Packaging bag sorting device

A sorting device and packaging bag technology, applied in the field of packaging bag processing, can solve problems such as the inability to realize automatic filling of double-layer packaging bags

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

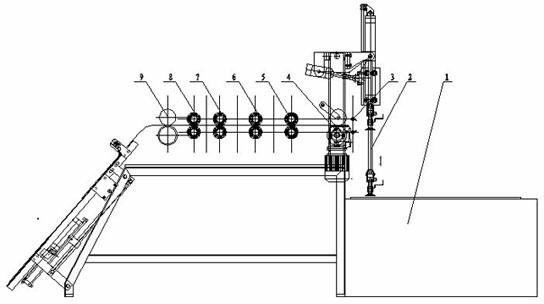

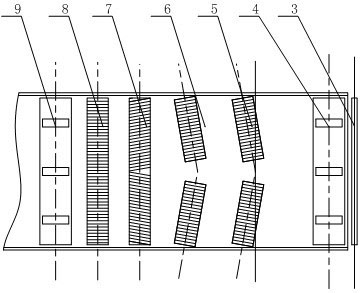

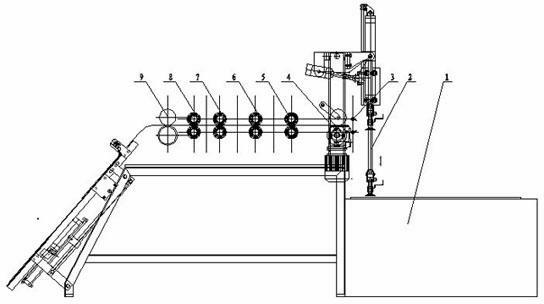

[0013] figure 1 It is a front view of an embodiment of the packaging bag finishing device of the present invention. As shown in the figure, the packaging bag finishing device of this embodiment includes a workbench 1, a bag-loading suction cup manipulator 2, an air injection pipe 3, an introduction roller 4, and a brush roller 5 -8 and tension roller 9. Among them, the workbench 1 is used to place the packaging bags to be sorted; the bag-up suction cup manipulator 2 is arranged above the workbench 1, and is used to suck up the packaging bags from the workbench 1 and send them to the introduction roller 4; The mouth is aligned with the introduction roller 4, which is used to initially flatten the bag-up suction cup manipulator 2 from the workbench 1 and the packaging bag to be sorted by the introduction roller 4; the introduction rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com