High-speed and high-precision photoelectric encoder with two-piece deployment

A photoelectric encoder, high-precision technology, applied in the direction of instruments, conversion sensor output, measuring devices, etc., can solve the problem of unable to achieve real-time position positioning requirements, unable to work, etc., to achieve large installation tolerance, fewer installation components, coding high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0197] Figure 24 Schematic diagram of the illustrated embodiment-2D bidirectional light splitting and unidirectional coding based on precision machining process 2 8 Passive optical encoding components are segmented. This part is the 4 code BAR of the rotor assembly-passive optical coding part. Horizontal 3mm, 4bite MSB code, vertical incidence left and right light splitting unit, 4bite LSB code are constructed from left to right.

[0198] The photo was taken non-vertically. It can work normally if the distance between the stator assembly and PCBA is within 15mm without the light exit lens. If it is necessary to increase the distance between the stator assembly-PCBA and the rotor assembly-passive optical encoding component, the light exit lens or the light exit lens and the light receiving port collimating lens need to be used to constrain and process the encoded beam.

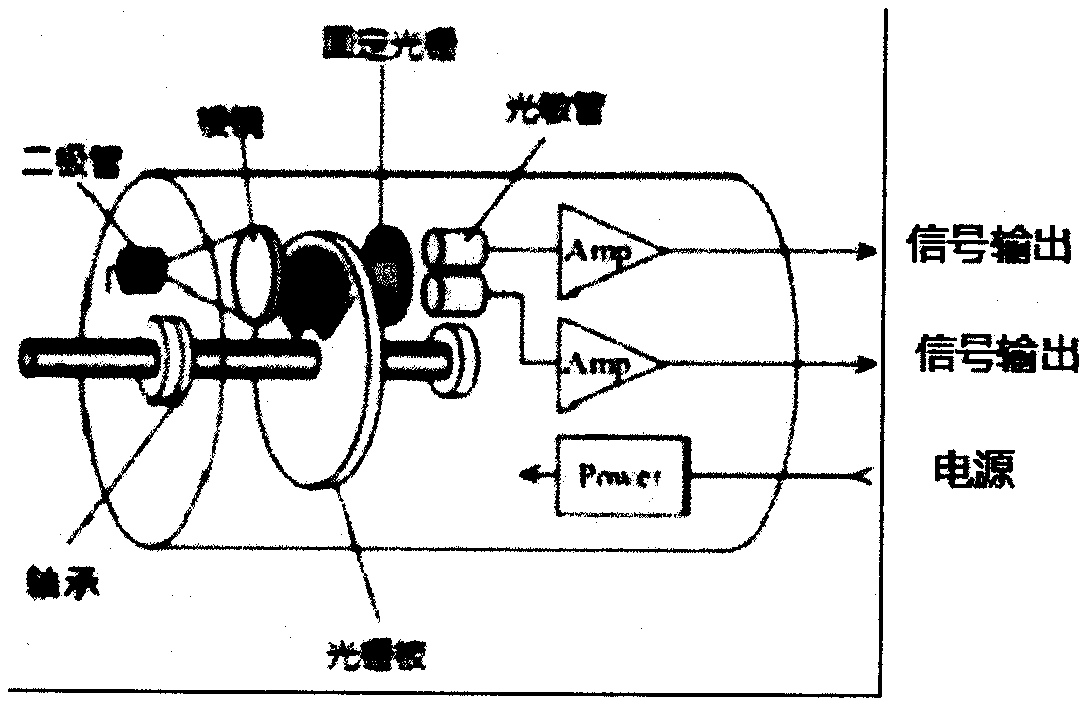

[0199] Figure 25 Schematic diagram of the illustrated embodiment-PCBA of the stator assembly. A light source ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com