Automatic Chinese chestnut huller

A shelling machine and automatic technology, applied in the fields of shelling, pod removal, food science, etc., can solve the problems of large investment in steam shelling equipment, low efficiency of manual shelling, coking of chestnuts, etc., to achieve compact structure, saving The effect of extending space and scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention will be further described below through the accompanying drawings and embodiments.

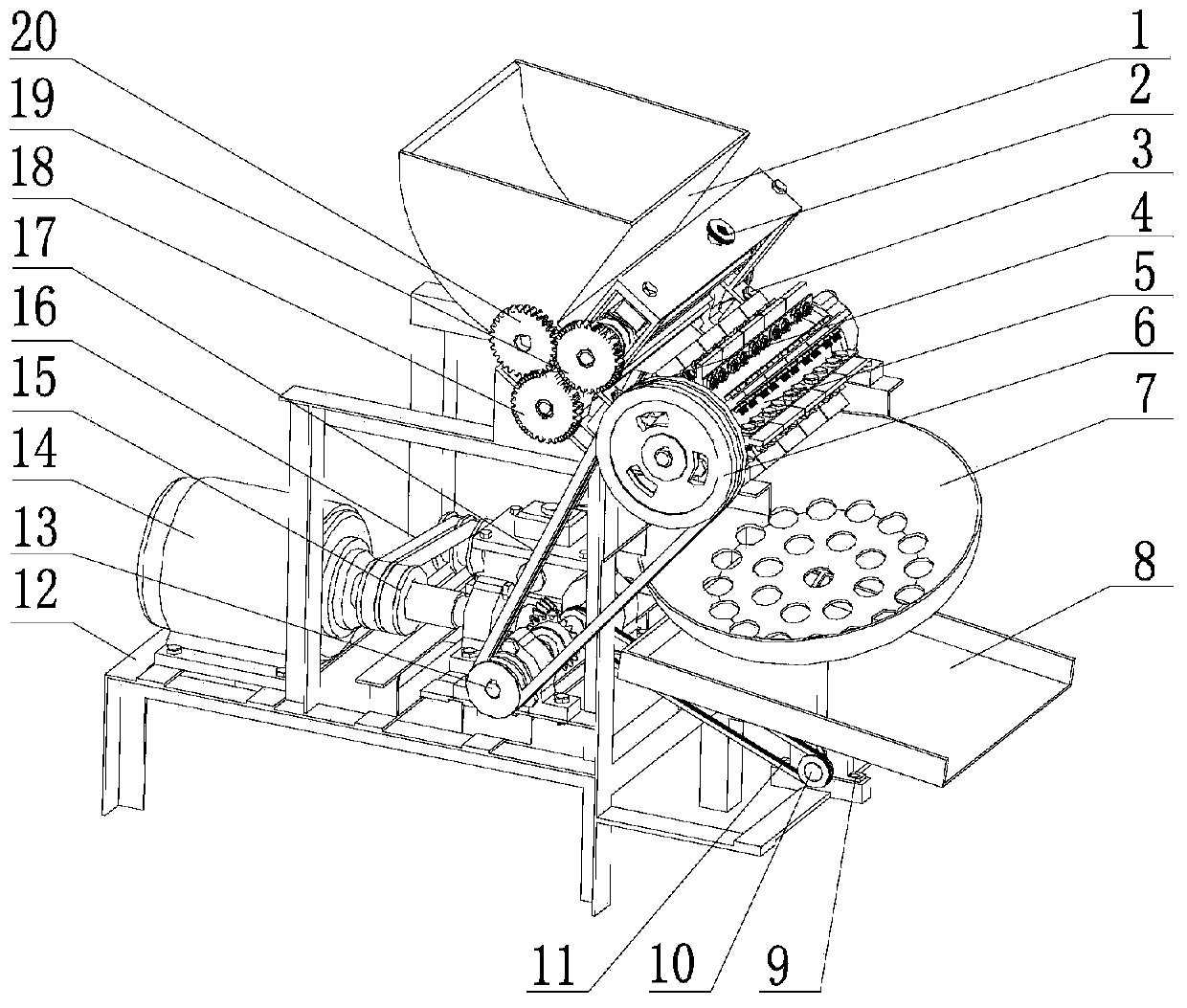

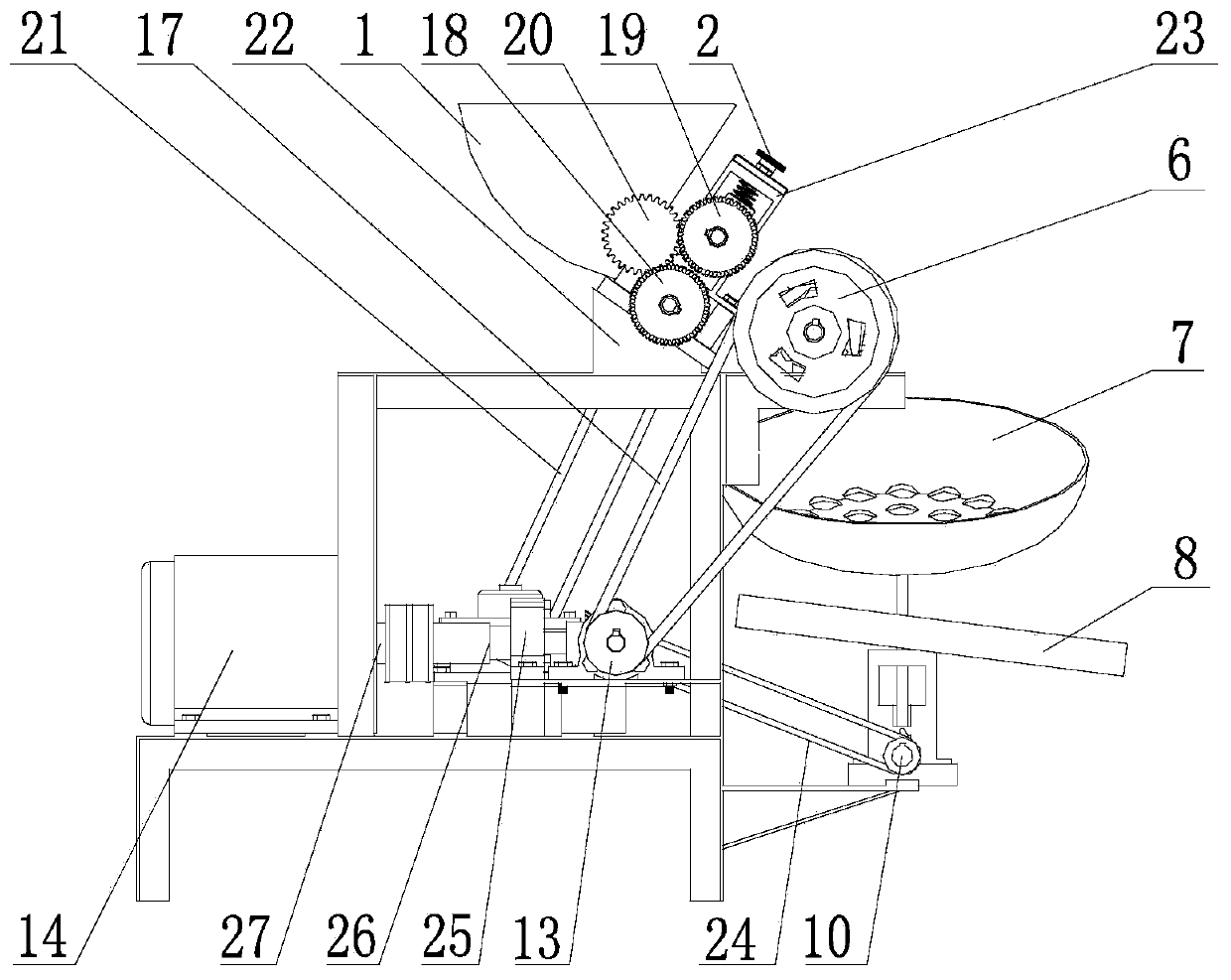

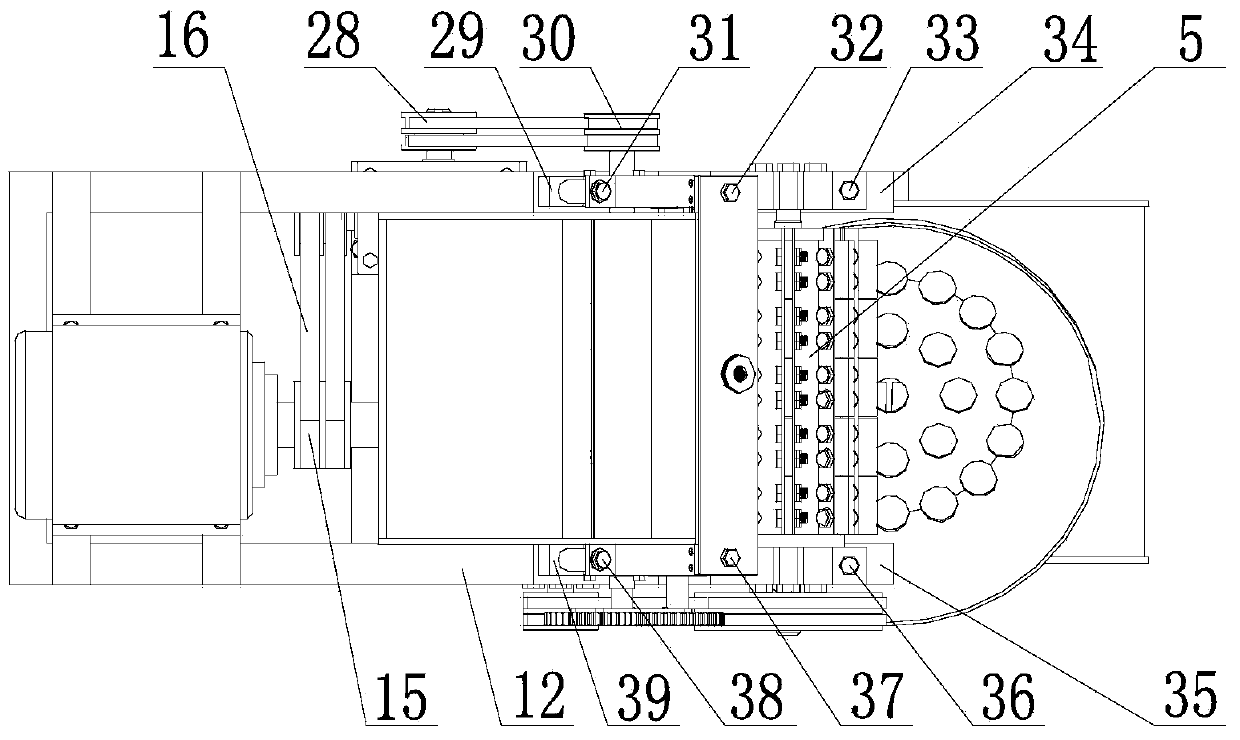

[0036] like Figure 1 to Figure 7As shown, the chestnut automatic shelling machine of the present invention includes a power transmission mechanism, an automatic adjustment device, a shelling roller knife and a screening mechanism, and the specific structure and connection mode are:

[0037] like figure 2 , 3 , 4, the power transmission mechanism includes the motor 14, the reducer 45, the driving shaft 26, the driven shaft 52, the driving shaft bevel gear 53, the driven shaft bevel gear 54, the first driving pulley 13, the first pulley 15 , the first driven pulley 6, the second pulley 28, the first reducer shaft 44, the second driving pulley 51, the second driven pulley 10, the third pulley 30, the fourth pulley 40, the first belt 21, the second pulley The belt 17 , the third belt 24 , the fourth belt 16 , the second reducer shaft 42 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com