High precision tunnel type accelerometer and preparation method thereof

An accelerometer, tunnel-type technology, applied in the direction of using inertial force for acceleration measurement, etc., can solve the problems of difficult control of the height and initial spacing of the tunnel tip, rapid corrosion of lobes, and complicated processes, so as to avoid adhesion and tunnel tip. The effect of contamination, improved measurement accuracy, and improved sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

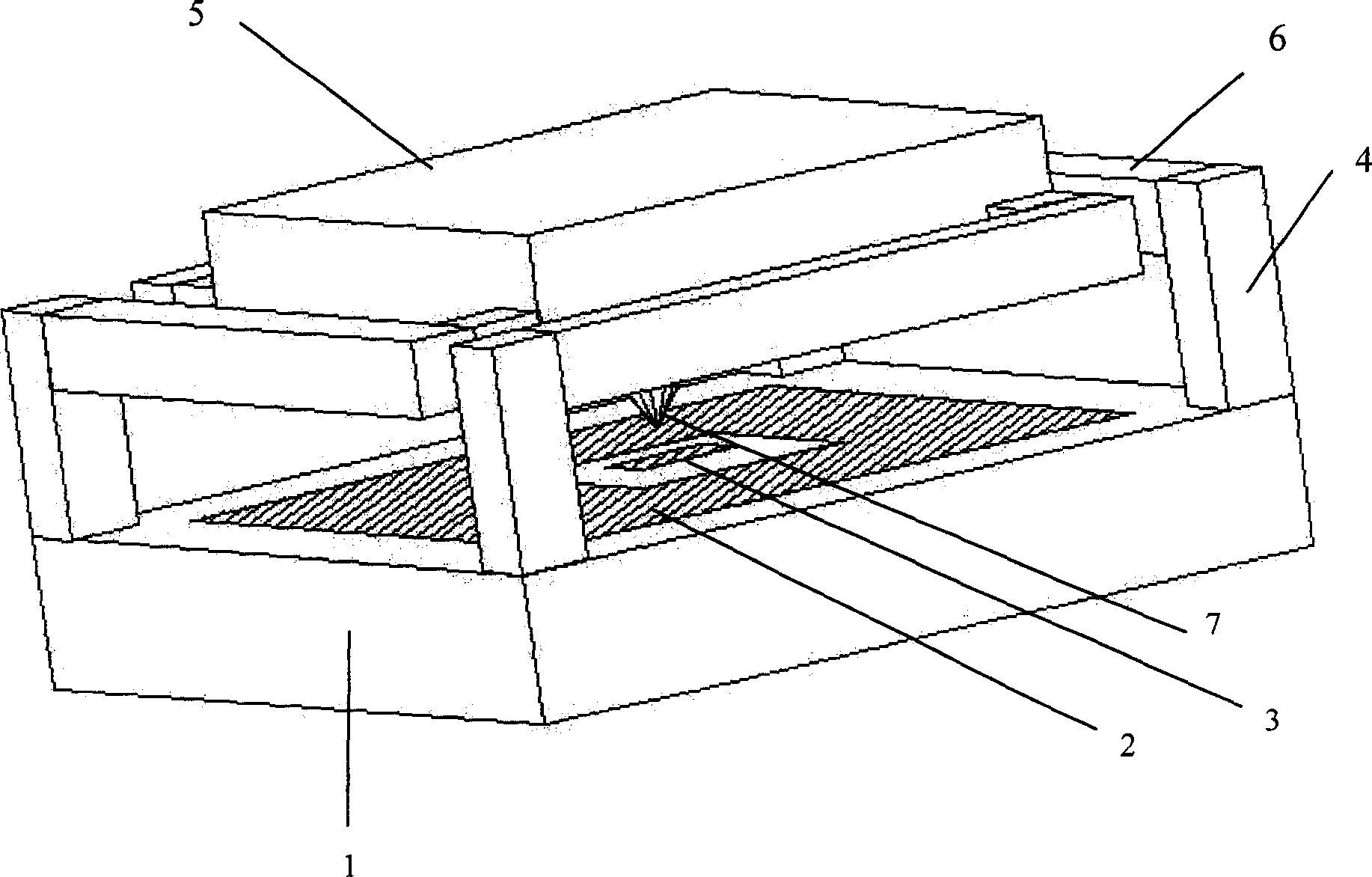

[0028] Embodiment 1: High precision tunnel accelerometer structure

[0029] Such as figure 1 Shown is a schematic diagram of a high-precision tunnel accelerometer. It includes a glass substrate 1, on which there are driving electrodes 2 and tunnel tip corresponding electrodes 3, and the glass substrate 1 is fixedly connected to the rotary support beam 6 distributed around the detection mass 5 through anchor points 4, and the detection mass 5 It is fixedly connected with the support beam 6 , the tunnel tip 7 is located under the center of the proof mass 5 , the tunnel tip 7 is conical, and the thickness of the support beam 6 is smaller than that of the proof mass 5 .

Embodiment 2

[0030] Embodiment 2: the preparation method of high precision tunnel accelerometer

[0031] Figure 2 shows the fabrication process of the high-precision tunnel accelerometer.

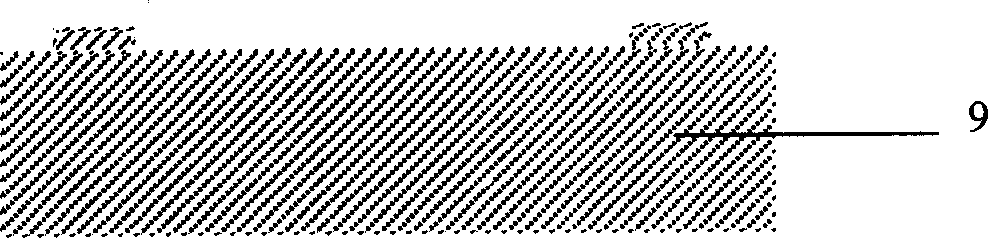

[0032] 1. The starting material is a double-polished N-type (100) silicon wafer 9 with a thickness of 400±10 microns;

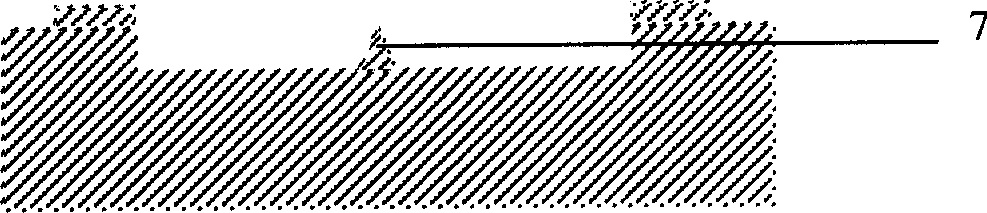

[0033] 2. KOH corrosion, prepare the initial distance between the tunnel tip and the corresponding electrode, as shown in Figure 2(a), the depth of the shallow groove is the initial distance;

[0034] 3. HNA isotropically etched to prepare the tunnel tip 7, as shown in Figure 2(b);

[0035] 4. Lift-off process, deposit metal Ti / Pt / Au or Cr / Au on the tunnel tip as the tunnel current emitter electrode 8, as shown in Figure 2(c);

[0036] 5. Lift-off process, prepare the substrate electrode on the glass substrate 1, including the driving electrode 2 and the tunnel tip corresponding electrode 3, the electrode is Ti / Pt / Au or Cr / Au, as shown in Figure 2(d);

[0037] 6. Anode bonding, real...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com