High-performance carbon nanotube/carbon composite fiber and rapid preparation method thereof

A carbon nanotube composite, carbon nanotube fiber technology, applied in the direction of carbon fiber, fiber processing, textiles and papermaking, can solve the problems of time-consuming, energy consumption, electrical performance degradation, etc., to reduce the cross-sectional area, overcome agglomeration, improve The effect of inter-tube forces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

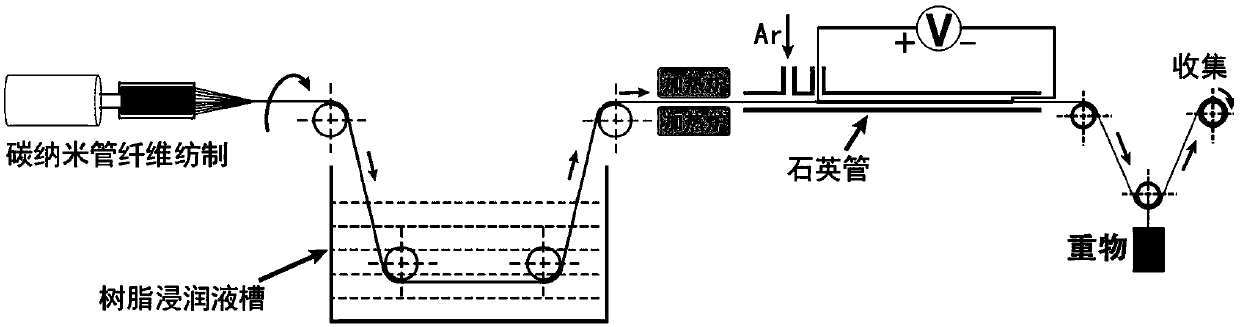

[0038] An aspect of the embodiments of the present invention provides a rapid preparation method of high-performance carbon nanotubes / carbon composite fibers, which includes:

[0039] During the carbon nanotube fiber spinning process and / or after the spinning is completed, fully infiltrate and twist the carbon nanotube fiber with a high carbon content polymer precursor solution, and then remove the solvent on the surface of the carbon nanotube fiber;

[0040] And, apply drawing force to the obtained carbon nanotube composite fiber, pass electric current into the described carbon nanotube composite fiber at the same time, make the precursor of the high carbon residue rate polymer in the described carbon nanotube composite fiber intersect Combined curing, followed by carbonization of the formed polymer, to prepare high-performance carbon nanotube / carbon composite fibers.

[0041] In some typical implementation cases, the preparation method specifically includes:

[0042] (1) In...

Embodiment 1

[0087]The carbon nanotube fibers were prepared by floating chemical vapor deposition method. The specific process was as follows: using ethanol as the carbon source, ferrocene as the catalyst, and thiophene as the growth aid. The formed mixed solution is injected into the reaction area, and the generated continuous carbon nanotube airgel is shrunk through a sealed water tank to obtain flat carbon nanotube filaments. During the preparation process, a certain amount of high-purity hydrogen will be introduced, with a flow rate of 60-80 sccm. The injection speed of the mixed solution was controlled at 6-8 μL / min. Alumina corundum tubes are used in the reaction zone, the growth temperature of carbon nanotubes in the furnace is set at 1300°C, and the length of the high-temperature reaction zone is >40cm. In order to protect the whole reaction, the carrier gas is high-purity argon (99.99%), and the flow rate is 80-120 sccm.

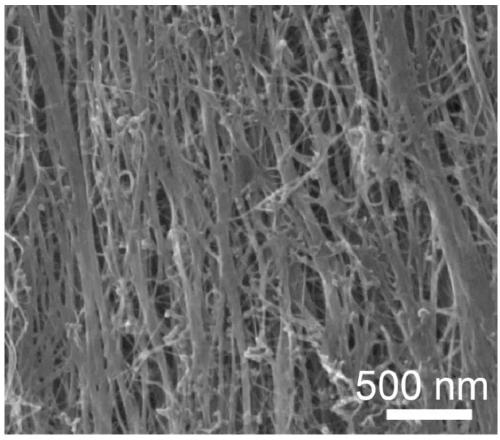

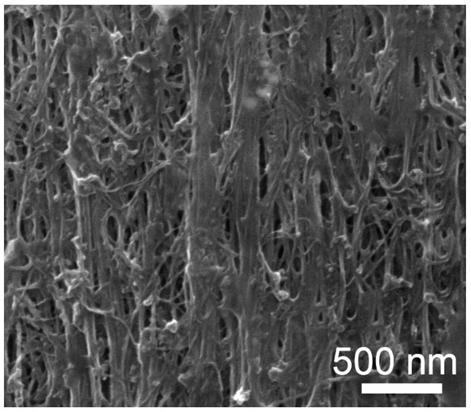

[0088] Such as figure 1 As shown, after the carbon nano...

Embodiment 2

[0092] Growth of carbon nanotube airgel by floating CVD method, that is, under the flow of argon and hydrogen, the mixture of ethanol, ferrocene and thiophene is injected into a high-temperature tube furnace at 1300 °C at a rate of 6-8 μL / min , the carrier gas flow rate is 80-120sccm, and the continuous carbon nanotube aerogel is formed at the other end of the high-temperature tube furnace, and the generated continuous carbon nanotube aerogel is shrunk through a sealed water tank to obtain a carbon nanotube flat filament.

[0093] After the carbon nanotube flat filament comes out of the furnace, let it pass through the PAN / DMF solution with a mass fraction of 3wt%, then draw and twist the carbon nanotube flat filament after infiltration to obtain CNT / PAN composite fiber, and then CNT / PAN The composite fibers were passed through a heating furnace set at 50°C to remove the solvent from the fibers. Let the dried CNT / PAN composite fiber pass through the quartz tube that allows the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com