Capacitive micro-electromechanical system (MEMS) accelerometer and manufacturing method thereof

An accelerometer, capacitive technology, applied in the measurement of acceleration, speed/acceleration/impact measurement, measurement devices, etc., can solve the problems of reduced yield and reliability, poor flexibility, and difficulty in repairing, to improve the yield, High reliability, flexible design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

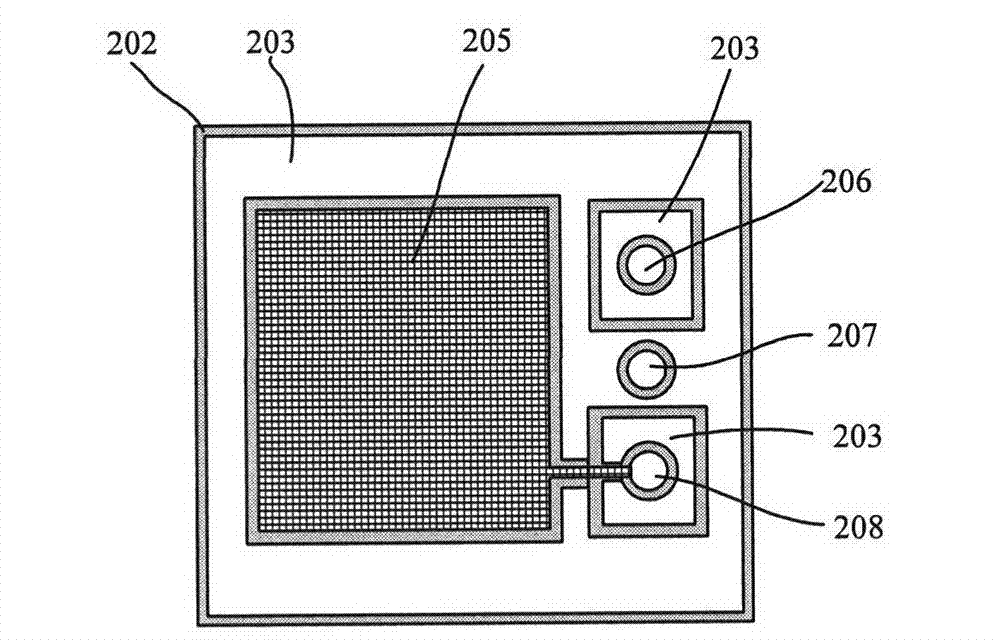

[0035] According to the working principle of capacitance detection, the MEMS accelerometer with all-silicon structure adopts a three-layer silicon structure: the metal electrode of the first silicon cover plate and the upper surface of the mass block of the middle silicon layer form the first capacitance, and the metal electrode of the second silicon cover plate and the mass of the middle silicon layer The lower surface of the block forms a second capacitor; under the action of acceleration perpendicular to the direction of the mass block, the mass block will shift, causing changes in the upper and lower capacitances. Acceleration can be measured by detecting changes in capacitance.

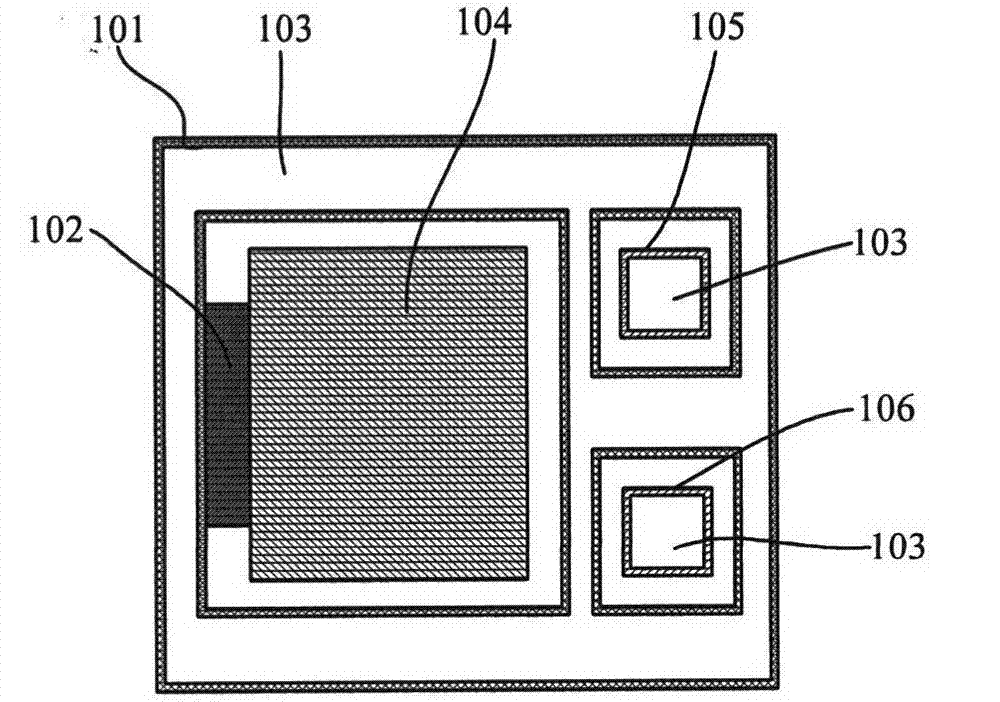

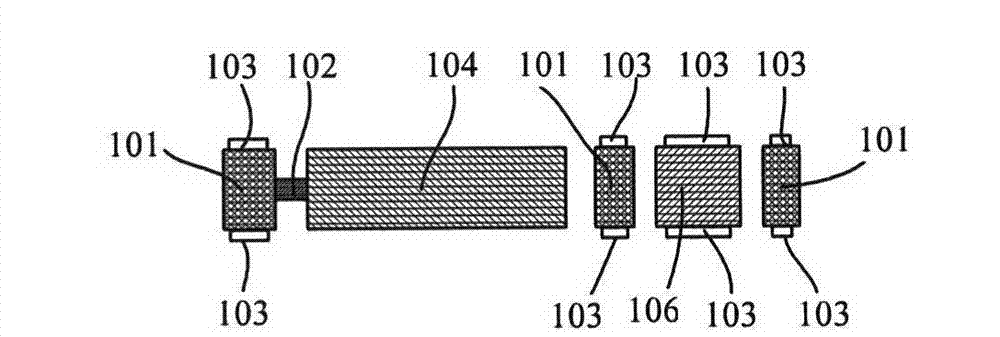

[0036]FIG. 1 is a schematic structural diagram of a silicon structure layer 1 , which includes a silicon frame 101 , a proof mass 104 , a support beam 102 , and silicon islands 105 and 106 . The mass block 104 is formed inside the silicon frame 101 , one end of the mass block 104 is connected to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com