Adhesive for imperial crown cap polyolefin pad for beer or beverage and preparation thereof

A crown cap and adhesive technology, which is applied in the direction of adhesive types, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problem of not being able to bond polyolefin bottle cap gaskets, and achieve Good environmental performance and resource saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The adhesive of the crown cap polyolefin gasket and the preparation method thereof are compounded from raw materials in parts by weight:

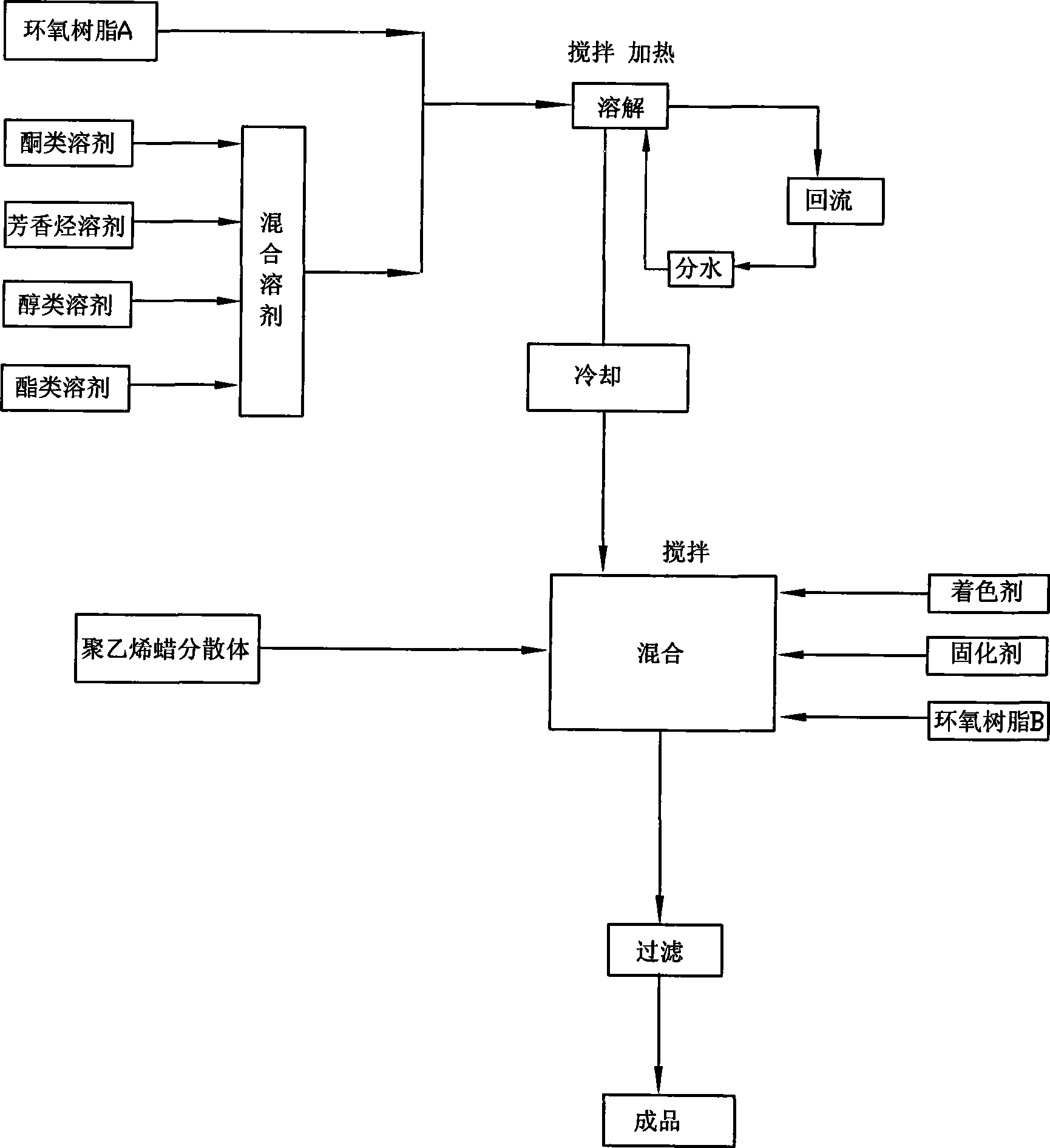

[0030] Preparation of epoxy resin A solution: first add methyl isobutyl ketone, xylene, butanol, and butyl acetate into the mixer at a ratio of 25:45:15:15, and stir at room temperature for 30-40 minutes. become a homogeneous mixed solvent. Add 55.2 parts of it and 26.5 parts of epoxy resin A (609) into the reaction kettle with stirring, heating, heat preservation, cooling, and can carry out reflux and water separation device, gradually heat up to the reflux temperature, at 100 ~ Stir, heat, keep warm, reflux, and separate water at 140°C for 3-4 hours until the epoxy resin A is completely dissolved, cool to 40-60°C, and filter to make an epoxy resin A solution.

[0031] Add 81.7 parts of the above-mentioned epoxy resin A solution, 6 parts of epoxy resin B, 3.5 parts of polyethylene wax dispersion, 0.8 parts of colorant, and 8 parts ...

Embodiment 2

[0034] The raw materials of the adhesive are proportioned in parts by weight: 37.5 parts of epoxy resin A, 4.5 parts of epoxy resin B, 46 parts of mixed solvent, 4.5 parts of polyethylene wax dispersion, 1.1 parts of coloring agent, solidified 6.4 parts of agent, and used curing agent is amino polyurethane, and all the other materials that adopt are with embodiment 1.

[0035] The preparation process of the adhesive is the same as in Example 1.

Embodiment 3

[0037] The proportioning of each raw material of the adhesive is in parts by weight: 43 parts of epoxy resin A, 3 parts of epoxy resin B, 43 parts of mixed solvent, 5 parts of polyethylene wax dispersion, 1.1 parts of coloring agent, 4.9 parts of curing agent, And the materials used are the same as in Example 2. The preparation process of the adhesive is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com