Frequency tunable micromirror

a micromirror and frequency-tunable technology, applied in the field of optical scanning devices, can solve the problem that the reflection area of the micromirror is the limiting factor for fully utilizing the photon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

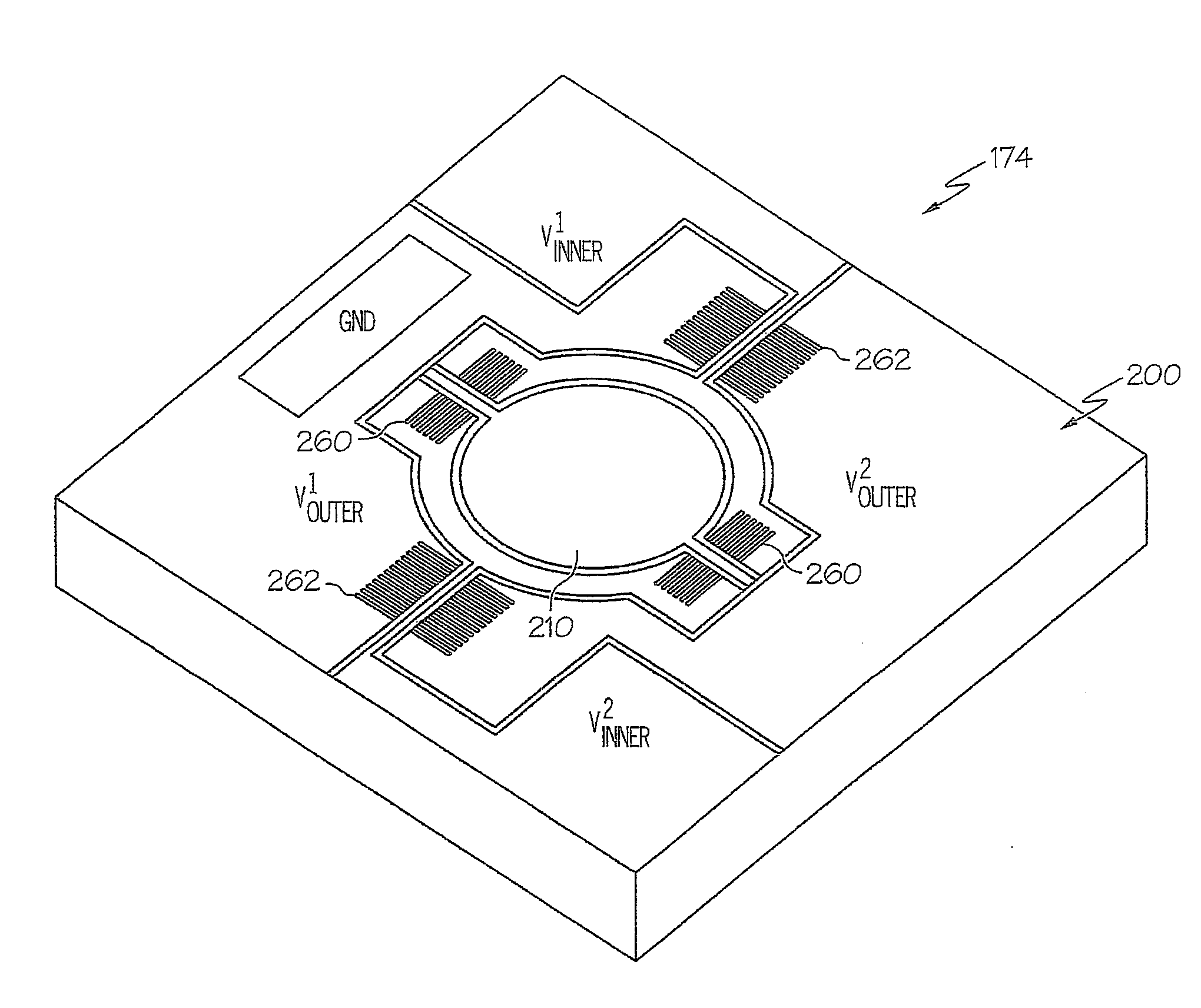

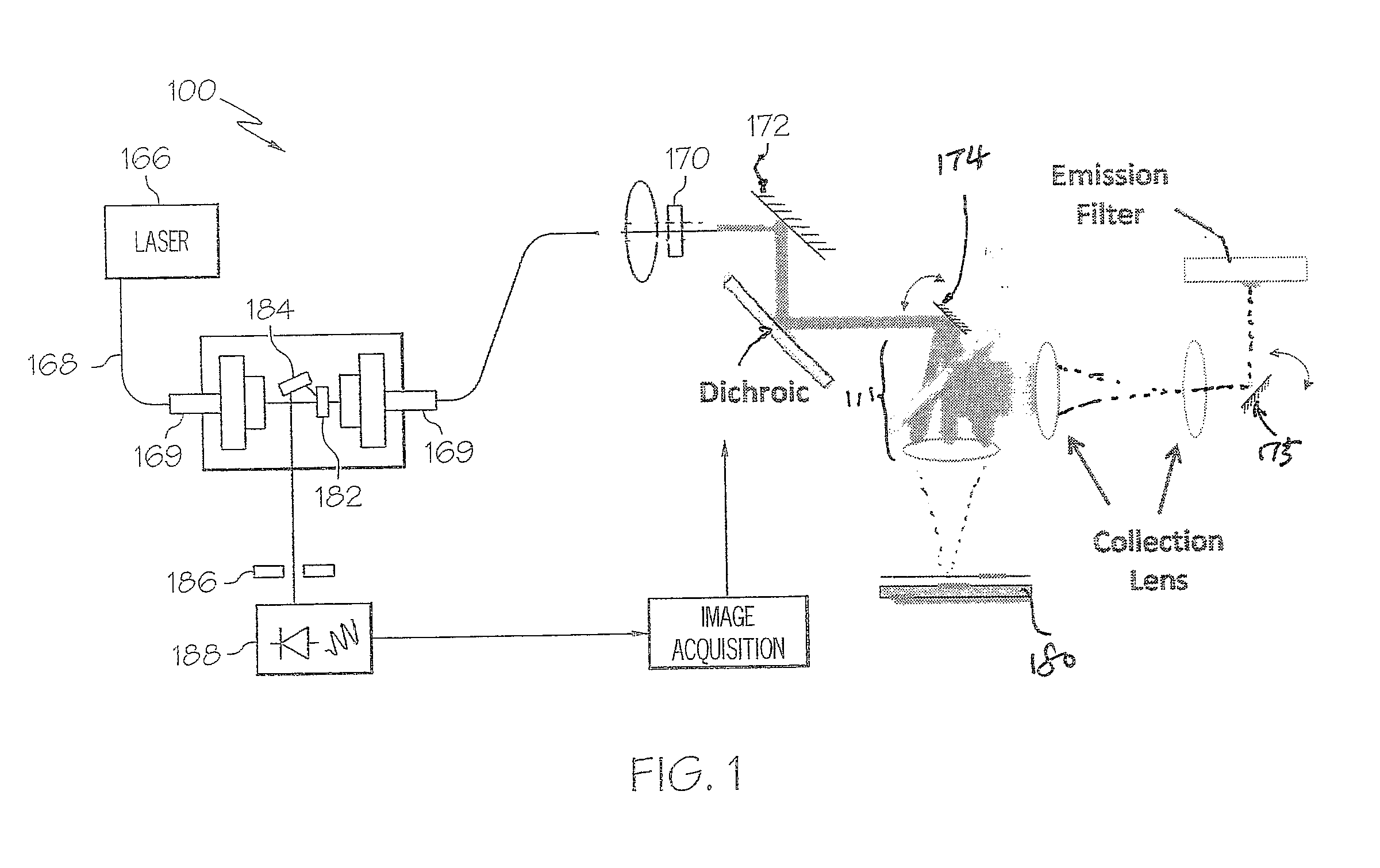

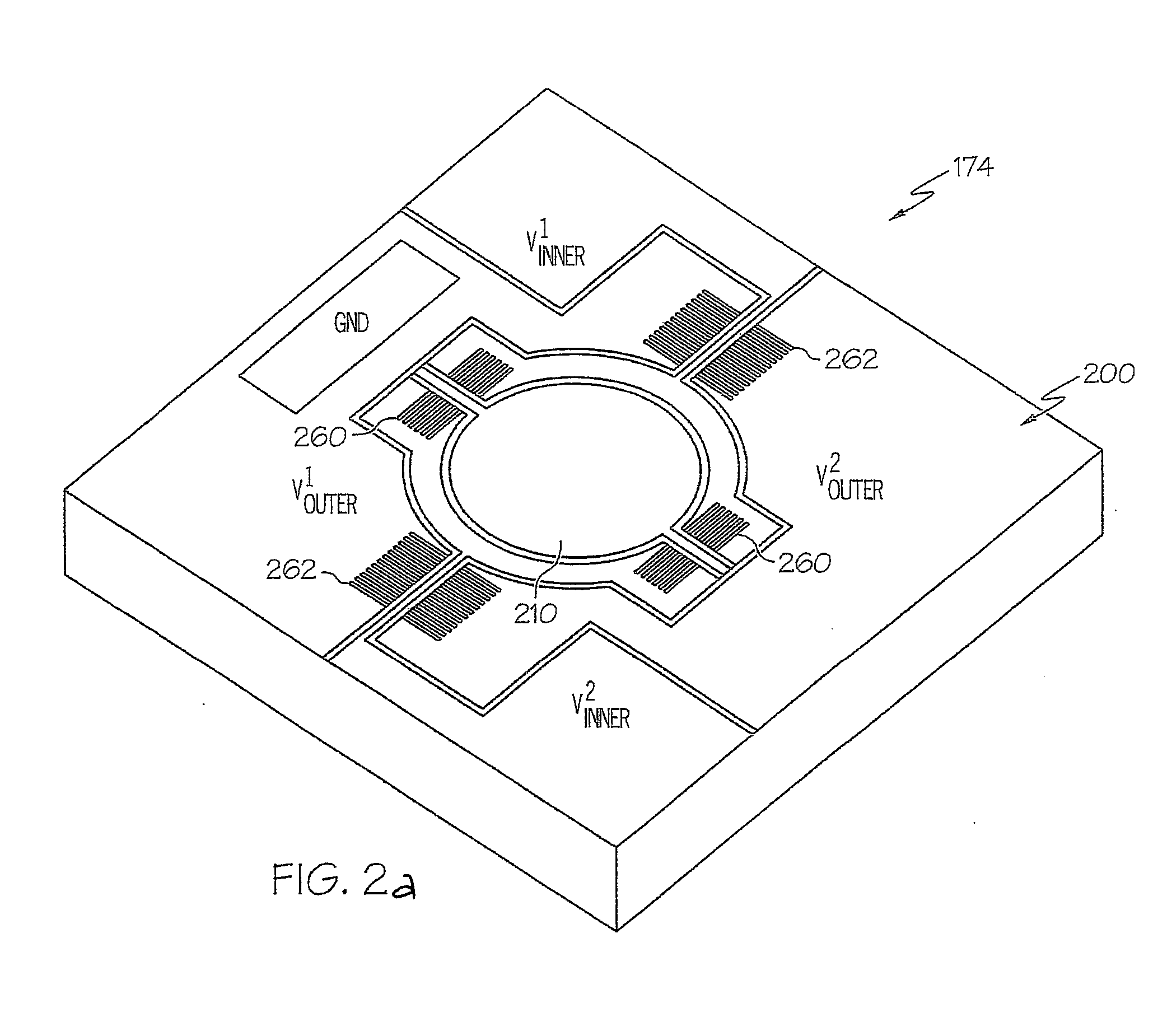

[0015]Referring now to the drawings and in particular to FIG. 1, there is depicted a diagram of a laser-scanning confocal microscope in which a preferred embodiment of the present invention is applicable. As shown, a laser-scanning confocal microscope 100 includes a diode laser 166, an avalanche photodetector 188, a stationary mirror 172, a movable micromirror 174, a movable frequency tunable micromirror 175 and an objective system 111.

[0016]A linearly-polarized laser beam from diode laser 166 is initially coupled into a single-mode polarization maintaining (PM) fiber 168. Light exiting PM fiber 168 is then collimated by collimators 169 to a 1 mm diameter beam through a zero-order quarter wave-plate 170 whose axis is oriented at 45° to the incident polarization angle in order to convert the illumination to a circular polarization. After reflection off stationary mirror 172, the illumination is incident on micromirror 174 at 22.5° to micromirror 174 normal. Micromirror 174 scans the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com