A kind of porous ceramic composite lithium metal negative electrode and preparation method thereof

A porous ceramic and metal negative electrode technology, applied in the field of lithium metal negative electrode, can solve the problems of poor cycle stability, uncontrolled growth of lithium dendrites, easy to pierce the separator, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

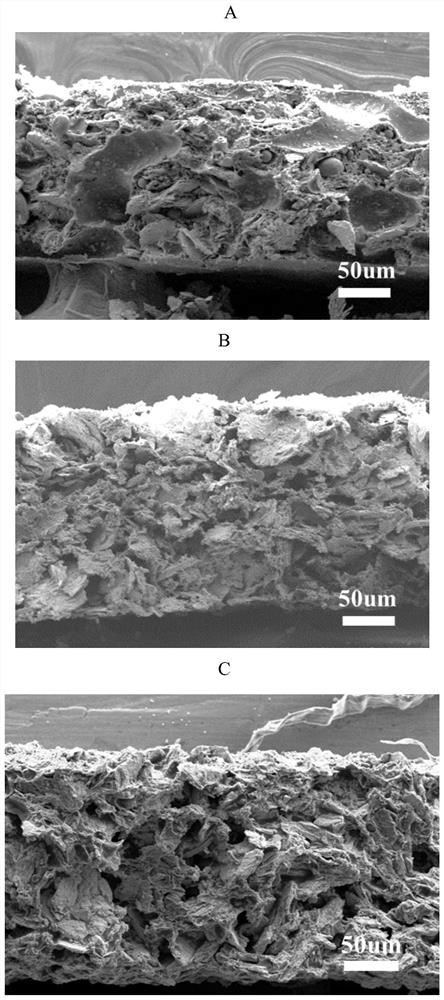

[0037]Accurate weighing 5.4 g of cerium oxide (CEO2The powder was grinded from 0.6 g of PMMA powder and was added to the agate mortar for 20 min to obtain a uniform mixed powder. A 0.6 g of a polyether sulfone (PESF) powder was reproduced into the powder, and then 2.5 ml of N, N-dimethylpyrrolidone (NMP) was added thereto, and a uniform viscous slurry was obtained from 30 min. Transferring the slurry to the normal temperature vacuum oven to stand 2 min to remove the bubbles in the slurry, and then use the coating machine to be uniformly applied to the cropping of the viscous slurry at a speed of 1 m / min using a coating machine at a speed of 1 m / min. In a good flat aluminum foil, the aluminum foil coated with a slurry was immersed in 30 ml of ethylene glycol. After soaking 24 h, the cerium oxide film was separated from the aluminum foil, and the cerium oxide film separated from aluminum foil was washed with aluminum foil and washed at 60 ° C. Drying in the oven, referred to as a ...

Embodiment 2

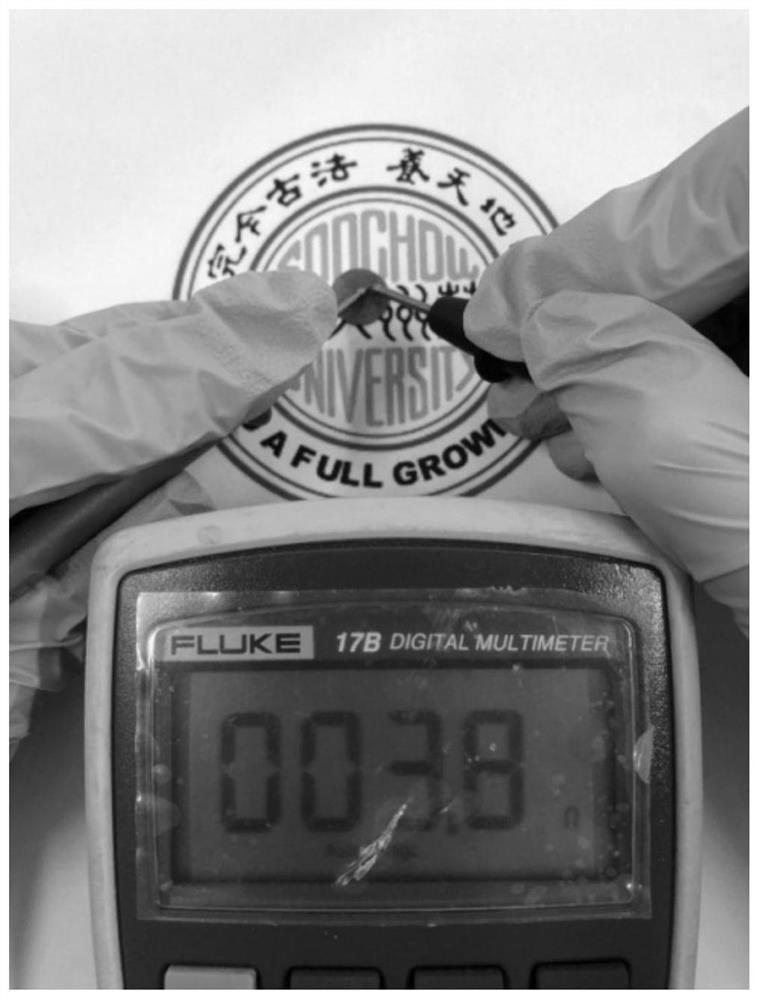

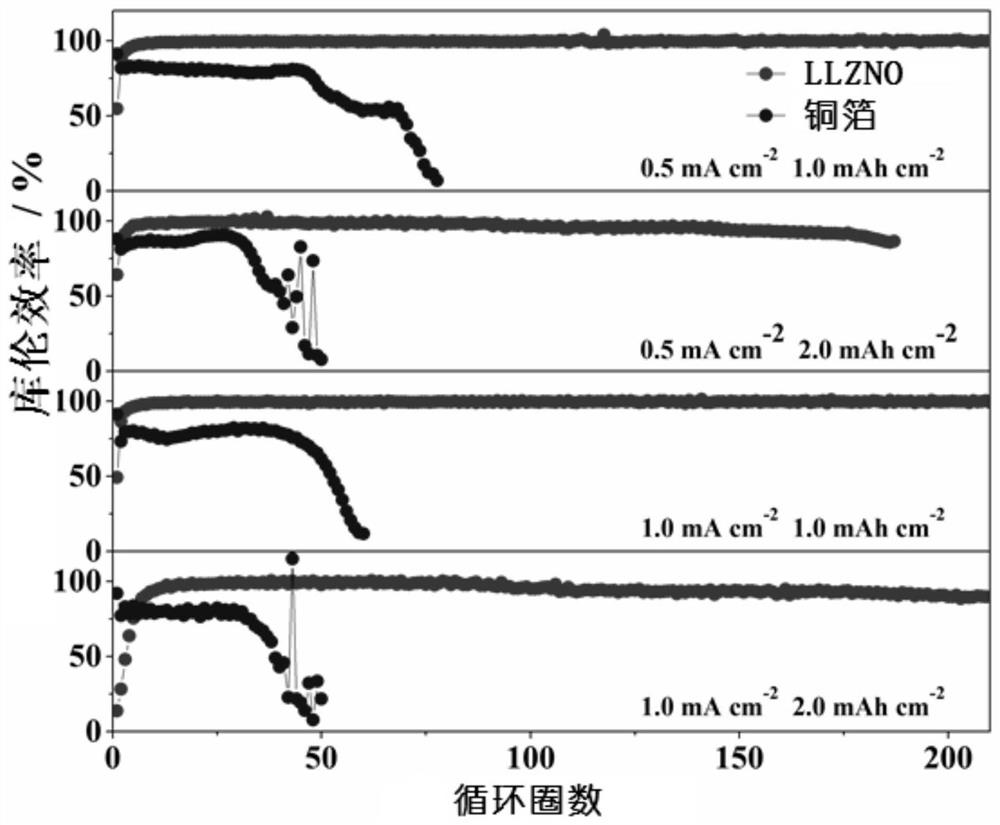

[0042]Accurately weighed 4.8 g li6.6LA3Zr1.6Ta0.4O12 (LLZTO) solid electrolyte powder and 1.2 g of plant starch powder and added to the agate mortar for 20 minutes to obtain a uniform mixed powder. 0.6 g of the polyvinylidene fluoride (PVDF) powder was reproduced into the powder, then 2 ml N, N-dimethyl sulfoxide (DMSO) was added thereto, and then rapidly ground 30 min to obtain a uniform viscous slurry. Transfer the slurry to the normal temperature vacuum oven to stand 2 min to remove the bubbles in the slurry, and then use the thickness of 1000 um, use the coating machine to uniformly apply the mixed slurry to the cropped flatness at a speed of 1 m / min. On the aluminum foil, the coated slurry is immersed in 50 ml of isopropanol along with the aluminum foil. After soaking for 24 h, the solidified LLZTO film separated from the aluminum foil was washed fine with aluminum foil and dried in a 60 ° C oven.

[0043]The dried LLZTO film was cut into a circumfer of 13 mm, and then placed in...

Embodiment 3

[0046]Accurately weighed 5.7 g Li0.35La0.55TiO3 (LLTO) powder and 0.3 g of acetylene black powder and added to the agate mortar for 20 minutes to obtain a uniform mixed powder. The ratio of 0.6 g of a polyether sulfone (PESF) powder was reproduced into the powder, and then 2.5 ml of N, N-dimethylpyrrolidone (NMP) was added thereto, and then rapidly ground 30 min to obtain a uniform viscous slurry. Transfer the slurry to the normal temperature vacuum oven to stand 2 min to remove the bubbles in the slurry, then use a doctor blade having a thickness of 400 um, use the coating machine to uniformly coat the mixed slurry to the cropping of the cropping of 1 m / min. On the aluminum foil, the coated slurry is immersed in 30 ml of ultrapure water along with the aluminum foil. After soaking 24 h, the cured film isolated from the aluminum foil was washed fine with aluminum foil and dried in an oven at 60 ° C. The drawings are referred to as dry films, as in the following examples.

[0047]The d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com