Preservative film for short-term storage of fruits and vegetables, preparation method of preservative film and prepared preservative bag

A fresh-keeping film and fresh-keeping bag technology, applied in bags, applications, sacks, etc., can solve problems such as loss, and achieve the effects of slowing water loss, slowing down the speed of mature decay, and prolonging the time of decay.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] HDPE: 30kg, copolymer of LLDPE and LDPE: 38kg; sodium carboxymethyl starch: 30kg, sulfate modified metal oxide additive A1Br 3 2kg;

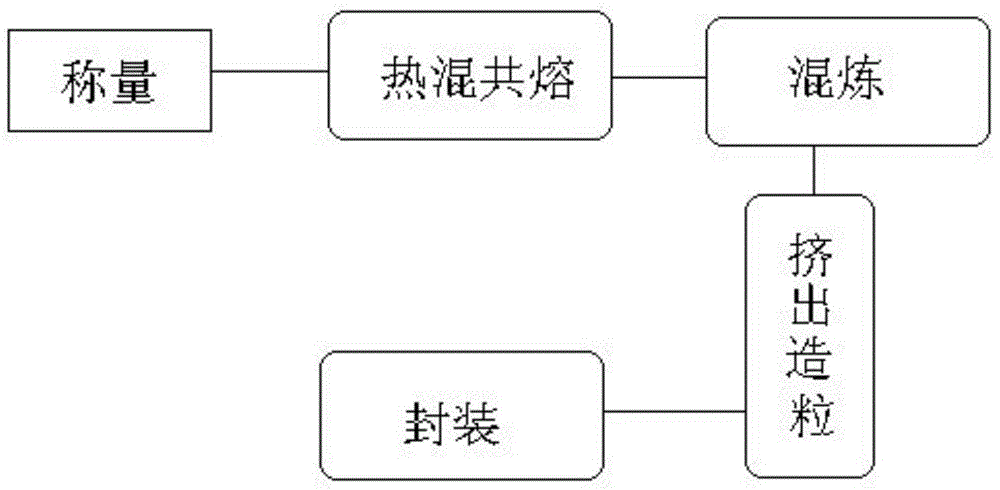

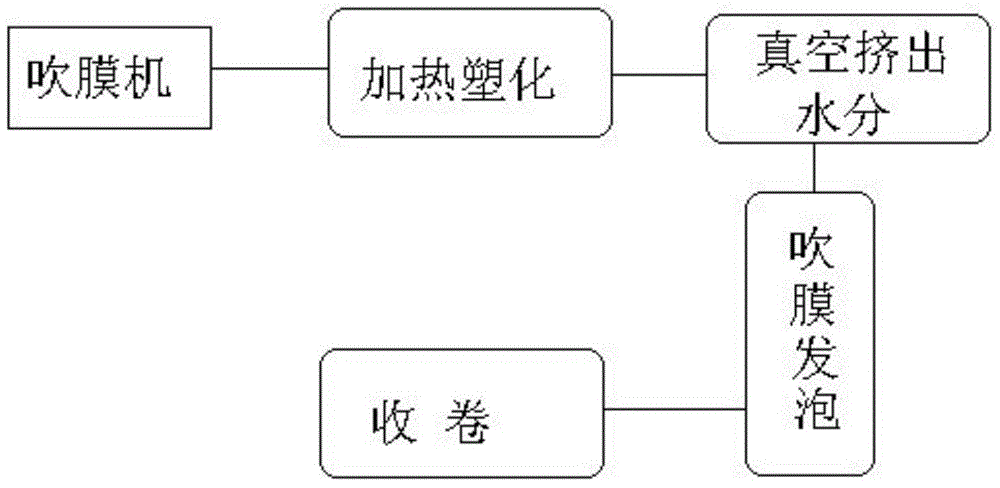

[0038] The preparation steps of membrane material are as follows:

[0039] (1) The copolymer of 30kg of HDPE, 38kg of LLDPE and LDPE, 2kg of solid additive A1Br 3 Carry out thermal mixing with 30kg of modified starch sodium carboxymethyl starch to make it eutectic, and the temperature of thermal mixing is 140°C;

[0040] (2) Mixing, discharge gas and excess water during the mixing process, and then plasticize and extrude;

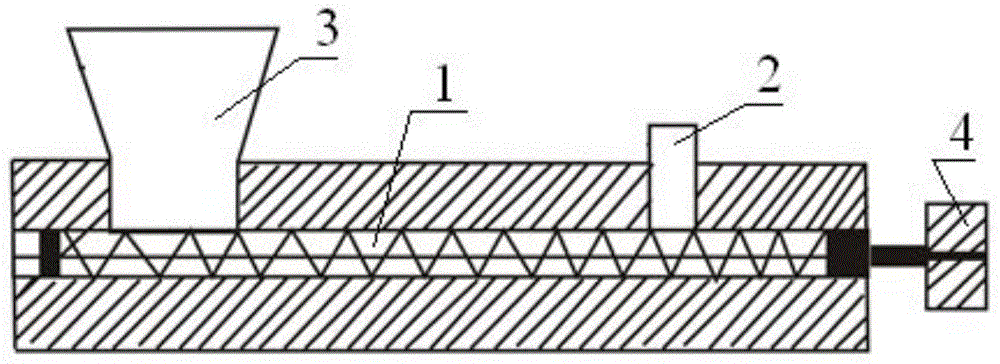

[0041] Mixing and extrusion adopts a granulator with an exhaust device. The exhaust device of the granulator is an exhaust pipe 2 placed vertically on the screw 1 at one end. The axis of the exhaust pipe 2 is parallel to the axis of the hopper 3. The exhaust pipe 2 is located at one end close to the die head 4, and is plasticized and extruded after removing excess moisture in the hot mixture;

[0042] (3) The extru...

Embodiment 2

[0046] LLDPE: 32kg, copolymer of HDPE and LDPE: 34kg; modified starch: 30kg, molecular sieve additives: 2kg;

[0047] The preparation steps of membrane material are as follows:

[0048] (1) 32kg of LLDPE, 34kg of copolymers of HDPE and LDPE, 2kg of molecular sieve additives and 30kg of modified starch were hot-mixed to make them eutectic, and the temperature of the hot-mixing was 120°C;

[0049] (2) Mixing, discharge gas and excess water during the mixing process, and then plasticize and extrude;

[0050] Mixing and extrusion adopts a granulator with an exhaust device. The exhaust device of the granulator is an exhaust pipe 2 placed vertically on the screw 1 at one end. The axis of the exhaust pipe 2 is parallel to the axis of the hopper 3. The exhaust pipe 2 is located at one end close to the die head 4, and is plasticized and extruded after removing excess moisture in the hot mixture;

[0051] (3) The extruded material is cut into pellets and packaged for subsequent use af...

Embodiment 3

[0055] LDPE: 40kg, copolymer of HDPE and LLDPE: 34kg; CMS industrial starch: 25kg, mixed metal salt additive AICl 3 -CuCl 2 1kg;

[0056] The preparation steps of membrane material are as follows:

[0057] (1) The copolymer of 40kg of LDPE, 34kg of HDPE and LLDPE, 1kg of mixed metal salt additive AICl 3 -CuCl 2 Hot mixing with 25kg of CMS industrial starch to make it co-melt, the temperature of hot mixing is 120°C;

[0058] (2) Mixing, discharge gas and excess water during the mixing process, and then plasticize and extrude;

[0059] Mixing and extrusion adopts a granulator with an exhaust device. The exhaust device of the granulator is an exhaust pipe 2 placed vertically on the screw 1 at one end. The axis of the exhaust pipe 2 is parallel to the axis of the hopper 3. The exhaust pipe 2 is located at one end close to the die head 4, and is plasticized and extruded after removing excess moisture in the hot mixture;

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com