Early-removal formwork system for concreting of constructions comprising beams, plates and columns

一种早拆模板、建筑物的技术,应用在建筑物构造、建筑构件在现场的制备、建筑等方向,能够解决转运、存放占用空间大、运输和存放不方便、制造成本增加等问题,达到减少库房容量和运力、节省存储和运输空间、方便存储和运输的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

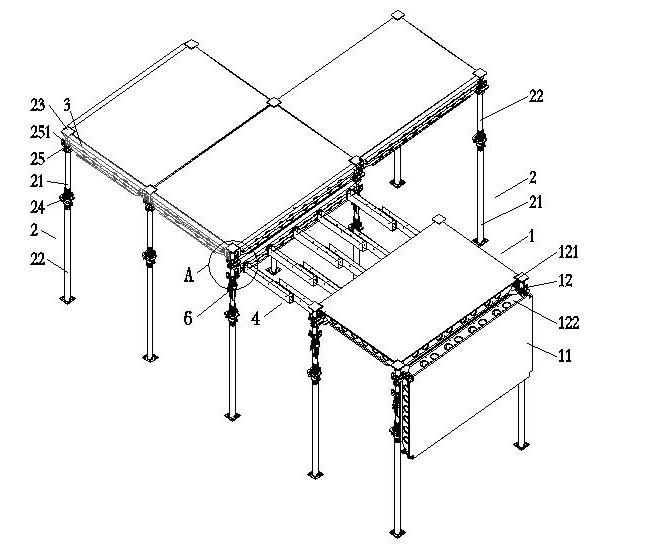

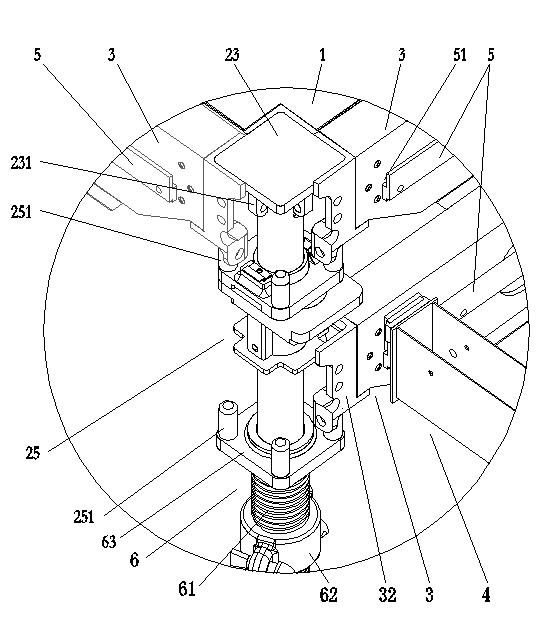

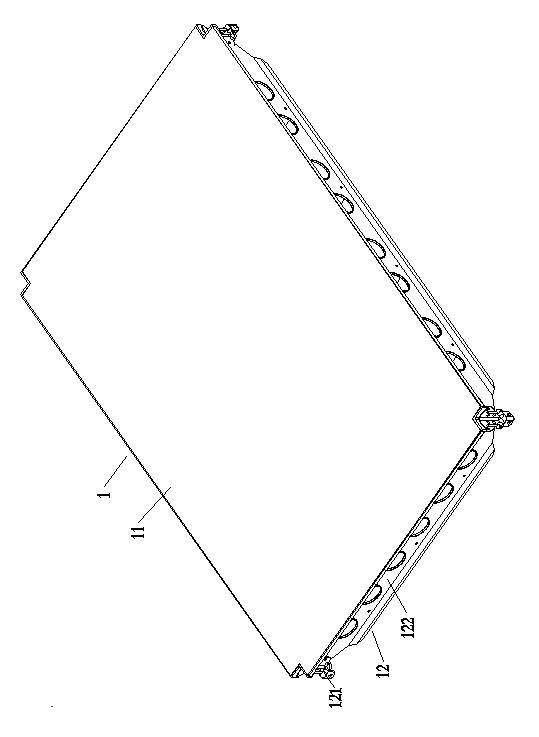

[0046] see figure 1 , figure 2 , an early demolition formwork system for pouring buildings with beam, slab and column structures, including several standard formworks 1, multiple early demolition support columns 2, several auxiliary beams mainly used to support floor structural beams 3, Auxiliary formwork; said standard formwork 1 is made up of panel 11 and formwork frame 12, and standard formwork 1 is a right-angled quadrilateral shape, and the four corners of formwork frame 12 of standard formwork 1 are provided with L-shaped corner 121; The upper pillar 21 and the lower pillar 22 that are telescopically connected are formed. The top of the upper pillar 21 is provided with a rectangular top plate 23. One corner of the top plate 23 is complementary to the inner corner of any L-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com