Stop wall structure for removably mounting to a metal-wire shelf

a technology of stop structure and metal wire shelf, which is applied in the field of stop structure, can solve the problems of increasing the manufacturing cost and overall weight of metal, reducing the competitive ability of metal racks in the market, and affecting the appearance of the produ

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

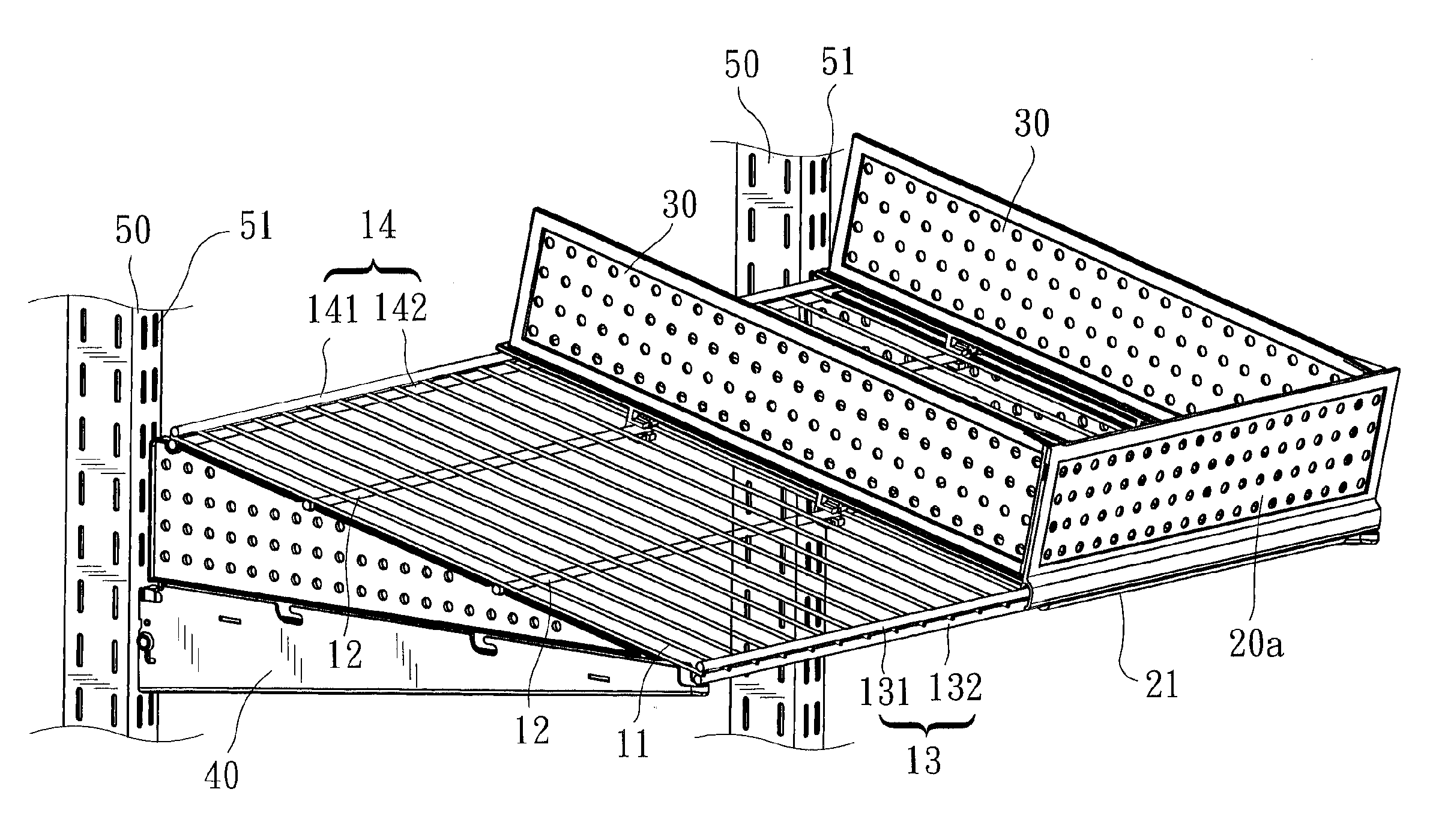

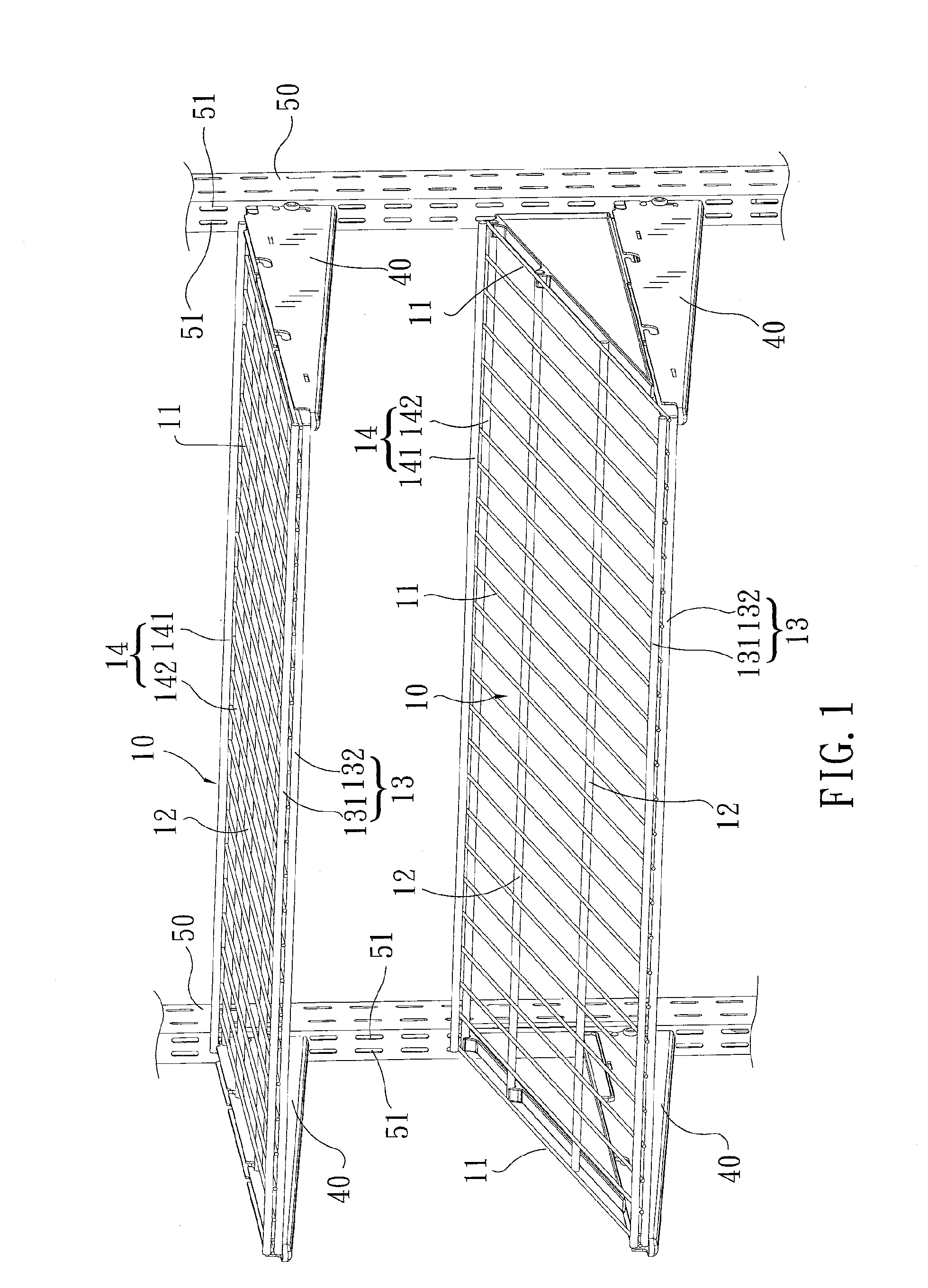

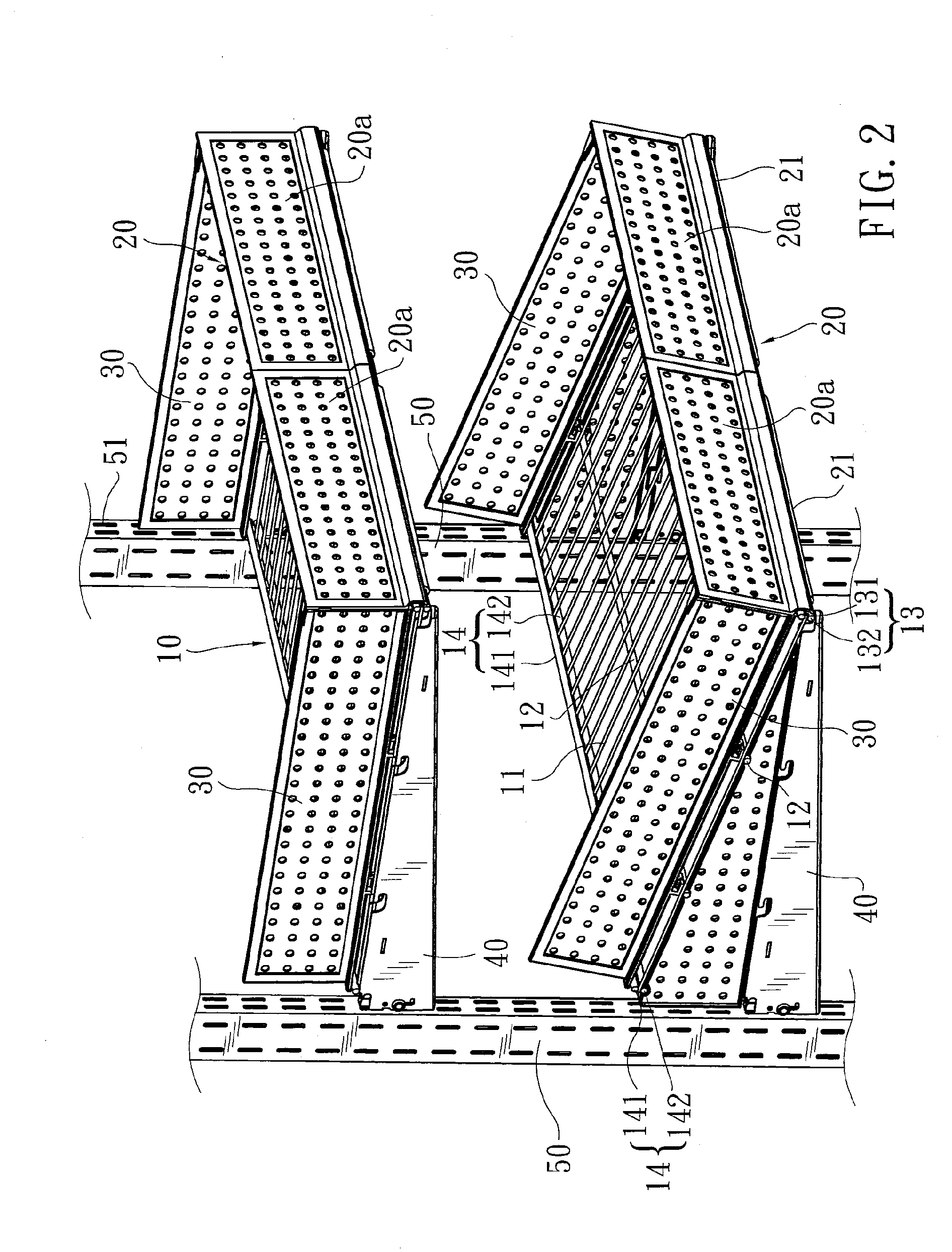

[0022]Please refer to FIG. 2. The present invention provides a stop wall structure for removably mounting to a metal-wire shelf 10 supported on, for example, a sectional rack, so that stop walls are raised from a front and two lateral edges of the metal-wire shelf 10 to protect articles positioned on the metal-wire shelf 10 against undesirable falling therefrom. As can be seen from FIG. 2, the stop wall structure of the present invention includes a front stop wall 20 for mounting to the front edge of the metal-wire shelf 10 and two side stop walls 30 for mounting to two lateral edges of the metal-wire shelf 10. The metal-shelf 10 illustrated in FIG. 2 is similar to that shown in FIG. 1, and is formed by welding a plurality of longitudinally extended metal wires 11 to a plurality of transversely extended intermediate metal bars 12, a front metal-bar set 13, and a rear metal-bar set 14, so that the metal wires 11 and the metal bars 12, 13, 14 intersect at a right angle. The front meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com