Jaw clutch capable of achieving engagement under high rotating speed condition

A jaw clutch, high-speed technology, applied in the direction of clutches, mechanical drive clutches, mechanical equipment, etc., can solve the problems of large impact, increased torque, and easy wear of teeth, and achieve small impact, long life, and convenient maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. The following description is a preferred embodiment of the present invention, it should be pointed out that for those of ordinary skill in the art, without departing from the concept of the present invention, some improvements or adjustments can be made, and these improvements or adjustments should fall within the scope of the present invention. within the scope of protection.

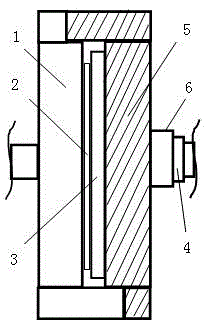

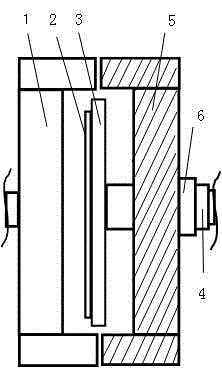

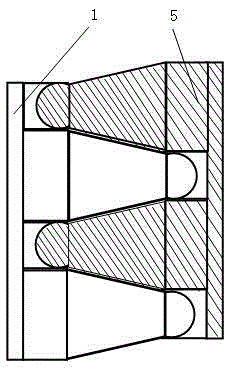

[0020] Such as Figure 1-3 As shown, the clutch of the present invention at least includes: active jaw disc 1, friction plate 2, friction disc 3, friction disc sleeve 4, driven jaw disc 5, driven jaw disc sleeve 6, pressing mechanism 7 (not shown in the figure) and transmission mechanism 8 (not shown in the figure).

[0021] The active jaw disc 1 is fixed on the driving shaft, the friction disc 3 is fixed on the friction disc sleeve 4, and is connected with the driven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com