Offshore platform dry type pile leg inner wall crawling robot

A technology of crawling robot and offshore platform, applied in the field of mechanical design, can solve the problems of difficult operation, complex structure, low efficiency, etc., and achieve the effect of small structure, stable and reliable structure, and strong system controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

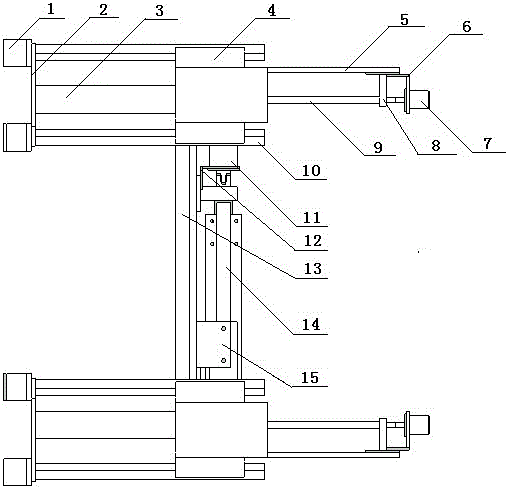

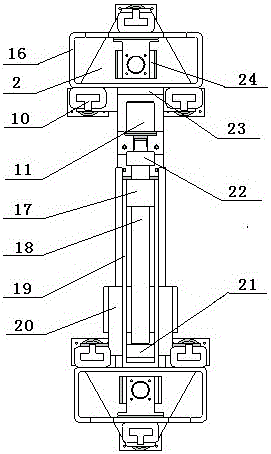

[0028] The robot is generally composed of three parts: upper leg group, lower leg group and torso.

[0029] The structure of the upper leg group of the robot is exactly the same as that of the lower retreat group, mainly consisting of an electromagnetic chuck (1), a triangular bottom plate (2), a U-shaped push plate for the leg group (3), a leg group frame (16), and a leg frame bottom plate (5 ), "T" type leg bar (10), "T" type chute (4), leg screw (9), small stepping motor (7) and other parts. One ends of the three "T"-shaped leg rods (10) are respectively connected by screw triangular bottom plates (2) and distributed in a triangular shape. Three groups of electromagnetic chucks (1) are respectively fixed on the other side of the triangular bottom plate (2) by screws, and are arranged in a triangular distribution. Three sets of "T"-shaped chutes (4) are respectively fixed on the leg frame (16) by screws, and the three "T"-shaped leg rods (10) can be respectively pivoted in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com