Straight-ejection inclined core-pulling device for multiple parallel linked core blocks for injection mold

A technology of injection mold and straight top, which is applied in the field of oblique core-pulling devices, and can solve problems such as increased cost, high cost, and increased shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

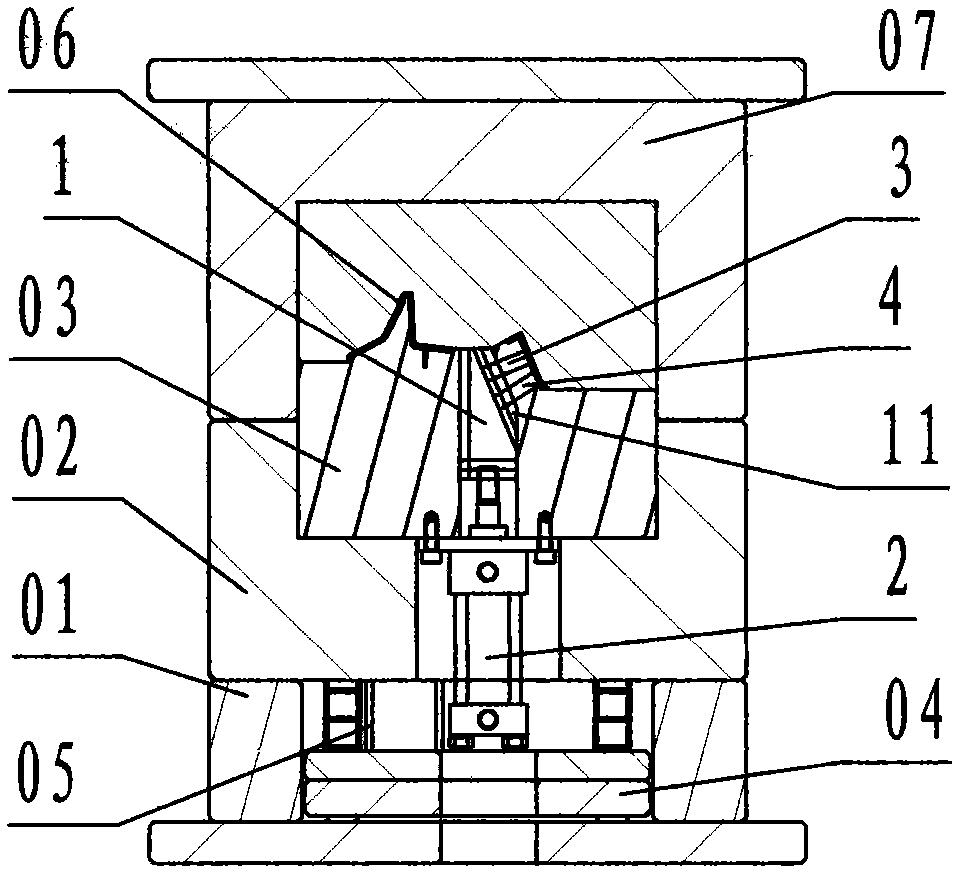

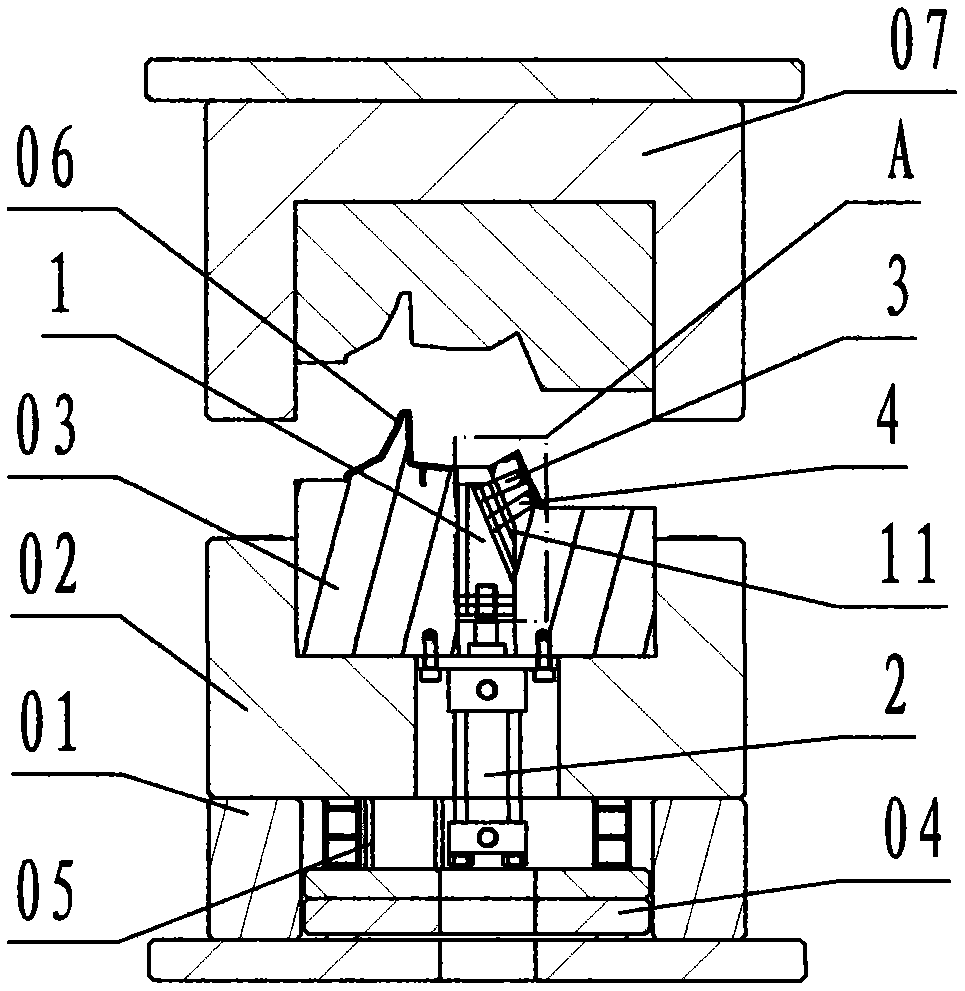

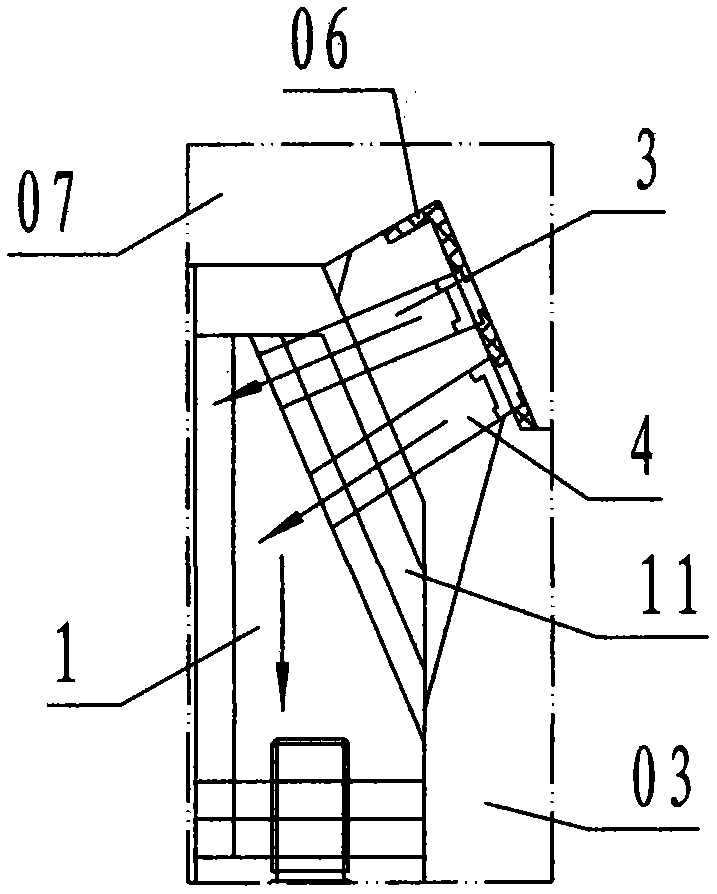

[0021] refer to Figure 1 ~ Figure 4 , a straight top slant pumping device for parallel multi-core block linkage of an injection mold according to the present invention, comprising a straight top slant rail slider 1, an oil cylinder 2, A slant core block 3, B slant core block 4, wherein: the The straight top ramp slider 1 is a wedge-shaped block-shaped steel member, and the right side of the straight top ramp slider 1 is provided with a protruding T-shaped track that is inclined from up to down to the right and is called a ramp slide 11;

[0022] The oil cylinder 2 is a hydraulically telescopic actuator composed of a cylinder body and a piston rod;

[0023] The A oblique core block 3 is a hexagonal block-shaped steel member, the cross section of the A oblique core block 3 is rectangular, and the right side of the A oblique core block 3 is provided with a molded product 06 inside hook The core-pulling profile of the structure, the left side of the A inclined core-pulling block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com