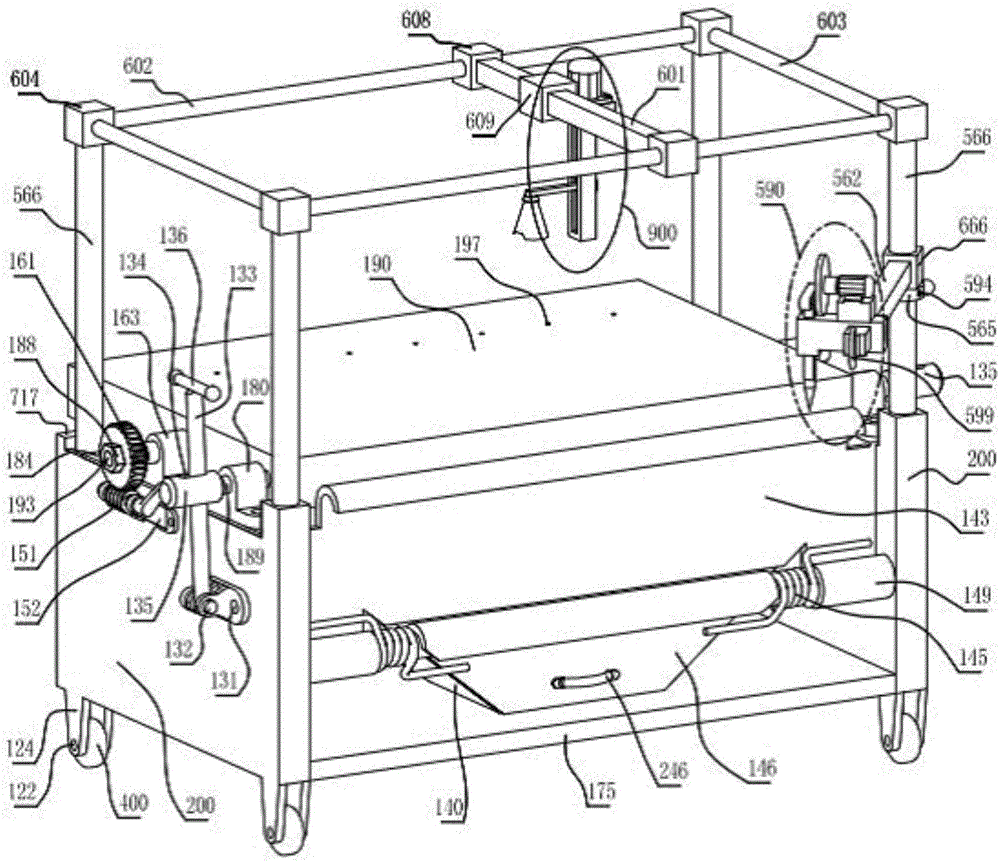

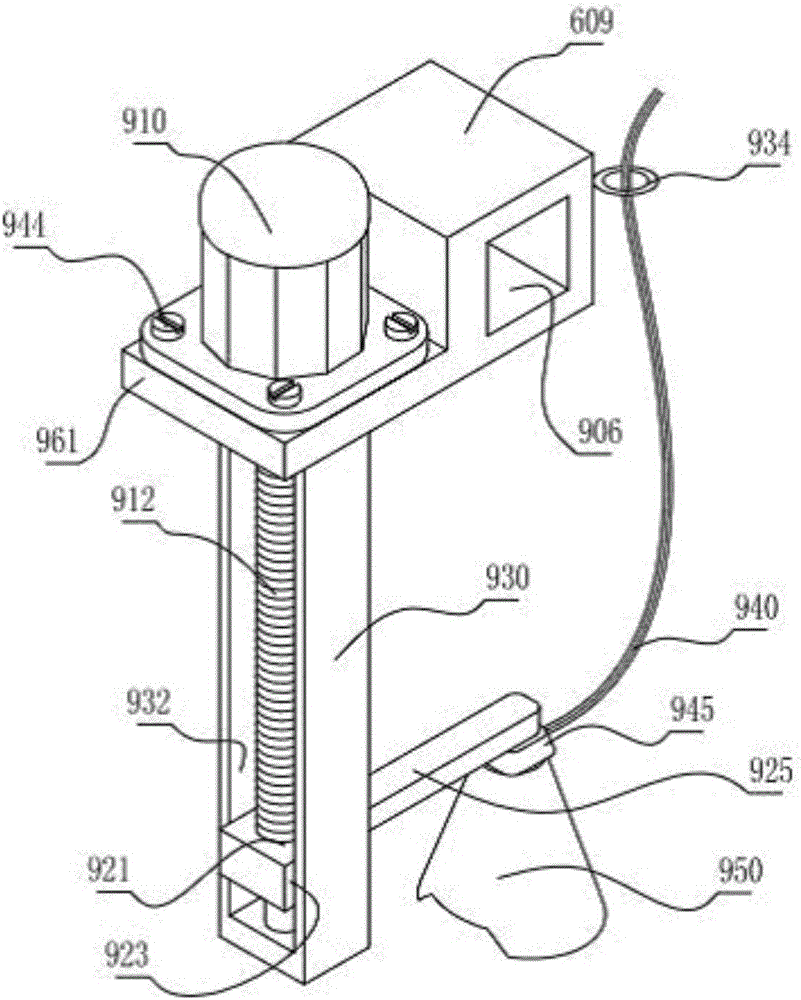

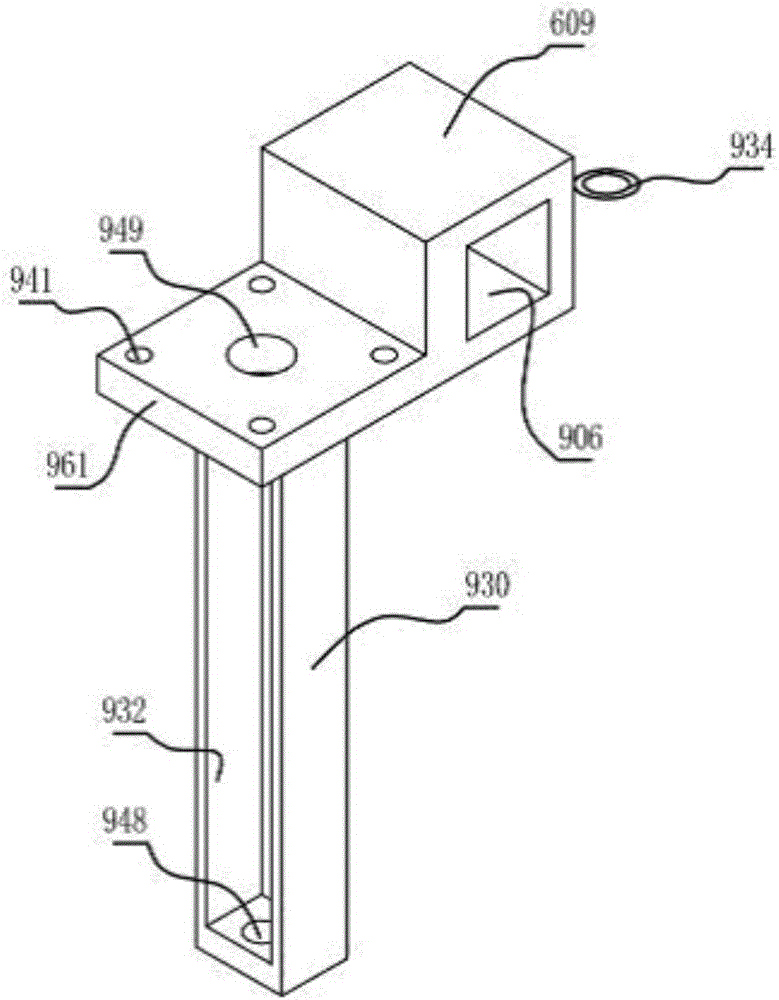

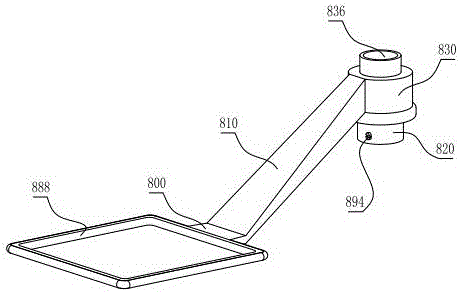

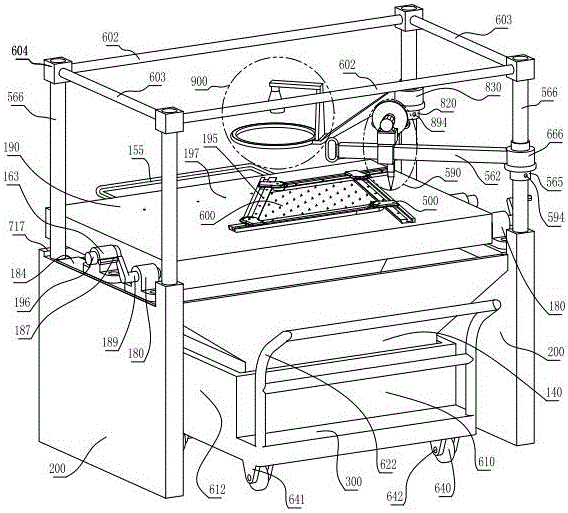

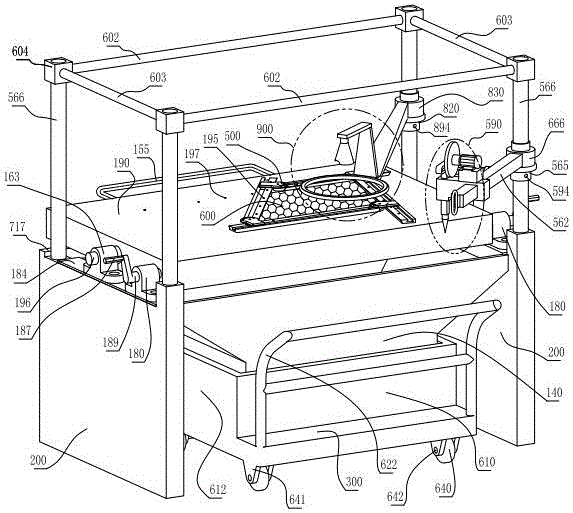

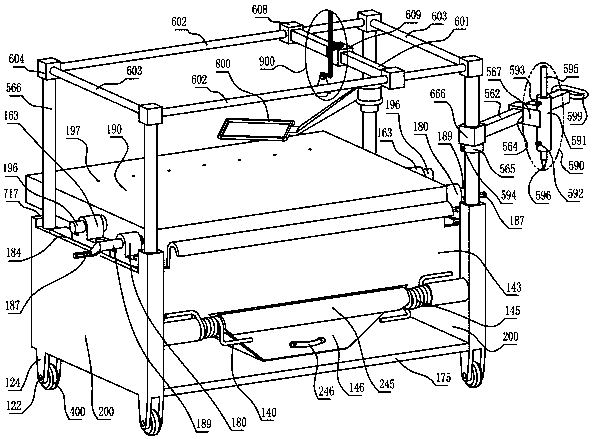

The invention relates to a toughened glass test rack, in particular to a glass detecting rack. As improvement, the glass detecting rack is characterized in that a transmission worm is matched with a worm shaft; the two ends of the worm shaft can be rotatably fixed in worm supporting bases separately; the worm supporting bases are fixedly arranged on the outer side surface of a corresponding supporting side plate; one end of the worm shaft is further provided with a worm cranking handle; a screw lifting camera group is arranged on a camera shooting square rod; a rotary impactor can be fixedly arranged on an impact cross rod in a sliding manner; a step corner pressure plate assembly comprises a first pressure plate, a second pressure plate, a third pressure plate and a fourth pressure plate which are the same in structural dimension; and each pressure plate is composed of a clamping part and a sliding corner part. According to the glass detecting rack, labor intensity of fragment detecting is changed, camera shooting is carried out, and fragment images are transmitted to a computer processing center; the rotary impactor is applied, so that hammering every time is consistent is force, and therefore, breaking test specifications are unified.

Owner:徐明

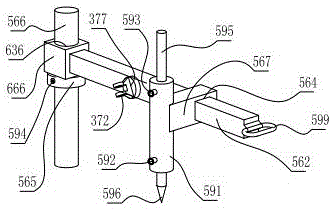

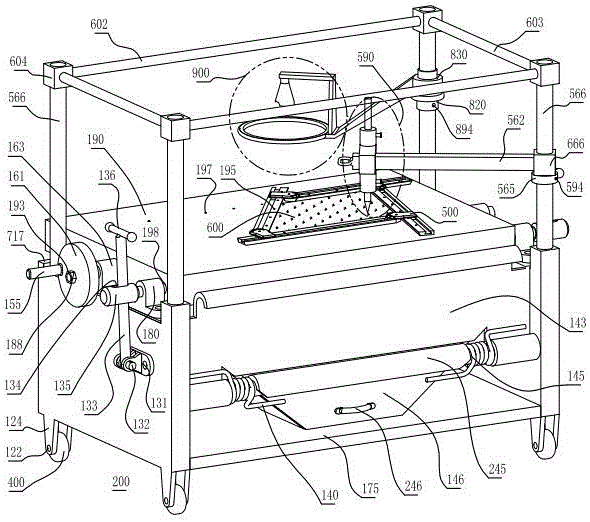

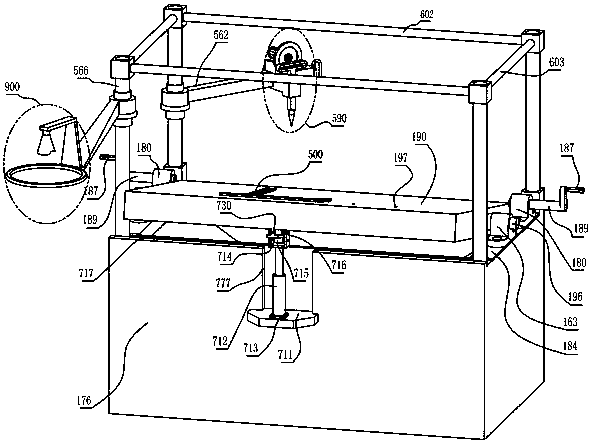

Glass inspection apparatus having gear rotary table, ring light camera and titanium alloy stepped slot corner clamping plate

InactiveCN105758745AThe accuracy of boundary discrimination is improvedFirmly connectedStands/trestlesMicroscopesEngineeringTitanium alloy

The invention relates to a tempered glass testing and inspecting apparatus, and in particular relates to an improved glass inspection apparatus having a gear rotary table, a ring light camera and a titanium alloy stepped slot corner clamping plate. A transmission gear is also fixed on a rotary table rotating shaft at one side, and is cooperated with a hand-operated gear, the hand-operated gear is rotationally fixed on a hand-operated axle, an axle flange is arranged at the inner end of the hand-operated axle and is fixed on the outer side surface of a supporting side plate correspondingly, a clamp spring for a shaft is arranged at the outer end of the hand-operated axle and is stopped on the outer side surface of the hand-operated axle, a hand wheel stepped round is arranged on the outer side surface of the hand-operated gear, a hand wheel cross bar is fixedly connected on the hand wheel stepped round, a hand wheel crack handle is arranged at the outer end of the hand wheel cross bar, a rack hoisting camera set is arranged on a camera shooting square bar, a square fluorescent tube is arranged on a mobile light ring, an air cylinder impactor is fixed on an impacting cross bar in a sliding manner, a stepped rail clamping plate assembly is fixed on the upper plane of the testing rotating table, and quadrilateral glass having different included angles can be fixed by the stepped rail clamping plate assembly.

Owner:WENZHOU ECONOMIC TECH DEV ZONE BINHAI XIONGJIE ELECTROMECHANICAL RES & DEV STUDIO

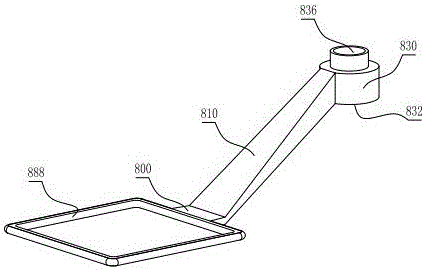

Molybdenum alloy glass detection device with gear rotary table, aperture camera shooting assembly and bearing corner clamping plates

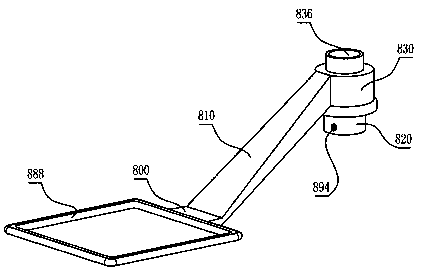

InactiveCN105823681AThe accuracy of boundary discrimination is improvedEasy to removeMaterial strength using single impulsive forceEngineeringAlloy

The invention relates to a tempered glass test and check device, in particular to a molybdenum alloy glass detection device with a gear rotary table, an aperture camera shooting assembly and bearing corner clamping plates. A bearing corner clamping plate assembly is fixed on the upper plane of a test rotary table; a rotary impactor is slidably fixed to an impact cross rod; as an improvement, a transmission gear matches with a manual gear; the manual gear is rotatably fixed to a manual wheel shaft; a shaft clamp spring blocks the outer side surface of the manual wheel shaft; a hand wheel cross rod is fixedly connected to the stepped circle of a hand wheel; a hand wheel crank handle is further arranged at the outer end of the hand wheel cross rod; the transmission gear is fixed to a gear section of a rotary shaft; an aperture camera shooting oblique long handle is arranged on an aperture camera shooting rotary plate of the aperture camera shooting assembly; a horizontal aperture frame and a vertical cross arm camera shooting frame are arranged at the outer lower end of the aperture camera shooting oblique long handle; a camera end is arranged at the upper outer end of the vertical cross arm camera shooting frame; an industrial camera is arranged on the lower front surface of the camera end; and a round fluorescent tube is arranged on the horizontal aperture frame. By applying the rotary impactor, the hammer driving force each time is consistent and crushing tests are ensured to be normalized and unified.

Owner:WENZHOU ECONOMIC TECH DEV ZONE BINHAI XIONGJIE ELECTROMECHANICAL RES & DEV STUDIO

Titanium alloy wheel sliding groove four-edge controllable natural rubber clamps

InactiveCN105823680AEven by forcePrecise control of local forceStrength propertiesEngineeringTitanium alloy

The invention relates to tempered glass testing clamps, in particular to titanium alloy wheel sliding groove four-edge controllable natural rubber clamps .As the improvement, the clamping part of each clamp comprises a clamp upper plane, a clamping slope and a vertical face gear, wherein a blind groove space is formed in the perpendicular portion of the clamp upper plane and the vertical face gear, and the clamping slope is provided with an anti-disengagement groove .A sliding framework on each clamp comprises a sliding lower plane and a sliding step face, the outer end of each wheel hole matched section is the outer end of a corresponding shaft pin, and a shaft pin screw hole is formed in the center of the outer end of each shaft pin .The outer ring of each sliding wheel is provided with a wheel I-shaped outer circle .The inner side of each sliding wheel is a wheel inner side face, a wheel inner hole is formed in each wheel inner side face, a wheel step hole is formed in each wheel outer side face, and a wheel step face is arranged between each wheel step hole and the corresponding wheel inner hole .The outer circle of each wheel hole matched section is rotationally matched with one wheel inner hole .Each wheel inner side face is attached to a corresponding shaft pin step .The sliding wheel of each clamp is in sliding fit with a wheel sliding groove of the adjacent clamp .A tempered glass plate can be continuously and freely adjusted.

Owner:温州雄杰机电研发有限公司

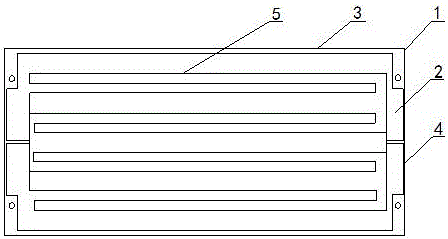

Mounting structure of straight retractable door combined with retractable barrier

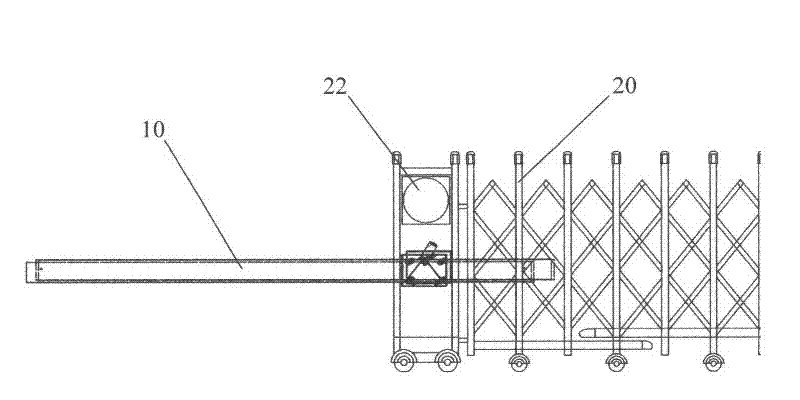

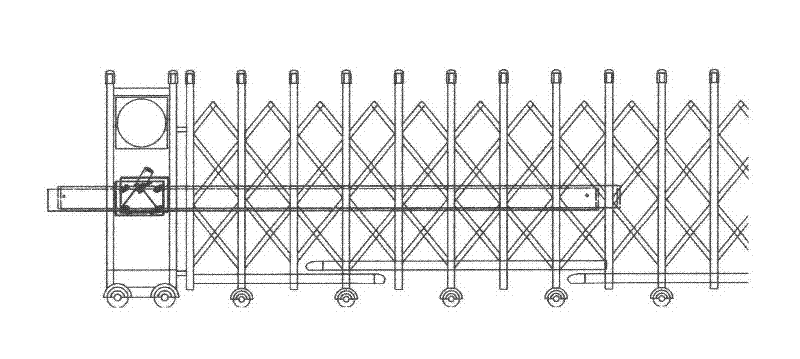

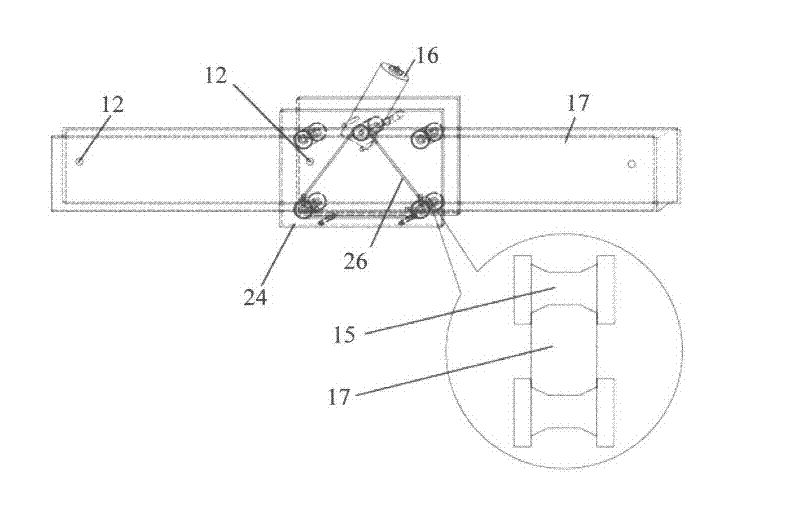

InactiveCN102518386ARealize automatic protectionEasy combined installationGates/doorsMagnetEngineering

The invention provides a mounting structure of a straight retractable door combined with a retractable barrier. The barrier is arranged in a middle gap of the retractable door and is connected with a machine head of the retractable door, a barrier rod guiding wheel is fixed on an aluminum plate of the machine head, a barrier rod is disposed on guiding wheels, and the three groups of guiding wheels are driven by a motor to rotate via a conveying belt so that the barrier rod is driven to extend and retract. The barrier rod is provided with an induction magnet which is used for sensing persons or vehicles so as to control actions of the barrier rod. The mounting structure of the straight retractable door combined with the retractable barrier realizes convenience in combination and installation of the retractable barrier and the retractable door, is low in cost, convenient in use and safe in running, can stop suddenly when encountering resistance, and automatically protects the barrier rod.

Owner:无锡市金凯旋特种门窗制造有限公司

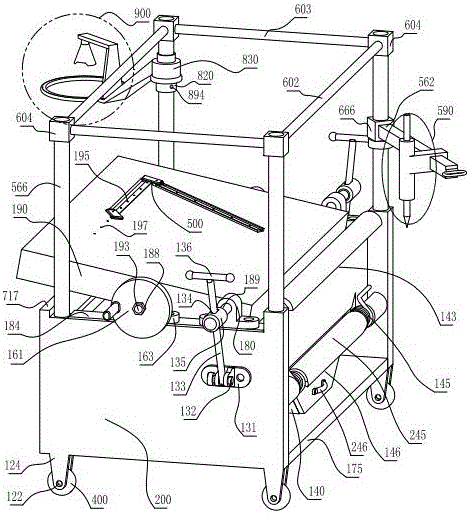

Glass detecting frame with worm wheel aperture linked camera shooting chromium alloy wheel slide way corner clamp

PendingCN105758712AThe accuracy of boundary discrimination is improvedImprove operational efficiencyStrength propertiesUniversal jointRotating disc

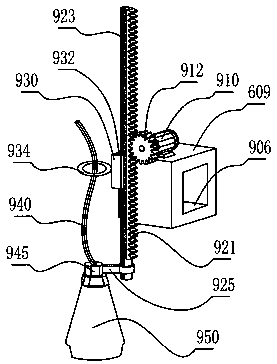

The invention relates to a test detection frame for tempered glass, in particular to a glass detecting frame with a worm wheel aperture linked camera shooting chromium alloy wheel slide way corner clamp.The glass detecting frame is characterized in that a transmission worm wheel is further fixed to a turning plate rotating shaft on one side and matched with a worm shaft, the two ends of the worm shaft are fixed inside worm supporting bases respectively in a rotatable mode, the worm supporting bases are fixed to the outer side faces of corresponding supporting side plates, and a worm crank handle is arranged at one end of the worm shaft; an aperture camera shooting assembly comprises an aperture camera shooting rotating disc and an aperture camera shooting inclined handle, and an industry camera is arranged on the front face below a camera end; a round fluorescent tube is arranged on a horizontal aperture frame, an inclined handle fixing joint is arranged on the aperture camera shooting inclined handle, a transverse rod fixing joint is arranged on an impact transverse rod, a transverse rod universal joint is connected with an inclined handle universal joint through a linkage connecting rod, and an air cylinder impactor is fixed to the impact transverse rod in a sliding mode.By the adoption of the wheel slide way corner clamp assembly, quadrilateral glass of different specifications and dimensions and different clamping angles can be continuously adjusted to be fixed.

Owner:JINJIANG CITY CHIDIAN TOWN XIAOQIU ELECTRICAL MACHINERY SPECIAL EQUIP DESIGN STUDIO

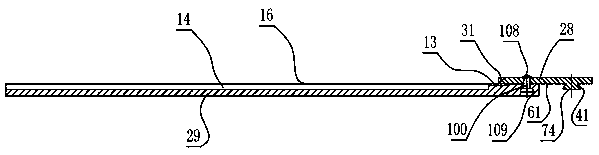

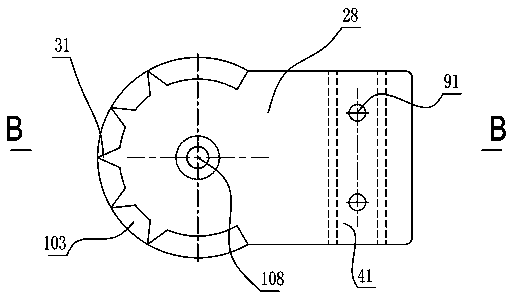

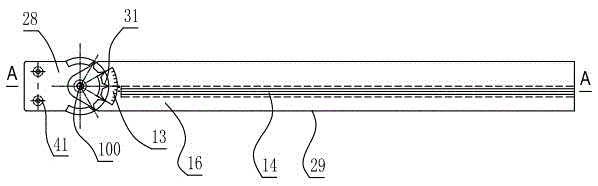

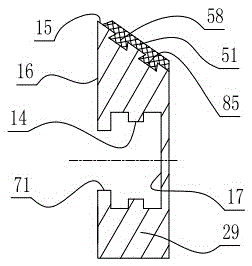

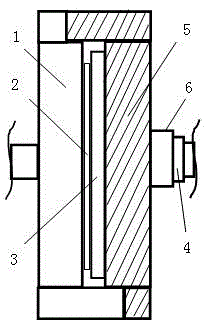

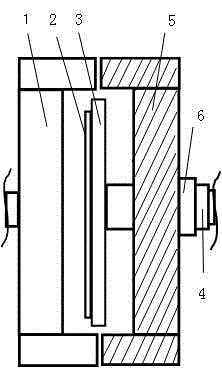

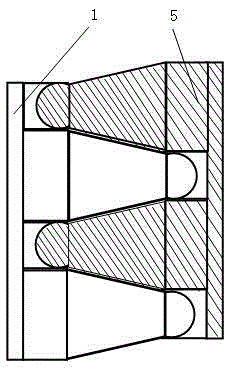

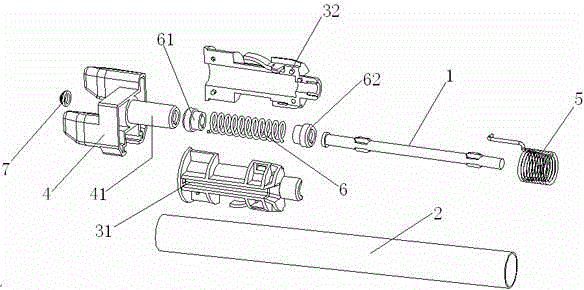

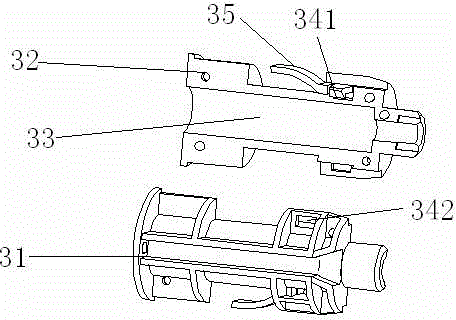

Jaw clutch capable of achieving engagement under high rotating speed condition

InactiveCN105587798ANo mutual tensionSmall maintenance bondMechanical actuated clutchesDrive shaftEngineering

The invention discloses a jaw clutch capable of achieving engagement under a high rotating speed condition. The jaw clutch capable of achieving engagement under the high rotating speed condition at least comprises a driving jaw disk, a friction plate, a friction disk, a friction disk sleeve, a driven jaw disk, a driven jaw disk sleeve, a pressing mechanism and a transmission mechanism. The driving jaw disk is fixed to a driving shaft. The driven jaw disk and the friction disk are connected with a driven shaft. When engagement is required, the friction disk is controlled by the transmission mechanism to approach the driving jaw disk in the axial direction, the friction plate on the friction disk firstly makes contact with the driving jaw disk and generates friction force under the action of the pressing mechanism, and the friction disk and the driven jaw disk rotate along with the driving jaw disk and accelerate gradually; when the rotating speed difference between the driven jaw disk and the driving jaw disk is zero or reaches a preset value, the transmission mechanism controls the driven jaw disk to approach the driving jaw disk in the axial direction, trapezoidal teeth, provided with protruding columnar surfaces, on the disks make contact with one another and are engaged and locked automatically. When separation is required, the transmission mechanism firstly separates the driven jaw disk from the driving jaw disk, and then the friction disk is separated from the driving jaw disk.

Owner:上海洲跃生物科技有限公司

Glass detector having rotary table with handle, rack ring light camera and copper alloy bearing angle backup plate

InactiveCN105758747AThe accuracy of boundary discrimination is improvedAvoid accidental splash damageStrength propertiesEngineeringToughened glass

Owner:WENZHOU ECONOMIC TECH DEV ZONE BINHAI XIONGJIE ELECTROMECHANICAL RES & DEV STUDIO

Optical-ring photographing type chromium alloy glass detection rack provided with disc wheel, rotary table and wheel corner clamp

InactiveCN105758710AThe accuracy of boundary discrimination is improvedOvercome the defect of no self-lockingStrength propertiesEngineeringToughened glass

The invention relates to a tempered glass testing detection rack and provides an optical-ring photographing type chromium alloy glass detection rack provided with a disc wheel, a rotary table and a wheel corner clamp. A wheel slide way corner clamp assembly is fixed on the upper plane of the testing rotary table; a rotary impacting device is fixed on an impacting transverse rod in a slipping manner; as improvements, a table plate rotary shaft on one side is further fixedly provided with the manual disc wheel; a disc wheel crank handle is further arranged on the outer side face of the manual disc wheel; an optical-ring photographing rotary table on an optical-ring photographing assembly is provided with an optical-ring photographing inclined long handle; a horizontal optical-ring frame and a vertical transverse arm photographing frame are arranged at the lower end of the optical-ring photographing inclined long handle; a camera end is arranged at the upper outer end of the vertical transverse arm photographing frame; an industrial camera is arranged just under the camera machine end; a round fluorescent tube is arranged on the horizontal optical-ring frame; the optical-ring photographing assembly is additionally arranged on the whole rack and annular light generated by the round fluorescent tube assists in photographing; and the wheel slide way corner clamp assembly is adopted, so that quadrilateral glass with different specifications and different included angles can be continuously adjusted and fixed.

Owner:WENZHOU ECONOMIC TECH DEV ZONE BINHAI XIONGJIE ELECTROMECHANICAL RES & DEV STUDIO

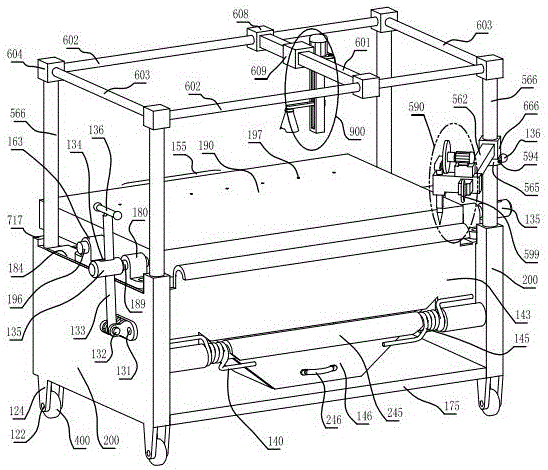

Glass detection machine provided with worm wheel, rotary table, rack optical-ring camera and molybdenum alloy wheel corner clamp

InactiveCN105758746AThe accuracy of boundary discrimination is improvedAvoid accidental splash damageStrength propertiesEngineeringAlloy

The invention relates to a tempered glass testing detection machine and provides a glass detection machine provided with a worm wheel, a rotary table, a rack optical-ring camera and a molybdenum alloy wheel corner clamp. As improvements, a rotary table rotary shaft on one side is further fixedly provided with a transmission worm wheel; the transmission worm wheel is matched with a worm rod shaft; the two ends of the worm rod shaft are respectively rotatably fixed in a worm rod support; the worm rod support is fixed on the outer side face of a corresponding supporting side plate; a worm rod crank handle is further arranged at one end of the worm rod shaft; two transverse horizontal rods are slidingly matched with photographing transverse slide blocks; a photographing square rod is fixed between the two photographing transverse slide blocks; a screw rod hoisting camera set is arranged on the photographing square rod; a square fluorescent tube is arranged on a movable optical ring; an optical ring inclined long handle is arranged on one side of a frame of the square fluorescent tube; a rotary table is arranged at the tail end of the optical ring inclined long handle; the rotary table is provided with a rotary table inner hole and a rotary table lower end face; a cylinder impacting device is fixed on an impacting transverse rod in a slipping manner; a wheel slide way corner clamp assembly is fixed on the upper plane of the testing rotary table, so that quadrilateral glass with different angles can be fixed.

Owner:WENZHOU ECONOMIC TECH DEV ZONE BINHAI XIONGJIE ELECTROMECHANICAL RES & DEV STUDIO

Worm gear platen screw camera shooting bearing rotation angle pressing plate aluminum alloy glass detection device

The invention relates to a tempered glass testing and detection device and provides a worm gear platen screw camera shooting bearing rotation angle pressing plate aluminum alloy glass detection device.According to the improvement, a transmission worm gear is further fixed to a platen rotary shaft on one side and matched with a worm shaft, the two ends of the worm shaft are rotationally fixed into worm supporting bases respectively, the worm supporting bases are fixed to the outer side faces of corresponding supporting side plates, and one end of the worm shaft is further provided with a worm jiggle bar.A rotary shaft worm gear section and a rotary shaft thread are further arranged at the outer end of the platen rotary shaft on one side.The rotary shaft worm gear section is provided with a rotary shaft key groove, and a worm gear flat key is arranged in the rotary shaft key groove in a matched mode.A camera shooting square bar is provided with a screw lifting camera unit.An impact transverse rod is fixedly provided with a cylinder impactor in a sliding mode.A bearing rotation angle pressing plate assembly is fixed to the upper plane of a testing platen, and cameras shoot pictures and transmit the fragment pictures to a computer processing center.Hammering strength is consistent every time when the cylinder impactor is used.By means of the bearing rotation angle pressing plate assembly, quadrangular glass in different specifications and sizes and with different included angles can be fixed.

Owner:WENZHOU ECONOMIC TECH DEV ZONE BINHAI XIONGJIE ELECTROMECHANICAL RES & DEV STUDIO

Glass detection instrument with handle turntable, halo camera and nickel alloy ladder track corner splint

InactiveCN105758801AThe accuracy of boundary discrimination is improvedReduce labor intensityMaterial analysis by optical meansEngineeringNickel alloy

The invention relates to a tempered glass test detection instrument. The improvement of a glass detection instrument with a handle turntable, a halo camera and a nickel alloy ladder track corner splint is as follows: a platen handle is arranged on a rear-end vertical surface of a test turntable; two bent arc ends of the platen handle are arranged as handle heads; the handle heads at the two bent arc ends are fixedly arranged on the rear-end vertical surface of the test turntable; two horizontal rods are in sliding fit with horizontal shooting slide blocks; a square shooting rod is fixed between the two horizontal shooting slide blocks; a screw lifting camera unit is arranged on the square shooting rod; a square fluorescent tube is arranged on a moveable halo; a ladder track splint component is fixedly arranged on the upper surface of the test turntable; a broken glass guide is fixedly arranged between a turntable support base and a lock pin support base as well as the upper surface of a supporting lateral plate; a rotatable impacting device is slidably and fixedly arranged on a horizontal impacting rod; the ladder track splint component is applied to a direct turning structure of the platen handle of the test turntable, so that the fixing for quadrilateral glass at different included angles can be realized.

Owner:WENZHOU ECONOMIC TECH DEV ZONE BINHAI XIONGJIE ELECTROMECHANICAL RES & DEV STUDIO

Method for detecting glass by meas of handled table, screws and camera wheel corner clamps

InactiveCN105758743AChange labor intensityOvercome the defect of no self-lockingStrength propertiesEngineeringNational standard

The invention relates to an armored glass testing method, in particular to a method for detecting glass by means of a handled table, screws and camera wheel corner clamps.As improved, armored glass fragment test includes steps of (1), fastening a test table in a horizontal state; (2) arranging four clamps which are of the same structures and dimensions on the test table; (3) closely attaching rubber press pieces of each clamp onto four edges of a to-be-tested trapezoidal glass sheet; (4), breaking the trapezoidal glass sheet; (5) taking pictures by cameras and sending the pictures of fragments to a computer processing center, and then determining whether the broken trapezoidal glass sheet is qualified or not according to national standards; (6) clearing the fragments of the armored glass and collecting the same in a glass fragment collector through a glass fragment guide; and (7), downwardly griping a handle of the table again with hands to reset the test table in the horizontal state again.During test, cylinder impactors are applied to guarantee uniform hamming each time so as to guarantee normal and unified breakage test.

Owner:WENZHOU ECONOMIC TECH DEV ZONE BINHAI XIONGJIE ELECTROMECHANICAL RES & DEV STUDIO

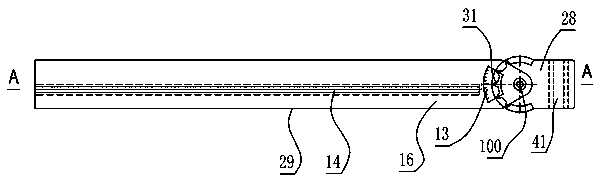

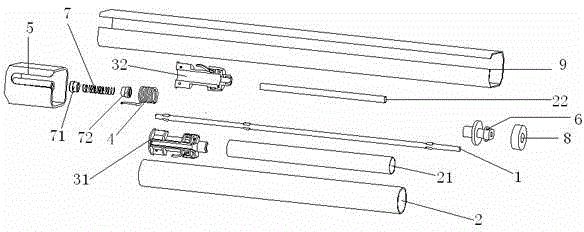

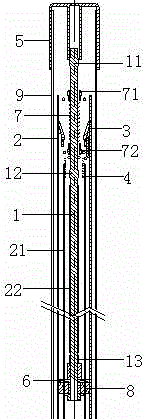

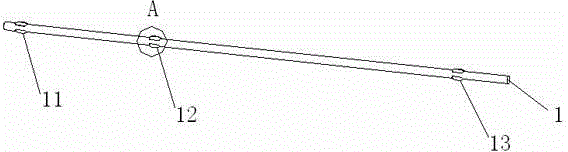

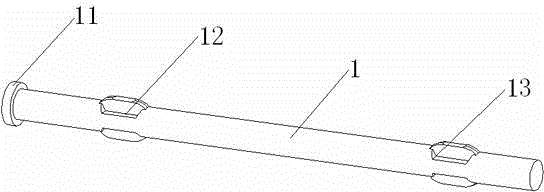

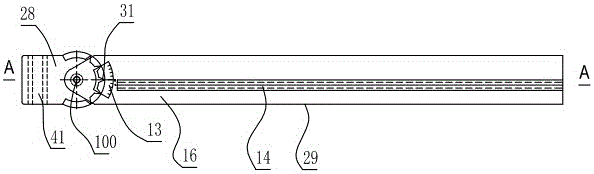

Integrated shielding curtain winding device

ActiveCN104675311AReduce usageIncrease the gapDoor/window protective devicesVehicle componentsEngineeringConductor Coil

The invention discloses an integrated shielding curtain winding device, which comprises core iron, an inner pipe for winding a shielding curtain, and a spring ball and a torsion spring arranged in one end of the inner pipe, wherein the spring ball is formed by buckling a male spring ball and a female spring ball; a central hole coaxial to the core iron is preserved on the spring ball; one end of the core iron is connected with an outer seal cap, and the other end of the core iron is connected with a core iron fixing block; a compressed spring is also sleeved on the core iron and is arranged in the central hole preserved on the spring ball. According to the integrated shielding curtain winding device, three clamping tenons are arranged on the core iron and are used for fixing the core iron and relevant parts, the usage of partial parts is reduced, the product cost is reduced, the assembling is convenient, the whole stability is excellent, and meanwhile, the clearance between the shielding curtain and a side body can also be effectively improved.

Owner:KUSN HUANGTIAN AUTO PARTS INDAL

A glass detection device provided with a worm gear, a platen, aperture camera shooting, stepped corner pressing plates and a copper alloy

The invention relates to a tempered glass testing and detecting device, particularly a glass detection device provided with a worm gear, a platen, aperture camera shooting, stepped corner pressing plates and a copper alloy. According to improvements, a transmission worm gear is fixed to a rotating shaft at one side of the platen and is matched with a worm shaft, two ends of the worm shaft are respectively rotatably fixed to the inside of a worm shaft support, the worm shaft support is fixed to the external surface of a corresponding supporting side plate, one end of the worm shaft is provided with a worm shaft cranking handle, an aperture camera shooting rotary disk of an aperture camera shooting assembly is provided with an aperture camera shooting inclined long handle, the lower outside end of the aperture camera shooting inclined long handle is provided with a horizontal aperture rack and a vertical cross-arm camera shooting rack, the outer end of the vertical cross-arm camera shooting rack is provided with a camera end head, an industrial camera is under the camera end head, and the horizontal aperture rack is provided with a circular fluorescent tube. The device additionally arranges aperture camera shooting assembly to the overall rack and adopts a stepped corner pressing plate assembly. An interference fit exists among two side inclined surfaces of anti-shedding raised bars and two side inclined surfaces of anti-shedding grooves so as to generate extrusion expansive force, thus facilitating installation and combination.

Owner:WENZHOU ECONOMIC TECH DEV ZONE BINHAI XIONGJIE ELECTROMECHANICAL RES & DEV STUDIO

Compressed type shading curtain winding device of internal sealing tube

ActiveCN104695844ARealize integrated designEasy combined installationDoor/window protective devicesEngineeringTorsion spring

The invention discloses a compressed type shading curtain winding device of an internal sealing tube. The compressed type shading curtain winding device includes core iron, an inner tube, a spring bead and a torsion spring, wherein the inner tube is used for winding the shading curtain, and the spring bead and the torsion spring are accommodated in one end of the inner tube. A center hole coaxial with the core iron is preserved in the spring bead. The spring bead is formed by clamping a male spring bead and a female spring bead. One end of the core iron is connected with an internal sealing cover, and the other end of the core iron is connected with a fixing block of the core iron. A compressed spring is sleeved on the core iron and is accommodated in the center hole preserved in the spring bead. At least two clamping tenons are arranged on the core iron. Compression through the internal sealing cover replaces integral compression of the external sealing cover, and the external sealing cover only needs to be fixedly matched with the external tube, so friction noise and friction marks generated through sliding fit of the external sealing cover and the external tube are reduced.

Owner:KUSN HUANGTIAN AUTO PARTS INDAL

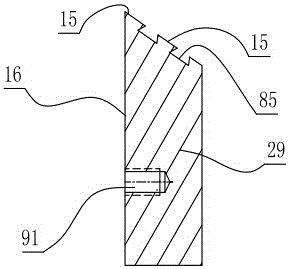

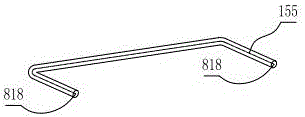

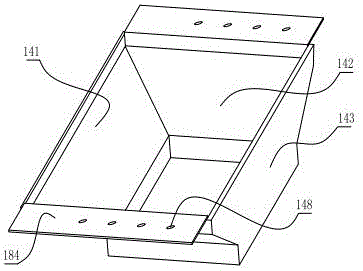

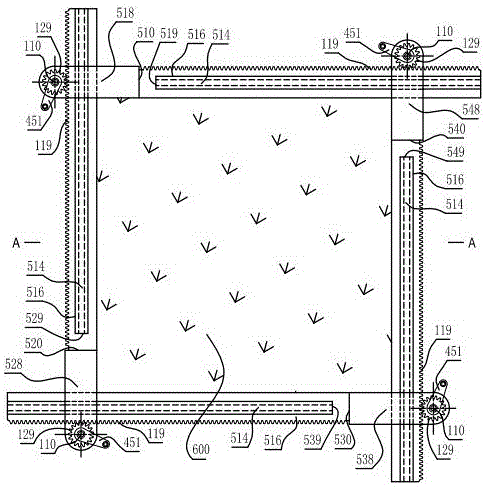

Stair corner free quadrilateral natural rubber fixing pressing plate

InactiveCN105675391AAchieve fixationAvoid stickingStrength propertiesEngineeringMechanical engineering

The invention relates to a fixing pressing plate for glass detection and a stair corner free quadrilateral natural rubber fixing pressing plate. The stair corner free quadrilateral natural rubber fixing pressing plate comprises a first clamping plate, a second clamping plate, a third clamping plate and a fourth clamping plate, all of which are the same in structural size. Each clamping plate is composed of a clamping part and a sliding corner part. The stair corner free quadrilateral natural rubber fixing pressing plate is characterized in that each lower sliding plane is provided with a rotating through hole, a rotary table chamfer cambered surface is arranged on the other side of each rotating through hole, and each rotary table chamfer cambered surface is provided with a corner cambered surface protruding pointer, a stair groove is formed in the other side of each rotating through hole, an arch cambered surface is arranged on the back face of each stair groove position, a transition groove is formed between each stair groove and the corresponding lower sliding plane, and the two ends of the stair groove are open; a stair protruding rail is arranged at one end of each upper clamping plane, and each upper clamping plane and a corresponding transition protruding rail are separable; each protruding rail screw penetrates through a corresponding protruding rail stepped hole, each protruding rail screw and a corresponding plane screw hole are in a spiral immovable fitting mode, each protruding rail contact face is fixed to the corresponding upper clamping plane, and continuous and free adjustment can be achieved for trapezoidal glass plates with different widths.

Owner:张志雄

Plate wheel turntable aperture camera shooting molybdenum alloy bearing corner clamp glass detection device

InactiveCN105891021AThe accuracy of boundary discrimination is improvedOvercome the defect of no self-lockingStrength propertiesEngineeringAlloy

The invention relates to a tempered glass testing frame, in particular to a plate wheel turntable aperture camera shooting molybdenum alloy bearing corner clamp glass detection device. As improvement, a hand-operated plate wheel is fixed to a platen rotary shaft on one side, a plate wheel flat key is arranged between the platen rotary shaft and the hand-operated plate wheel, and a plate wheel jiggle bar is further arranged on the outer side face of the hand-operated plate wheel; a rotary shaft plate wheel section and a rotary shaft thread are arranged at the outer end of the platen rotary shaft, a rotary shaft key groove is formed in the rotary shaft plate wheel section, a plate wheel flat key is arranged in the rotary shaft key groove in a matched mode, the hand-operated plate wheel is fixed to the rotary shaft plate wheel section, and a plate wheel nut is arranged on the outer side face of the hand-operated plate wheel to be matched with the rotary shaft thread; a horizontal aperture frame and an erect cross arm camera shooting frame are arranged at the outer lower end of an aperture camera shooting oblique long handle, a camera terminal is arranged at the outer upper end of the erect cross arm camera shooting frame, an industrial camera is arranged on the front under the camera terminal, a round fluorescent tube is arranged on the horizontal aperture frame, and a cylinder impactor is fixed to an impact cross rod in a sliding mode. By the adoption of a bearing corner clamp component, fixation of quadrilateral glass with different included angles is achieved.

Owner:WENZHOU ECONOMIC TECH DEV ZONE BINHAI XIONGJIE ELECTROMECHANICAL RES & DEV STUDIO

Glass test equipment with handle rotated table, screw camera unit and zinc alloy bevel corner clamp component

InactiveCN105738195AChange labor intensityEasy to removeMaterial strength using single impulsive forceZinc alloysEngineering

The invention relates to tempered glass test and inspection equipment, in particular to glass test equipment with a handle rotated table, a screw camera unit and a zinc alloy bevel corner clamp component.For improvement, a table handle is arranged on a vertical face of the rear end of a test table, and two arc ends of the table handle are handle tips which are both fixed to the vertical face of the rear end of the test table; the screw lifting camera unit is arranged on a camera square bar, a rotary impacter is slidably fixed to a transverse impact rod, and the bevel corner clamp component is fixed to the upper plane of the test table.The camera unit takes photos and transmits fragment images to a computer processing center, and suitableness for large-scale glass test is achieved; by application of the rotary impacter to realize uniformity of each-time hammering level, and generalization and standardization of crushing tests are guaranteed; by adoption of the bevel corner clamp component, continuous regulation and fixation of quadrangular glass different in specification, dimension and included angle can be realized; the height of anti-shedding ribs and the depth of anti-shedding grooves are in clearance fit, and mounting and combination are facilitated.

Owner:WENZHOU ECONOMIC TECH DEV ZONE BINHAI XIONGJIE ELECTROMECHANICAL RES & DEV STUDIO

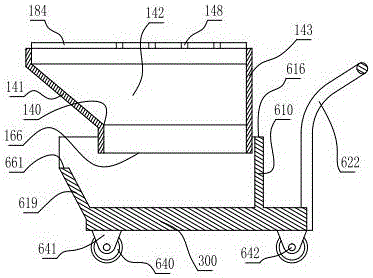

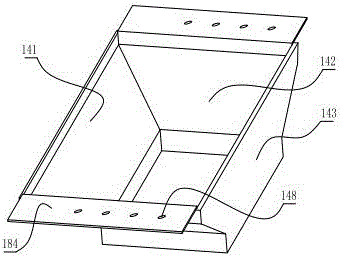

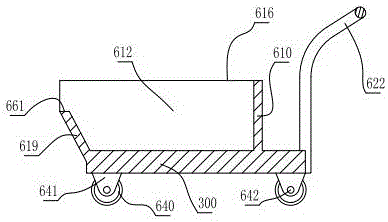

Glass inspection apparatus having disc wheel rotary table, ring light camera and titanium alloy circular groove corner pressing plate

InactiveCN105758709AThe accuracy of boundary discrimination is improvedReduce labor intensityMaterial strength using single impulsive forceTransverse levelToughened glass

The invention relates to a tempered glass testing and inspecting apparatus, and in particular relates to a glass inspection apparatus having a disc wheel rotary table, a ring light camera and a titanium alloy circular groove corner pressing plate. The improvement is as follows: a hand-operated disc wheel is also fixed on a rotary table rotating shaft at one side, a disc wheel flat key is arranged between the rotary table rotating shaft and the hand-operated disc wheel, a disc wheel crank handle is also arranged on the outer side surface of the hand-operated disc wheel, transverse camera shooting sliding blocks are matched with two transverse leveling rods in a sliding manner, a camera shooting square rod is fixed between two transverse camera shooting sliding blocks, a screw rod lifting camera set is arranged on the camera shooting square rod, a square fluorescent tube is arranged on a mobile light ring, a circular rail corner pressing plate assembly is fixed on the upper plane of the testing rotating table, a rotary impactor is fixed on an impacting cross bar in a sliding manner, the structure that the hand-operated disc wheel overturns the testing rotating table, in combination with the design that the lower port of a broken glass guider faces the upper port of a broken glass collecting trolley, can ensure that glass pieces can fall into the broken glass collecting trolley through the broken glass guider, and also the broken glass collecting trolley can be separated from the broken glass guider conveniently.

Owner:WENZHOU ECONOMIC TECH DEV ZONE BINHAI XIONGJIE ELECTROMECHANICAL RES & DEV STUDIO

Detecting system for nickel alloy glass of circular corner backup plate for handle turntable aperture shooting

InactiveCN105865951AThe accuracy of boundary discrimination is improvedOvercome the defect of no self-lockingStrength propertiesEngineeringNickel alloy

The invention relates to a test check system for tempered glass. A detecting system for nickel alloy glass of a circular corner backup plate for handle turntable aperture shooting is characterized in that a circular orbit corner backup plate component is fixed on an upper plane of a testing turntable; a glass breaking guider is fixed between a turntable supporting base and a lock pin supporting base as well as the upper plane of a supporting lateral plate; a lower hole of the glass breaking guider falls into an upper hole of a broken glass gathering vehicle; a rotating impactor is fixed on an impacting cross bar in a sliding manner; the improvement is as follows: a platen handle is arranged on a vertical surface at the rear end of the testing turntable; handle heads at two arc ends are fixed on the vertical surface at the rear end of the testing turntable; an aperture shooting inclined long handle is arranged on an aperture shooting turntable on an aperture shooting component; a horizontal aperture rack and a vertical cross arm shooting rack are arranged at the outer lower end of the aperture shooting inclined long handle; a camera end is arranged at the external end on the vertical cross arm shooting rack; an industrial camera is arranged on the lower front surface of the camera end; a circular fluorescent tube is arranged on the horizontal aperture rack; the circular fluorescent tube is utilized to generate circular light for assisting shooting.

Owner:WENZHOU ECONOMIC TECH DEV ZONE BINHAI XIONGJIE ELECTROMECHANICAL RES & DEV STUDIO

Molybdenum alloy glass detection device with disc wheel rotating table, screw camera and wheel rotating angle clamps

InactiveCN105784513AChange labor intensityOvercome the defect of no self-lockingStrength propertiesAlloyUltimate tensile strength

The invention relates to a tempered glass testing and inspecting device, in particular to a molybdenum alloy glass detection device with a disc wheel rotating table, a screw camera and wheel rotating angle clamps.The molybdenum alloy glass detection device is characterized in that a manual disc wheel is fixed to a platen rotating shaft on one side, a disc wheel flat key is arranged between the platen rotating shaft and the manual disc wheel, and a disc wheel cranking handle is arranged on the outer side face of the manual disc wheel; a screw lifting camera unit is arranged on a camera square rod, a rotation impacter is fixed to an impact cross rod in a sliding mode, a wheel rotating angle clamp assembly is fixed to the upper plane of a testing platen, and a cullet recovering container is fixed between a platen supporting base and a lockpin supporting base and the upper planes of supporting side plates; labor intensity of cullet detection is changed, camera shooting and photographing are conducted, cullet images are transmitted to a computer processing center, and the molybdenum alloy glass detection device is particularly suitable for detecting and processing glass in large batches; by means of the structure arrangement that the manual disc wheel can drive the testing platen to turn over, cullet is convenient to clear, and as the cullet recovering container is arranged, it is ensured that the cullet is not scattered; intensity of all hammer driving actions is uniform by using the rotation impacter.

Owner:WENZHOU ECONOMIC TECH DEV ZONE BINHAI XIONGJIE ELECTROMECHANICAL RES & DEV STUDIO

Glass detection apparatus with hydraulic platen, aperture shooting assembly and titanium-alloy inclined-plane corner leaning clamp assembly

InactiveCN105910922AThe accuracy of boundary discrimination is improvedEasy to removeMaterial analysis by optical meansMaterial strength using single impulsive forceEngineeringRubber sheet

The invention relates to a toughened glass testing and examination apparatus, especially to a glass detection apparatus with a hydraulic platen, an aperture shooting assembly and a titanium-alloy inclined-plane corner leaning clamp assembly. The upper plane of a testing rotary table is fixedly provided with an inclined-plane slideway corner leaning clamp assembly, and an impact cross bar may be slidably fixed with a rotary impacter. According to an improved embodiment in the invention, the upper plane of a rear plate is provided with a broken gap, the lower end of the broken gap is fixedly provided with a supporting base plate, a T-shaped guide rail is arranged on the center of a lower plane of the rear end of the testing rotary table, and a hydraulic lifting mechanism is arranged between the T-shaped guide rail and the supporting base plate; and an aperture shooting rotating disc on the aperture shooting assembly is provided with an oblique long aperture shooting handle, the exterior lower end of the oblique long aperture shooting handle is provided with a horizontal aperture rack and a vertical transverse-arm shooting rack, an exterior end on the vertical transverse-arm shooting rack is provided with a camera end tip, and an industrial camera is located just under the camera end tip. Since the aperture shooting assembly is additionally installed on the integral frame of the apparatus, the boundary discrimination accuracy of glass fragments is improved by 30%; and the inclined-plane corner leaning clamp assembly is employed, and a layer of compressed rubber sheet is arranged on a clamping slope.

Owner:WENZHOU ECONOMIC TECH DEV ZONE BINHAI XIONGJIE ELECTROMECHANICAL RES & DEV STUDIO

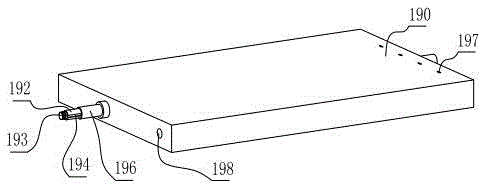

FPC board light source packaging structure and production method thereof

PendingCN106783827ALow calorific valueTo achieve cooling effectSolid-state devicesSemiconductor/solid-state device manufacturingPower flowAdhesive

The invention relates to a FPC board light source packaging structure and a production method thereof. The FPC board light source packaging structure comprises a FPC packaging board piece and is characterized in that the outer surface of the FPC packaging board piece is provided with a fluorescent powder adhesive layer, and a chip packaging layer is packaged in the fluorescent powder adhesive layer; the left side and the right side of the FPC packaging board piece are short edges which are identical in length and serve as arrangement edges, the upper side and the lower side of the FPC packaging board piece are long edges which are identical in length and serve as bending edges, the anode and the cathode of the chip packaging layer are respectively located in packaging areas close to the bending edges, and the FPC packaging board piece can be optionally bent leftwards and rightwards. The FPC board light source packaging structure has the advantages that the heat generation amount of a chip is lowered by using the large-power chip and lowering working currents, a radiator is not needed due to the fact that the heat generation amount of the whole FPC COB can be lowered, and production and mounting can be performed favorably according to different use requirements.

Owner:中山市雅能照明科技有限公司

Molybdenum alloy step slide rail four-edge adjustable type engineering rubber backup plate

InactiveCN105910897AEven by forcePrecise control of local forceStrength propertiesAlloyMaterials science

The invention relates to a tempered glass testing backup plate, in particular to a molybdenum alloy step slide rail four-edge adjustable type engineering rubber backup plate. The molybdenum alloy step slide rail four-edge adjustable type engineering rubber backup plate adopts an improvement that an upper clamping part of a backup plate comprises an upper plane of the backup plate, a clamping slope and an elevation gear rack, wherein a step slide rail is arranged on each upper plane of the backup plate, and each upper plane of the backup plate is connected with the corresponding step slide rail by a transition convex rail; each step slide rail and the corresponding transition convex slide are connected into a whole, and one side of each transition convex rail is provided with a convex rail contact surface; each convex rail screw penetrates through a convex rail step hole, and is spirally tightened and matched with a plane screw hole, and each convex rail contact surface is fixedly arranged on the corresponding upper plane of the backup plate; an upper sliding skeleton of each backup plate comprises a sliding lower plane and a sliding step surface, a vertical shaft hole is formed in each sliding step surface, and a step horizontal groove is formed in each sliding lower plane; each sliding lower plane and the corresponding step horizontal groove are connected by a transition groove; the step horizontal groove of each backup plate and the step slide rail of the adjacent backup plate are in sliding fit, so as to realize the continuous and free adjusting of tempered glass plates with different widths.

Owner:WENZHOU ECONOMIC TECH DEV ZONE BINHAI XIONGJIE ELECTROMECHANICAL RES & DEV STUDIO

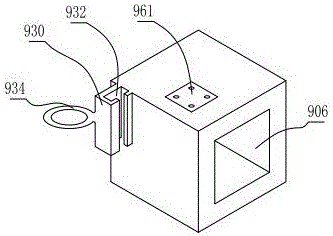

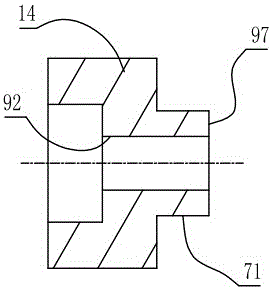

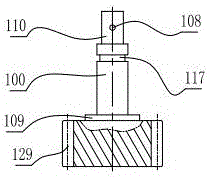

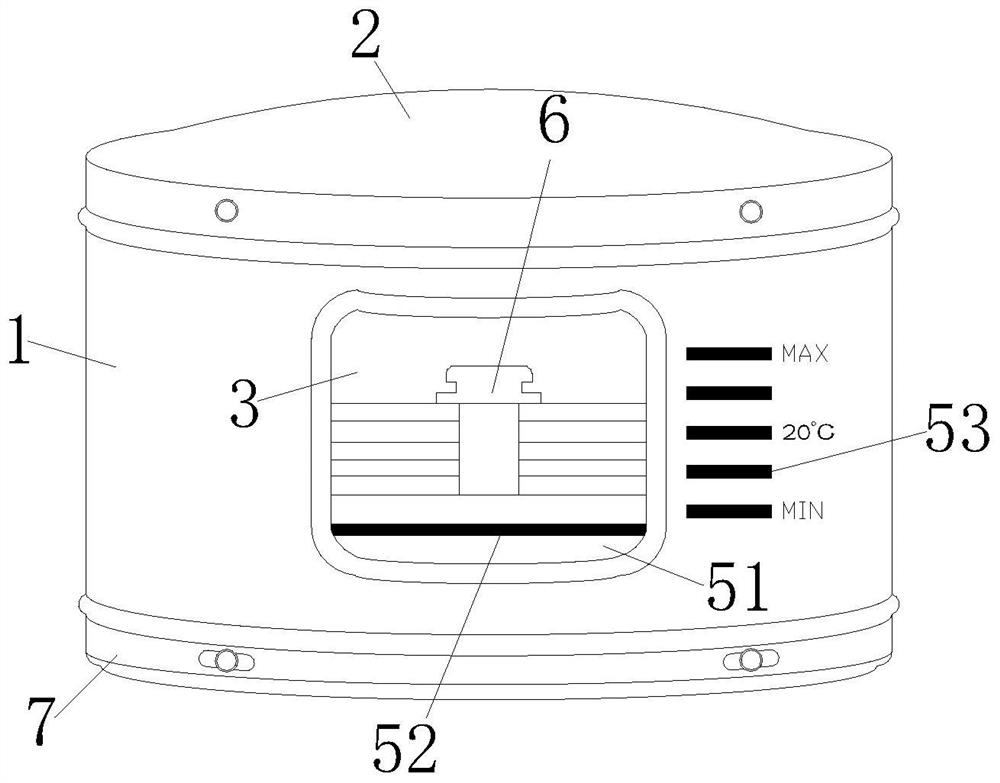

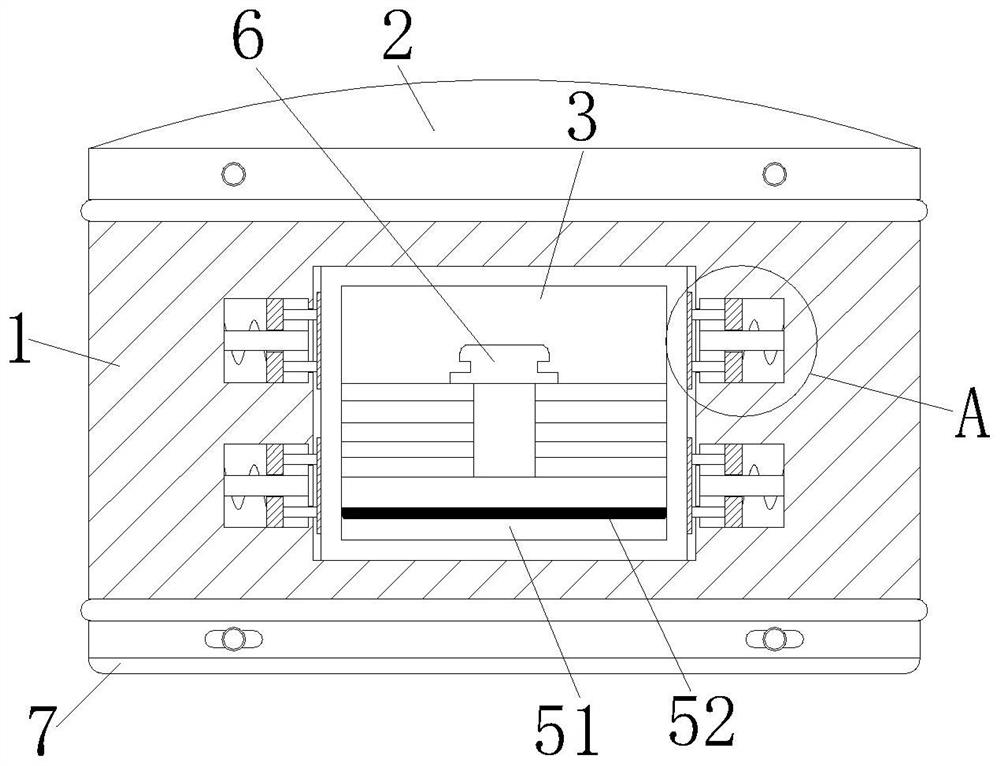

Novel expander for mutual inductor capable of reliably operating in power grid

PendingCN114203399APlay a fixed roleEasy combined installationTransformers/inductances coolingPower gridEngineering

The invention belongs to the technical field of expanders, and particularly relates to a novel expander for a mutual inductor capable of reliably operating in a power grid, which comprises a shell wall, an upper cover, an oil level inspection window and a mounting assembly, the upper cover is arranged at the top of the shell wall; a mounting groove is formed in the inner wall of the shell wall; the oil level inspection window is arranged in the mounting groove; the installation assemblies are arranged on the inner wall of the shell wall and located on the two sides of the installation groove. The mounting assembly comprises a supporting column, a sliding plate, a spring, a supporting rod and a fixing plate. Sliding grooves are symmetrically formed in the inner walls of the two sides of the mounting groove. The supporting column is arranged in the sliding groove, and the two ends of the supporting column are fixedly connected with the side wall of the sliding groove. The sliding plate is slidably connected to the outer wall of the supporting column. By arranging the mounting assembly, the oil level inspection window and the shell wall can be conveniently combined and mounted, so that the mounting efficiency of the oil level inspection window is improved, and relatively accurate oil level judgment can be conveniently provided for operation and maintenance personnel.

Owner:BAODING TIANWEI TRANSFORMER CO LTD

Glass check frame with hydraulic turntable, rack, halo camera, zinc alloy circular rail and corner pressing plate

InactiveCN105758744AThe accuracy of boundary discrimination is improvedAvoid accidental splash damageStrength propertiesTransverse levelZinc alloys

The invention relates to a tempered glass check frame. The improvement of a glass check frame with a hydraulic turntable, a rack, a halo camera, a zinc alloy circular rail and a corner pressing plate is as follows: a disconnected gap is arranged on an upper plane of a rear plate; a supporting base plate is fixedly arranged at the lower end of the disconnected gap; a T-shaped guiderail is arranged at the center of the lower plane at the rear end of a test turntable; a hydraulic lifting mechanism is arranged between the T-shaped guiderail and the supporting base plate; two horizontal rods are in sliding fit with horizontal camera slide blocks; a square camera rod is fixed between the two horizontal camera slide blocks; a rack lifting camera unit is arranged on the square camera rod; a square fluorescent tube is arranged on a moveable halo; a cylinder impacting device is fixed on a horizontal impacting rod in a sliding form; a circular rail corner pressing plate component is fixed on the upper plane of the test turntable. According to the invention, a moveable halo combined rack lifting camera unit is added on the whole frame; an auxiliary camera utilizing the square fluorescent tube to generate circular light is used for shooting; compared with the shooting of single camera without the square fluorescent tube for generating peripheral circular light, the shooting has the advantage that the boundary distinguishing accuracy of the broken glass is increased by 30%.

Owner:WENZHOU ECONOMIC TECH DEV ZONE BINHAI XIONGJIE ELECTROMECHANICAL RES & DEV STUDIO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

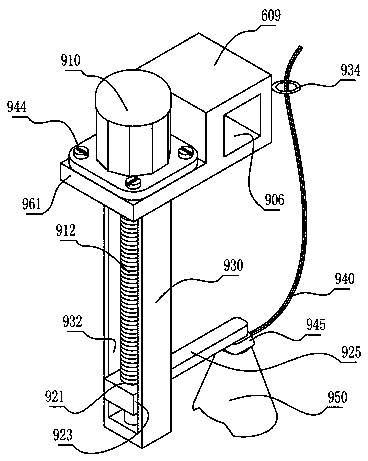

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com